|

市場調查報告書

商品編碼

1689769

乙烯基酯:市場佔有率分析、行業趨勢和統計、成長預測(2025-2030 年)Vinyl Ester - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

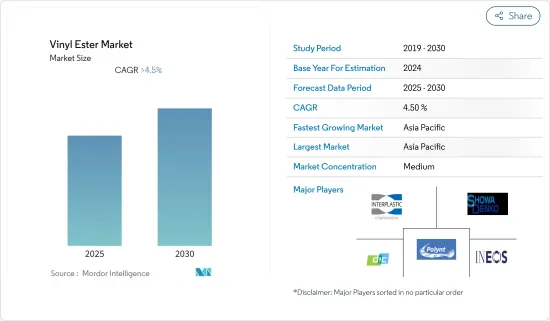

預測期內,乙烯基酯市場預計將以超過 4.5% 的複合年成長率成長。

儘管COVID-19疫情在2020年對市場產生了負面影響,但據估計和預測,市場規模已達到疫情前的水平,預計在預測期內(2022-2027年)將實現穩定成長。

推動市場發展的首要因素是纖維增強塑膠在製造罐體和容器中的應用日益增多以及在製造耐腐蝕設備中的應用日益增多。

然而,乙烯基酯樹脂的毒性阻礙了市場的成長。

預計預測期內排煙脫硫應用的不斷擴大將為市場成長提供各種機會。

亞太地區佔據乙烯基酯市場主導地位,其中中國、印度和日本對市場需求貢獻巨大。

乙烯基酯市場趨勢

管道和儲罐行業有望主導市場

為了避免耗時的維護和維修,各行各業都在選擇能夠抗腐蝕和耐高溫且不會失去強度和耐久性的複合材料。

近年來,纖維增強塑膠(FRP)在管道和儲存槽中的使用增加。乙烯基酯樹脂因具有優異的耐化學性和低滲透性而廣泛應用於許多行業。

它廣泛用於製造纖維增強塑膠(FRP)儲存槽、管道和鴨系統。據估計,管道和儲罐部分佔據乙烯基酯市場的最大佔有率。

乙烯基酯基玻璃鋼管道及儲槽廣泛應用於氯鹼及化學工業、發電工業、礦山冶金工業、工業用水及污水工業、食品加工業、紙漿工業等。

乙烯基酯玻璃鋼管道在電力工業中有廣泛的應用。例如,漿液管路、脫硫噴淋集管、儲存槽等。

乙烯基酯管道在工業污水應用中也很受歡迎,因為它可以降低長期維護和泵浦的營業成本。

考慮到上述因素,管道和儲罐部分預計將佔據市場主導地位。

中國可望主導亞太市場

在亞太地區,中國是GDP最大的經濟體。

根據中國石油天然氣集團公司預測,2020年中國天然氣消費量預計將增加至3,200億立方米,到2040年將激增至約6,000億立方米。為了滿足日益成長的天然氣需求,該計劃在2040年將天然氣產量加倍,達到3,250億立方公尺。

未來五年,該國計劃建造多家化工廠。BASF已開始在中國南部廣東省建設一個投資 100 億美元的綜合石化計劃。該工廠一期預計將於 2022年終運作。

中國是世界上最大的汽車生產國。 2021年1-9月產量與2020年同期相比成長了53%。

鑑於上述情況,預計中國將主導亞太市場。

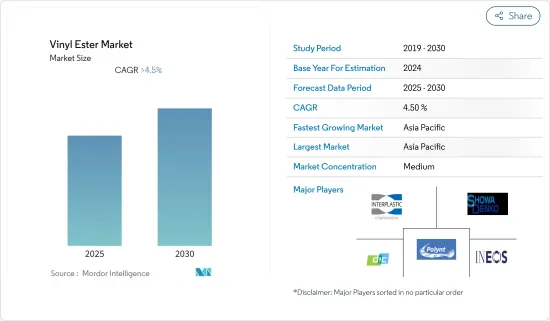

乙烯基酯產業概況

乙烯基酯市場部分整合,主要企業佔有相當大的佔有率。前五大企業合計佔60%以上的市佔率。主要參與者(不分先後順序)包括 Polynt、INEOS、DIC CORPORATION、Interplastic Corporation 和 Showa Denko K.K.

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 調查前提條件

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 驅動程式

- 擴大在纖維增強塑膠罐和容器製造的應用

- 在製造耐腐蝕設備的應用日益廣泛

- 限制因素

- 樹脂毒性

- 其他阻礙因素

- 產業價值鏈分析

- 波特五力分析

- 新進入者的威脅

- 買家的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭程度

- 進出口趨勢

- 原料分析

- 技術簡介

- 定價分析

第5章 市場區隔

- 類型

- 雙酚 A 二縮水甘油醚(DGEBA)

- 環氧PHENOLIC NOVOLAC(EPN)

- 其他類型

- 應用

- 管道和儲罐

- 油漆和塗料

- 運輸

- 其他用途

- 地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭格局

- 併購、合資、合作、協議

- 市場佔有率(%)**/排名分析

- 主要企業策略

- 公司簡介

- AOC

- Bkdj Polymers India

- DIC CORPORATION

- INEOS

- Interplastic Corporation

- Poliya

- Polynt

- Scott Bader Company Ltd

- SHOWA DENKO KK

- Sino Polymer Co. Ltd

- Swancor

第7章 市場機會與未來趨勢

- 排煙脫硫應用的成長

The Vinyl Ester Market is expected to register a CAGR of greater than 4.5% during the forecast period.

The COVID-19 pandemic impacted the market negatively in 2020; however, it has been estimated to have reached pre-pandemic levels and is expected to grow at a steady rate during the forecast period (2022-2027).

The major factors driving the market are growing application in the manufacture of fiber-reinforced plastic tanks and vessels and increasing application in making corrosion-resistant equipment.

On the flip side, the toxicity of vinyl ester resin is hindering the growth of the market studied.

The growing application in flue gas desulphurization is expected to offer various opportunities for the growth of the market studied over the forecast period.

The Asia-Pacific region dominated the market for vinyl ester, with China, India, and Japan being the major contributors to the market demand.

Vinyl Ester Market Trends

The Pipes and Tanks Segment is Expected to Dominate the Market

To avoid losing a large amount of time to maintenance and repairs, the corrosion industry is choosing composite materials that are resistant to corrosion and can withstand high temperatures without losing their strength or durability.

The fiber-reinforced plastic (FRP) application in pipes and tanks has been rising in recent years. Vinyl ester resins are widely used in many industries due to their superior chemical resistance and low permeability.

They are being extensively used to fabricate fiber-reinforced plastic (FRP) storage tanks, pipelines, and duck systems. The pipes and tanks segment is estimated to have the largest share in the vinyl ester market.

Vinyl ester-based FRP pipes and tanks are widely used in industries such as the chlor-alkali and chemical industry, power generation industry, mining and metal industry, industrial water and wastewater industry, food processing industry, and pulp and paper industry.

Vinyl ester-based FRP pipings are used for many applications in the power industry. Some of these include slurry piping, FGD absorber spray headers, and storage tanks.

Vinyl ester-based pipes are also popular in industrial wastewater applications as they reduce long-term maintenance and pump operating costs.

Based on the above-mentioned aspects, the pipes and tanks segment is expected to dominate the market.

China is Expected to Dominate the Asia-Pacific Market

In the Asia-Pacific region, China is the largest economy in terms of GDP.

According to China National Petroleum Corp. (CNPC), the gas consumption in China was expected to rise to 320 billion cubic meters (BCM) in 2020; gas consumption is expected to surge to around 600 BCM by 2040. In order to meet the growing gas demand, the country is planning to double its gas production to 325 BCM by 2040.

There are numerous chemical plants lined up for construction within the period of the next five years in the country. BASF started the construction of its USD 10 billion integrated petrochemicals project, located in the southern province of Guangdong in China. The first phase of this plant is scheduled to come online by the end of 2022.

China is the world's largest automotive producer. The production increased by 53% in the first nine months of 2021 in comparison to the same period of 2020.

Based on the aforementioned aspects, China is expected to dominate the Asia-Pacific market.

Vinyl Ester Industry Overview

The vinyl ester market is partially consolidated, with the top players holding a significant share. The top five players account for a share of more than 60% of the total market. Some of the major players (in no particular order) include Polynt, INEOS, DIC CORPORATION, Interplastic Corporation, and SHOWA DENKO K.K., among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Application in the Manufacture of Fiber Reinforced Plastic Tanks and Vessels

- 4.1.2 Increasing Application in Making Corrosion-resistant Equipment

- 4.2 Restraints

- 4.2.1 Toxicity of the Resin

- 4.2.2 Other Restraints

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Threat of New Entrants

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Bargaining Power of Suppliers

- 4.4.4 Threat of Substitute Products

- 4.4.5 Degree of Competition

- 4.5 Import-export Trends

- 4.6 Feedstock Analysis

- 4.7 Technological Snapshot

- 4.8 Price Analysis

5 MARKET SEGMENTATION

- 5.1 Type

- 5.1.1 Bisphenol A Diglycidyl Ether (DGEBA)

- 5.1.2 Epoxy Phenol Novolac (EPN)

- 5.1.3 Other Types

- 5.2 Application

- 5.2.1 Pipes and Tanks

- 5.2.2 Paints and Coatings

- 5.2.3 Transportation

- 5.2.4 Other Applications

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share(%)**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 AOC

- 6.4.2 Bkdj Polymers India

- 6.4.3 DIC CORPORATION

- 6.4.4 INEOS

- 6.4.5 Interplastic Corporation

- 6.4.6 Poliya

- 6.4.7 Polynt

- 6.4.8 Scott Bader Company Ltd

- 6.4.9 SHOWA DENKO K.K

- 6.4.10 Sino Polymer Co. Ltd

- 6.4.11 Swancor

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Growing Application in Flue Gas Desulphurization