|

市場調查報告書

商品編碼

1690889

倉庫自動化-市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Warehouse Automation - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

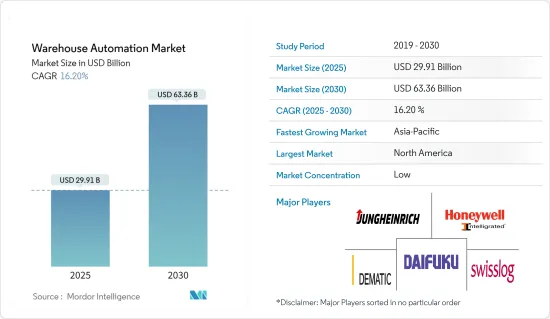

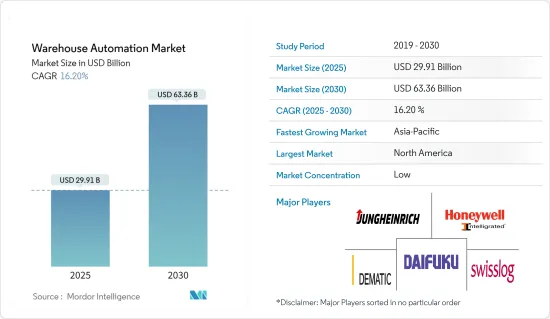

2025 年倉庫自動化市場規模估計為 299.1 億美元,預計到 2030 年將達到 633.6 億美元,預測期內(2025-2030 年)的複合年成長率為 16.2%。

關鍵亮點

- 物流自動化是指使用控制系統、機器和軟體來提高業務效率。這通常適用於必須在倉庫或配送中心進行且需要最少人工干預的流程。自動化物流的好處包括改善客戶服務、可擴展性和速度、組織控制和減少錯誤。

- 倉庫自動化可以在最少的人工協助下自動完成庫存進出倉庫、在倉庫內以及從倉庫到客戶的移動。作為自動化計劃的一部分,公司可以消除涉及重複體力勞動或手動資料輸入和分析的勞動密集型業務。

- 此外,全球電子商務行業的成長以及對高效倉儲和庫存管理日益成長的需求正在推動市場研究。倉庫管理自動化對於降低整體業務成本和減少產品交付錯誤非常有用。據著名的第三方物流公司和倉庫自動化解決方案的重要終端用戶 DHL 稱,儘管有這些好處,但 80% 的倉庫「仍然在沒有任何自動化支援的情況下手動操作」。此外,使用輸送機、分類機和取放解決方案的倉庫佔所有倉庫的 15%。同時,目前只有 5% 的倉庫實現了自動化。

- 不可預測的需求以及供應鏈缺乏透明度和協作對許多製造商實現其業務目標構成了重大障礙。然而,希望製造商能夠評估複雜性的來源並最佳化倉庫管理,以有效應對波動的需求,同時提高其供應鏈的可視性。

- 同樣,雖然倉庫管理系統 (WMS) 可以提高工作流程效率、減少錯誤、節省與錯誤相關的成本並縮短訂單履行的周轉時間,但對於電子商務企業來說,操作 WMS 可能會耗時且成本高昂。運行 WMS 需要大量的前期硬體成本、大量的培訓以及額外的每月維護成本。

倉庫自動化市場趨勢

零售業大幅成長

- 倉庫自動化應用於各種零售業,包括電子商務和雜貨。倉庫自動化具有多種好處,從提高生產力到降低勞動力相關風險。電子商務倉庫自動化包括在物流設施中實施技術以提高業務績效。根據美國商務部人口普查局的數據,2022 年電子商務銷售總額為 1.341 兆美元,比 2021 年成長 7.7%(+-0.4%)。 2022 年零售總額較 2021 年成長 8.1%(+-0.9%)。

- 為了滿足這一巨大的需求,倉庫自動化(將手動倉庫轉換為自動化履約業務)正在迅速擴展,這對於滿足大量客戶需求同時控制未來營運成本至關重要。許多零售商現在都轉向倉庫自動化解決方案,以應對電子商務物流業務日益成長的規模和複雜性,並更快、更經濟地滿足不斷成長的客戶需求。

- 零售倉庫可以採用各種自動化解決方案來完成任何任務,從自動處理設備到儲存貨物,再到最大限度組織庫存的數位系統。領先的零售商正在使用自動導引車 (AGV) 和自主移動機器人 (AMR) 與工人一起工作,以簡化其電子商務和全通路設施中的履約業務。

- 此外,為了滿足快速擴張的電子商務領域的需求並吸取全球疫情的教訓,領先的零售商正在努力提高其倉庫的響應能力、彈性和可靠性。例如,2022 年 4 月,亞馬遜推出了亞馬遜工業創新基金 (AIIF),這是一項 10 億美元的新興企業資金籌措計劃,專注於自動化和職場機器人技術,以「刺激供應鏈、履約和物流的創新」。

預計亞太地區將佔很大佔有率

- 由於亞太地區產業數量的增加及其與自動化的整合以提高投資收益(ROI),該地區的倉庫自動化市場正在大幅擴張。由於自動化產品的生產、銷售和貿易不斷增加,預計亞太地區的倉庫自動化將由中國主導。

- 此外,中國政府計劃根據「中國製造2025」國家計劃,將中國從製造業大國轉變為全球製造業強國,因此倉庫自動化產業預計將受益於中國在製造業領域的主導地位。該計劃還包括加強中國機器人供應商的力量,並進一步擴大國內外市場佔有率。

- 倉庫自動化的需求包括自動化供應鏈,並得到有利投資的進一步支持。目前,該國正在探索多項投資以進一步促進市場成長,主要主要企業正在向該地區擴張,創業投資公司也正在向有前景的新興企業投入資金。

- 製造業也已成為印度高成長領域之一。例如,「印度製造」計畫使印度成為世界重要的製造地,並讓印度經濟獲得了全球認可。 「印度製造」宣傳活動推動了印度推出多款新型工業機器人,為倉庫自動化帶來了機會。

倉庫自動化產業概況

倉庫自動化市場競爭激烈。該市場的一些主要全球參與企業包括 Dematic Group、Daifuku Co.Ltd.、Swisslog Holding AG、Honeywell Intelligrated 和 Jungheinrich AG。產品發布、收購和夥伴關係是倉庫自動化產業市場參與企業採用的關鍵策略。

2023年1月,永恆力股份公司收購了美國領先的貨架和倉庫自動化解決方案提供商印第安納州的Storage Solutions集團,以加強其在美國倉庫自動化市場的地位。

2022 年 9 月,Dematic 與 Upshopto 合作推出一項將與雜貨業共同成長的綜合履約服務。此次合作將為希望擴大其履約業務的雜貨商提供儲存和管理消費者資料的工具。 Dematic 正在分享他們的自動化經驗,使用簡單的軟體連接到您目前的 Upshop 流程。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概覽

- 產業吸引力-波特五力分析

- 買家的議價能力

- 供應商的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

- 產業價值鏈分析

- COVID-19 工業影響評估

- 倉庫投資場景

- 宏觀經濟因素對倉庫自動化市場的影響

第5章市場動態

- 市場促進因素

- 電子商務行業的快速成長和客戶期望

- 製造複雜性和技術可用性不斷提高

- 市場問題

- 高資本投入

第6章市場區隔

- 按組件

- 硬體

- 移動機器人(AGV、AMR)

- 自動儲存和搜尋系統(AS/RS)

- 自動輸送機和分類系統

- 卸垛/碼垛系統

- 自動識別資料收集(AIDC)

- 揀選機器人

- 軟體(倉庫管理系統(WMS)、倉庫執行系統(WES))

- 服務(附加價值服務、維護等)

- 硬體

- 按最終用戶

- 食品和飲料(包括製造設施和配送中心)

- 郵政和小包裹

- 零售

- 服飾

- 製造業(耐久財/非耐久財)

- 其他

- 按地區

- 北美洲

- 歐洲

- 亞洲

- 澳洲和紐西蘭

- 拉丁美洲

- 中東和非洲

第7章競爭格局

- 公司簡介

- Dematic Group(Kion Group AG)

- Daifuku Co. Limited

- Swisslog Holding AG(KUKA AG)

- Honeywell Intelligrated(Honeywell International Inc.)

- Jungheinrich AG

- Murata Machinery Ltd

- Knapp AG

- TGW Logistics Group GmbH

- Kardex Group

- Mecalux SA

- BEUMER Group GmbH & Co. KG

- SSI Schaefer AG

- Vanderlande Industries BV

- WITRON Logistik+Informatik GmbH

- Oracle Corporation

- One Network Enterprises Inc.

- SAP SE

第8章投資分析

第9章:市場的未來

The Warehouse Automation Market size is estimated at USD 29.91 billion in 2025, and is expected to reach USD 63.36 billion by 2030, at a CAGR of 16.2% during the forecast period (2025-2030).

Key Highlights

- Automation in logistics refers to using control systems, machinery, and software to enhance the efficiency of operations. It usually applies to the processes that must be performed in a warehouse or distribution center, which requires minimal human intervention. Some benefits of automation logistics are improved customer service, scalability and speed, organizational control, and reduction of mistakes, among others.

- Warehouse automation automates inventory movement into, within, and out of warehouses to customers with minimal human assistance. As part of an automation project, a business can eliminate labor-intensive duties that involve repetitive physical work and manual data entry and analysis.

- Moreover, the growth in the e-commerce industry worldwide and the growing need for efficient warehousing and inventory management are driving the market studied. Automation in warehousing offers extreme convenience when cutting down overall business costs and reducing errors in product deliveries. According to DHL, a prominent 3PL company and a significant end-user of warehouse automation solutions, despite the advantages, 80% of warehouses are 'still manually operated with no supporting automation.' Furthermore, warehouses, i.e., those that use conveyors, sorters, and pick and place solutions, account for 15% of the entire warehouses. In contrast, only 5% of current warehouses are automated.

- Unpredictable demand and a lack of transparency and collaboration with the supply chain present a significant barrier to reaching business goals for many manufacturers. However, when manufacturers evaluate the sources of complexity and optimize warehouse management, they are expected to efficiently meet variable demand while increasing their view of the supply chain.

- Similarly, while warehouse management systems (WMS) can improve workflow efficiency, reduce errors, save on costs associated with errors, and get faster turn-around time for order fulfillment, running a WMS can be time-consuming and expensive for an e-commerce business. It requires huge upfront costs for hardware, extensive training, and additional monthly costs for upkeep.

Warehouse Automation Market Trends

Retail to Have a Significant Growth

- Warehouse automation is used in various retail activities, including e-commerce and grocery. For warehouses, automation has multiple advantages, from boosting production to lowering labor-related risks. E-commerce warehouse automation consists of implementing technologies in logistics facilities to boost operational performance. According to the Census Bureau of the Department of Commerce, Total e-commerce sales for 2022 were USD 1,034.1 billion, an increase of 7.7 percent (+-0.4%) from 2021. Total retail sales in 2022 increased by 8.1 percent (+-0.9%) from 2021.

- To address this massive demand, warehouse automation is rapidly expanding to transform manual warehouses into automated fulfillment operations, which are proving vital to meeting customer demand at scale while managing operating costs in the future. Currently, many retailers are increasingly implementing warehouse automation solutions that seek to handle the growing scale and complexity of their e-commerce logistics operations and meet the ever-increasing demand of their customers more quickly and cost-effectively.

- A retail warehouse can be outfitted with various automated solutions to carry out all tasks, from automatic handling equipment for storing products to digital systems that maximize product organization. Big retailers are utilizing automated guided vehicles (AGVs) and the next level of automation-automated mobile robots (AMRs)-working alongside workers to simplify the fulfillment operations of their e-commerce and omnichannel facilities.

- Moreover, to meet the rapidly expanding e-commerce sector and consider the lessons learned from the worldwide pandemic, leading retailers strive to make warehouses responsive, resilient, and dependable. For instance, in April 2022, Amazon established the Amazon Industrial Innovation Fund (AIIF), a USD 1 billion startup funding program that will be used to "spur supply chain, fulfillment, and logistics innovation," focusing on automation and workplace robotics.

Asia-Pacific is Expected to Hold Significant Share

- The market for warehouse automation in the Asia-Pacific is expanding significantly due to the rising number of industries in the region and their integration with automation to increase the return on investment (ROI). The Asia-Pacific warehouse automation is predicted to be dominated by China with the growing production, sales, and trade of automation products.

- Moreover, The warehouse automation industry is expected to benefit from China's dominance in the manufacturing sector as the Chinese government plans to transform China from a manufacturing giant to a global manufacturing power under the national plan "Made in China 2025". This plan includes strengthening Chinese robot suppliers and further surging their market shares in China and abroad.

- The demand for warehouse automation includes an automated supply chain, further supported by favorable investments. The country has been marked with several investments to further the market's growth studied, with major key players expanding into the region and introducing funds by venture capitalists in emerging start-ups with potential.

- Manufacturing has emerged as one of the high-growth sectors in India as well. For instance, the Make in India program places India on the world map as a significant manufacturing hub and provides global recognition to the Indian economy. The Made in India campaign has bolstered multiple new launches in industrial robots in the country, thus driving opportunities for warehouse automation.

Warehouse Automation Industry Overview

The warehouse automation market is highly competitive. Some key global players in this market are Dematic Group, Daifuku Co. Limited, Swisslog Holding AG, Honeywell Intelligrated, and Jungheinrich AG. Product launch, acquisition, and partnership are key strategies market players operating in the warehouse automation industry adopt.

In January 2023, JungheinrichAG acquired Indiana-based Storage Solutions group, a leading provider of racking and warehouse automation solutions in the United States, to gain enhanced access to the US warehousing and automation market.

In September 2022, Dematic partnered with Upshopto to offer integrated fulfillment services that grow with the grocery industry. With the help of the alliance, grocery stores wishing to expand their fulfillment businesses will have access to tools that let them store and manage their consumer data. Dematic will offer its experience in automation along with simple software to connect with current Upshop processes.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Buyers

- 4.2.2 Bargaining Power of Suppliers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Degree of Competition

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the Impact of COVID-19 on the Industry

- 4.5 Warehouse Investment Scenario

- 4.6 Impact of Macro-economic Factors on the Warehouse Automation Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Exponential Growth of the E-commerce Industry and Customer Expectation

- 5.1.2 Increasing Manufacturing Complexity and Technology Availability

- 5.2 Market Challenges

- 5.2.1 High Capital Investment

6 MARKET SEGMENTATION

- 6.1 By Component

- 6.1.1 Hardware

- 6.1.1.1 Mobile Robots (AGV, AMR)

- 6.1.1.2 Automated Storage and Retrieval Systems (AS/RS)

- 6.1.1.3 Automated Conveyor & Sorting Systems

- 6.1.1.4 De-palletizing/Palletizing Systems

- 6.1.1.5 Automatic Identification and Data Collection (AIDC)

- 6.1.1.6 Piece Picking Robots

- 6.1.2 Software (Warehouse Management Systems(WMS), Warehouse Execution Systems (WES))

- 6.1.3 Services (Value Added Services, Maintenance, etc.)

- 6.1.1 Hardware

- 6.2 By End-User

- 6.2.1 Food and Beverage (Including Manufacturing Facilities and Distribution Centers)

- 6.2.2 Post and Parcel

- 6.2.3 Retail

- 6.2.4 Apparel

- 6.2.5 Manufacturing (Durable and Non-Durable)

- 6.2.6 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Dematic Group (Kion Group AG)

- 7.1.2 Daifuku Co. Limited

- 7.1.3 Swisslog Holding AG (KUKA AG)

- 7.1.4 Honeywell Intelligrated (Honeywell International Inc.)

- 7.1.5 Jungheinrich AG

- 7.1.6 Murata Machinery Ltd

- 7.1.7 Knapp AG

- 7.1.8 TGW Logistics Group GmbH

- 7.1.9 Kardex Group

- 7.1.10 Mecalux SA

- 7.1.11 BEUMER Group GmbH & Co. KG

- 7.1.12 SSI Schaefer AG

- 7.1.13 Vanderlande Industries BV

- 7.1.14 WITRON Logistik + Informatik GmbH

- 7.1.15 Oracle Corporation

- 7.1.16 One Network Enterprises Inc.

- 7.1.17 SAP SE