|

市場調查報告書

商品編碼

1689761

數位伺服壓力機:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Digital Servo Press - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

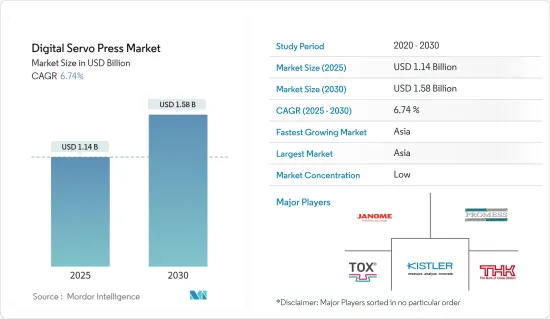

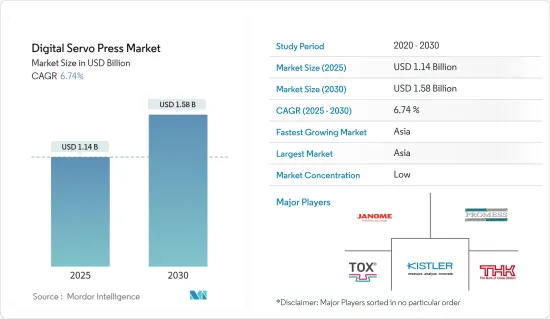

預計 2025 年數伺服壓力機市場規模將達到 11.4 億美元,預計到 2030 年將達到 15.8 億美元,預測期內(2025-2030 年)的複合年成長率為 6.74%。

由於製造自動化程度的提高和對組裝過程精度的要求不斷提高,數位伺服壓力機市場正在迅速發展。數位伺服壓力機在汽車、航太和電子產業中至關重要,因為它們提供精確的壓力控制並提高生產效率。這些系統的市場特點是伺服壓力機技術的創新,使製造商能夠實現更高的精度和操作靈活性。

數位伺服壓力機利用電動伺服馬達精確控制壓力機沖頭的移動。這項特性對於汽車、電子等精密組裝至關重要的產業尤其有益。伺服壓力機系統在各行各業的廣泛應用證明了伺服在現代製造流程中的重要性。

革命性的伺服壓力機技術

先進的控制系統:現代數位伺服壓力機具有先進的控制系統,可在壓制過程中進行即時調整。這些系統提高了施力的精度,這對於對零件組裝精度有較高要求的行業來說極為重要。將此控制系統納入伺服壓平機可提高其效率和多功能性,使其成為尋求最佳化生產線的製造商的首選機器。

提高能源效率:與傳統液壓機氣壓動機相比,數位伺服壓力機改用電動伺服馬達大大降低了能耗。這些電動系統不僅提高了能源效率,也減少了生產過程對環境的影響。製造業對永續性和降低成本的持續關注推動了節能伺服壓床的採用。

汽車需求:汽車產業是數位伺服壓力機的主要終端用戶,利用數位伺服壓力機組裝安全氣囊、變速箱和其他安全相關系統等關鍵零件。這些應用所需的精度推動了對能夠提供一致、可靠結果的高性能伺服壓力機的需求。隨著汽車製造商不斷創新和提高車輛安全標準,對先進伺服壓力機系統的需求預計將保持強勁。

數位伺服壓力機市場趨勢

電子製造商增加支出

電子製造業的成長:電子產業是數位伺服壓力機的另一個重要市場,特別是在精密零件的組裝中,最大限度地減少力量的波動至關重要。消費性電子產品的興起和電子設備的小型化增加了對精密組裝製程的需求,從而進一步增加了對伺服壓力機系統的需求。隨著電子設備變得越來越複雜,先進組裝壓機系統的市場可能會擴大。

數位伺服壓力機市場競爭激烈,幾家主要企業積極投資研發以增強其產品供應。 Janome Industrial Equipment、Promess 和 Kistler 等公司負責推出滿足各行業不斷變化的需求的創新。市場競爭可望推動伺服壓力機技術的進一步進步,促進全球市場成長和製造流程的持續改進。

電子製造商加大對數位伺服壓力機技術的投入:

電子製造業正在經歷顯著的成長,這推動了對數位伺服壓力機技術的投資增加。在電子組裝中,精度和效率至關重要,因此數位伺服壓力機必不可少。這些機器提供無與倫比的壓力控制,確保即使最精密的零件也能高精度地組裝,並最大限度地減少廢品。隨著電子設備的小型化,對於能夠處理複雜小型零件的先進伺服壓力機的需求正在快速成長,極大地促進了市場的擴張。將數位印刷自動化納入製造流程的趨勢對於尋求提高生產效率、減少廢棄物、減少停機時間和保持競爭力的電子製造商來說是一項策略性投資。

亞太地區引領電子製造市場:

該地區的領先地位部分歸功於製造工廠快速採用機器人和自動化技術,從而提高了效率和生產力。電子設備日益複雜,需要高精度的壓力系統,這推動了該地區對伺服壓力機的需求。因此,數伺服壓力機對於維持生產標準至關重要,特別是在將連接器連接到印刷電路基板等應用中。該地區的趨勢反映了全球採用先進製造技術來提高生產能力的動力。

汽車製造商對輕量化汽車的關注預計將推動對數位伺服壓力機的需求

汽車產業對減輕車輛重量的關注正在推動伺服壓力機市場的發展:

汽車產業正在努力減輕車輛重量,主要是為了提高燃油效率並滿足更嚴格的排放法規,這極大地推動了對數位伺服壓力機的需求。鋁和高強度鋼等對於輕型車輛的生產至關重要的材料需要這些壓力機提供的精確的成型能力。伺服壓力機技術提供的一致、可重複的結果對於生產車身面板和結構部件等零件至關重要,因為即使是最輕微的變化也會影響車輛的性能和安全性。隨著產業轉向電動車(EV),需要更多種類的零件,這些零件通常由輕量材料製成,數位伺服壓力機在確保品質和耐用性方面的作用變得更加關鍵。

全球對汽車輕量化的追求正在擴大伺服壓力機的應用範圍:

全球汽車市場越來越注重減輕汽車重量以提高燃油效率並減少對環境的影響。這一趨勢推動了對用於漸進伺服應用的數位伺服壓力機的需求,特別是那些能夠承受超過 200KN 力的壓力機。預計汽車製造業中高抗張強度鋼和輕鋁合金的使用將會增加,加速全球伺服壓力機的銷售。這一趨勢在亞洲尤其明顯,亞洲是乘用車生產的主要市場,隨著全球汽車製造商面臨減輕重量和提高汽車性能的雙重挑戰,這一趨勢預計還將持續下去。

電動車製造必備的伺服壓力機技術:

電動車(EV)的興起也是推動數位伺服壓力機技術需求的主要因素。電動車需要獨特的部件和組件,其中許多由輕量材料製成,需要精密的成型工藝。數伺服壓力機提供所需的精度和控制,以確保這些零件符合電動車製造所需的嚴格品質標準。隨著汽車產業不斷向電動車轉變,伺服壓力機技術的採用預計將加速,從而進一步推動市場成長。

伺服壓力機在各行各業的應用日益廣泛:

數位伺服壓力機系統的採用不僅限於汽車和電子產業。其他注重精度和效率的行業,例如航太和醫療設備製造,也正在加大對該技術的投資。伺服壓力機非常適合那些對精度要求較高的應用,因為它們可以提供一致的高品質結果。隨著行業不斷發展和採用更複雜的製造程序,對先進伺服壓力機技術的需求預計會增加,這些系統將成為現代生產線的關鍵組成部分。

數位伺服壓力機市場的未來前景:

由於技術進步和各行業的日益普及,數位伺服壓力機市場預計將持續成長。伺服壓力機技術的創新正在提高這些機器的效率和產能,使其更通用、更能滿足現代製造業的需求。隨著工業越來越重視永續性、精確度和效率,數位伺服壓力機將在生產過程中發揮更重要的作用。現在投資這項技術的公司將獲得競爭優勢,提高產品品質和業務效率,並在快速發展的市場環境中獲得長期成功。

數位伺服壓力機產業概況

分散的市場結構:數位伺服壓力機市場的特點是市場結構分散,全球和區域參與者的混合加劇了產業的競爭動態。雖然少數主要企業佔據了大部分市場佔有率,但大量較小的公司提供專門的產品,從而形成了多樣化的競爭格局。這種分散化導致了激烈的競爭和創新,推動企業改進其產品供應,以持續保持其市場地位。因此,市場為各種工業應用提供了廣泛的產品選擇。

主要企業及其優勢 數位伺服印刷機市場的主要企業為 Janome Industrial Equipment、Promess、Kistler、Tox Pressotechnik、THK 等。這些公司因其技術進步、強大的產品系列和全球影響力而聞名。透過不斷創新和策略夥伴關係,我們確立了領導地位,並提供全面的解決方案來滿足客戶的多樣化需求。該公司的優勢進一步得益於其廣泛的研發投入和對品質的承諾,幫助其在市場上保持競爭優勢。

策略重點與市場趨勢:數位伺服壓力機市場正在見證物聯網和工業 4.0 技術融合等趨勢,這些趨勢正在塑造製造業和自動化的未來。企業越來越注重開發具有更高精度、效率和連接性的先進伺服壓力機。在這個市場取得成功取決於技術創新、提供客製化解決方案的能力以及透過策略合作夥伴關係和收購擴大我們的全球影響力等因素。在這些領域表現出色的公司很可能會在競爭激烈的市場中佔據更有利的地位。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 調查結果

- 調查前提

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 市場概況

- 市場促進因素

- 電子製造商增加支出

- 汽車製造商的車輛輕量化預計將推動數位伺服壓力機的需求

- 市場限制

- 初期成本高

- 市場機會

- 對永續性的關注促使製造商採用更節能、環保的技術。

- 波特五力分析

- 新進入者的威脅

- 購買者/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭強度

第5章 市場區隔

- 強度範圍

- 小於100KN

- 100KN~200KN

- 200KN以上

- 應用

- 車

- 航太

- 電子產品

- 地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 北美其他地區

- 歐洲

- 德國

- 英國

- 法國

- 俄羅斯

- 西班牙

- 其他歐洲國家

- 亞太地區

- 印度

- 中國

- 日本

- 其他亞太地區

- 南美洲

- 巴西

- 阿根廷

- 中東

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 其他中東地區

- 北美洲

第6章 競爭格局

- 供應商市場佔有率

- 合併和收購

- 公司簡介

- Janome Industrial Equipment

- Promess

- Kistler

- Tox Pressotechnik

- THK

- Soress

- Intelligent Actuator

- FEC

- Sintokogio

- C and M Robotics

第7章 未來趨勢

The Digital Servo Press Market size is estimated at USD 1.14 billion in 2025, and is expected to reach USD 1.58 billion by 2030, at a CAGR of 6.74% during the forecast period (2025-2030).

The digital servo press market has been evolving rapidly, driven by advancements in manufacturing automation and the need for precision in assembly processes. Digital servo presses are integral to the automotive, aerospace, and electronics industries because they provide precise press force control and enhance production efficiency. The market for these systems is characterized by innovations in servo press technology, enabling manufacturers to achieve higher accuracy and flexibility in their operations.

Digital servo presses utilize electric servo motors to control the movement of the press ram with high precision, which is critical in applications where exact force control is required. This capability is particularly beneficial in sectors such as automotive and electronics, where precision assembly is paramount. The growing adoption of servo press systems across various industries underscores their importance in modern manufacturing processes.

Innovations in Servo Press Technology:

Advanced Control Systems: Modern digital servo presses are equipped with sophisticated control systems that allow for real-time adjustments during the pressing process. These systems enhance the precision of force application, which is crucial in industries where component assembly requires high accuracy. The integration of these control systems into servo press machines has improved their efficiency and versatility, making them a preferred choice for manufacturers seeking to optimize production lines.

Energy Efficiency Improvements: The shift towards electric servo motors in digital servo presses has significantly reduced energy consumption compared to traditional hydraulic and pneumatic presses. These electric systems not only offer better energy efficiency but also reduce the environmental impact of manufacturing processes. The ongoing focus on sustainability and cost reduction in manufacturing is driving the adoption of energy-efficient servo press machines.

Automotive Sector Demand: The automotive industry is a major end-user of digital servo presses, utilizing them in the assembly of critical components such as airbags, transmissions, and other safety-related systems. The need for precision in these applications drives the demand for high-performance servo presses that can deliver consistent and reliable results. As automotive manufacturers continue to innovate and improve vehicle safety standards, the demand for advanced servo press systems is expected to remain strong.

Digital Servo Press Market Trends

Increase in Expenditure of Electronics Manufacturers

Electronics Manufacturing Growth: The electronics industry is another significant market for digital servo presses, particularly in the assembly of delicate components where minimal force variation is essential. The rise of consumer electronics and the miniaturization of electronic devices has increased the need for precise assembly processes, further boosting the demand for servo press systems. As electronic devices become more complex, the market for advanced assembly press systems will likely expand.

The digital servo press market's landscape is competitive, with several key players actively investing in research and development to enhance their offerings. Companies like Janome Industrial Equipment, Promess, and Kistler are in charge of introducing innovations that cater to the evolving needs of various industries. The market's competitive nature is expected to foster further advancements in servo press technology, contributing to the market's growth and the continuous improvement of manufacturing processes globally.

Electronics Manufacturers Increasing Expenditure on Digital Servo Press Technology:

The electronics manufacturing sector has seen substantial growth, which is driving an increased investment in digital servo press technology. Precision and efficiency are paramount in electronics assembly, making digital servo presses indispensable. These machines offer unparalleled control over press force, ensuring that even the most delicate components are assembled with high accuracy, thus minimizing defects. As electronic devices continue to miniaturize, the demand for advanced servo presses capable of handling intricate and tiny components has surged, contributing significantly to the market's expansion. The trend towards integrating digital press automation into manufacturing processes has further enhanced production efficiency, reduced waste, and minimized downtime, making it a strategic investment for electronics manufacturers aiming to remain competitive.

Asia-Pacific Leading in Electronics Manufacturing Market:

The region's leadership is partly due to the rapid adoption of robotics and automation in manufacturing plants, which boosts efficiency and productivity. The growing complexity of electronic devices requires high-precision press systems, which is driving the demand for servo presses in the region. As a result, digital servo presses are becoming essential in maintaining production standards, especially in applications like installing connectors on printed circuit boards. This regional trend reflects the broader global move towards adopting advanced manufacturing technologies to enhance production capabilities.

Focus of Automobile Manufacturers on Reducing Vehicle Weight Expected to Boost the Demand for Digital Servo Press:

Automotive Industry's Focus on Vehicle Weight Reduction Driving Servo Press Market:

The automotive industry's ongoing efforts to reduce vehicle weight, primarily to improve fuel efficiency and meet stringent emissions regulations, are significantly boosting the demand for digital servo presses. Materials like aluminum and high-strength steel, which are critical for lightweight vehicle manufacturing, require the precise forming capabilities provided by these presses. The consistent, repeatable results offered by servo press technology are vital in producing components such as body panels and structural parts, where even minor variations can impact vehicle performance and safety. As the industry shifts towards electric vehicles (EVs), which demand different components often made from lightweight materials, the role of digital servo presses in ensuring quality and durability is becoming even more crucial.

Global Push for Lightweight Vehicles Expanding Servo Press Applications:

The global automotive market increasingly focuses on producing lighter vehicles to enhance fuel efficiency and reduce environmental impact. This trend is driving the demand for digital servo presses, particularly those capable of handling more than 200KN force, for progressive forming applications. The use of high tensile strength steel and lightweight aluminum alloys in vehicle manufacturing is expected to grow, which in turn is accelerating the sales of servo presses worldwide. This trend is particularly strong in Asia, now a leading market for passenger vehicle production, and is expected to continue as automakers globally strive to meet the dual challenges of improving vehicle performance while reducing weight.

Servo Press Technology Critical for EV Manufacturing:

The rise of electric vehicles (EVs) is another significant factor driving the demand for digital servo press technology. EVs require unique components and assemblies, many of which are crafted from lightweight materials that need precise forming processes. Digital servo presses provide the necessary accuracy and control, ensuring these components meet the stringent quality standards required in EV manufacturing. As the automotive industry continues to shift towards electric mobility, the adoption of servo press technology is likely to accelerate, further driving market growth.

Increasing Servo Press Adoption Across Industries:

The adoption of digital servo press systems is not limited to the automotive and electronics industries. Other sectors that prioritize precision and efficiency, such as aerospace and medical device manufacturing, are also increasingly investing in this technology. The ability of servo presses to deliver consistent, high-quality results makes them ideal for applications where accuracy is critical. As industries continue to evolve and adopt more complex manufacturing processes, the demand for advanced servo press technology is expected to grow, positioning these systems as a key component in modern production lines.

Future Prospects for the Digital Servo Press Market:

The digital servo press market is poised for continued growth, driven by technological advancements and increasing adoption across various industries. Innovations in servo press technology are enhancing the efficiency and capabilities of these machines, making them more versatile and effective in meeting the demands of modern manufacturing. As industries increasingly prioritize sustainability, precision, and efficiency, digital servo presses are set to play an even more critical role in production processes. Companies that invest in this technology now are likely to gain a competitive edge, improving product quality and operational efficiency, and positioning themselves for long-term success in a rapidly evolving market environment.

Digital Servo Press Industry Overview

Fragmented Market Structure: The digital servo press market is characterized by a fragmented market structure, with a mix of global and regional players contributing to the industry's competitive dynamics. While a few key players hold a significant portion of the market share, numerous smaller companies offer specialized products, creating a diverse competitive landscape. This fragmentation allows for intense competition and innovation, driving companies to improve their offerings to maintain their market positions continuously. As a result, the market sees a wide range of product options catering to various industrial applications.

Key Players and Their Dominance: Major players in the digital servo press market include Janome Industrial Equipment, Promess, Kistler, Tox Pressotechnik, and THK. These companies are recognized for their technological advancements, robust product portfolios, and strong global presence. They have established themselves as leaders through continuous innovation and strategic partnerships, providing comprehensive solutions that cater to the diverse needs of their customers. Their dominance is further supported by extensive R&D efforts and a commitment to quality, which helps them maintain a competitive edge in the market.

Strategic Focus and Market Trends: The digital servo press market is witnessing trends such as the integration of IoT and Industry 4.0 technologies, which are shaping the future of manufacturing and automation. Companies are increasingly focusing on developing advanced servo presses that offer enhanced precision, efficiency, and connectivity. Success in this market will depend on factors like technological innovation, the ability to offer customized solutions, and expanding global footprints through strategic alliances and acquisitions. Companies that excel in these areas are likely to secure a stronger position in this competitive market.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Increase in Expenditure of Electronics Manufacturers

- 4.2.2 Automobile Manufacturers on Reducing Vehicle Weight Expected to Boost the Demand for Digital Servo Press

- 4.3 Market Restraints

- 4.3.1 High Initial Cost

- 4.4 Market Opportunities

- 4.4.1 Emphasis on sustainability is pushing manufacturers to adopt more energy-efficient and eco-friendly technologies

- 4.5 Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers/Consumers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 Force Range

- 5.1.1 Less than 100KN

- 5.1.2 100KN - 200KN

- 5.1.3 More than 200KN

- 5.2 Application

- 5.2.1 Automotive

- 5.2.2 Aerospace

- 5.2.3 Electronics

- 5.3 Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Mexico

- 5.3.1.4 Rest of North America

- 5.3.2 Europe

- 5.3.2.1 Germany

- 5.3.2.2 United Kingdom

- 5.3.2.3 France

- 5.3.2.4 Russia

- 5.3.2.5 Spain

- 5.3.2.6 Rest of Europe

- 5.3.3 Asia-Pacific

- 5.3.3.1 India

- 5.3.3.2 China

- 5.3.3.3 Japan

- 5.3.3.4 Rest of Asia-Pacific

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.5 Middle East

- 5.3.5.1 United Arab Emirates

- 5.3.5.2 Saudi Arabia

- 5.3.5.3 Rest of Middle East

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Vendor Market Share

- 6.2 Mergers and Acquisitions

- 6.3 Company Profiles

- 6.3.1 Janome Industrial Equipment

- 6.3.2 Promess

- 6.3.3 Kistler

- 6.3.4 Tox Pressotechnik

- 6.3.5 THK

- 6.3.6 Soress

- 6.3.7 Intelligent Actuator

- 6.3.8 FEC

- 6.3.9 Sintokogio

- 6.3.10 C and M Robotics