|

市場調查報告書

商品編碼

1687925

工業電腦X光照相術:市場佔有率分析、行業趨勢和統計、成長預測(2025-2030 年)Industrial Computed Radiography - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

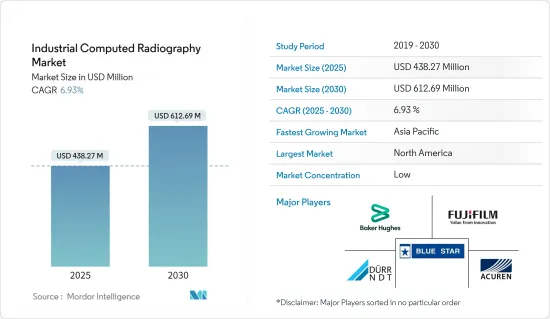

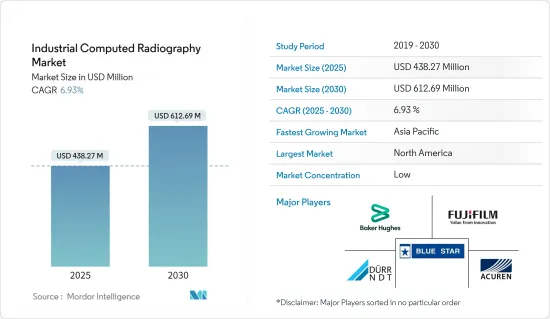

工業電腦X光照相術市場規模預計在 2025 年為 4.3827 億美元,預計到 2030 年將達到 6.1269 億美元,預測期內(2025-2030 年)的複合年成長率為 6.93%。

電腦X光照相術技術為您的實驗室業務帶來了顯著的好處,最大程度地減少了消耗品的使用,進一步減少了生成影像所需的時間。預計這些因素將增加市場採用率。

主要亮點

- 與傳統 X 光膠片相比,它具有更高的動態範圍,可以視覺化和分析精細的細節。此外,它還提供簡化的工作流程、為操作員提供安全的工作環境以及環保、無化學製品的製程。

- 各個供應商都改進了數位 X 光掃描儀、磷光體成像板和軟體程式。結果是,新產品直接滿足了航太和國防、石油和天然氣等產業的需求。

- 市面上各種各樣的產品都使用圓柱和平板掃描器以及從 14 位元對數到 16 位元線性的軟體。最小像素尺寸範圍為 12.5-25、25-35、35-70 和 70-100 像素,從而顯著提高了固有空間解析度、訊號雜訊比值和灰階值,以滿足許多當前標準。這些對檢測材料缺陷的機會有很大影響。

- 目前的 CR 掃描儀和磷光體成像板可以以 12.5 至 25 之間的解析度進行掃描(相當於射線膠片的 D4/IX50)。這些滿足 2% 或更好的X光相片靈敏度的規定靈敏度標準,大大增加了檢測到缺陷的可能性。

- 然而,高昂的安裝成本和進一步的技術改進可能會擾亂市場。

- 根據印度國家統計局和統計和計劃部(MOSPI)發布的2020-21年第一季國內生產總值(GDP)數據,新冠疫情對建設業、製造業和採礦業附加價值毛額的影響分別為-12.6%、-9.4%和-12.4%。因此,這些行業成長放緩預計會在短期內導致市場成長停滯並影響市場成長。

工業電腦X光照相術的市場趨勢

無損檢測可望推動市場成長

- 電腦X光照相術是工業中用於驗證製造的零件和組件的安全性和完整性的一種無損檢測 (NDT)。例如,石油和天然氣作業需要無損檢測來確保所有關鍵部件均符合運作中。用於輸送石油和天然氣的管道是需要適當維護和檢查的重要零件。因此,工業對無損檢測的需求不斷成長,也導致電腦X光照相術技術在工業應用中的應用不斷增加。

- 此外,隨著工業製造和基礎設施領域的自動化程度提高,對裂縫、孔隙率、製造故障等缺陷檢測的需求顯著增加。

- 此外,美國機械工程師學會 (ASME) 和國際標準化組織 (ISO) 等一些政府和區域組織也制定了嚴格的措施來確保設備安全並監督工程服務測試。因此,各行各業對無損檢測的需求日益增加。

- 此外,電腦X光照相術在航太的應用包括檢測厚的、複雜幾何形狀、金屬和非金屬特徵的內部缺陷,以及關鍵航太零件、結構和組裝的品質。此外,對安全標準的日益重視、更短的服務間隔、低排放目標、新材料和新製程是推動航太電腦X光檢測市場的主要因素。

北美可望主導市場

- 由於電腦X光照相術的日益普及和技術進步,北美預計將主導全球電腦X光照相術市場。FUJIFILM和西門子醫療等主要企業也佔有重要地位。

- 2021年9月,福特和SK Innovation宣布計劃在美國投資114億美元,創造約11,000個新工作。三家新的 BlueOval SK 電池工廠(兩家位於肯塔基州,總合位於田納西州)將使福特在美國擁有 129 千兆瓦時的年生產能力。

- 2021 年 2 月,總統拜登表示國內半導體製造業是其政府的優先事項。新政府準備解決日益嚴重的晶片短缺問題,並消除立法者對外包晶片製造使美國更容易受到供應鏈中斷影響的擔憂。拜登啟動了為期100天的審查計劃,旨在透過額外的政府援助和新政策來推動美國晶片公司的發展。

- 此外,北美醫療保健的擴張及其在醫療保健業務中的應用正在推動該地區市場的成長。

工業電腦X光照相術產業概況

在預測期內,市場研究中競爭公司之間的競爭將非常激烈。隨著放射線攝影市場的發展,預計供應商和最終用戶將轉向新技術。因此,現有參與者正在創新其產品以保住市場佔有率。此外,許多公司將地域擴張視為獲得市場吸引力的途徑。

- 2022 年 2 月-加拿大政府宣布對加拿大半導體和光電產業進行重大投資。這項 2.4 億加元的投資預計將鞏固加拿大在光電的全球領先地位,並促進半導體的開發和製造。加拿大擁有100多家從事微晶片研發的國內外半導體公司。在複合半導體、電子機械系統(MEMS)和先進封裝等領域擁有 30 多個應用實驗室和 5 個商業設施。

- 2021 年 3 月-英特爾將在亞利桑那州開設另外兩家製造工廠(晶圓廠)。這項消息發布之際,全球晶片短缺問題正困擾著汽車、電子等多個產業,人們擔心美國在半導體製造業方面落後。該代工廠準備生產一系列基於 ARM 技術的晶片,該技術用於移動設備,歷史上曾與英特爾青睞的 x86 技術競爭。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法

- 研究框架

- 二次調查

- 初步調查

- 資料三角測量與洞察生成

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭強度

- 產業價值鏈分析

- COVID-19 市場影響評估

第5章 市場動態

- 市場促進因素

- 減少輻射暴露的需求日益增加

- 無損檢測的需求日益增加

- 市場限制

- 安裝成本高

第6章 市場細分

- 按應用

- 石油和天然氣

- 石油化學和化學品

- 鑄件

- 航太和國防

- 其他用途

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 世界其他地區

第7章 競爭格局

- 公司簡介

- Durr Ndt Gmbh & Co. Kg

- Baker Hughes

- Fujifilm Corporation

- Applus Services Sa

- Rigaku Corporation

- Shawcor Ltd

- Bluestar Limited

- Virtual Media Integration

- Acuren

第8章 市場投資

第9章 市場機會與未來趨勢

The Industrial Computed Radiography Market size is estimated at USD 438.27 million in 2025, and is expected to reach USD 612.69 million by 2030, at a CAGR of 6.93% during the forecast period (2025-2030).

Computed radiography technology offers enormous advantages for inspection tasks, and the use of consumables is virtually eliminated, further reducing the time to produce an image. These factors are expected to increase market adoption.

Key Highlights

- Minute details are visible and analyzable due to a higher dynamic range than a film in traditional x-ray machines. Further, it provides a simplified workflow, a safer working environment for operators, and a more environmentally-friendly chemical-free process.

- Various computed radiography vendors have improved digital radiography scanners, phosphor imaging plates, and software programs. As a result, new products have been introduced that directly meet the needs of industries such as aerospace and defense, oil and gas, etc.

- Various products on the market use cylinder or flat panel scanners with software ranging from 14-bit logarithmic to 16-bit linear. Minimum pixel sizes range from 12.5-25, 25-35, 35-70, and 70-100 pixels, resulting in significantly increased essential spatial resolution, signal-to-noise ratio values, and grey values to fulfill many of the current standards. These have a substantial impact on the likelihood of detecting faults in materials.

- Current CR scanners and phosphor imaging plates can scan resolutions of 12.5 - 25 (equal to D4/IX50 in radiography film). These fulfill the sensitivity criteria in specifications, such as 2% radiographic sensitivity or greater, and the likelihood of fault identification has increased significantly.

- However, high installation costs and further technological improvements may disrupt the market.

- As per the Gross Domestic Product (GDP) for the Q1 of 2020-21 released by the National Statistical Office and Ministry of Statistic and Program Institute (MOSPI) India, the impact of COVID-19 on the gross value-added of construction, manufacturing, and mining sector accounted for -12.6%, -9.4%, and -12.4%. Thus, the decline in the growth of these industries is expected to stall the market growth for a short period, impacting the market growth.

Industrial Computed Radiography Market Trends

Nondestructive Testing Expected to Drive the Market Growth

- Computed radiography is a sort of non-destructive testing (NDT) used in industrial settings to check the safety and integrity of manufactured components and assemblies. For example, NDT must ensure that all in-service and crucial parts are fit-for-purpose in the oil and gas business. Pipes used to transfer oil or gas are essential components to be well maintained and inspected. Hence, due to the growing demand for NDT in industries, the adoption of computed radiography techniques is also increasing in industrial applications.

- Also, with the increase in automation in the industrial manufacturing and infrastructure sectors, there has been a substantial hike in demand for flaw detection related to cracks, porosity, manufacturing disorders, and so on.

- Moreover, several governmental agencies and regional bodies, like the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO), have instituted to take stringent measures to ensure the safety of instruments and oversee engineering services testing. Hence, the demand for non-destructive testing is increasing across industries.

- Also, computed radiography applications in aerospace include detecting internal defects in thick and complex shapes, metallic and non-metallic forms, and the quality of critical aerospace components, structures, and assemblies. Further, increasing emphasis on safety standards, decreasing service intervals, low emission targets, and new materials and processes are the major factors driving the computed radiography market in the aerospace segment.

North America Expected to Dominate the Market

- North America is expected to dominate the global computed radiography market due to the increasing adoption of added radiography equipment coupled with technological advancements in the region. Key players like Fujifilm Corporation and Siemens Healthcare also have a strong presence.

- In September 2021, Ford and SK Innovation announced a plan to invest USD11.4 billion and create nearly 11,000 new jobs in the United States. Three new BlueOval SK battery plants, two in Kentucky and one in Tennessee enable 129-gigawatt hours a year of US production capacity for Ford.

- In February 2021, President Joe Biden stated that domestic semiconductor manufacturing is a priority for the country's administration. The new administration is poised to fix growing chip shortages and address lawmakers' concerns that outsourcing chipmaking had made the United States more vulnerable to supply chain disruptions. In an executive action, Biden started began a 100-day review that could boost American chip companies with additional government support and new policies.

- Furthermore, the expansion of healthcare in the North American region and its application in the healthcare business boost the area's market growth.

Industrial Computed Radiography Industry Overview

The intensity of competitive rivalry in the market studied is high during the forecast period. With the technological developments in the radiography market, the vendors and end-users are expected to shift towards the new technology. Hence, the existing players are innovating their products to maintain their market share. Also, many companies view geographical expansion as a path to gaining market traction.

- February 2022 - The Government of Canada announced a significant investment in the Canadian semiconductor and photonics industries. The investment of CAD 240 million is expected to help solidify Canada's role as a global leader in photonics and may bolster the development and manufacturing of semiconductors. Over 100 domestic and international semiconductor companies are working on microchip research and development in Canada. In areas including compound semiconductors, microelectromechanical systems (MEMS), and advanced packaging, it has over 30 applied research laboratories and five commercial facilities.

- March 2021 - Intel committed to two more new fabrication plants, or fabs, in Arizona. The news comes during a global chip shortage that is snarling industries from automobiles to electronics and worries the United States is falling behind in semiconductor manufacturing. The foundry is poised to manufacture a range of chips based on ARM technology used in mobile devices and has historically competed with Intel's favored x86 technology.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumption and Market Definition

- 1.2 Scope of The Study

2 RESEARCH METHODOLOGY

- 2.1 Research Framework

- 2.2 Secondary Research

- 2.3 Primary Research

- 2.4 Data Triangulation and Insight Generation

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 The Increasing Demand for Decreasing the Exposure to Radiation

- 5.1.2 Growing Need for Nondestructive Testing

- 5.2 Market Restraints

- 5.2.1 High Installation Costs

6 MARKET SEGMENTATION

- 6.1 By Applications

- 6.1.1 Oil and Gas

- 6.1.2 Petrochemical and Chemical

- 6.1.3 Foundries

- 6.1.4 Aerospace and Defense

- 6.1.5 Other Applications

- 6.2 By Geography

- 6.2.1 North America

- 6.2.2 Europe

- 6.2.3 Asia Pacific

- 6.2.4 Rest of the World

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Durr Ndt Gmbh & Co. Kg

- 7.1.2 Baker Hughes

- 7.1.3 Fujifilm Corporation

- 7.1.4 Applus Services Sa

- 7.1.5 Rigaku Corporation

- 7.1.6 Shawcor Ltd

- 7.1.7 Bluestar Limited

- 7.1.8 Virtual Media Integration

- 7.1.9 Acuren