|

市場調查報告書

商品編碼

1686566

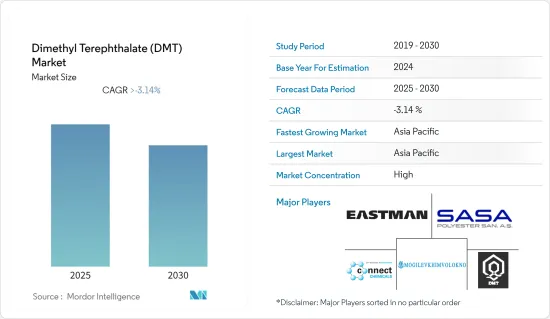

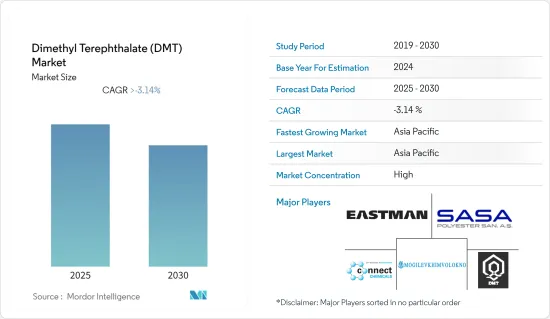

對苯二甲酸二甲酯(DMT):市場佔有率分析、產業趨勢和成長預測(2025-2030年)Dimethyl Terephthalate (DMT) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

預計預測期內對苯二甲酸二甲酯市場將會下滑。

COVID-19疫情對市場產生了負面影響。許多國家實施封鎖措施以遏制病毒傳播。許多公司和工廠關閉,擾亂了全球供應鏈,影響了全球的生產、交貨時間和產品銷售。

主要亮點

- 短期內,聚對苯二甲酸乙二醇酯(PET)、聚丁烯對苯二甲酸酯(PBT)的需求上升,以及紡織業對聚酯纖維的需求上升是推動市場成長的主要因素。

- 另一方面,PTA(精對苯二甲酸)等經濟替代品的可用性可能會抑制市場成長。

- 亞太地區佔據了最高的市場佔有率,並可能在預測期內佔據市場主導地位。

對苯二甲酸二甲酯(DMT)市場趨勢

聚酯纖維佔據市場主導地位

- 聚酯纖維是以對苯二甲酸二甲酯為原料製成的合成纖維。聚酯纖維具有優異的機械抗性,可以收縮和拉伸而不會損失強度。

- 這些纖維通常用於製造紗線、繩索、輸送機織物、安全帶、塑膠增強材料和其他工業應用。它也用於紡織工業,製造服飾、地毯、家居用品以及作為機械增強的輔助材料。此外,這種材料以其卓越的強度和耐用性而聞名。這就是為什麼它也用於運動服和製服的原因。

- 聚酯纖維採用合成材料製成,比天然纖維便宜,但吸水性低,不適合製造需要吸收水分的產品,如運動服、毛巾和床上用品。

- 根據 ITC Trademap 的數據,2022 年全球整體聚酯短纖維(未經梳理、精梳或紡紗加工)出口國包括中國(包括台北)(1,221,267 噸)、韓國(624,362 噸)、泰國(318,081 噸)、印度(254,531 噸)、泰國(31.85 萬噸)噸)。

- 2022年全球整體聚酯短纖維主要進口國包括斯里蘭卡(2,593,370噸)、美國(455,384噸)、越南(326,289噸)、土耳其(210,140噸)和德國(175,604噸)。

- 雖然聚酯纖維薄膜的成長呈現出正面的趨勢,但由於新工廠通常更傾向於使用TPA製程(DMT的替代品),因此該領域對DMT的需求正在下降。

- 因此,未來聚酯纖維對DMT的需求可能會下降。

亞太地區佔市場主導地位

- 亞太地區佔據全球市場佔有率。由於聚酯和PET樹脂的持續生產,亞太地區是市場研究中最大的地區。

- PET、聚酯薄膜及纖維、PBT是中國對苯二甲酸二甲酯的主要消費者。然而,由於聚酯樹脂生產中 PTA 的使用量不斷增加,預計 DMT 的需求將會下降。

- 華彩、東亞紡織技術有限公司、中國石化和常熟阿祖爾是中國主要的聚酯纖維製造商/供應商。

- 2022年中國新增聚酯產能507.5萬噸/年。運力成長率為 8.7%,但由於一些老舊機組退役,成長率下調至 7.3%。聚酯產能仍在上升,預計2022年底將達到7,000萬噸/年以上。

- 在印度,由於紡織和包裝行業的蓬勃發展,過去幾年一直推動著市場的成長,對聚酯樹脂、薄膜、纖維和 PET 的需求正在迅速成長。然而,隨著印度精對苯二甲酸(PTA)生產能力的擴大,PTA的使用量正在取代DMT而上升。

- 紡織業對聚酯的需求正在蓬勃發展。據印度紡織部稱,2022會計年度印度紡織品和服裝出口(包括手工藝品)達444億美元,比上年度成長41%。印度佔全球紡織品和服裝貿易的佔有率為4.0%。

- 因此,由於上述因素,亞太地區很可能會佔據市場主導地位。

對苯二甲酸二甲酯(DMT)產業概況

全球對苯二甲酸二甲酯 (DMT) 市場本質上是整合的。市場的主要企業包括伊士曼化學公司、Connect Chemicals、SASA Polyester Sanayi AS、OAO Mogilevkhimvolokno 和 Fiber Intermediate Products Company。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 調查前提條件

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 驅動程式

- 聚對苯二甲酸乙二醇酯(PET)和聚丁烯對苯二甲酸酯(PBT)的需求不斷增加

- 紡織業對聚酯纖維的需求不斷增加

- 限制因素

- 有經濟的替代品,例如 PTA(精對苯二甲酸)

- 其他阻礙因素

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

第5章市場區隔

- 按類型

- 片狀(固體)DMT

- 液體 DMT

- 按應用

- 聚酯薄膜

- 聚酯纖維

- PET樹脂

- 其他用途(包括PBT)

- 按地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 東南亞國協

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭格局

- 併購、合資、合作與協議

- 市場佔有率(%)/排名分析

- 主要企業策略

- 公司簡介

- Connect Chemicals

- Eastman Chemical Company

- Fiber Intermediate Products Company

- OAO Mogilevkhimvolokno

- Sarna Chemicals

- SASA Polyester Sanayi AS

- SK chemicals

- Yangzhou Juhechang Technology Co. Ltd

第7章 市場機會與未來趨勢

The Dimethyl Terephthalate Market is expected to decline during the forecast period.

The COVID-19 pandemic negatively impacted the market. Several countries worldwide applied lockdowns to curb the spread of the virus. The shutdown of numerous companies and factories disrupted worldwide supply networks and harmed global production, delivery schedules, and product sales.

Key Highlights

- In the short term, major factors driving the market's growth are the rising demand for polyethylene terephthalate (PET), polybutylene terephthalate (PBT), and the rising demand for polyester fiber in the textile industry.

- On the flip side, the availability of economical substitutes like PTA (Purified Terephthalic Acid) may likely restrain the market's growth.

- Asia-Pacific accounted for the highest market share, and the region may likely dominate the market during the forecast period.

Dimethyl Terephthalate (DMT) Market Trends

Polyester Fiber to Dominate the Market

- Polyester fibers are synthetic fibers which are produced from dimethyl terephthalate. Polyester fibers exhibit superior mechanical resistance and can shrink and stretch without losing strength.

- These fibers are increasingly used in manufacturing yarns, ropes, conveyor belt fabrics, seatbelts, plastic reinforcements, and others for industrial purposes. It is also used in the textile industry to manufacture clothing, carpets, and home furnishing, and as a mechanical reinforcement aid. In addition, the material is known for its superior strength and durability. Hence, it is used in sportswear and uniforms.

- Polyester fibers are manufactured using synthetic materials and are less expensive than natural fibers. They have low absorbency and are not ideal for manufacturing products that need to soak moisture, including activewear, towels, or bedding.

- According to ITC Trademap, the exporters of polyester staple fiber (not carded, combed, or otherwise processed for spinning) across the globe in 2022 are China (including Taipei, China) (12,21,267 tons), South Korea (624,362 tons), Thailand (318,081 tons), India (254,531 tons), Indonesia (212,413 tons), and Turkey (157,542), among others.

- The key importers of polyester staple fiber across the globe in 2022 are Sri Lanka (2,593,370 tons), the United States (455,384 tons), Vietnam (326,289 tons), Turkey (210,014 tons), and Germany (175,604 tons), among others.

- Although the growth of polyester fiber film is following a positive trend, the demand for DMT in this segment is declining since the newer plants generally tend to use the TPA process (an alternative for DMT).

- Hence, the demand for DMT in polyester fiber may decline in the future.

Asia-Pacific to Dominate the Market

- Asia-Pacific accounts for the highest global Dimethyl Terephthalate (DMT) market share. Continuous polyester and PET resin production make the Asia-Pacific region the largest in the market studied.

- PET, polyester film and fiber, and PBT are China's major consumers of dimethyl terephthalate. However, the demand for DMT is projected to decline due to the rising applications of PTA for polyester resin production.

- HUACAI, EAST ASIA TEXTILE TECHNOLOGY LTD, Sinopec Inc., and Changshu Azue Co. Ltd are the major manufacturers/suppliers of polyesters in China.

- In 2022, China's new polyester capacity was 5,075 kilotons per year. The capacity growth rate was 8.7%, but it was revised to 7.3% after some old units were eliminated. Polyester capacity still edged and was above 70 million tons/year by the end of 2022.

- In India, the demand for polyester resins, film, fiber, and PET is increasing rapidly due to the surging textile and packaging sectors, which have driven the market's growth in past years. However, the expanding production facility for purified terephthalic acid (PTA) in India is increasing the usage of PTA rather than DMT.

- The demand for polyester is increasing rapidly in the textile industry. According to the Ministry of Textiles, India's textile and apparel exports (including handicrafts) stood at USD 44.4 billion in FY22, a 41% increase YoY. India has a 4.0% share of the global trade in textiles and apparel.

- Therefore, due to the above factors, Asia-Pacific may dominate the market studied.

Dimethyl Terephthalate (DMT) Industry Overview

The global Dimethyl Terephthalate (DMT) market is consolidated in nature. Some major companies in the market include Eastman Chemical Company, Connect Chemicals, SASA Polyester Sanayi AS, OAO Mogilevkhimvolokno, and Fiber Intermediate Products Company.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Rising Demand for Polyethylene Terephthalate (PET) and Polybutylene Terephthalate (PBT)

- 4.1.2 Rising Demand for Polyester Fiber in the Textile Industry

- 4.2 Restraints

- 4.2.1 Availability of Economical Substitutes Like PTA (Purified Terephthalic Acid)

- 4.2.2 Other Restraints

- 4.3 Industry Value-chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION

- 5.1 By Form

- 5.1.1 Flake (Solid) DMT

- 5.1.2 Liquid DMT

- 5.2 By Application

- 5.2.1 Polyester Film

- 5.2.2 Polyester Fiber

- 5.2.3 PET Resin

- 5.2.4 Other Applications (Including PBT)

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share(%)/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Connect Chemicals

- 6.4.2 Eastman Chemical Company

- 6.4.3 Fiber Intermediate Products Company

- 6.4.4 OAO Mogilevkhimvolokno

- 6.4.5 Sarna Chemicals

- 6.4.6 SASA Polyester Sanayi AS

- 6.4.7 SK chemicals

- 6.4.8 Yangzhou Juhechang Technology Co. Ltd