|

市場調查報告書

商品編碼

1644617

遠端油箱監控系統:市場佔有率分析、行業趨勢和統計、成長預測(2025-2030 年)Remote Tank Monitoring System - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

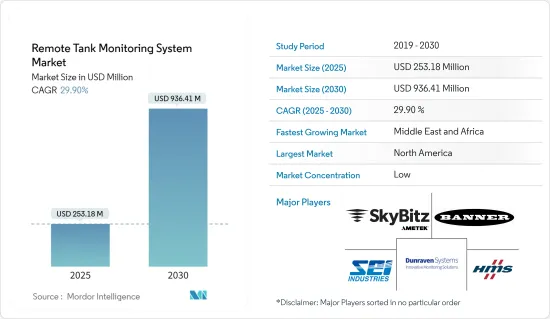

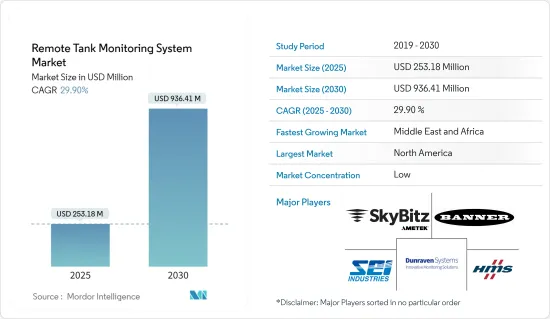

遠端油箱監控系統市場規模預計在 2025 年為 2.5318 億美元,預計到 2030 年將達到 9.3641 億美元,預測期內(2025-2030 年)的複合年成長率為 29.9%。

支援物聯網的遠端油箱監控系統透過即時監控油箱液位,徹底改變了流體管理。這些系統由安裝在油箱上的感測器和匯總感測器資料的中央閘道器設備組成。隨著物聯網和感測器技術的進步,這些系統正在提高資料分析的準確性和可靠性。

主要亮點

- 在市場對更高服務標準和競爭力的需求的推動下,越來越多的企業採用先進的監控技術。這些系統不僅滿足了客戶的期望,而且還提供了能源管理優勢,例如最佳化能源使用和減少浪費,進一步促進了它們的廣泛採用。因此,遠端油箱監控系統在各個領域越來越受歡迎。

- 智慧物聯網系統將使能源公司能夠監控石油和天然氣倉儲設施,以確保它們能夠滿足消費者的需求。 Software AG 和 Infosys 等產業參與者正在開發客製化解決方案來滿足這些特定需求,例如支援智慧物聯網的遠端油箱監控系統。儘管倉儲設施分佈在全球各地,這些解決方案仍可即時洞察儲存、接收和消費模式。

- 當今,生產活動對石油燃料的需求不斷上升。這項需求涉及從運輸原油到精製,再到最終以汽油和柴油等各種形式將精製油發行給最終用戶的複雜過程。這個複雜過程涉及車輛運輸、精製油罐儲存、加油站等,凸顯了對強大的遠端油罐監控系統的需求。

- 2024 年 4 月,工業資產監控領域的全球領導者 Anova 推出了具有雷達液位感測器的通用油箱監控器。此項技術發展勢頭強勁,尤其是在管理中型散貨箱(IBC)中液體的公司。除了減少包裝浪費,該公司還旨在簡化這些公司的追蹤和管理流程。

- 遠端油箱操作的挑戰各不相同,並且可能受油箱類型和監控設備的影響。常見問題包括液位測量設備故障、控制閥失靈以及潛在洩漏。這些挑戰在維護和維修資源有限的偏遠地區更加嚴重,阻礙了市場的成長。

遠端油箱監控系統的市場趨勢

石油和天然氣行業的擴張推動了對遠端油罐監控系統的需求

- 石油天然氣和化學工業正在快速成長,對遠端油箱監控系統的需求也隨之增加。隨著這些產業的擴張,對高效、安全的儲存槽管理的需求也隨之增加。遠端油箱監控系統可即時了解儲罐液位、壓力和溫度,讓您能夠微調庫存管理、減少停機時間並避免洩漏和溢出。

- 這些系統不僅提高了業務效率並確保了法規遵循,而且還透過及早發現潛在問題提高了安全性。利用遠端監控的企業可以透過簡化物流和減少人工檢查和維護來降低營運成本。

- 因此,石油天然氣和化學工業擴大轉向先進的遠端監控解決方案,以應對其不斷擴大的業務的規模和複雜性,同時保持生產力和安全基準。

- 國際能源總署(IEA)報告稱,美國已連續六年位居全球原油產量首位,凸顯了美國在石油生產領域的主導地位。預計 2023 年美國原油產量(包括冷凝油)平均為 1,290 萬桶/日,12 月將達到 1,330 萬桶/日以上。

- 2023年,美國、沙烏地阿拉伯和俄羅斯將共同貢獻全球石油產量的40%(3,280萬桶/日)。儘管自1971年以來,主要生產國的位置偶爾會發生變化,但這三個國家的表現一直優於其他國家。相較之下,接下來的三大生產國伊拉克、加拿大和中國到 2023 年的總合將達到 1,310 萬桶/天,超過美國產量。

- 展望未來,石油輸出國組織(OPEC)預測輕質石油產品(主要是汽油和乙烷)的需求將增加。到 2045 年,汽油需求預計將激增至每天 2,880 萬桶,柴油和汽油總需求預計將達到每天 3,170 萬桶,從而支持市場成長。

北美佔有最大市場佔有率

- 受技術型產業、石油和天然氣需求激增以及數位化推動的推動,北美預計將見證遠端油箱監控系統的顯著成長。

- 美國公司處於領先地位,不僅為石油和天然氣提供此類系統,還為水資源管理和農業提供此類系統。這些系統通常在油箱中安裝感測器,並將從填充水平到溫度的重要資料傳遞到中央資料庫或儀表板。透過利用 GSM 網路和 SMS,這些系統比以前更經濟高效且更易於存取。

- 2023 年 5 月,Gallagher Group Limited 與 Gasbot Pty Ltd 簽署獨家協議,將先進的基於衛星的液體監測系統引入北美。該系統採用 Gasbot 的無線感測器技術,提供液位的即時資料,讓農民了解精確的液體管理。此外,衛星通訊意味著偏遠地區的農民可以透過行動電話輕鬆取得油箱資料。

- 美國是世界化學製造中心,遠端油罐監控系統的應用範圍不僅限於石油和天然氣。化學品的出口和分銷受到嚴格審查,運輸部、國際航空運輸協會、環保署等機構發揮關鍵作用。

- 安格斯能源 (Angus Energy)、Anova 和 ATEK Access Technologies (TankScan) 等公司在北美不斷發展的遠端油箱監控領域處於領先地位,並迅速適應最尖端科技。

遠端油罐監控系統產業概況

遠端油箱監控系統市場分散,有 SkyBitz Inc.、Banner Engineering Corp.、EI Industries Ltd. 等多家參與者。市場參與者不斷創新新產品和解決方案以滿足客戶的複雜需求。它還達成了各種合作、收購和協議,以更好地滿足不斷變化的消費者需求。

2024 年 5 月,AMETEK 液位測量解決方案 (LMS) 推出了 BrightTEK,這是一款尖端的無線工業物聯網 (IIoT) 解決方案,旨在重新定義各行業的業務效率和成本效益。 BrightTEK 利用無線技術促進 AMETEK LMS 品牌發射器(包括 Magnetrol、Drexelbrook、Orion Instruments、SWI 和 B/W Controls)的無縫資料傳輸,提供關鍵變數的可視性以最佳化現場操作。 BrightTEK 網路伺服器提供對製程變數(例如儲罐液位、容量和位置資料)的即時可見性。可自訂的通知、警報和警報允許用戶主動管理營運、供應鏈和庫存。

2023 年 12 月,Halo Systems 推出了其 X 系列遠端監控解決方案。 Halo 的 X 系列具有兩個數位輸入、一個類比輸入和 SDI-12,可簡化流程並最大限度地減少冗餘,以滿足各種監控需求,包括流量測量、罐和筒倉液位監控、土壤濕度監控等。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 供應商的議價能力

- 買家的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭強度

- COVID-19 市場影響評估

第5章 市場動態

- 市場促進因素

- 石油天然氣和化學工業的快速成長推動了對遠端油箱監控系統的需求

- 雲端基礎的遠端油箱監控系統解決方案的興起

- 市場挑戰

- 成本和營運問題

第6章 市場細分

- 按類型

- 完整性監測

- 儲罐液位監控

- 基於資產的狀態監測

- 按最終用戶產業

- 石油和天然氣

- 化學

- 飲食

- 水資源管理和處理

- 醫療

- 其他最終用戶產業

- 按地區

- 北美洲

- 歐洲

- 亞洲

- 澳洲和紐西蘭

- 拉丁美洲

- 中東和非洲

第7章 競爭格局

- 公司簡介

- SkyBitz Inc.

- Banner Engineering Corp.

- SEI Industries Ltd

- Dunraven Systems

- HMS Networks

- ATEK Access Technologies

- Mobiltex

- Schneider Electric

- Powelectrics Limited

- Oriel Systems Limited

第8章投資分析

第9章:市場的未來

The Remote Tank Monitoring System Market size is estimated at USD 253.18 million in 2025, and is expected to reach USD 936.41 million by 2030, at a CAGR of 29.9% during the forecast period (2025-2030).

Remote tank monitoring systems powered by IoT revolutionize fluid management by enabling real-time monitoring of tank fluid levels. These systems consist of sensors affixed to tanks and a central gateway device that aggregates sensor data. With global advancements in IoT and sensor technologies, these systems offer heightened accuracy and reliability in data analysis.

Key Highlights

- Driven by a market demanding higher service standards and a competitive edge, companies are increasingly turning to advanced monitoring technologies. Beyond meeting customer expectations, these systems offer energy management benefits, such as optimized energy usage and reduced wastage, further fueling their adoption. Consequently, remote tank monitoring systems are gaining traction across diverse sectors.

- Smart IoT-enabled systems empower energy companies to oversee their oil and gas storage facilities, ensuring they align with consumer demands. Industry players like Software AG and Infosys have developed tailored solutions, like the smart IoT-enabled remote tank monitoring system, to cater to these specific needs. Despite the global distribution of storage facilities, these solutions provide real-time insights into storage, receipt, and consumption patterns.

- Today, the demand for petroleum fuels in production operations is on the rise. This demand encompasses a complex journey, from crude oil transportation to refining and eventually distributing refined oil to end users in various forms like gasoline and diesel. This intricate process, involving fleet transportation, refined oil tank storage, and filling stations, underscores the necessity for robust remote tank monitoring systems.

- In April 2024, Anova, a global leader in industrial asset monitoring, unveiled its Universal Tank Monitor featuring a radar-level sensor. This technology is gaining momentum, especially among companies managing liquids in intermediate bulk containers (IBCs). It is poised to not only reduce container waste but also streamline tracking and management processes for these businesses.

- Challenges in remote tank operations can vary and can be influenced by the tank type and monitoring equipment. Common issues include faulty level measurement devices, malfunctioning control valves, and potential leakages. These challenges are compounded in remote locations, where access to maintenance and repair resources is limited, posing hurdles to market growth.

Remote Tank Monitoring System Market Trends

The Expanding Oil and Gas Industry is Fueling the Demand for Remote Tank Monitoring Systems

- The oil and gas and chemical industries are witnessing rapid growth, intensifying the need for remote tank monitoring systems. The imperative for efficient and secure storage tank management grows as these industries expand. Remote tank monitoring systems offer real-time insights on tank levels, pressure, and temperature, empowering firms to fine-tune inventory management, curtail downtime, and avert leaks or overflows.

- These systems not only boost operational efficiency and ensure regulatory adherence but also bolster safety by flagging potential issues early. Companies leveraging remote monitoring can streamline logistics, slashing operational costs by reducing manual checks and maintenance.

- Consequently, the oil and gas and chemical industries are increasingly turning to advanced remote monitoring solutions to navigate their expanding operations' scale and complexity, all while upholding productivity and safety benchmarks.

- Highlighting the United States' dominance in oil production, the International Energy Agency (IEA) reported that the country had led global crude oil production for the past six years. In 2023, crude oil production in the United States, including condensate, averaged 12.9 million barrels per day (b/d), peaking at over 13.3 million b/d in December.

- The United States, Saudi Arabia, and Russia collectively contributed 40% (32.8 million b/d) to global oil production in 2023. These three nations have consistently outproduced others since 1971, albeit with occasional shifts in the top producer. In contrast, the combined production of the next three largest producers, Iraq, Canada, and China, stood at 13.1 million b/d in 2023, surpassing the United States' output.

- Looking ahead, the Organization of the Petroleum Exporting Countries (OPEC) projects a rising demand for lighter oil products, particularly gasoline and ethane. Gasoline demand is set to surge to 28.8 million barrels per day by 2045, with diesel and gasoline combined expected to hit 31.7 million barrels daily, underpinning market growth.

North America Holds the Largest Market Share

- North America is poised for significant growth in remote tank monitoring systems, driven by a tech-savvy industry, a surge in oil and gas demands, and a push toward digitization.

- US companies are at the forefront, offering these systems not just for oil and gas but also for water management and agriculture. Typically, these systems employ sensors on tanks, relaying crucial data, from fill levels to temperature, to a central database or dashboard. Leveraging GSM networks and SMS, these systems are now more cost-effective and accessible than ever.

- In a notable move in May 2023, Gallagher Group Limited inked an exclusive deal with Gasbot Pty Ltd, introducing a cutting-edge satellite-based liquid monitoring system to North America. This system, powered by Gasbot's wireless sensor tech, provides real-time data on liquid levels, empowering farmers with precise liquid management insights. Furthermore, it utilizes satellite communication, ensuring that even remote farmers can easily access tank data on their cell phones.

- The United States stands out as a global chemical manufacturing hub where remote tank monitoring systems find applications beyond oil and gas. Oversight on chemical exports and deliveries is stringent, with bodies like the Department of Transportation, the International Air Transport Association, and the Environmental Protection Agency playing pivotal roles.

- Companies like Angus Energy, Anova, and ATEK Access Technologies (TankScan) are leading the charge in North America's evolving remote tank monitoring landscape, adapting swiftly to cutting-edge technologies.

Remote Tank Monitoring System Industry Overview

The remote tank monitoring system market is fragmented, with various players like SkyBitz Inc., Banner Engineering Corp., and EI Industries Ltd. The market players constantly innovate new products and solutions to cater to their customers' complex needs. They are also entering various partnerships, acquisitions, and agreements to better cater to the evolving demands of consumers.

In May 2024, AMETEK Level Measurement Solutions (LMS) introduced BrightTEK, a state-of-the-art wireless Industrial Internet of Things (IIoT) solution built to redefine operational efficiency and cost-effectiveness in various industries. BrightTEK leverages wireless technology to facilitate seamless data transmission from AMETEK LMS branded transmitters, including Magnetrol, Drexelbrook, Orion Instruments, SWI, and B/W Controls, providing visibility to key variables to help optimize on-site operations. The BrightTEK web server provides real-time insights into process variables such as tank levels, volume, and location data. Users can proactively manage their operations, supply chain, and inventory with customizable notifications, alerts, and alarms.

In December 2023, Halo Systems launched its X Series remote monitoring solution. With two digital inputs, one analog input, and SDI-12, Halo's X Series streamlines processes and minimizes redundancy for various monitoring needs, including flow metering, tank or silo level monitoring, and soil moisture monitoring.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Buyers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Assessment of COVID-19 Impact on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rapid growth of Oil and gas and Chemical Industries Creating Growing Requirement for Remote Tank Monitoring Systems

- 5.1.2 Increasing Cloud-based Solutions for Remote Tank Monitoring Systems

- 5.2 Market Challenges

- 5.2.1 Cost and Operational Concerns

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Integrity Monitoring

- 6.1.2 Tank Level Monitoring

- 6.1.3 Equipment-Based Condition Monitoring

- 6.2 By End-user Industry

- 6.2.1 Oil and Gas

- 6.2.2 Chemical

- 6.2.3 Food and Beverage

- 6.2.4 Water Management and Treatment

- 6.2.5 Medical

- 6.2.6 Other End-user Industries

- 6.3 By Geography

- 6.3.1 North America

- 6.3.2 Europe

- 6.3.3 Asia

- 6.3.4 Australia and New Zealand

- 6.3.5 Latin America

- 6.3.6 Middle East and Africa

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 SkyBitz Inc.

- 7.1.2 Banner Engineering Corp.

- 7.1.3 SEI Industries Ltd

- 7.1.4 Dunraven Systems

- 7.1.5 HMS Networks

- 7.1.6 ATEK Access Technologies

- 7.1.7 Mobiltex

- 7.1.8 Schneider Electric

- 7.1.9 Powelectrics Limited

- 7.1.10 Oriel Systems Limited