|

市場調查報告書

商品編碼

1444960

石墨電極:市場佔有率分析、產業趨勢與統計、成長預測(2024-2029)Graphite Electrode - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

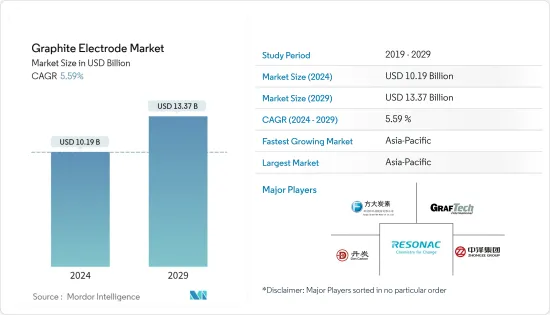

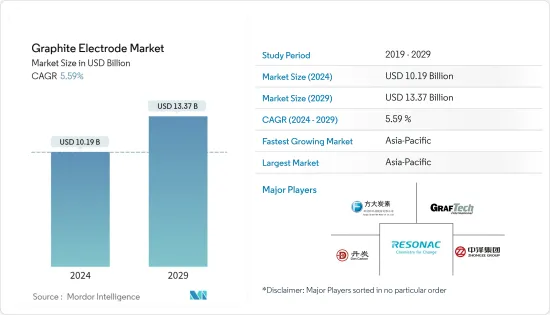

石墨電極市場規模預計到2024年為101.9億美元,預計到2029年將達到133.7億美元,預測期內(2024-2029年)年複合成長率為5.59%。

2020年,市場受到COVID-19爆發的負面影響。然而,隨著主要終端用戶產業恢復營運,2021年出現顯著復甦。

主要亮點

- 短期內,新興國家鋼鐵產量的強勁成長以及中國廢鋼供應量的增加預計將推動市場成長。

- 另一方面,針狀焦價格上漲可能會阻礙所研究市場的成長。

- 中國透過電弧爐(EAF)技術增加鋼鐵產量預計將成為未來幾年市場的機會。

- 由於中國的強勁需求,預計亞太地區將主導市場。

石墨電極市場趨勢

電爐領域佔據市場主導地位

- 電弧爐 (EAF) 透過熔化廢鐵、DRI(直接還原鐵)、HBI(用 DRI 壓縮的熱煤球)或固體生鐵來生產鋼。在電弧爐製程中,電力提供熔化原料所需的動力。

- 石墨電極主要用於熔化電弧爐(EAF)煉鋼過程中的廢鋼。電極由石墨製成,可以承受高溫。在 EAF 中,電極尖端可達到 3,000°F,這是太陽表面溫度的一半。電極尺寸範圍為直徑 75 毫米至 750 毫米、長度 2,800 毫米。煉鋼廠和煉鋼廠的電弧爐(EAF)通常分別使用UHP電極(通常為350毫米或以上)和HP和UHP電極(通常為400毫米或以下)。

- 近期石墨電極價格上漲,增加了電爐製造成本。截至2022年2月16日,我國石墨電極均價較年初上漲5.17%,較去年同期上漲44.48%。

- 在中國,電爐鋼約佔總市場佔有率的10%。然而,由於國內廢鋼供應量的增加以及政府支持廢鋼使用的政策,預計情況將會改變。由於這些因素,電爐應用中使用的石墨電極的需求預計在預測期內穩定成長。

- 下游石墨電極鋼廠處於恢復狀態。石墨電極較往年供不應求。隨著鋼廠重啟,需求預計將增加。

- 根據世界鋼鐵協會的數據,2023 年 2 月 63 個國家的粗鋼產量為 1.424 億噸。 2023年2月,中東粗鋼產量為350萬噸。與 2022 年同期相比,成長了 11.5%。

- 因此,強勁的需求、有限的供應和高成本預計將在預測期內提高石墨電極價格。

中國將主導亞太地區

- 中國決策機構大力支持電爐煉鋼技術,努力減少碳排放,實現國內鋼鐵業的永續性。

- 在世界範圍內,中國石墨電極消費量和產能均佔最大佔有率。目前,中國有40多家官方石墨電極製造商,還有30家新參與企業在過去幾年將其他耐火材料產品與電極一起推向市場。

- 2022年3月,新餘鋼鐵100噸電爐計劃動工。新廠預計鋼水產能為100萬噸/年。

- 中國的石墨電極製造商始終致力於透過進口或國內採購來獲取高品質的針狀焦,同時確保技術提高品質。中國電極製造商也專注於生產尺寸超過700毫米的UHP級石墨電極。

- 今年7月7日,中國的經濟規劃機構國家發展和改革委員會(國家發改委)公佈了國家資源循環利用產業規劃,以加速發展低碳循環經濟。該計畫包括2025年鋼鐵業廢鋼使用量達到3.2億噸的目標。

- 展望未來10年,預計電爐鋼佔全球鋼鐵產量的比重將從2020年的30%達到40%,2030年我國電爐鋼佔比將由10%左右上升至10%左右%,預計將達到全國的25% 。據 Fastmarket 鋼鐵調查團隊稱,

- 因此,上述因素將導致預測期內中國研究市場的成長。

石墨電極產業概況

石墨電極市場部分整合。主要企業包括(排名不分先後)GrafTech International、Resonac Holdings Corporation、方大炭新材料、中澤集團、丹炭。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 調查先決條件

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 促進因素

- 煉鋼電爐技術需求旺盛

- 中國廢鋼供應量增加

- 抑制因素

- 針狀焦價格飆升

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 消費者議價能力

- 新進入者的威脅

- 替代產品和服務的威脅

- 競爭程度

- 各國鋼鐵產能

第5章市場區隔(數量和金額方面的市場規模)

- 電極等級

- 高功率(UHP)

- 高功率(小功率)

- 正常輸出(RP)

- 目的

- 電爐

- 鹼性氧氣爐

- 有色金屬應用

- 地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 其他中東和非洲

- 亞太地區

第6章 競爭形勢

- 併購、合資、合作與協議

- 市場佔有率(%)分析

- 主要企業採取的策略

- 公司簡介

- Dan Carbon

- EPM Group

- Fangda Carbon New Material Co., Ltd.

- GrafTech International

- Graphite India Limited

- HEG Limited

- Kaifeng Pingmei New Carbon Materials Technology Co., Ltd.

- Nantong Yangzi Carbon Co. Ltd.

- Nippon Carbon Co Ltd.

- Resonac Holdings Corporation

- SANGRAF International

- SEC CARBON, LIMITED

- Tokai Carbon Co., Ltd.

- ZHONGZE GROUP

第7章市場機會與未來趨勢

- 中國透過電爐技術提高鋼鐵產量

The Graphite Electrode Market size is estimated at USD 10.19 billion in 2024, and is expected to reach USD 13.37 billion by 2029, growing at a CAGR of 5.59% during the forecast period (2024-2029).

The market was affected negatively by the COVID-19 outbreak in 2020. However, with the resumption of operations in major end-user industries, it recovered significantly in 2021.

Key Highlights

- In the short term, the strong growth in steel production in emerging countries and the rising availability of steel scrap in China are expected to drive the market's growth.

- On the flip side, soaring prices of needle coke are likely to hinder the growth of the studied market.

- The rising production of steel through electric arc furnace (EAF) technology in China is expected to act as an opportunity for the market in the coming years.

- The Asia-Pacific region is expected to dominate the market due to strong demand from China.

Graphite Electrode Market Trends

The Electric Arc Furnace Segment to Dominate the Market

- An electric arc furnace (EAF) melts steel scrap, DRI (directly reduced iron), HBI (hot briquetted iron, which is compacted DRI), or pig iron in solid form to produce steel. On the EAF route, electricity provides the required power to melt the feedstock.

- Graphite electrodes are primarily used in the electric arc furnace (EAF) steelmaking process to melt steel scrap. Electrodes are made of graphite due to their ability to withstand high temperatures. In EAF, the tip of the electrode can reach 3,000º F, which is half the temperature of the sun's surface. The size of electrodes varies widely, from 75 mm to as large as 750 mm in diameter and up to 2,800 mm in length. Electric arc furnaces (EAF) in steel mills and iron and steel foundries commonly use UHP electrodes (usually 350 mm and larger) and HP and UHP electrodes (typically 400 mm and smaller), respectively.

- The recent price surge for graphite electrodes has boosted EAF mills' costs. As of February 16, 2022, the average price of the graphite electrode in China was up by 5.17% from the beginning of the year and 44.48% from the same period last year.

- In China, EAF steel accounts for around 10% of the overall share. However, the situation is expected to change due to the growing availability of steel scrap in the country and the government's policies supporting the use of steel scrap. Due to such factors, the demand for graphite electrodes used for EAF applications is expected to increase steadily during the forecast period.

- The downstream graphite electrode steel plants are in a recovery state. The graphite electrode stock is insufficient compared to previous years. With the resumption of steel plants, demand is expected to increase.

- According to the World Steel Association, the production of crude steel for 63 countries in the month of February 2023 was 142.4 million metric tons (Mt). In February 2023, the Middle East produced 3.5 million metric tons of crude steel. This was up by 11.5% as compared to the same period in 2022.

- As a result, there will be a rise in the price of graphite electrodes during the forecast period due to favorable demand, limited supply, and high cost.

China to Dominate the Asia-Pacific Region

- The decision-making bodies in China have strongly supported EAF steelmaking technologies in their efforts to decrease carbon emissions and achieve sustainability in the nation's steel industry.

- China holds the largest share in terms of consumption and production capacity of graphite electrodes in the global scenario. At present, there are more than 40 official graphite electrode producers in China, with 30 new entrants that have added other refractory products, along with electrodes, to the market in the past 2-3 years.

- In March 2022, Xinyu Steel started constructing its 100-metric-ton EAF project. The new mill is expected to have a liquid steelmaking capacity of 1 million metric tons annually.

- Chinese graphite electrode producers are constantly trying to procure quality needle coke via imports or domestic procurement while securing technology for quality improvement. Chinese electrode manufacturers are also focusing on producing more UHP-grade graphite electrodes with sizes larger than 700 mm.

- The National Development and Reform Commission (NDRC), China's economic planning body, published a plan for the country's resource recycling industry on July 7 this year to accelerate the development of a low-carbon circular economy. The plan included a goal for scrap usage in the steel sector to reach 320 million tons in 2025.

- Looking into the next decade, the share taken by EAF steel is estimated to reach 40% of global steel output, against 30% in 2020, with EAF steel in China at 25% of the country's total in 2030, compared with around 10% last year, according to Fastmarkets' steel research team.

- Hence, the above factors will lead to the growth of the studied market in China over the forecast period.

Graphite Electrode Industry Overview

The graphite electrode market is partially consolidated. Some of the key players (not in any particular order) include GrafTech International, Resonac Holdings Corporation, Fangda Carbon New Material Co., Ltd., Zhongze Group, and Dan Carbon among others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Strong Demand For EAF Technology For Steelmaking

- 4.1.2 Rising Availability Of Steel Scrap In China

- 4.2 Restraints

- 4.2.1 Soaring Prices Of Needle Coke

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

- 4.5 Steel Production Capacity by Country

5 MARKET SEGMENTATION (Market Size in Volume and Value)

- 5.1 Electrode Grade

- 5.1.1 Ultra High Power (UHP)

- 5.1.2 High Power (SHP)

- 5.1.3 Regular Power (RP)

- 5.2 Application

- 5.2.1 Electric Arc Furnace

- 5.2.2 Basic Oxygen Furnace

- 5.2.3 Non-steel Application

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Share (%) Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Dan Carbon

- 6.4.2 EPM Group

- 6.4.3 Fangda Carbon New Material Co., Ltd.

- 6.4.4 GrafTech International

- 6.4.5 Graphite India Limited

- 6.4.6 HEG Limited

- 6.4.7 Kaifeng Pingmei New Carbon Materials Technology Co., Ltd.

- 6.4.8 Nantong Yangzi Carbon Co. Ltd.

- 6.4.9 Nippon Carbon Co Ltd.

- 6.4.10 Resonac Holdings Corporation

- 6.4.11 SANGRAF International

- 6.4.12 SEC CARBON, LIMITED

- 6.4.13 Tokai Carbon Co., Ltd.

- 6.4.14 ZHONGZE GROUP

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Rising Production of Steel through EAF Technology in China