|

市場調查報告書

商品編碼

1640497

單乙二醇:市場佔有率分析、產業趨勢與統計、成長預測(2025-2030 年)Mono-ethylene Glycol - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

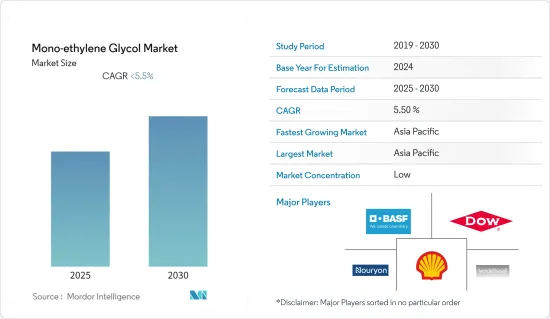

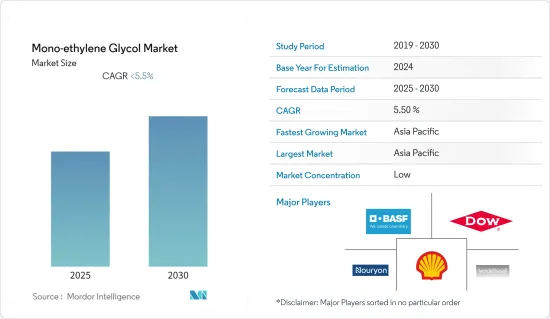

預測期內,單乙二醇市場預計將以高達 5.5% 的複合年成長率成長。

新冠肺炎疫情的蔓延導致全球主要國家停工,影響大多數產業,並導致煉油廠依照法規要求關閉。由於產量下降以及對各種衍生物和最終產品的需求減弱,對乙二醇(MEG)的需求下降。然而,2021 年汽車、紡織和其他活動的增加導致市場穩定成長。

關鍵亮點

- 短期內,包裝領域對PET的需求增加是推動乙二醇市場成長的關鍵因素。

- 另一方面,原油價格波動導致的原物料價格波動可能會限制市場成長。

- 生物基 MEG 材料日益普及,很可能在不久的將來為全球市場創造豐厚的成長機會。

- 預計在評估期內,亞太地區的乙二醇市場將呈現健康成長。

乙二醇市場趨勢

紡織業佔市場主導地位

- 紡織業是乙二醇及其衍生物的主要終端用戶產業,用於合成各種聚酯纖維。

- 2021 年全球紡織纖維產量達 1.136 億噸,而 2020 年為 1.083 億噸,成長 4.8%。

- 印度、中國和美國是世界主要紡織品生產國。由於投資增加和基礎設施改善,預測期內該行業的需求可能會增加。

- 根據印度紡織品和服飾出口聯合會(IBEF)統計,2021年4月至12月,包括手工藝品在內的印度紡織品和服裝出口總額為298億美元,高於去年同期的212億美元。此外,有利的人口結構和對品牌產品的偏好偏好預計將提振紡織業的需求,從而促進單乙二醇市場的發展。

- 美國是紡織相關產品的主要出口國之一。根據美國全國紡織組織理事會的報告,2021年美國纖維、紡織品和服裝出口總額為284億美元,紡織品和服裝出貨收益為652億美元。

- 因此,預計上述因素將對預測期內的市場成長產生重大影響。

亞太地區佔市場主導地位

- 亞太地區佔據全球市場佔有率的主導地位。由於中國、印度和日本等國家的紡織和汽車工業不斷發展,對乙烯的需求也不斷成長,因此該地區對乙烯的需求也日益成長。

- 中國是世界上最大的乙二醇及其衍生對苯二甲酸乙二醇酯(PET)消費國之一。充足的原料供應和低廉的生產成本支持了該地區的生產擴張。

- 中國是PET樹脂的重要生產國,其中中油集團、江蘇三房巷等企業產量位居世界前列,產能超過200萬噸。因此,終端用戶產業對 PET 的需求不斷增加,也增加了對單乙二醇的需求。

- 中國紡織業是全球主要產業之一,也是全球最大的服飾出口國。據中國工業和資訊化部(MIIT)稱,2021年前9個月,中國紡織業實現穩定成長,利潤總額較去年同期成長31.7%,至人民幣1,711億元(約268億美元)。

- 據印度化學和石化工業協會稱,2020-2021會計年度MEG年產能為2,215噸,產量約2,000噸。

- 該地區也是最大的汽車製造地。根據OICA統計,2021年汽車總產量為46,732,785輛,較去年同期成長6%。

- 因此,預計上述因素將在整個預測期內推動該地區對乙二醇的需求。

乙二醇產業概況

單乙二醇市場依其性質可分為部分細分市場。主要參與企業(不分先後順序)包括 Nouryon、 BASF SE、Dow、LyondellBasell Industries Holdings BV 和 Shell PLC。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第 1 章 簡介

- 調查前提條件

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場動態

- 驅動程式

- 包裝領域對 PET 的需求不斷增加

- 其他促進因素

- 限制因素

- 原物料價格波動

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭程度

- 貿易分析

- 價格趨勢

- 技術簡介

- 監理政策分析

第5章 市場區隔(市場規模:數量)

- 應用

- 聚酯纖維

- 寶特瓶

- PET 薄膜

- 防凍液

- 工業的

- 最終用戶產業

- 纖維

- 包裝

- 塑膠

- 汽車和運輸

- 其他終端用戶產業(電子、塗料)

- 地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 義大利

- 法國

- 歐洲其他地區

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲地區

- 亞太地區

第6章 競爭格局

- 併購、合資、合作與協議

- 市場佔有率**/排名分析

- 主要企業策略

- 公司簡介

- Nouryon

- BASF SE

- Dow

- India Glycols Limited

- LACC

- LyondellBasell Industries Holdings BV

- Mitsubishi Chemical Corporation

- Nan Ya Plastics Corporation

- Reliance Industries Limited

- Royal Dutch Shell PLC

- SABIC

- Solventis

第7章 市場機會與未來趨勢

- 生物基 MEG 材料日益流行

The Mono-ethylene Glycol Market is expected to register a CAGR of less than 5.5% during the forecast period.

Due to the COVID-19 spread, major economies imposed lockdowns globally, which impacted most industries, and refineries went non-operational following regulations and rules. There was a decline in the demand for mono ethylene glycol (MEG) due to the dip in the production and various derivatives and end product demand. However, the market is growing steadily, owing to increased automotive, textile, and other activities in 2021.

Key Highlights

- Over the short term, the growing demand for PET in the packaging sector is a significant factor driving the growth of the mono-ethylene glycol market.

- On the flip side, the fluctuation in raw material prices due to volatility in crude oil prices can restrict market growth.

- Nevertheless, the increased popularity of bio-based MEG materials will likely create lucrative growth opportunities for the global market soon.

- Asia-Pacific is estimated to witness healthy growth in the momo-ethylene glycol market over the assessment period.

Monoethylene Glycol Market Trends

Textile Sector to Dominate the Market

- Textile is a primary end-user industry for mono-ethylene glycol, as the derivatives synthesize a wide variety of polyester fibers.

- The global production volume of textile fibers reached volume of 113,600 thousand metric tons in 2021 and registered a growth of 4.8% compared to 108,300 thousand metric tons in 2020.

- India, China, and the United States represent major textile manufacturing countries in the world. With growing investments and improved infrastructure facilities, the demand from the sector is likely to increase in the forecast period.

- According to the IBEF, in India, exports of textiles and apparel, including handicrafts, totaled USD 29.8 billion from April to December 2021, up from USD 21.2 billion in the same period last year, thus registering a robust 41% increase over the previous year. Furthermore, favorable demographics and a shift in preference for branded products are expected to boost demand for the textile sector, thus boosting the mono-ethylene glycol market.

- The United States is among the key countries in exports of textile-related products. In 2021, US Fiber, textile, and apparel exports combined were USD 28.4 billion, and the value of shipments for textiles and apparel was USD 65.2 billion, according to the National Council of Textile Organizations report.

- Thus, the abovementioned factors are expected to significantly impact market growth during the forecast period.

Asia-Pacific to Dominate the Market

- The Asia-Pacific region dominated the global market share. With growing, textile and automotive activities and the increasing demand for mono-ethylene in countries such as China, India, and Japan, the need for mono-ethylene is increasing in the region.

- China is one of the largest global consumers of mono-ethylene glycol and its derived polyethylene terephthalate (PET). The abundant raw materials availability and low-cost production supported the region's production growth.

- China is a significant PET resin producer, home to companies such as PetroChina Group and Jiangsu Sangfangxiang, among the most prominent manufacturers globally in terms of volume, with capacities of more than 2 million tons. Thus, the rising demand for PET from end-user industries is driving the need for mono-ethylene glycol.

- China's textile sector is one of its major sectors, and the country is the largest clothing exporter in the world. China's textile industry grew steadily during the first nine months of 2021 with collective profits worth CNY 171.1 billion (~ USD 26.80 billion), a 31.7% year-on-year (YoY) increase, according to the Ministry of Industry and Information Technology (MIIT).

- According to the Chemical and Petrochemicals Manufacturers Association, India, in FY2020-21, the annual capacity of MEG stood at 2,215 KT, with production amounting to almost 2000 KT.

- Also, the region is the largest automotive manufacturing hub. According to OICA, in 2021, the total production of vehicles stood at 46,732,785 units, which was an increase of 6% compared to the same period last year.

- Thus, the factors mentioned above are expected to boost the mono-ethylene glycol demand through the forecast period in the region.

Monoethylene Glycol Industry Overview

The mono-ethylene glycol market is partially fragmented in nature. Major players (not in any particular order) include Nouryon, BASF SE, Dow, LyondellBasell Industries Holdings BV, and Shell PLC.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Demand for PET in the Packaging Sector

- 4.1.2 Other Drivers

- 4.2 Restraints

- 4.2.1 Fluctuation in Raw Material Prices

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

- 4.5 Trade Analysis

- 4.6 Price Trends

- 4.7 Technological Snapshot

- 4.8 Regulatory Policy Analysis

5 MARKET SEGMENTATION (Market Size in Volume)

- 5.1 Application

- 5.1.1 Polyester Fiber

- 5.1.2 PET Bottle

- 5.1.3 PET Film

- 5.1.4 Antifreeze

- 5.1.5 Industrial

- 5.2 End-user Industry

- 5.2.1 Textile

- 5.2.2 Packaging

- 5.2.3 Plastic

- 5.2.4 Automotive and Transportation

- 5.2.5 Other End-user Industries (Electronics, Paints)

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 US

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 UK

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East & Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East & Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share**/Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Nouryon

- 6.4.2 BASF SE

- 6.4.3 Dow

- 6.4.4 India Glycols Limited

- 6.4.5 LACC

- 6.4.6 LyondellBasell Industries Holdings BV

- 6.4.7 Mitsubishi Chemical Corporation

- 6.4.8 Nan Ya Plastics Corporation

- 6.4.9 Reliance Industries Limited

- 6.4.10 Royal Dutch Shell PLC

- 6.4.11 SABIC

- 6.4.12 Solventis

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Increased Popularity of Bio-based MEG Materials