|

市場調查報告書

商品編碼

1690118

工業 4.0 -市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Industry 4.0 - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

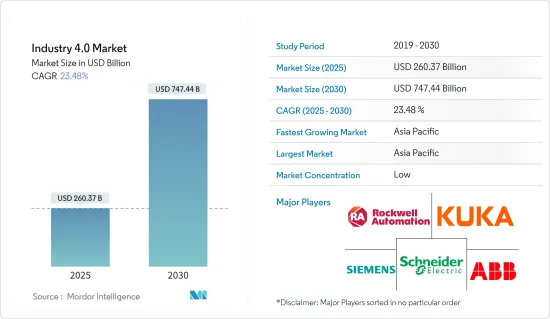

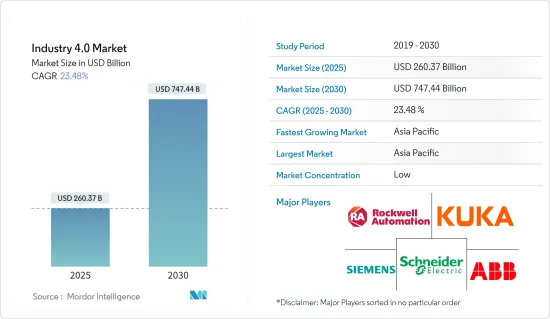

預計 2025 年工業 4.0 市場規模為 2,603.7 億美元,到 2030 年將達到 7,474.4 億美元,預測期內(2025-2030 年)的複合年成長率為 23.48%。

快速成長的全球工業 4.0 市場正在改變全球眾多產業。工業4.0,又稱第四次工業革命,是將最新技術和數位解決方案融入生產流程,打造智慧工廠,提高生產效率的過程。

關鍵亮點

- 工業 4.0 市場正在經歷快速成長,這得益於智慧製造的廣泛應用、連網型設備的激增以及對即時資料分析以支持敏捷決策的日益成長的需求。在快速發展的工業格局中,企業正在轉向工業 4.0 解決方案,以抓住機會簡化業務、最佳化資產利用率並開闢新的收益來源。

- 製造商必須接受以工業 4.0 為導向的數位轉型,以變得更加靈活、敏捷並應對力客戶需求。這種轉變的關鍵促進因素包括利潤預期、新的市場機會、勞動力問題、不斷變化的客戶需求、競爭壓力以及對品質驅動的品牌形象的追求。

- 例如,工業 4.0 是由不斷變化的最終客戶需求所驅動的。 3D 列印等技術正在將數位設計轉化為有形產品,這種轉變在工業環境中正在獲得發展動力。最終產品可以大規模生產,但又可以依照個人喜好進行客製化。使用數位系統設計和創造產品為公司和最終用戶提供了靈活性。人類洞察力和即時資料分析的結合可能很快就會催生一個數位生態系統,在這個生態系統中,人類的判斷能力會透過演算法得到增強。

- 然而,要使所研究的市場實現永續成長,需要解決幾個障礙。例如,第四次工業革命面臨著許多挑戰,例如解決與人工智慧相關的倫理問題、保護資料隱私、提高勞動力在數位經濟中的角色技能以及確保公平獲得技術。

- 新冠肺炎疫情影響了基礎建設、交通運輸和製造業等多個領域。作為回應,一些國家的政府實施了封鎖規定。因此,公眾基本上遵守了居家令和社交距離準則。結果導致汽車等產品的需求急劇下降,迫使主要企業削減營運能力。但在動盪之中,該地區的一些工業公司已轉向自動化,以應對疫情帶來的挑戰。鑑於這些技術帶來的好處,疫情期間預計獲得的見解將激勵供應商進一步採用自動化和工業控制解決方案。這種轉變將在預測期內所研究的市場中創造機會。

工業4.0市場趨勢

工業物聯網技術領域佔主要市場佔有率

- 作為工業 4.0 的基石,物聯網 (IoT) 在製造業和服務業的生產系統監控中發揮著至關重要的作用。物聯網使製造商能夠為創新鋪平道路並提高業務績效。物聯網的核心是透過連接到網際網路的機器和設備收集和傳播資料。每個設備都有一個獨特的識別號碼或代碼,可以透過智慧型手機等日常設備進行控制。

- 該技術的主要組成部分是軟體和硬體,它們透過網路互連來收集和修改資料。物聯網不僅僅是一種工具;它是製造業顛覆性創新的催化劑。實現物聯網的潛力對於現代生產系統至關重要。在工業 4.0 領域,物聯網是個重大飛躍,能夠對製造過程進行全面、智慧的監控。

- 工業物聯網 (IIoT) 技術在推動工業 4.0舉措方面發揮關鍵作用,並以多種方式展現其影響。其中一個關鍵體現就是智慧工廠方法,其中感測器和互連的監控和分析設備交換資料以實現即時增強。 5G 網路的快速普及增強了這種無縫通訊,確保了快速的資料傳輸,並透過保護這些連接的強大網路安全措施得到了加強。

- 製造業、汽車業和醫療業擴大採用工業IoT技術,推動市場擴張。在傳統製造業數位轉型的浪潮中,工業物聯網正站在變革的前沿,開啟智慧互聯的新工業革命。這種轉變正在重塑公司管理先進系統和機械的方式,旨在提高生產力並最大限度地減少停機時間。

- 工業 4.0 和 IIoT 是智慧工廠自動化中物流鏈開發、生產和管理的核心。隨著工業 4.0 和 IIoT 的實施顛覆製造業,企業被迫採用敏捷和創新的方法。這些方法不僅旨在透過使用機器人技術補充人類勞動來提高生產力,而且還旨在減少因製程故障造成的工傷。

- 製造業中連網型設備、感測器和 M2M通訊的激增導致資料點的激增。據愛立信稱,預計2022年至2028年間,全球連網設備的數量將增加近一倍。這一成長主要歸因於近距離物聯網 (IoT) 設備的數量將達到 287.2 億。

- 這些資料點包括基本指標(例如材料完成一個製程週期所需的時間)以及更高級的計算(例如評估汽車領域材料的應力能力)。 IIoT 有望成為滿足此類使用案例需求的解決方案。

亞太地區經濟強勁成長

- 幾年前,印度開始提出將自己轉變為製造業和出口強國的願景。該計劃旨在減少對進口的依賴,並增強該國作為全球製造業領導者的地位,能夠為國內消費和國際市場生產商品。

- 印度推出了「印度製造」和「自力更生印度」等宣傳活動來推動製造業的發展,目標是到2025年將其對GDP的貢獻率從目前的16%提高到25%。憑藉先進的技術和龐大的國內消費群,印度完全有能力生產出在品質和價格上具有全球競爭力的產品。但要實現這一潛力,印度需要超越單純的雄心壯志,擁抱工業 4.0。印度物聯網的出現預示著這場技術革命的到來,尤其是在政府的「數位印度」計畫下。

- 在全球範圍內,各行各業都在見證工業 4.0 帶來的好處。對印度來說,這是一個及時的機會來重新建構其敘事,特別是考慮到全球政治格局的變化以及已開發國家對擺脫傳統製造地的興趣重新燃起。

- 面對地緣政治變化、技術落後和競爭優勢,中國產業正經歷轉型期。隨著工業4.0的清晰軌跡,中國製造業必將迎來快速加速。作為全球最大的製造地,中國正處於數位革命的前沿,利用其龐大的工業基礎和技術力始終處於創新前沿。

- 中國政府已推出「中國製造2025」等計劃,推動工業4.0技術的應用,提升製造能力,培育高科技產業。受德國工業4.0的啟發,「中國製造2025」專注於開發雲端物聯網和量身定做的工業自動化系統。

- 為了加強全球影響力,日本機器人自動化供應商不僅擴大了生產能力,還在海外建立製造地。例如,2024年7月,FANUC美國子公司在密西根州開設了一家價值1.1億美元的工廠。該設施將專門用於儲存、銷售和維護日本製造的工業機器人,特別針對北美客戶。

工業4.0行業概覽

工業 4.0 市場較為分散,主要參與者包括 ABB、西門子股份公司、羅伯特博世有限公司和羅克韋爾自動化。該市場的參與企業正在採取夥伴關係、投資和收購等策略來加強其產品供應並獲得永續的競爭優勢。

- 2024年8月-施耐德電機在多個城市舉辦的2024年創新日推出了八款尖端產品和解決方案。這些活動為施耐德電機提供了一個動態平台,展示其最新的創新成果,並專注於效率、可靠性、永續性和安全性方面的改進。此外,產業專家還將舉辦會議,旨在推動整個生態系統的轉型。

- 2024 年 6 月—ABB 機器人公司推出 OmniCore,這是一個優先考慮速度、精度和永續性的先進自動化平台。 OmniCore 平台在下一代機器人技術上投資超過 1.7 億美元,標誌著其向模組化、先進控制架構邁出了關鍵一步。該架構無縫整合了人工智慧、感測器、雲端和邊緣運算,為尖端自主機器人應用奠定了基礎。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 市場概覽

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 市場促進因素

- 政府積極措施和相關人員之間的合作

- 工業機器人需求不斷成長

- 中小企業如何因應數位轉型

- 市場限制

- 對工業 4.0 採用的投資報酬率 (ROI) 認知相對缺乏

- 勞動力和標準化挑戰

- 宏觀經濟趨勢對市場的影響

- 技術簡介

第5章市場區隔

- 依技術類型

- 工業機器人

- IIoT

- 人工智慧和機器學習

- 區塊鏈

- 擴增實境

- 數位雙胞胎

- 3D列印

- 其他

- 按最終用戶產業

- 製造業

- 車

- 石油和天然氣

- 能源公共產業

- 電子鑄件

- 飲食

- 航太與國防

- 其他

- 按地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 亞洲

- 印度

- 中國

- 日本

- 澳洲和紐西蘭

- 拉丁美洲

- 中東和非洲

- 北美洲

第6章 競爭格局

- 公司簡介

- ABB Ltd

- Siemens AG

- Schneider Electric

- Swisslog Holding AG(Kuka AG)

- Rockwell Automation Inc.

- Cognex Corporation

- Honeywell International Inc.

- Robert Bosch GmbH

- Johnson Controls International PLC

- Emerson Electric Company

- General Electric Company

- Cisco Systems Inc.

- Intel Corporation

- Fanuc Corporation

- Denso Corporation

第7章投資分析

第8章:市場的未來

The Industry 4.0 Market size is estimated at USD 260.37 billion in 2025, and is expected to reach USD 747.44 billion by 2030, at a CAGR of 23.48% during the forecast period (2025-2030).

Numerous industries all around the world are being transformed by the global Industry 4.0 market, which is growing quickly. Industry 4.0, also referred to as the fourth industrial revolution, is the process of integrating modern technologies and digital solutions into production processes in order to build intelligent factories and increase production efficiency.

Key Highlights

- The Industry 4.0 market is experiencing rapid growth, fueled by the rising adoption of smart manufacturing, the surge of connected devices, and the escalating demand for real-time data analytics to enhance agile decision-making. In a fast-evolving landscape, organizations are turning to Industry 4.0 solutions, seizing opportunities to streamline operations, optimize asset use, and tap into new revenue streams.

- Manufacturers find it imperative to embrace digital transformation toward Industry 4.0, enhancing their flexibility, agility, and responsiveness to customer needs. Key drivers for this shift include anticipated benefits, emerging market opportunities, labor challenges, evolving customer demands, competitive pressures, and the pursuit of a strong quality-centric brand image.

- For example, Industry 4.0 is being driven by the changing demands of end customers. Technologies like 3-D printing are transforming digital designs into tangible products, and this shift is gaining momentum in industrial settings. As a result, products can be tailored to individual preferences, even while being produced in masse. Leveraging digital systems for product design and creation offers flexibility for both businesses and end users. By merging human insights with real-time data analysis, the world may soon see the emergence of a digital ecosystem where human decisions are enhanced by algorithms.

- However, there are several hurdles that need to be addressed for uninterrupted growth of the studied market. For example, the 4th industrial revolution faces challenges such as tackling ethical concerns tied to artificial intelligence, safeguarding data privacy, upskilling the workforce for roles in a digital economy, and guaranteeing fair access to technology.

- The COVID-19 outbreak challenged various sectors, including infrastructure, transportation, and manufacturing. In response, the government across several countries imposed lockdown restrictions. As a result, the public largely followed stay-at-home orders and social distancing guidelines. This adherence led to a significant drop in the demand for products like automobiles, forcing companies to operate at reduced capacities. Yet, amidst this turmoil, several regional industrial enterprises turned to automation as a means to navigate the pandemic's challenges. Given the advantages these technologies present, the insights gained during the pandemic are expected to motivate vendors to further embrace automation and industrial control solutions. This shift is poised to create opportunities in the market studied during the forecast period.

Industry 4.0 Market Trends

IIoT Technology Segment Holds Significant Market Share

- As a cornerstone of Industry 4.0, the Internet of Things (IoT) plays a pivotal role in monitoring production systems across both manufacturing and service sectors. By harnessing IoT, manufacturers can unlock innovative avenues, driving enhanced performance. At its core, IoT excels in gathering and disseminating data via internet-connected machines and devices. Each device is tagged with a unique identification number or code, allowing control through everyday gadgets like smartphones.

- Key components of this technology encompass software and hardware, all interconnected through a network for data collection and alteration. IoT is not just a tool; it is a catalyst for disruptive innovation in manufacturing. Recognizing the potential of IoT is essential for modern production systems. Within the realm of Industry 4.0, IoT stands out as a significant leap forward, enabling comprehensive smart monitoring of manufacturing processes.

- IIoT technologies play a pivotal role in driving Industry 4.0 initiatives, showcasing their impact in various forms. A dominant manifestation is the smart factory approach, where sensors and interconnected monitoring/analysis devices exchange data, enabling real-time enhancements. This seamless communication is bolstered by the swift adoption of 5G networks, ensuring rapid data transfer and fortified by robust cybersecurity measures to safeguard these connections.

- The growing adoption of industrial IoT technology across manufacturing, automotive, and healthcare sectors is driving positive market expansion. As the traditional manufacturing sector undergoes a digital transformation, the IIoT is spearheading this evolution, heralding a new industrial revolution of intelligent connectivity. This transformation is reshaping how businesses manage their sophisticated systems and machinery, aiming to boost productivity and minimize downtime.

- At the heart of the logistics chain's development, production, and management, termed smart factory automation, lie Industry 4.0 and IIoT. As manufacturing undergoes seismic shifts due to Industry 4.0 and the embrace of IIoT, businesses are compelled to adopt agile, innovative methods. These methods not only enhance production through technologies that complement human labor with robotics but also aim to curtail industrial accidents stemming from process failures.

- The surge in connected devices, sensors, and M2M communication in the manufacturing sector has led to an explosion of generated data points. According to Ericsson, Between 2022 and 2028, the global count of connected devices is projected to nearly double. This surge is largely attributed to the rise of short-range IoT (Internet of Things) devices, with forecasts estimating 28.72 billion of these devices by 2028.

- These data points vary widely, from basic metrics like the time taken for materials to complete a process cycle to advanced calculations, such as assessing material stress capabilities in the automotive sector. IIoT is expected to be the solution to address the requirements of such use cases.

Asia Pacific to Register Significant Growth

- Years ago, India embarked on a vision to transform into a manufacturing and export powerhouse. This initiative aimed to reduce the nation's reliance on imports and elevate India's status as a global manufacturing leader, capable of producing goods for both domestic consumption and international markets.

- Campaigns such as 'Make In India' and 'Atmanirbhar Bharat' were introduced to bolster the manufacturing sector, targeting a GDP contribution of 25% by 2025, up from the current 16%. With advanced technology and a vast internal consumer base, India stands poised to produce globally competitive products in quality and price. Yet, to realize this potential, India requires more than just ambition; and it needs to embrace Industry 4.0. The advent of IoT in India, especially under the government's "Digital India" initiative, heralds this technological revolution.

- Globally, industries are witnessing the benefits of Industry 4.0, which promises to minimize defects and wastage in production. For India, this presents a timely opportunity to reshape its narrative, especially given the shifting global political landscape and the renewed interest from developed nations in diversifying away from their traditional manufacturing hubs.

- Amidst geopolitical shifts, technological lags, and competitive advantages, China's industries are in a state of transformation. With a clear trajectory toward Industry 4.0, China's manufacturing sector is set for rapid acceleration. As the world's largest manufacturing hub, China is at the helm of the digital revolution, harnessing its expansive industrial base and technological capabilities to spearhead innovation.

- The Chinese government, with initiatives like "Made in China 2025", is championing the adoption of Industry 4.0 technologies, aiming to elevate manufacturing capabilities and nurture high-tech industries. Drawing inspiration from Germany's Industry 4.0, "Made in China 2025" focuses on developing cloud-driven IoT and tailored industrial automation systems.

- In a bid to enhance their global footprint, Japanese robot and automation suppliers have not only increased their production capacities but have also established manufacturing sites overseas. For example, in July 2024, Fanuc's US subsidiary inaugurated a USD 110 million facility in Michigan. This facility is dedicated to storing, selling, and maintaining industrial robots, all manufactured in Japan, specifically catering to North American clientele.

Industry 4.0 Industry Overview

The Industry 4.0 Market is fragmented, with the presence of major players like ABB Ltd, Siemens AG, Robert Bosch GmbH, and Rockwell Automation Inc., among others. Players in the market are adopting strategies such as partnerships, investments, and acquisitions to enhance their product offerings and gain sustainable competitive advantage.

- August 2024 - During its Multi-city INNOVATION DAYS 2024, Schneider Electric introduced eight state-of-the-art products and solutions. These events serve as a dynamic platform for Schneider Electric to present its newest innovations, highlighting improvements in efficiency, reliability, sustainability, and safety. Furthermore, the event features sessions conducted by industry experts with the goal of fostering transformative changes across the ecosystem.

- June 2024 - ABB Robotics launched OmniCore, an advanced automation platform that prioritizes speed, precision, and sustainability, with the goal of empowering businesses for the future. With over USD 170 million invested in next-gen robotics, the OmniCore platform marked a pivotal move toward a modular and forward-thinking control architecture. This architecture seamlessly integrates AI, sensors, cloud, and edge computing, setting the stage for cutting-edge autonomous robotic applications.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Market Drivers

- 4.3.1 Favorable Governmental Initiatives and Collaborations Between Stakeholders

- 4.3.2 Growth in Demand for Industrial Robotics

- 4.3.3 Digital Transformation Initiatives Undertaken by SMEs

- 4.4 Market Restraints

- 4.4.1 Relative Lack of Awareness on the ROI Related to Adoption of Industry 4.0

- 4.4.2 Workforce and Standardization Related Challenges

- 4.5 Impact of Macroeconomic Trends on the Market

- 4.6 Technology Snapshot

5 MARKET SEGMENTATION

- 5.1 By Technology Type

- 5.1.1 Industrial Robotics

- 5.1.2 IIoT

- 5.1.3 AI and ML

- 5.1.4 Blockchain

- 5.1.5 Extended Reality

- 5.1.6 Digital Twin

- 5.1.7 3D Printing

- 5.1.8 Other Technology Types

- 5.2 By End-user Industry

- 5.2.1 Manufacturing

- 5.2.2 Automotive

- 5.2.3 Oil and Gas

- 5.2.4 Energy and Utilities

- 5.2.5 Electronics and Foundry

- 5.2.6 Food and Beverage

- 5.2.7 Aerospace and Defense

- 5.2.8 Other End-user Industries

- 5.3 By Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.2 Europe

- 5.3.2.1 Germany

- 5.3.2.2 United Kingdom

- 5.3.2.3 France

- 5.3.2.4 Spain

- 5.3.3 Asia

- 5.3.3.1 India

- 5.3.3.2 China

- 5.3.3.3 Japan

- 5.3.4 Australia and New Zealand

- 5.3.5 Latin America

- 5.3.6 Middle East and Africa

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 ABB Ltd

- 6.1.2 Siemens AG

- 6.1.3 Schneider Electric

- 6.1.4 Swisslog Holding AG (Kuka AG)

- 6.1.5 Rockwell Automation Inc.

- 6.1.6 Cognex Corporation

- 6.1.7 Honeywell International Inc.

- 6.1.8 Robert Bosch GmbH

- 6.1.9 Johnson Controls International PLC

- 6.1.10 Emerson Electric Company

- 6.1.11 General Electric Company

- 6.1.12 Cisco Systems Inc.

- 6.1.13 Intel Corporation

- 6.1.14 Fanuc Corporation

- 6.1.15 Denso Corporation