|

市場調查報告書

商品編碼

1687934

印度金屬加工:市場佔有率分析、行業趨勢和統計數據、成長預測(2025-2030 年)India Metal Fabrication - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

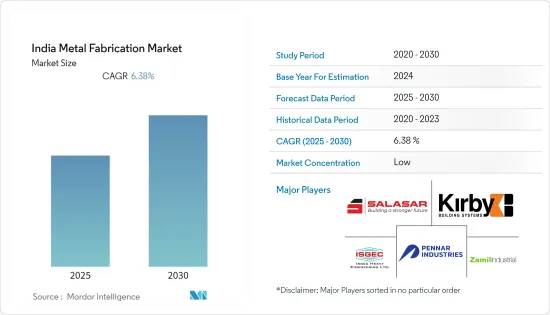

預計印度金屬加工市場在預測期內的複合年成長率將達到 6.38%

關鍵亮點

- 隨著印度經濟的成長和市場的發展,印度的金屬製造市場正在蓬勃發展。隨著政府雄心勃勃的基礎設施發展計劃,印度對金屬製品的需求預計將進一步增加。

- 全國各地有許多鋼鐵加工企業。其中大部分位於孟買和加爾各答,其餘位於清奈。印度的鋼鐵工業高度分散。眾多中小企業在鋼材加工市場經營。 JSW Steel 是印度最大的鋼鐵加工商,其次是塔塔鋼鐵和 SAIL。

- 印度鋼鐵加工市場進入門檻低,競爭激烈。鋼鐵製造商面臨國內外參與企業的競爭。它還面臨來自其他行業的競爭,例如鋁和混凝土,它們可以在某些應用中取代鋼鐵。

- 目前印度鋼骨製造市場的規模約為 120 億印度盧比(1,448 萬美元),並且以 15-20% 的成長率擴張。鋼骨製造市場的成長主要歸因於印度不斷成長的基礎設施開發和建設活動。印度有5000多家鋼鐵加工企業,其中大部分是中小型企業。該行業僱用了 1,000 多名員工,並且與鋼鐵業有著緊密的後向聯繫。

- 為了在這個競爭激烈的市場中生存和發展,鋼鐵製造商提供滿足客戶需求的創新產品和服務。此外,為了保持成本競爭力,我們必須採用高效率的製造流程並投資於最新技術。

- 印度各行業對商品和服務的需求不斷成長,全球製造商紛紛在中國和印度等國家設立低成本工廠,實現生產多元化,預計將推動印度製造業的發展,並刺激金屬製造業的發展,助力該國的基礎設施計劃。

- 預計在預測期內,金屬和製造業的擴張、汽車和航太領域的成長以及研發支出的增加將推動印度金屬加工市場的發展。由於政府的支持政策,金屬加工產業也不斷發展。

印度金屬加工市場趨勢

製造業塑造市場

- 預計印度金屬加工產業將受到多個產業對商品和服務需求不斷成長以及全球製造公司尋求透過在中國和印度等國家建立低成本工廠實現生產多元化的推動。預計到2025年,印度製造業規模將成長1兆美元,是目前的六倍。印度製造業的成長可能會導致該國製造設施的增加,從而增加市場需求。

- 在優先產業成長和有利的大戰略的推動下,印度製造業正在向新的地區和市場領域擴張。憑藉熟練勞動力和低人事費用的優勢,製造業也受益於活性化的資本投資和併購併購,從而提高了製造業產出並增加了出口貢獻。

- 印度大規模電子製造業的 PLI 計劃已公佈。該計劃的目標是吸引對行動電話製造和特定電子元件(包括組裝、測試、標記和包裝(ATMP))的大規模投資。印度電子系統設計與製造 (ESDM) 產業得到了「印度製造」、「數位印度」和「創業印度」等多項措施的支持,以促進印度電子系統設計和製造業的發展。

印度基礎建設活動推動市場

- 印度預計到2047年將成為已開發國家。但要實現這一目標,我們需要發展基礎設施。基礎設施是適應氣候並支持經濟成長的城市生活、工作和居住的基礎。為此,政府在2024年預算中將GDP的3.3%撥給基礎建設領域,特別關注交通運輸和物流。

- 其中,公路和高速公路佔比最大,其次是鐵路和城市公共交通。政府在交通運輸領域設定了雄心勃勃的目標,包括到 2025 年建成 2,000 公里的國家公路網,到 2030 年將機場數量增加到 220 個。

- 2030年,將開闢23條水道,開發35個多式聯運物流園區(MMLP)。基礎建設相關部會和機構的總預算從上年度(FY23)的約3.7億印度盧比增加到FY24的約5億印度盧比。

- 交通運輸部門正準備應對永續性的挑戰,私部門也準備利用有利的政策環境來刺激基礎設施投資。公私合作模式在私營部門參與基礎設施建設方面發揮關鍵作用,尤其是在印度各地的機場、港口、高速公路和物流園區的建設。

- 印度要實現2025年成為5兆美元經濟體的目標,除了中央和各邦透過各種計畫提供支持外,還需要公私合作的強力推動。因此,印度的基礎設施發展活動可能會對金屬加工產業產生重大影響。高速公路、橋樑、鐵路、機場、港口和城市發展等基礎建設計劃對各種金屬製品和結構的需求日益成長。

印度金屬加工產業概況

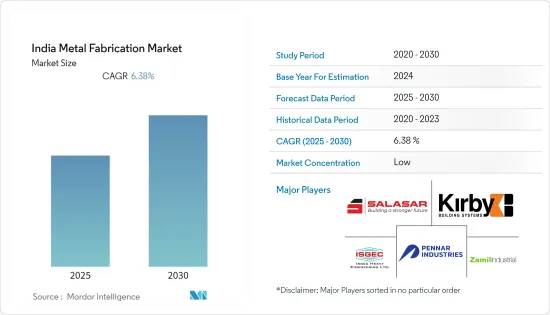

印度金屬製造市場較為分散,由眾多中小企業和 EPC 企業組成。受調查市場中的大多數大型製造商主要是 EPC 公司,為結構鋼製造和製程設備加工服務提供端到端解決方案。在結構鋼領域,市場上的製造商正專注於透過預製建築擴大產品系列為客戶提供工程解決方案。

建築業的成長和對預製建築的偏好預計將進一步加劇市場競爭。 Salasar Techno Engineering Ltd、Kirby Building Systems、Zamil Industrial Investment Co.、Pennar Group 和 ISGEC Heavy Engineering Ltd 是印度金屬製造市場的一些領先企業。其他主要企業包括 Godrej Process Equipment、TEMA India、Larsen & Toubro Ltd、Diamond Group、Novatech Projects (India) Private Limited、SKV Engineering India Pvt.Ltd 和 Karamtara Engineering Pvt.Ltd。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 調查結果

- 調查前提

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 市場概覽

- 市場促進因素

- 金屬製品需求的不斷成長推動了市場

- 市場驅動的技術進步

- 市場限制

- 原物料價格波動是市場的一個限制因素

- 技術純熟勞工短缺是市場的一個限制因素

- 市場機會

- 航太業的擴張推動市場

- 電動車日益普及

- 印度金屬加工市場的技術進步

- 印度金屬加工市場的政府法規和關鍵舉措

- 產業吸引力-波特五力分析

- 新進入者的威脅

- 買家/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭強度

- 價值鏈分析

- COVID-19對市場的影響

第5章市場區隔

- 按最終用戶產業

- 製造業

- 電力和公共產業

- 建造

- 石油和天然氣

- 其他

- 按材質

- 鋼

- 鋁

- 其他

- 按服務類型

- 鑄件

- 鍛造

- 加工

- 焊接和管材

- 其他

第6章 競爭格局

- 市場集中度概覽

- 公司簡介

- Salasar Techno Engineering Ltd

- Kirby Building Systems

- Zamil Industrial Investment Co.

- Pennar Group

- ISGEC Heavy Engineering Ltd

- Godrej Process Equipment

- TEMA India

- Larsen & Toubro Ltd

- Diamond Group

- Novatech Projects (India) Private Limited

- SKV Engineering India Pvt. LTD

- Karamtara Engineering Pvt. Ltd*

- 其他公司

第7章:市場的未來

第 8 章 附錄

The India Metal Fabrication Market is expected to register a CAGR of 6.38% during the forecast period.

Key Highlights

- The Indian metal fabrication market is growing at a fast pace as the country's economic growth and infrastructure development are on the rise. The demand for metal-fabricated products in India is expected to increase further due to the government's ambitious plans for infrastructure development.

- There are many steel fabricators across the country. Most of them are located in Mumbai and Kolkata, while the rest are located in Chennai. The steel fabricators industry in India is highly fragmented. Many SMEs are operating in the steel fabricators market. JSW Steel is the largest steel fabricator in India, followed by Tata Steel and SAIL.

- In the Indian steel fabrication market, the entry barriers are low, and the competition is very high. Steel fabricators face a lot of competition from both domestic and foreign players. In addition, they also face competition from other industries like aluminum and concrete, which can replace steel in some applications.

- The Indian steel fabrication market is currently valued at around INR 1,200 crore (USD 14.48 million) and is expanding at a growth rate of 15% to 20%. The growth of the steel fabrication market is largely attributed to the growth of infrastructure development and construction activity in India. In India, there are more than 5,000 steel fabricators, the majority of which are SMEs. The industry employs more than 1 lakh people and has a strong backward-link relationship with the steel sector.

- In order to survive and succeed in this competitive market, steel fabricators are providing innovative products and services to meet the needs of customers. Furthermore, they must adopt efficient manufacturing processes and invest in modern technology in order to stay cost-competitive.

- The rising demand for goods and services across various sectors in India, along with the global manufacturing companies' focus on diversifying their production by setting up low-cost plants in countries like China and India, is expected to drive the Indian manufacturing sector, fueling the metal fabrication sector in the country for infrastructure projects.

- During the forecast period, the expanding metal and manufacturing industries, expanding automotive and aerospace sectors, and rising R&D expenditures are expected to drive the Indian market for metal fabrication. The metal fabrication industry is also growing because of government policies that aid the industry.

India Metal Fabrication Market Trends

Manufacturing Sector is Shaping the Market

- The Indian metal fabrication sector is expected to be driven by the rising demand for goods and services in many sectors, as well as global manufacturing companies' aim to diversify their production by setting up low-cost plants in countries like China and India. The Indian manufacturing sector is expected to register six times more growth than its current value by 2025, to USD 1 trillion. This growth in the manufacturing sector in India is likely to lead to more manufacturing facilities in the country, which is expected to increase demand in the market studied.

- Driven by growth in priority industries and favorable mega-strategies, the Indian manufacturing industry has expanded into new regions and market segments. Building on the advantages of a skilled labor force and low labor costs, the manufacturing industry is also benefitting from higher capital expenditure and increased mergers and acquisitions (M&A) activity, resulting in an increase in manufacturing output and, hence, an increase in export contribution.

- PLI scheme for large-scale electronics manufacturing in India has been notified. The aim of the scheme is to bring in large investments in mobile phone manufacturing as well as specified electronic components, including assembly, testing, marking, and packaging (ATMP). The ESDM industry in India has been supported by several initiatives, such as Make in India, Digital India, and Startup India, which have boosted the electronics system design and manufacturing industry in India.

Infrastructure Development Activities in India are Boosting the Market

- India is expected to become a developed country by 2047. However, it will do so by improving its infrastructure. Infrastructure is the foundation for living, working, and living in cities that are resilient to climate change and conducive to economic growth. To this end, the government has allocated 3.3 % of GDP in the budget year 2024 to the infrastructure sector, with a particular emphasis on transport and logistics.

- Roads and highways account for the largest share, followed by railways and urban public transport. The government has set ambitious objectives in the transport sector, such as the development of a 2-lakh-km national highway network by 2025 and increasing the number of airports to 220 by 2030.

- Twenty-three waterways will be operationalized by 2030, and 35 multi-modal logistics parks (MMLP) will be developed. The total budget of infrastructure-related Ministries increased from around INR 3.7 lakh crore in the year-earlier year (FY23) to around INR 5 lakh crore in FY24.

- The transport sector is preparing to face sustainability challenges, and the private sector is well-positioned to take advantage of the favorable policy environment to catalyze infrastructure investments. PPPs have played a crucial role in the private sector's involvement across infrastructure domains, particularly in the development of airports and ports, highways, and logistics parks across India.

- India needs a strong push from PPPs in addition to central government and state support across various schemes to reach its goal of a USD 5 trillion economy by 2025. Thus, infrastructure development activities in India can indeed have a significant impact on the metal fabrication industry. As infrastructure projects such as highways, bridges, railways, airports, ports, and urban development projects are undertaken, there is a heightened demand for various metal-fabricated products and structures.

India Metal Fabrication Industry Overview

The Indian metal fabrication market is fragmented, with the presence of many small- and medium-sized companies and EPC companies. Most large fabricators in the market studied are primarily EPC companies, which handle end-to-end solutions for structural steel fabrication and process equipment fabrication services. In structural steel, fabricators in the market are focusing on expanding their product portfolios through prefabricated buildings and providing engineering solutions to their clients.

The growing construction sector and the preference for pre-engineered buildings are expected to further increase competition within the market studied. Salasar Techno Engineering Ltd, Kirby Building Systems, Zamil Industrial Investment Co., Pennar Group, and ISGEC Heavy Engineering Ltd are some of the leading players in the Indian metal fabrication market. Some other major players in the market are Godrej Process Equipment, TEMA India, Larsen & Toubro Ltd, Diamond Group, Novatech Projects (India) Private Limited, SKV Engineering India Pvt. Ltd, and Karamtara Engineering Pvt. Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS & DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing Demand for Fabricated Metal Products Driving the Market

- 4.2.2 Technological Advancements Driving the Market

- 4.3 Market Restraints

- 4.3.1 Fluctuating Raw Materials Prices Hindering the Market

- 4.3.2 Lack of Skilled Labor Hindering the Market

- 4.4 Market Opportunities

- 4.4.1 Expansion of Aerospace Industry Driving the Market

- 4.4.2 Rising Adoption of EVs

- 4.5 Technological Advancements in the Indian Metal Fabrication Market

- 4.6 Government Regulations and Key Initiatives in the Indian Metal Fabrication Market

- 4.7 Industry Attractiveness - Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers/Consumers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitute Products

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Value Chain Analysis

- 4.9 Impact of COVID-19 on the Market

5 MARKET SEGMENTATION

- 5.1 By End-user Industry

- 5.1.1 Manufacturing

- 5.1.2 Power and Utilities

- 5.1.3 Construction

- 5.1.4 Oil and Gas

- 5.1.5 Other End-user Industries

- 5.2 By Material Type

- 5.2.1 Steel

- 5.2.2 Aluminum

- 5.2.3 Other Material Types

- 5.3 By Service Type

- 5.3.1 Casting

- 5.3.2 Forging

- 5.3.3 Machining

- 5.3.4 Welding and Tubing

- 5.3.5 Other Services

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration Overview

- 6.2 Company Profiles

- 6.2.1 Salasar Techno Engineering Ltd

- 6.2.2 Kirby Building Systems

- 6.2.3 Zamil Industrial Investment Co.

- 6.2.4 Pennar Group

- 6.2.5 ISGEC Heavy Engineering Ltd

- 6.2.6 Godrej Process Equipment

- 6.2.7 TEMA India

- 6.2.8 Larsen & Toubro Ltd

- 6.2.9 Diamond Group

- 6.2.10 Novatech Projects (India) Private Limited

- 6.2.11 SKV Engineering India Pvt. LTD

- 6.2.12 Karamtara Engineering Pvt. Ltd*

- 6.3 Other Companies