|

市場調查報告書

商品編碼

1690805

採礦業傳送帶:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Conveyor Belt In Mining Industry - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

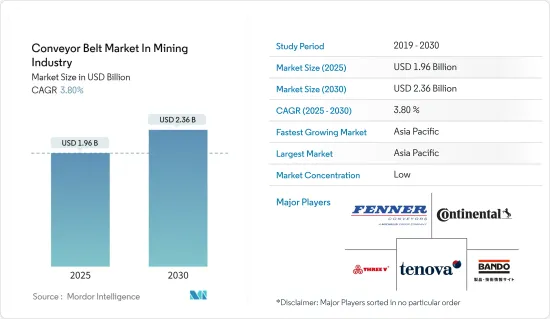

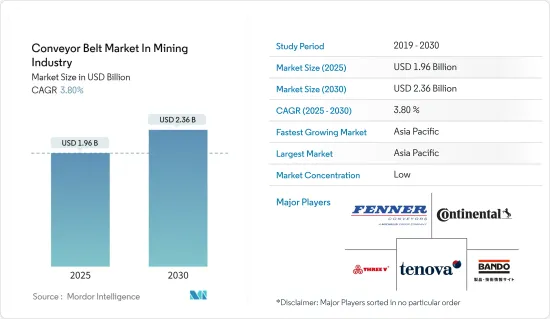

採礦市場傳送帶預計將從 2025 年的 19.6 億美元成長到 2030 年的 23.6 億美元,預測期內(2025-2030 年)的複合年成長率為 3.8%。

在印度等國家,由於政府措施和煤礦數量的增加,需求正在增加。例如,根據該公司發布的技術路線圖文件,在第二波疫情期間,印度煤炭公司計劃採用能夠每小時處理高達 4,500 噸煤炭的輸送機。傳統傳送帶的傾斜角度限制在 16 至 18 度左右。採用先進傳送帶升級礦山的重點正在推動市場成長。

主要亮點

- 在挖礦實務中,所需的功率輸出是確定的,礦工指定旋轉速度作為設計參數,這決定了要消散的熱量。這會對尺寸標註過程產生很大影響。因此,在某些運轉條件下,需要使用輸出功率大於實際所需的齒輪組。如果在異常溫暖的氣候或容易出現極熱或極冷的氣候中使用輸送機,則必須特別注意冷卻。為此,西門子針對三個齒輪組系列、46種規格的輸送機驅動裝置開發了高效率的冷卻解決方案。因此,在許多情況下,較小的齒輪組就足夠了。

- 印度能否在2047年成為已開發國家取決於基礎建設的改善。這是培育宜居、氣候適應性和包容性城市並推動經濟成長的基石。政府的承諾也體現在2024會計年度將把GDP的3.3%分配給基礎建設領域,重點是建構高階工業部門。

- 確保職業安全和健康是採礦業的首要任務。採礦工作本身就很困難,為工人帶來各種危險和風險。透過優先考慮安全並實施有效的安全措施,公司可以保護工人,防止事故和傷害,並為其營運的整體永續性做出貢獻。

- 採礦業必須遵守重要的法規和標準,以確保安全、環境保護和負責任的做法。這包括礦山安全和健康法規,例如美國礦山安全和健康管理局 (MSHA) 的法規。

- 高昂的初始成本是限制只有較大的組織才能使用自動化物料輸送系統(包括輸送機和系統)的主要原因。同時也考慮長期利益。中小企業可能無法從這筆交易中獲益。這些系統需要高水準的維護。

- 預計全球疫情將對各市場產生直接和長期影響。例如,疫情發生以來,一些受到影響的國家經濟尚未如預期復甦,尤其是北美和歐洲籠罩在景氣衰退的陰影之下。

- 例如,國際貨幣基金組織(IMF)估計,美國實際GDP成長率預計將在2024年放緩,然後恢復勢頭。這種趨勢可能會減少對新金屬和採礦廠的投資,從而減緩市場發展。

- 根據國際貨幣基金組織(IMF)2023年7月的最新預測,由於各國央行提高利率以對抗通膨且經濟活動放緩,預計2023年和2024年全球經濟成長將從2022年的3.5%放緩至3%左右。

採礦傳送帶的市場趨勢

紡織增強傳送帶成長強勁。

- 紡織增強傳送帶通常用於輸送磨料或重負載。對於較短的運輸距離和較小的運輸量,紡織增強傳送帶比鋼絲傳送帶價格更實惠。紡織增強傳送帶是採礦、礦物加工和採石產業的理想選擇。它們具有多種特性,包括耐油性、耐熱性、耐磨性、耐衝擊性和耐火性。高強度輸送帶的加強結構有四種基本結構:簾線織物、直經織物、實心織物和纜繩織物。

- 織物帶的汽車胎體或編織內部結構由夾在橡膠基減震層之間的一系列單層或多層合成纖維層組成。上下皮帶皆採用橡膠覆蓋層構造,耐用、耐磨、防切割。此蓋可保護皮帶免受損壞,尤其是在傳送帶的裝載點處。它為採礦業使用的傳送帶提供抗張強度。

- 技術紡織品中使用的合成纖維比以前使用的天然纖維具有更高的強度、伸長率和柔韌性。主要纖維有棉、黏膠纖維、尼龍、聚酯纖維、玻璃和芳香聚醯胺。芳香聚醯胺的韌性是鋼的七倍,但重量卻比芳香聚醯胺輕。它可耐受 400-500°C 的溫度、潮濕、化學品,並且還具有很強的耐磨性。這就是它們被用於採礦傳送帶的原因。其強度對採礦業輸送帶的承載能力和生產安全有重要的影響。因此,預計紡織增強傳送帶等材料將變得更加受歡迎,以增加傳送帶的強度。

- 皮帶製造商提供編織皮帶表,該表反映了根據皮帶上所承載的各種材料類型和等級提案的皮帶層數。在傳送帶中,編織織物優於鋼筋,因為它們更靈活、強度更高、節能、耐腐蝕且重量更輕。

- 由於多個地區採礦活動的增加以及對採礦業的投資增加,預計預測期內對紡織增強輸送帶的需求將會上升。

亞太地區成長強勁

- 中國政府雄心勃勃的「中國製造2025」舉措在某種程度上受到德國的啟發,該計畫面向工業4.0,旨在提高中國在工業領域的競爭力。該十年規劃於2015年5月推出,是政府競標推動製造業向全球產業價值鏈的中高階邁進並培育若干先進製造業叢集做出的努力。工業化程度的提高可能會推動採礦業傳送帶解決方案市場的成長。

- 據國家發展和改革委員會稱,2024年4月,中國宣布將建造更多煤礦,以幫助增加國內供應並抑制價格上漲。中國是世界上最大的煤炭生產國和消費國,已設定目標,到2030年新增約3億噸/年的開採能力,作為「應急儲備」。

- 政府對基礎設施的投資和來自產業的投資增加,再加上「印度製造」計劃,預計將推動市場研究。印度政府已將工業部門在國內生產總值(GDP)中的佔有率從2018年的17%提高到2022年的25%。

- 2024年2月,印度國有印度煤炭公司宣布將在5個新煤礦投入營運,並擴大至少16個現有煤礦的產能,以滿足日益成長的石化燃料需求。該礦計劃在下一會計年度啟動五座新礦,總合年產量達 1,430 萬噸。印度採礦業的這些發展可能會推動該地區的市場探索。

礦用輸送帶產業概況

由於存在小型、中型和大型企業以及全球性公司,採礦輸送帶市場高度分散。市場的主要企業包括3D控股集團、芬納鄧祿普澳洲有限公司(米其林集團)、阪東化學工業有限公司、康迪泰克德國有限公司(大陸集團)和 Tenova SPA(Techint 集團)。市場參與者正在採取收購和夥伴關係等策略來加強其產品供應並獲得永續的競爭優勢。

- 2024 年 1 月 - Fenner Dunlop BV 和 Fenner Dunlop Americas 宣布,將於 2024 年 1 月 1 日起合併為 Fenner Dunlop Conveyor Belting 品牌。此舉旨在統一各地區和部門的品牌,以增強全球影響力。兩個部門都將以芬納鄧祿普輸送帶公司的名義進行經營,並協調一致的品牌策略。這項變化凸顯了芬納集團對加強合作和市場影響力的承諾。

- 2023 年 11 月 - Gebr.Kufferath AG 宣布 Durensite 獲得 IATF 16949 認證。此項認證證實了 GKD 對各行業最高品質標準的承諾。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 新冠肺炎疫情和其他宏觀經濟趨勢對市場的影響

- 在採礦業中,針對不同負載容量採用不同類型的輸送機解決方案

- 採礦設施中傳送系統的平均成本

第5章 市場動態

- 市場促進因素

- 基礎建設和建築業的成長

- 更重視職場的安全

- 市場限制

- 資本要求高,技術純熟勞工短缺

- 評估新冠肺炎對產業的影響

第6章 市場細分

- 按類型

- 鋼絲

- 紡織加固

- 其他類型

- 按地區

- 北美洲

- 歐洲

- 亞洲

- 澳洲和紐西蘭

- 拉丁美洲

- 中東和非洲

第7章 競爭格局

- 公司簡介

- Sanwei Holding Group Co. Ltd

- Fenner Dunlop Australia Pty Ltd(Michelin group)

- Bando Chemical Industries Ltd

- ContiTech Deutschland GmbH(Continental AG)

- Tenova SpA(Techint Group)

- Dynamic Rubbers Pvt. Ltd

- Oriental Rubber Industries Pvt. Ltd

- Zhejiang Double Arrow Rubber Co. Ltd

- Bridgestone Corporation

- GKD Gebr. Kufferath AG

第8章投資分析

第9章 市場機會與未來趨勢

The Conveyor Belt Market In Mining Industry is expected to grow from USD 1.96 billion in 2025 to USD 2.36 billion by 2030, at a CAGR of 3.8% during the forecast period (2025-2030).

The demand is boosted owing to increasing government initiatives and the number of coal mines in countries such as India. For instance, during the second pandemic wave, the Technology Roadmap document released by Coal India outlines that conveyors that may handle coal up to 4,500 tph/hr have been planned in Coal India. Conventional conveyors are limited to inclined angles around 16 to 18 degrees. The focus on upgrading the mines with advanced conveyor belts is aiding the market's growth.

Key Highlights

- In mining industry practices, the required output is desired, and the mining operator specifies rotary speed as a design parameter, determining the heat to be dissipated. This may strongly influence the dimensioning processes. This resulted in operating conditions that make a gear unit advisable larger than the output originally necessitates. If the conveyor belts operate in climatic zones that are unusually warm or even prone to extreme heat-cold fluctuations, much attention must be paid to cooling. For this reason, Siemens developed correspondingly efficient cooling solutions for its three gear-unit series, comprising 46 conveyor belt drive sizes. Therefore, in various cases, a smaller gear unit may be sufficient.

- India's journey toward becoming a developed nation by 2047 depends on improving its infrastructure. This is a cornerstone for fostering liveable, climate-resilient, and inclusive cities that drive economic growth. The government's commitment is evident through its allocation of 3.3% of GDP to the infrastructure sector in the fiscal year 2024, focusing on building high-end industrial segments.

- Ensuring occupational health and safety is a top priority in the mining industry. Mining operations are inherently challenging and pose various hazards and risks to workers. By prioritizing safety and implementing effective safety measures, companies may protect their workers, prevent accidents and injuries, and contribute to the overall sustainability of their operations.

- The mining industry operates under critical regulations and standards to ensure safety, environmental protection, and responsible practices. These include mine safety and health regulations, such as the Mine Safety and Health Administration (MSHA) in the United States.

- High initial costs have been the primary reason for restricting the use of automated material-handling systems, including conveyor belts and systems, to only large-scale organizations. At the same time, their long-term benefits are also considered. Small-and medium-scale enterprises may not benefit from this bargain. These systems require high levels of maintenance.

- Besides the direct impact on various market verticals, the global pandemic is also anticipated to have a long-term effect. For instance, since the pandemic, economies of multiple countries, which feel significant, are still unable to recover as anticipated, bringing a shadow of economic recession, especially in North American and European regions.

- For instance, according to the International Monetary Fund (IMF) estimates, the US real GDP growth is anticipated to remain slowed until 2024 before regaining momentum. Such trends may slow down the market by reducing investments in new metal and mining plants.

- According to the International Monitory Fund's (IMF's) July 2023 update, global economic growth was anticipated to fall from 3.5% in 2022 to about 3% in both 2023 and 2024 owing to the rising central bank policy rates to fight inflation, which is slowing down economic activities.

Mining Conveyor Belt Market Trends

Textile-reinforced Conveyor Belts to Witness Significant Growth

- Conveyor belts with textile reinforcement are typically used for abrasive and heavy-duty goods. They are a more affordable alternative to steel cord belts for shorter transporting distances and lesser capacities. The textile-reinforced conveyor belt is ideal for mining, mineral processing, and quarrying sectors. It may be blended with many different qualities, such as covers that are grease, heat, abrasion, impact, and fire-resistant quality. There are four basic types of construction for reinforcing high-strength belts: cord fabrics, straight warp fabrics, solid woven fabric, and cabled cords.

- The internal structure of a fabric belt carcass or textile consists of a single or multi-layered series of synthetic fabric layers interlaced between rubber-based shock-absorbent layers. The top and bottom sides of the belt consist of hard-wearing, abrasion, and cut-resistant rubber covers. The covers protect the belt from damage, especially at the loading points of the conveyor. This provides the tensile strength to the conveyor belt used in the mining industry.

- The strength, extension, and flexibility of synthetic fibers used in technical woven fabrics are higher than natural fibers used earlier. The primary fibers are cotton, viscose rayon, nylon, polyester, glass, and aramid. The aramid tenacity is seven times that of steel, and aramid is lighter than steel. It resists temperatures of 400-500 0C, dampness, and chemicals and has high abrasion resistance. Thus, it is used in mining conveyor belts. Its strength significantly influences the mining industry's carrying capacity and operating safety of conveyor belts. Therefore, materials like textile-reinforced conveyor belts are anticipated to become more prevalent to boost the conveyor belt's strength.

- The belting manufacturers supply tables for fabric belting, reflecting the number of plies proposed for a belt based on the different types and grades of materials to be transported on the belt. The fabric is better than steel reinforcement in conveyor belts as textiles make it much more flexible, high-strength, energy-efficient, corrosion-resistant, and lightweight.

- With rising mining activities across several regions and increased investments in the mining industry, the need for textile-reinforced conveyor belts is expected to rise in the forecast period.

Asia-P acific to Register Major Growth

- The government's ambitious 'Made in China 2025' initiative, partially inspired by Germany, for Industry 4.0 aims to boost the country's competitiveness in the industrial sector. The ten-year plan, introduced in May 2015, is the government's bid to shift the industries up to the medium-high end of the global industry value chain and foster several advanced manufacturing clusters. The increase in industrialization will grow the market for conveyor belt solutions for the mining sector.

- In April 2024, according to the National Development and Reform Commission, China announced it would build more coal mines to push for higher domestic supply and tame price increases. The world's biggest coal producer and consumer set targets to add about 300 million tons of annual mining capacity for "emergency storage reserves" by 2030.

- The increased government's infrastructure investments and investments from industries, coupled with the 'Make in India' initiative, are expected to drive the market studied. The Government of India increased the industrial sector's share of the gross domestic product (GDP) to 25% by 2022, from 17% in 2018.

- In February 2024, Indian state-run company Coal India announced it would begin operations at five new coal mines and expand the capacity of at least 16 existing mines to help meet the growing demand for fossil fuel. The miner plans to start operations at five new mines in the next fiscal year, with a combined annual capacity of 14.3 mt. These developments in the mining sector in India are likely to drive the market studied in the region.

Mining Conveyor Belt Industry Overview

The mining conveyor belt market is highly fragmented due to the presence of small and medium-sized enterprises and global players. Some of the major players in the market are Sanwei Holding Group Co. Ltd, Fenner Dunlop Australia Pty Ltd (Michelin Group), Bando Chemical Industries Ltd, Contitech Deutschland GMBH (continental AG), and Tenova SPA (Techint Group). Players in the market are adopting strategies such as acquisitions and partnerships to enhance their product offerings and gain sustainable competitive advantage.

- January 2024 - Fenner Dunlop BV and Fenner Dunlop Americas announced they would merge under the Fenner Dunlop Conveyor Belting brand starting January 1, 2024. The move aims to unify the brand across regions and divisions for a more robust global presence. Both divisions will trade under the Fenner Dunlop Conveyor Belting name, aligning their strategies for consistent branding. This change underscores the Fenner Group's commitment to enhanced coordination and market impact.

- November 2023 - Gebr. Kufferath AG announced the successful certification from IATF 16949 for the Durensite. The certification confirms GKD's commitment to the highest quality standards in various industries.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitutes

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Impact of COVID-19 Aftereffects and Other Macroeconomic Trends on the Market

- 4.5 Various Types of Conveyor Solutions for Various Payloads Handled in the Mining Industry

- 4.6 Average Cost for Conveyor Systems in a Mining Setup

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rise in Infrastructure Development and the Building Industry

- 5.1.2 Increased Emphasis on Workplace Safety

- 5.2 Market Restraints

- 5.2.1 High Capital Requirements and Unavailability for Skilled Workforce

- 5.3 Assessment of the Impact of COVID-19 on the Industry

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Steel Cord

- 6.1.2 Textile Reinforced

- 6.1.3 Other Types

- 6.2 By Geography

- 6.2.1 North America

- 6.2.2 Europe

- 6.2.3 Asia

- 6.2.4 Australia and New Zealand

- 6.2.5 Latin America

- 6.2.6 Middle East & Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Sanwei Holding Group Co. Ltd

- 7.1.2 Fenner Dunlop Australia Pty Ltd (Michelin group)

- 7.1.3 Bando Chemical Industries Ltd

- 7.1.4 ContiTech Deutschland GmbH (Continental AG)

- 7.1.5 Tenova SpA (Techint Group)

- 7.1.6 Dynamic Rubbers Pvt. Ltd

- 7.1.7 Oriental Rubber Industries Pvt. Ltd

- 7.1.8 Zhejiang Double Arrow Rubber Co. Ltd

- 7.1.9 Bridgestone Corporation

- 7.1.10 GKD Gebr. Kufferath AG