|

市場調查報告書

商品編碼

1642978

工廠資產管理:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Plant Asset Management - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

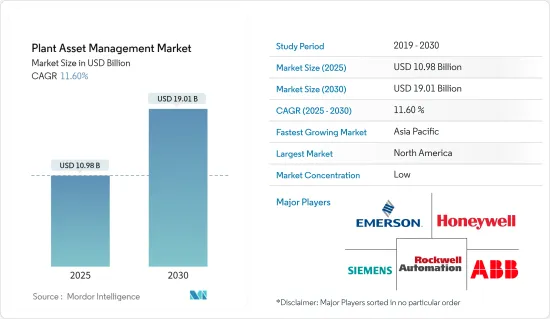

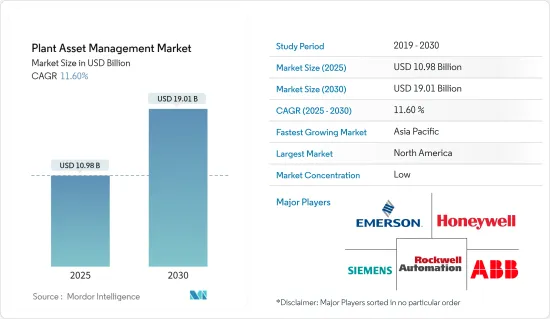

工廠資產管理市場規模預計在 2025 年為 109.8 億美元,預計到 2030 年將達到 190.1 億美元,預測期內(2025-2030 年)的複合年成長率為 11.6%。

基於工廠的資產管理系統允許製造商定期進行設備檢查並減少故障的可能性。工廠資產管理系統使公司能夠追蹤所有使用機械的位置。現場技術人員可以利用即時位置追蹤來規範設備使用情況並確保設備留給授權員工。此外,位置追蹤功能可確保生產所需的設備符合工廠安全準則。

Advantage Automotive Analytics 推出了革命性的定位技術平台 Revo Asset Management。該應用程式可即時追蹤、監控和定位寶貴資產。該應用程式利用低成本、智慧 GPS 技術保護施工機械、發電機和其他貴重物品。

意外的設備停機會影響生產計劃、延遲訂單履行、導致客戶不滿意和收入損失。在認知到這項挑戰後,Aptean 實施了雲端基礎的企業資產管理解決方案 (EAM) 來處理工作訂單、自動核准、追蹤備件庫存、安排預防性維護、部署具有適當技能的工人以及進行行動合規檢查。 CoreFx 是 Aptean EAM 的早期採用者,它發現總體事故減少,從而縮短了現場停機時間。

如果公司保持保固狀態和有用資產,則可以透過支付不必要的維修來節省實際業務成本。根據 ServiceChannel 的一項研究,企業因支付超出保固期的設備維修費用而損失了約 35% 的潛在保固節省費用。此類違約情況可以藉助資產管理軟體來管理。

資料安全可能會影響工廠資產管理市場的成長。雲端儲存是儲存海量資料的好方法,但如果管理得當,就不必擔心被盜。公司不僅會遭受經濟損失,負面宣傳也會損害公司形象。

由於世界各地實施封鎖,大多數產業在新冠疫情期間遭受了收益損失。其中一個行業是建設業,該行業必須由資料驅動,這意味著企業受到了沉重打擊。一些公司已經認知到這項挑戰,並轉向資產管理軟體,例如工具追蹤軟體Go Codes。該應用程式列出了有關公司資產的所有資訊,以提高生產力。例如,工程師可以透過查看應用程式即時檢查設備的運作狀態。

工廠資產管理市場趨勢

石油和天然氣佔據了市場顯著成長

石油和天然氣是功能性極強的資產,可在國際上進行交易,並被多個行業所使用。手動追蹤此交易的所有活動(從採購到銷售)可能會變得複雜。這就是資產管理軟體發揮關鍵作用的地方,它有助於最大限度地降低營運成本。預測性維護是一項關鍵的資產管理功能,有助於追蹤和安排維修週期,降低人事費用並利用公司資金。

石油和天然氣行業使用的大多數設備由公司擁有或租賃,因此即時監控所有資產的位置、性能和安全至關重要。壓力控制設備、測井設備、儲存容器、管道、人行橫道等是需要持續監控和維護的一些設備,以確保您的日常運作和業務順利運作。

石油和天然氣加工廠由複雜、昂貴且關鍵的設備組成。由於多種因素造成的磨損,工廠的狀況和性能會隨著時間的推移而惡化,對生產和相關成本產生負面影響。資產管理策略旨在透過系統地監控設備狀況、避免計劃外的生產停機以及透過最佳化維護計劃來降低營運費用來抵消這種影響。

上游石油和天然氣公司每年至少經歷 27 天的計劃外停工,造成 3,800 萬美元的損失。預測分析使用機器學習 (ML) 技術來預測機械或設備何時需要維修。這減少了停機的整體成本並幫助企業避免大量不必要的開支。

借助有效的維護計劃和資產登記,可以避免生產設施的漏油和其他事故等環境風險。透過預防性維護,公司最多可節省 18%。英國石油公司 (BP) 正在與微軟合作,提供 Azure 人工智慧 (AI) 和機器學習解決方案,以轉型其石油和天然氣業務。人工智慧 (AI) 增強了遠端勞動力的安全措施。

貝克休斯去年與 C3 AI、Accenture和微軟簽署協議,為能源和工業客戶提供工業資產管理 (IAM) 解決方案。此解決方案增強的數位技術提高了工業機械、現場設備和其他實體資產的安全性、效率和排放狀況。

北美佔據主要市場佔有率

北美在上年度簽署了122份石油和天然氣契約,其中美國以113份居首,佔總數的93%,其次是墨西哥,佔3%,加拿大僅佔2%。這表明石油和天然氣公司正在投資資產管理。

根據 Westwood 的陸上管道預測,預計 2022 年至 2028 年期間公司將在新的石油和天然氣管道上投資約 3,700 億美元。預計這段時期也將新建油氣管道31萬公里。預計中國和北美將引領這一趨勢。北美佔已安裝天然氣管道總長度的205,000公里。由於俄羅斯與烏克蘭衝突導致歐洲和亞洲的需求激增,北美去年成為最大的液化天然氣 (LNG) 出口地區。

在整個地區,雲端運算技術的進步使得工廠資產管理變得更加容易。這些解決方案可協助工廠改善維護計劃以降低成本、追蹤和管理庫存和設備利用率並解決勞動力短缺問題。公司正在宣布新的雲端解決方案來提高生產力。

美國Honeywell推出了監測和最佳化碳排放的永續性解決方案。這種基於感測器的解決方案使公司能夠近乎即時地監控和可視化排放。工業部門將從新鑰匙中受益,因為它致力於減少溫室氣體排放並實現碳減排目標。

工廠資產管理行業概覽

多家提供資產管理服務的供應商的競爭十分激烈。主要參與者包括ABB集團、艾默生電氣公司、西門子股份公司、羅克韋爾自動化和Honeywell國際公司。由於製造業對人工智慧(AI)的大力投資,資產管理服務的需求很高。為了保持營運的一致性並進一步擴大服務,資產管理提供者正在收購和投資新公司和新技術。

2022 年 11 月-醫療保健績效改善公司 Vizient 正在與醫療保健供應鏈分析公司 Handle Global 合作,幫助 Vizient 的成員醫療保健組織透過其資本資產管理系統管理資本支出和設備。該系統為醫療保健組織提供資料、分析和見解,以改善設備生命週期規劃、採購和資產利用率,最終節省成本。

2023 年 2 月—自然和建築資產設計和諮詢機構 Arcadis 與加拿大數位科技新興企業Niricson 合作。透過使用人工智慧 (AI) 驅動的機器人、電腦視覺和聲學技術,Arcadis 能夠使橋樑基礎設施的預測性維護更安全、更快捷、更具成本效益。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 調查結果

- 調查前提

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 市場概況

- 市場促進因素

- 採用即時資料分析

- 採用精實製造方法

- 市場限制

- 熟練勞動力短缺

- 產業價值鏈分析

- 產業吸引力-波特五力分析

- 新進入者的威脅

- 購買者/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭對手之間的競爭強度

第5章 市場區隔

- 透過提供

- 軟體

- 服務

- 按配置

- 本地

- 雲

- 按最終用戶

- 能源和電力

- 石油和天然氣

- 石油化工

- 礦業與金屬

- 航太和國防

- 車

- 其他最終用戶

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

第6章 競爭格局

- 公司簡介

- ABB Group

- Emerson Electric Co.

- Honeywell International Inc.

- Rockwell Automation, Inc.

- Siemens AG

- SFK Group

- Ramco Systems

- General Electric Co.

- Endress+Hauser AG

- Schneider Electric SE

- Investment Analysis

第7章 市場機會與未來趨勢

The Plant Asset Management Market size is estimated at USD 10.98 billion in 2025, and is expected to reach USD 19.01 billion by 2030, at a CAGR of 11.6% during the forecast period (2025-2030).

Using plant-based asset management systems, manufacturing firms may conduct routine equipment inspections to reduce the likelihood of failures. A plant asset management system enables companies to track every location where machines are being used. Field technicians can regulate equipment usage and ensure it stays with the authorized employees using real-time location tracking. The ability to track locations also ensures the equipment is handled within the plant's safety guidelines for production.

Advantage Automotive Analytics launched Revo Asset Management, a platform for innovative location-based technology. The application will track, monitor and locate valuable assets in real-time. The application safeguards construction equipment, generators, and other valuables with low-cost, smart GPS technology.

Sudden equipment downtime can affect production schedules, which can delay order fulfillment, lead to unhappy customers, and result in income loss. Recognizing this challenge, Aptean introduced a cloud-based enterprise asset management solution (EAM) to handle work orders, automate approvals, track spare parts inventories, schedule preventative maintenance, allocate appropriately skilled workers, and conduct mobile compliance inspections. CoreFx, the early adopters of Aptean EAM, observed a reduction in overall accidents leading to less downtime on the floor.

If a company keeps assets of the warranty status or avail assets, it could save the business real money by paying for unnecessary repairs. According to ServiceChannel research, firms lose almost 35% of potential warranty savings from paying for repair on under-warranty equipment. Such defaults can be managed with the help of Asset management software.

Data Security can affect the growth of the Plant Asset Management Market. Cloud facilities are a great way to store enormous amounts of data, but if managed well, it is safe from theft. The company can not only suffer financial loss, but a negative reputation can also damage a company's profile.

With lockdowns around the globe, most industries suffered a loss of revenue during the COVID-19 outbreak. One such sector was the construction business, where companies were hit hard because the industry needed to be data-driven. Some companies recognized this challenge and adopted asset management software like Go Codes tool tracking software. The app listed all the information about company assets for better productivity. For instance, a technician could check equipment availability in real time by checking in the app.

Plant Asset Management Market Trends

Oil and Gas Accounts For Significant Market Growth

Oil and gas are high-functioning assets traded internationally and used across multiple industries. It becomes complicated to manually track all the activities of this trade, from procurement to selling. The asset management software plays an important role here, ensuring operational costs are kept marginally low. Predictive maintenance is a crucial asset management feature that helps track and schedule repair cycles, lowering labor costs and utilizing company funds.

Real-time monitoring of all assets' location, performance, and safety is critical in the oil and gas industry, as most of the equipment used in this sector is owned or leased by the companies. Pressure control equipment, logging equipment, storage containers, pipes, and crossings are some of the instruments that require constant monitoring and maintenance for the smooth functioning of day-to-day operations and business.

The process plants in the oil and gas industry are complex and consist of expensive and critical equipment. As the plant's condition and performance degrade over time due to wear from several factors, this harms the production and the associated costs. Asset management strategies aim to counter this impact by systematically monitoring equipment conditions, avoiding unplanned production downtime, and reducing operational expenses by optimizing maintenance planning.

The upstream oil and gas industry companies undergo at least 27 days of unplanned downtime each year, costing them 38 million USD. Predictive Analysis uses Machine learning (ML) techniques to forecast when machinery and equipment need repairs. Thus it can reduce the overall downtime cost, thereby saving a lot of unnecessary expenses for the company.

Environmental risks, like oil spills or any other accident at the production facility, can be averted with the help of effective maintenance plans and asset registries. A company can save up to 18% with the help of preventive maintenance. British Petroleum (BP) has partnered with Microsoft for its Azure artificial intelligence (AI) and Machine Learning solutions to transform oil and gas operations. Artificial intelligence (AI) will increase safety measures for employees working in remote locations.

In the previous year, Baker Hughes signed a contract with C3 AI, Accenture, and Microsoft to provide industrial asset management (IAM) solutions for clients in the energy and industrial sectors. The enhanced digital technologies of the solution will improve the safety, efficiency, and emissions profile of industrial machines, field equipment, and other physical assets.

North America to Hold Significant Market Share

There were 122 oil and gas contracts in North America in the previous year, US contribution being the highest with 113 contracts, representing a 93% share of all the oil and gas contracts, followed by Mexico at 3% and Canada at only a 2% share. Operations & maintenance covered 99 of these contracts, which shows Oil and Gas companies are investing in asset management.

According to Westwood's onshore pipeline forecast, companies are expected to invest around 370 billion USD between 2022 and 2028 on new oil and gas pipelines. It is projected 310,000km of new oil and gas pipelines will be built during this period. China and North America are expected to lead the charge. North America will account for 205,000km of total installments for gas pipelines. North America became the largest LNG (liquified natural gas) exporter in the previous year, as the demand surged from Europe and Asia due to the Russia- Ukraine conflict.

Plant Asset Management is becoming more accessible due to advancements in the cloud in this region. These solutions can help plants refine maintenance schedules to cut costs, track and manage inventory and equipment usage, adapt to labor shortages, and more. Companies are introducing new cloud solutions exhibiting to improve productivity.

US-based Honeywell introduced a sustainability solution for carbon emissions monitoring and optimization. The sensor-based solution will enable organizations to monitor and visualize emissions in near real-time. Industrial sectors will benefit from the new key as they work to cut their greenhouse gas (GHG) emissions and achieve their carbon reduction targets.

Plant Asset Management Industry Overview

There is intense competition with several providers of Asset Management Services. The major players include ABB Group, Emerson Electric Co., Siemens AG, Rockwell Automation, and Honeywell International. Because manufacturing sectors invest extensively in artificial intelligence (AI), there is a high demand for Asset Management Services. To maintain consistency in the business and expand services further, asset management providers are making acquisitions and investments in new companies and technologies.

November 2022 - Vizient, the healthcare performance improvement company, collaborated with Handle Global, the healthcare supply chain analytics, to help Vizient member healthcare organizations manage their capital expenses and equipment through the capital asset management system. This system will offer healthcare organizations data, analytics, and insights for improved equipment lifecycle planning, procurement, and asset utilization that will ultimately reduce costs.

February 2023 - Arcadis design and consultancy organization for natural and built assets collaborated with Canada-based digital technology start-up Niricson. Using robotics, computer vision, and acoustic technology with artificial intelligence (AI), Arcadis can make predictive maintenance of bridge infrastructure safer, faster, and more cost-effective.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Deliverables

- 1.2 Study Assumptions

- 1.3 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Adoption Of Real-Time Data Analytics

- 4.2.2 Adoption of Lean Manufacturing Practices

- 4.3 Market Restraints

- 4.3.1 Lack of Skilled Personnel

- 4.4 Industry Value Chain Analysis

- 4.5 Industry Attractiveness - Porter's Five Forces Analysis

- 4.5.1 Threat of New Entrants

- 4.5.2 Bargaining Power of Buyers/Consumers

- 4.5.3 Bargaining Power of Suppliers

- 4.5.4 Threat of Substitute Products

- 4.5.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 Offerings

- 5.1.1 Software

- 5.1.2 Services

- 5.2 Deployment

- 5.2.1 On-Premise

- 5.2.2 Cloud

- 5.3 End-User

- 5.3.1 Energy and Power

- 5.3.2 Oil & Gas

- 5.3.3 Petrochemical

- 5.3.4 Mining & Metal

- 5.3.5 Aerospace & Defense

- 5.3.6 Automotive

- 5.3.7 Other End-Users

- 5.4 Geography

- 5.4.1 North America

- 5.4.2 Europe

- 5.4.3 Asia-Pacific

- 5.4.4 Latin America

- 5.4.5 Middle-East and Africa

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 ABB Group

- 6.1.2 Emerson Electric Co.

- 6.1.3 Honeywell International Inc.

- 6.1.4 Rockwell Automation, Inc.

- 6.1.5 Siemens AG

- 6.1.6 SFK Group

- 6.1.7 Ramco Systems

- 6.1.8 General Electric Co.

- 6.1.9 Endress+Hauser AG

- 6.1.10 Schneider Electric SE

- 6.2 Investment Analysis