|

市場調查報告書

商品編碼

1687046

無損檢測(NDT)設備-市場佔有率分析、產業趨勢與統計、成長預測(2025-2030)Non-Destructive Testing (NDT) Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

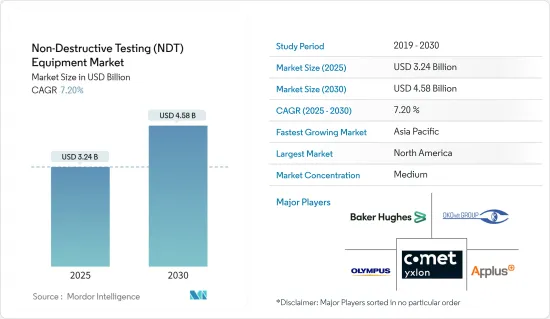

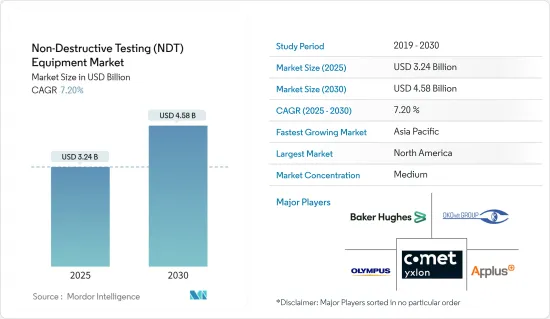

預計2025年非破壞性檢測設備市場規模為32.4億美元,2030年將達45.8億美元,預測期間(2025-2030年)的複合年成長率為7.2%。

主要亮點

- 無損檢測(NDT)涉及零件、材料和組件的檢查、測試和評估。檢查特性的不一致和不連續性,而不會影響產品或零件的可用性。

- NDT 設備無需拆卸,因此可以節省大量時間。例如,飛機維護以及剝離(更換)蒙皮後的內部結構件(如翼肋)的檢查,可以利用X光檢查系統進行。

- 世界各地的多個政府和地方機構都制定了嚴格的措施,主要是為了確保建築物的安全。這些措施要求使用 NDT 和其他評估技術來進行能力傾向測驗。這對於從相關部門獲得基礎設施計劃的建築許可非常重要。這些檢查包括結構強度評估、消防安全、緊急通訊協定合規性測試等。

- 2024 年 4 月,馬里拉克什曼雷迪理工學院 (MLRIT) 宣佈建立新的無損檢測和焊接實驗室,為學生提供航太、國防和工業領域的技能。該實驗室與 Synergem 合作建立,配備了 X光、超音波、液體液體滲透探傷和磁粉檢測等先進的檢測技術,為學生提供缺陷檢測和材料完整性評估的實務經驗。

- 無損檢測已成為定期監測結構劣化最可行的方法,取代了傳統方法。由於成本有限且建造新基礎設施面臨挑戰,導致現有基礎設施老化,促使企業尋找延長現有資產使用壽命的方法。

- 全球對熟練的無損檢測技術人員的需求正在增加。目前需求超過供應的原因有很多。無損檢測僅由經過認證的專家進行,他們在專家的監督下接受詳細的培訓,以獲得資料分析所涉及的各種技術和技能的專業知識。

- 此外,汽車產業需要對引擎零件和底盤等複雜零件進行快速且準確的檢測,這推動了非破壞性檢測設備的採用,以加強品管和遵守監管標準。同樣,市場需求受到製造和建築業迫切需要以非侵入性方式檢測缺陷、裂縫和材料不規則性,從而確保建築結構和製造零件的安全性和耐久性。

無損檢測(NDT)設備市場趨勢

石油和天然氣佔據最高市場佔有率

- 石油和天然氣行業佔據最大的市場佔有率,因為無損檢測在設備完整性以及石油精製和採礦作業的安全性方面發揮著至關重要的作用。超音波和渦流無損檢測解決方案通常用於工業領域,仔細檢查焊接和金屬的缺陷和腐蝕情況,有助於確保潛在危險的化學品和流體安全地容納在管道和壓力容器內。

- 此外,石油和天然氣中含有碳、氫和硫化物,這些物質會以意想不到的速度腐蝕鋼。 NDT 提供了一種有效的方法來檢查這些材料並在腐蝕造成更大規模的問題之前檢測出腐蝕。

- 無損檢測技術日益普及的主要促進因素之一是全球石油和天然氣管道數量的不斷成長以及即將實施的計劃。根據全球天然氣與石油網路(GGON)統計,截至2023年10月,全球共有1,869條運作中的天然氣管道,中國是全球運作天然氣管道最多的國家。

- 石油和天然氣行業的無損檢測對於設備完整性以及精製和生產作業的安全性至關重要。為了確保潛在危險的化學品和流體安全地儲存在管道和壓力容器中,必須使用無損超音波和電渦流檢測方案仔細檢查焊接和金屬是否有缺陷和腐蝕。

- 石油和天然氣行業的管道洩漏日益增多,推動了對 NDT 軟體的需求。例如,據美國海岸警衛隊海岸防衛隊稱,2023 年 11 月,約有 110 萬加侖原油洩漏到路易斯安那州海岸附近的墨西哥灣管道內。

- 近日,美國無損檢測協會(ASNT)發布了針對石油和天然氣行業的行業資格(ISQ)。該計劃為石油和天然氣行業提供了一支無損檢測勞動力隊伍,透過在職實踐資格考試來證明其在特定技術方面的能力。

北美佔據主要市場佔有率

- 美國的最終用戶產業,例如製造業、運輸業、航空業、石油天然氣業、海洋業和發電業,都受到各聯邦和州機構的管理,這些機構要求進行無損檢測以進行檢查。無損檢測 (NDT) 確保美國基礎設施和設施的持續運作和安全。美國法律通常要求使用無損檢測設備。

- 例如,根據美國聯邦航空管理局(FAA)的數據,美國有超過20萬架飛機必須接受NDT的定期安全檢查。軍事裝備須遵守國防部無損檢測標準。這些標準通常是根據美國無損檢測協會 (ASNT) 等獨立檢測協會的意見制定的。

- 美國是製造業無損檢測設備最重要的市場之一。根據美國製造商協會(NAM)的數據,美國有超過250,000家製造公司,各行各業的會員公司超過14,000家。美國製造業佔經濟總量的11.39%。

- 根據美國能源資訊署的數據,德克薩斯是美國最大的石油生產州。 2023年,德克薩斯石油總合超過20億桶。新墨西哥州則位居第二,今年的產量為 6.675 億桶。增加管道容量的需求和原油產量的上升正在刺激石油管線基礎設施的擴張。預計石油和天然氣基礎設施需求的成長將推動市場對非破壞性檢測設備的需求。

- 加拿大的GDP以石油和天然氣產業為主,包括資本投資和出口。有吸引力的省級激勵措施鼓勵鑽探、增加採用長水平井和頁岩資源多級壓裂是加拿大石油和天然氣行業成長的主要驅動力。

- 無損檢測是在不影響原有系統可用性的情況下評估油氣管道性能的最流行的方法之一,油氣產量的增加導致市場需求的增加。

- 加拿大的航太業繼續為經濟做出重大貢獻,佔該地區對無損檢測設備總需求的很大一部分。根據加拿大航空航太工業協會 (AIAC) 與加拿大創新、科學與經濟發展部 (ISED) 聯合發布的《加拿大航太工業狀況報告》,加拿大航太航太工業計劃在七年內投資 13.6 億美元作為聯邦戰略創新基金的一部分。

無損檢測(NDT)設備產業概況

無損檢測 (NDT) 設備市場集中度較高,主要企業包括Olympus公司、貝克休斯、Yxlon International GmbH (COMET Holding AG)、OkoNDT Group 和 AplusPlus Laboratories。市場參與者正在採取合作和收購等策略來增強其產品供應並獲得永續的競爭優勢。例如

- 2024 年 2 月,Pinnacle X-Ray Solutions LLC 收購了 Willick Engineering Co.,後者是為醫療設備、軍事和航太領域提供 NDT X光設備和相關服務的供應商。此次收購將擴大該公司面向現有和未來客戶的產品和服務。

- 2024 年 1 月,美國無損檢測學會 (ASNT) 宣佈建立策略合作夥伴關係,贊助愛荷華州立大學 (LSU) 無損檢測中心 (CNDE)。此次合作是測試和感測器技術領域研發進步的重要里程碑。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概覽

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 產業價值鏈分析

- COVID-19 的副作用和其他宏觀經濟因素將如何影響市場

第5章市場動態

- 市場促進因素

- 嚴格的法規要求安全

- 基礎設施老化,維護需求增加

- 市場限制

- 缺乏熟練的人力和培訓設施

第6章市場區隔

- 依技術

- 射線檢測設備

- 超音波檢測設備

- 磁粉探傷機

- 液體液體滲透探傷設備

- 視覺檢測設備

- 渦流檢測設備

- 其他技術設備

- 按最終用戶產業

- 石油和天然氣

- 電力和能源

- 航太與國防

- 汽車與運輸

- 建造

- 其他最終用戶產業

- 按地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 俄羅斯

- 義大利

- 亞洲

- 中國

- 印度

- 韓國

- 澳洲和紐西蘭

- 拉丁美洲

- 墨西哥

- 巴西

- 阿根廷

- 中東和非洲

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 卡達

- 北美洲

第7章競爭格局

- 公司簡介

- Olympus Corporation

- Baker Hughes

- YXLON International GmbH(COMET Holding AG)

- OkoNDT Group

- Applus+Laboratories

- Mistras Group Inc.

- Controle Mesure Systemes SA

- Fujifilm Corporation

- Bureau Veritas SA

- Nikon Metrology NV

- Intertek Group PLC

- Innospection Limited

- Magnaflux Corp.

第8章投資分析

第9章:市場的未來

The Non-Destructive Testing Equipment Market size is estimated at USD 3.24 billion in 2025, and is expected to reach USD 4.58 billion by 2030, at a CAGR of 7.2% during the forecast period (2025-2030).

Key Highlights

- Non-destructive testing (NDT) involves inspecting, testing, or evaluating components, materials, or assemblies. It involves examining disparities in characteristics or discontinuities without hampering the product's serviceability or part.

- NDT devices can save substantial time by eliminating the need for disassembly or dismantling. For instance, the maintenance of aircraft and the examination of internal structural components (like wing ribs), carried out by removing (and replacing) the outer skin, may be accomplished by radiographic inspection equipment.

- Several governmental agencies and regional bodies across the world formulated stringent measures, primarily for assuring the safety of buildings. These measures have mandated the use of NDT and other evaluation techniques for conducting fitness checks. This is important for gaining building clearances from concerned authorities for infrastructural projects. These checks include structural strength evaluation, fire safety, and emergency protocol compliance tests.

- In April 2024, The Marri Lakshman Reddy Institute of Technology (MLRIT) announced the set up of a new NDT and welding laboratory that will equip students with skills in the aerospace, defense, and industrial sectors. The lab was established in collaboration with Synergem and is equipped with advanced testing methodologies such as radiographic testing, ultrasonic testing, liquid penetrant testing, and magnetic particle testing to provide students with hands-on experience in detecting flaws and assessing material integrity.

- NDT emerged as the most feasible method for monitoring the aging of structures periodically in place of traditional methods. The restrictive cost and challenge of constructing new infrastructure resulted in the notable aging of existing structures and prompted companies to explore ways to extend the life of existing assets.

- There has been an incremental rise in the demand for skilled NDT technicians worldwide. The demand currently outweighs the supply due to many reasons. Non-destructive testing can only be performed by certified professionals who undergo detailed training in the presence of subject-matter experts to gain expertise on the various techniques and skills involved in analyzing the data.

- Moreover, in the automotive industry, the need for rapid and accurate inspection of complex components, such as engine parts and chassis, has propelled the adoption of NDT equipment to enhance quality control and compliance with regulatory standards. Likewise, in the manufacturing and construction sectors, the demand for the market is driven by the imperative to detect flaws, cracks, and material irregularities in a non-invasive manner, thereby ensuring the safety and durability of built structures and fabricated components.

Non-Destructive Testing (NDT) Equipment Market Trends

Oil and Gas Holds Highest Market Share

- The oil and gas industry accounts for the largest market share as non-destructive testing plays a critical role in the industry for both the integrity of equipment and the safety of petroleum refining and extraction operations. Ultrasonic and eddy current NDT testing solutions are often used in the industry to carefully inspect welds and metals for flaws and corrosion, which helps keep potentially hazardous chemicals and fluids safely contained within pipes and pressure vessels.

- Moreover, oil and gas have carbon, hydrogen, and sulfides that can corrode steel unpredictably and at an unexpected speed. NDT provides an effective method for inspecting these materials and detecting corrosion before it creates a larger-scale issue.

- One of the primary drivers of the increased deployment of NDT technologies is the rising number of oil and gas pipelines and upcoming projects globally. As per the Global Gas & Oil Network (GGON), as of October 2023, there were 1,869 operational gas pipelines in the world, with China being the country with the most significant number of operational gas pipelines worldwide.

- NDT in the oil and gas industry is critical to the integrity of equipment and the safety of oil refining and production operations. Safely storing potentially hazardous chemicals and fluids in pipes and pressure vessels requires careful inspection of welds and metals for defects and corrosion using non-destructive ultrasonic and eddy current testing solutions.

- The increasing cases of pipe leaks in the oil and gas industry demand the need for NDT software. For instance, in November 2023, about 1.1 million gallons of crude oil spilled into the Gulf of Mexico near a pipeline off the coast of Louisiana, according to the US Coast Guard.

- In recent years, the American Society for Non-destructive Testing (ASNT) announced the Industry Sector Qualification (ISQ) for oil and gas, which is a new non-destructive testing (NDT) qualification program for the oil and gas sector. This program provides NDT personnel to the oil and gas industry, demonstrating competency for specific techniques through the hands-on performance of demonstration qualification examinations.

North America to Hold Significant Market Share

- The end-user industries in the United States, such as manufacturing, transportation, aviation, oil and gas, marine, and power generation, are governed by many different federal and state agencies that require mandatory NDT testing for inspection. Non-destructive testing (NDT) ensures the continued operation and safety of infrastructure and equipment across the United States. The use of non-destructive testing equipment is often required in the United States as a law.

- For instance, according to the Federal Aviation Administration (FAA), the 200,000+ aircraft in the United States must undergo periodic safety inspections using NDT. The military equipment is subjected to Department of Defense NDT standards. These standards are often made using the information provided by independent testing associations, such as the American Society for Non-destructive Testing (ASNT).

- The United States is one of the most important markets for NDT equipment in manufacturing. According to the National Association of Manufacturers (NAM), there are more than 250,000 manufacturing companies in the United States and more than 14,000 member companies in all industries across the country. Manufacturers in the United States account for 11.39% of the economy's total output.

- According to the US Energy Information Administration, Texas is the largest oil-producing state in the United States. In 2023, Texas produced a total of more than two billion barrels. New Mexico is a distant second, producing 667.5 million barrels this year. The need for increased pipeline transportation capacity and increased crude oil production have stimulated the expansion of oil pipeline infrastructure. This increase in demand for oil and gas infrastructure is expected to boost the demand for non-destructive testing equipment in the market.

- The Canadian GDP is majorly dominated by the oil and gas sector, with capital investments and exports. Attractive provincial incentives to encourage drilling, increased implementation of long horizontal wells, and multistage fracturing in shale resources are the major drivers in the growth of the Canadian oil and gas industry.

- With NDT being one of the most common methods to evaluate the properties of oil and gas pipelines without destroying the serviceability of the original system, the increase in oil and gas production translates to a higher demand for the market.

- The aerospace industry in Canada continues to be a significant contributor to the economy and accounts for a substantial portion of the total demand for NDT equipment in the region. As per the State of Canada's Aerospace Industry Report released by the Aerospace Industries Association of Canada (AIAC), in partnership with Innovation, Science, and Economic Development Canada (ISED), the Canadian aerospace industry will invest USD 1.36 billion over seven years as a part of Federal Strategic Innovation Fund.

Non-Destructive Testing (NDT) Equipment Industry Overview

The non-destructive testing (NDT) equipment market concentration is moderately high with the presence of key players like Olympus Corporation, Baker Hughes, YXLON International GmbH (COMET Holding AG), OkoNDT group, and Applus+ Laboratories, among others. Players in the market are adopting strategies such as partnerships and acquisitions to enhance their product offerings and gain sustainable competitive advantage. For instance,

- In February 2024, Pinnacle X-Ray Solutions LLC announced the acquisition of Willick Engineering Co. Inc., a supplier of NDT X-ray equipment and provider of related services to the medical device, military, and aerospace sectors. Through this acquisition, the company will expand its products and services for current and prospective customers.

- In January 2024, The American Society for Non-Destructive Testing (ASNT) announced a strategic collaboration with the Center for Non-Destructive Testing (CNDE) at Lowa State University (LSU) as a sponsor. This partnership marks an important milestone in the advancement of research and development in the area of inspection and sensor technologies.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Impact of COVID-19 Aftereffects and Other Macroeconomic Factors on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Stringent Regulations Mandating Safety

- 5.1.2 Aging Infrastructure and Increasing Need for Maintenance

- 5.2 Market Restraints

- 5.2.1 Lack of Skilled Personnel and Training Facilities

6 MARKET SEGMENTATION

- 6.1 By Technology

- 6.1.1 Radiography Testing Equipment

- 6.1.2 Ultrasonic Testing Equipment

- 6.1.3 Magnetic Particle Testing Equipment

- 6.1.4 Liquid Penetrant Testing Equipment

- 6.1.5 Visual Inspection Equipment

- 6.1.6 Eddy Current Equipment

- 6.1.7 Other Technologies Equipment

- 6.2 By End-user Industry

- 6.2.1 Oil and Gas

- 6.2.2 Power and Energy

- 6.2.3 Aerospace and Defense

- 6.2.4 Automotive and Transportation

- 6.2.5 Construction

- 6.2.6 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.1.1 United States

- 6.3.1.2 Canada

- 6.3.2 Europe

- 6.3.2.1 United Kingdom

- 6.3.2.2 Germany

- 6.3.2.3 France

- 6.3.2.4 Russia

- 6.3.2.5 Italy

- 6.3.3 Asia

- 6.3.3.1 China

- 6.3.3.2 India

- 6.3.3.3 South Korea

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.5.1 Mexico

- 6.3.5.2 Brazil

- 6.3.5.3 Argentina

- 6.3.6 Middle East and Africa

- 6.3.6.1 Saudi Arabia

- 6.3.6.2 United Arab Emirates

- 6.3.6.3 Qatar

- 6.3.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Olympus Corporation

- 7.1.2 Baker Hughes

- 7.1.3 YXLON International GmbH (COMET Holding AG)

- 7.1.4 OkoNDT Group

- 7.1.5 Applus+ Laboratories

- 7.1.6 Mistras Group Inc.

- 7.1.7 Controle Mesure Systemes SA

- 7.1.8 Fujifilm Corporation

- 7.1.9 Bureau Veritas SA

- 7.1.10 Nikon Metrology NV

- 7.1.11 Intertek Group PLC

- 7.1.12 Innospection Limited

- 7.1.13 Magnaflux Corp.