|

市場調查報告書

商品編碼

1687201

倉庫機器人-市場佔有率分析、產業趨勢與統計、成長預測(2025-2030)Warehouse Robotics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

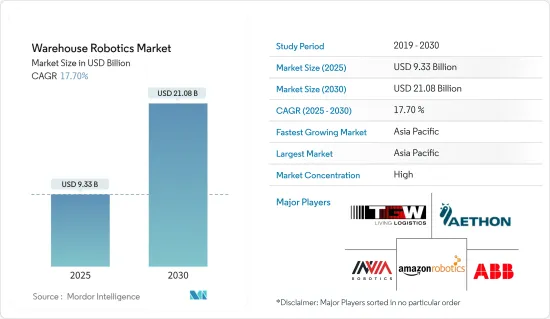

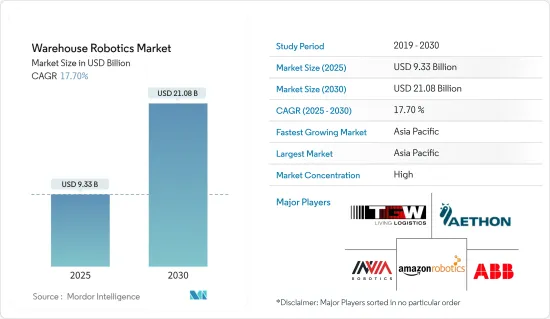

預計 2025 年倉庫機器人市場規模為 93.3 億美元,到 2030 年將達到 210.8 億美元,預測期內(2025-2030 年)的複合年成長率為 17.7%。

關鍵亮點

- SKU 多樣性的增加推動了倉庫自動化:受 SKU 多樣性激增的推動,倉庫機器人市場正在經歷加速成長。預計超過 50% 的公司將增加 SKU 數量,以滿足長尾消費者的需求。這一趨勢正在重塑傳統的倉儲模式,而大容量托盤訂購系統正在被小容量、多 SKU 訂購系統所取代。為了應對這項挑戰,自動化小批量儲存/檢索系統 (AS/RS) 至關重要。這些系統利用輕型起重機來管理手提箱、箱子和板條箱,從而最佳化儲存並釋放關鍵的勞動力和配送資源。

- 擴大倉庫規模:為了適應 SKU 的增加,倉庫面積從 2000 年的 65,000 平方英尺擴大到 2020 年的 20 萬多平方英尺。

- 改變零售商與批發商之間的動態:即時訂購和直接面對消費者的分銷正在減少大托盤訂單並加速對自動化的需求。

- 揀選機器人和 AGV:最新一代的揀選機器人和自動導引運輸車(AGV) 非常適合處理大型倉庫中大量 SKU 範圍內的小訂單。

- 投資激增推動技術進步:資本的湧入推動倉庫自動化技術的發展。創業投資公司正積極投資機器人技術,2020 年第一季倉庫機器人新興企業的資金籌措達到 3.81 億美元,年增 57%。

- Locus Robotics 擴張 2020 年 6 月,Locus Robotics 籌集了 4,000 萬美元,用於加強研發並擴展到歐盟。

- 亞馬遜創新中心:亞馬遜投資 4,000 萬美元在麻薩諸塞州開發最先進的機器人中心,旨在推動自動化進步。

- Shopify 的策略性收購:Shopify 於 2019 年以 4.5 億美元收購了 6 River Systems,透過整合雲端基礎的軟體和協作行動機器人來擴展履約能力。

- 電子商務熱潮推動採用:電子商務的快速成長持續推動倉庫機器人的採用。隨著網路零售的爆炸性成長,高效的庫存管理和履約業務變得至關重要。

- 市場規模預測:Cowen預測,2024年美國電商倉儲與物流機器人市場規模將達到近80億美元。

- 新的履約模式:Albertsons 和 Takeoff Technologies 正在試行城市履約中心,使用人工智慧和機器人技術來簡化較小的都市區倉庫業務。

- 克羅格擴張:克羅格正與 Ocado 合作,開設多達 20 個配備大型機器人設施的客戶履約中心。

- 勞動力短缺和成本降低推動創新:倉庫機器人擴大被用來解決勞動力短缺問題並降低營運成本。自動化透過減少不必要的勞動力流動和簡化操作來提高效率。

- 浪費的運動成本:美國倉庫每年因浪費的運動而損失 43 億美元,凸顯了機器人解決方案的重要性。

- 工業機器人的成長:預計運作中的工業機器人數量將從 2018 年的 240.8 萬台增加到 2021 年的 378.8 萬台。

- 阿里巴巴裁員:透過實施機器人勞動力,阿里巴巴將倉庫勞動力減少了 70%,同時為技術純熟勞工創造了更多機會。

倉庫機器人市場趨勢

移動機器人(AGV 和 AMR)是按類型分類的最大細分市場

移動機器人,尤其是自動導引運輸車(AGV) 和自主移動機器人 (AMR),佔據倉庫機器人市場主導地位。到 2021 年,該領域將佔全球銷售額的 22.80%,成為自動化的重要動力。

- 強勁成長:移動機器人是成長最快的領域,預計複合年成長率為 16.64%,顯示市場對適應性機器人解決方案的偏好。

- 收益預測:該部門 2021 年的銷售額預計將達到 22.5 億美元,到 2027 年將成長至 56.3 億美元,這將支撐其在倉庫中的日益普及。

- 技術進步:對感測器技術、人工智慧和電腦視覺的投資正在提高移動機器人的能力。亞馬遜收購 Canvas 先進自主機器人技術就是一個顯著的例子。

- 工業應用:移動機器人廣泛應用於各行各業,尤其是零售業(2021 年市場佔有率為 27.46%)和食品飲料產業,以提高產品處理和溫控環境的效率。

亞太地區預計將佔據主要市場佔有率

亞太地區是倉庫機器人市場占主導地位且成長最快的地區,2021 年佔全球佔有率的 46.72%。

- 預測複合年成長率:受中國和印度等國家快速採用機器人技術的推動,該地區預計將以 16.06% 的複合年成長率保持領先地位。

- 市場規模:預計亞太地區倉庫機器人市場 2021 年的收益將達到 46.2 億美元,到 2027 年將成長至 112 億美元。

- 電子商務擴張:印度和中國蓬勃發展的電子商務市場是主要驅動力,預計印度市場將從 2020 年的 462 億美元成長到 2030 年的 3,500 億美元。

- 製造業領導:亞太地區作為全球製造地的地位正在推動倉庫自動化技術的應用,尤其是在中國、日本和韓國。

- 技術創新:亞洲公司正在投資人工智慧機器人解決方案。中國機器人公司 Geek+ 在人工智慧物流機器人領域取得了長足進步,與全球知名企業競爭。

倉庫機器人產業概況

倉庫機器人市場由全球參與企業主導,市場格局趨於鞏固。現有的自動化和機器人純粹公司處於行業前沿,利用研究、合作和收購來保持其市場地位。

霍尼韋爾機器人中心:霍尼韋爾向機器人創新中心投資 5,000 萬美元,表明該公司致力於引領倉庫自動化領域。

投資者信心:GreyOrange 和 Vecna Robotics 等新興企業已經籌集了大量資金,顯示出對倉庫機器人的成長潛力充滿信心。

技術領導者塑造市場動態:ABB 有限公司、發那科公司、霍尼韋爾國際公司、庫卡股份公司和安川電機公司等主要企業正在引領市場。這些公司正在開發先進的解決方案,例如 AMR、AS/RS 和支援 AI 的系統。

Swisslog 的 KR SCARA機器人和 Locus Robotics 的 RaaS(機器人即服務)訂閱模式等創新解決方案正在顛覆傳統的市場方式,並提供經濟高效、易於存取的自動化解決方案。

策略夥伴關係:與電子商務平台和物流供應商的合作是市場擴張的關鍵策略,例如波克夏‧格雷與全球履約達成的 2,300 萬美元當日雜貨配送協議。

未來市場驅動力:要想取得成功,企業需要專注於人工智慧和機器學習的進步,以增強機器人的能力。適應不同倉庫配置的靈活解決方案、與零售商的夥伴關係以及可擴展的自動化平台將是關鍵。解決高昂的實施成本和監管挑戰對於跨行業廣泛採用也至關重要。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3個月的分析師支持

目錄

第1章 引言

- 研究假設和市場定義

- 研究範圍

第2章調查方法

第3章執行摘要

第4章 市場洞察

- 市場概覽

- 產業吸引力-波特五力分析

- 買家的議價能力

- 供應商的議價能力

- 新進入者的威脅

- 替代品的威脅

- 競爭對手之間的競爭

- 產業價值鏈分析

- COVID-19 工業影響評估

第5章市場動態

- 市場促進因素

- SKU數量增加

- 增加對科技和機器人技術的投資

- 市場問題

- 嚴格的監管要求

- 高成本

第6章市場區隔

- 按類型

- 工業機器人

- 分類系統

- 輸送機

- 堆垛機

- 自動儲存和搜尋系統(ASRS)

- 移動機器人(AGV 和 AMR)

- 按功能

- 貯存

- 包裝

- 轉運

- 其他

- 按最終用戶產業

- 飲食

- 車

- 零售

- 電氣和電子

- 製藥

- 其他

- 按地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 亞洲

- 中國

- 韓國

- 日本

- 澳洲和紐西蘭

- 拉丁美洲

- 中東和非洲

- 北美洲

第7章競爭格局

- 公司簡介

- ABB Limited

- Kiva Systems(Amazon Robotics LLC)

- TGW Logistics Group GMBH

- Singapore Technologies Engineering Ltd(Aethon Incorporation)

- InVia Robotics Inc.

- Fanuc Corporation

- Honeywell International Incorporation

- Toshiba Corporation

- Omron Adept Technologies

- Yaskawa Electric Corporation(Yaskawa Motoman)

- Kuka AG

- Fetch Robotics Inc.

- Geek+Inc.

- Grey Orange Pte Ltd

- Hangzhou Hikrobot Technology Co. Ltd

- Syrius Robotics

- Locus Robotics

第8章投資分析

第9章:市場的未來

The Warehouse Robotics Market size is estimated at USD 9.33 billion in 2025, and is expected to reach USD 21.08 billion by 2030, at a CAGR of 17.7% during the forecast period (2025-2030).

Key Highlights

- Expanding SKU Diversity Drives Warehouse Automation: The warehouse robotics market is witnessing accelerated growth driven by the surge in SKU diversity. Over 50% of businesses are expected to increase the number of SKUs to cater to long-tail consumer demands. This trend is reshaping traditional warehouse models, where large-pallet order systems are being replaced by small, multi-SKU orders. To meet this challenge, automated mini-load storage and retrieval systems (AS/RS) are becoming vital. These systems leverage lightweight cranes to manage totes, cases, and crates, optimizing storage and freeing up crucial labor and delivery resources.

- Increase in Warehouse Size: Warehouses have expanded from 65,000 sq. ft in 2000 to over 200,000 sq. ft in 2020 to accommodate the rising volume of SKUs.

- Shift in Retailer-Wholesaler Dynamics: Just-in-time ordering and direct-to-consumer distribution are reducing large-pallet orders, accelerating the need for automation.

- Picking Robots and AGVs: The latest generation of picking robots and Automated Guided Vehicles (AGVs) is ideal for handling small orders spread over vast SKU ranges in large warehouses.

- Surging Investments Fuel Technological Advancements: The influx of capital is propelling warehouse automation technologies forward. Venture capital firms have been actively investing in robotics, with funding for warehouse robotics startups reaching USD 381 million in Q1 2020, a 57% year-over-year increase.

- Locus Robotics' Expansion: In June 2020, Locus Robotics raised USD 40 million to enhance R&D and expand into the European Union.

- Amazon's Innovation Hub: Amazon's investment of USD 40 million to develop a cutting-edge robotics hub in Massachusetts is expected to boost automation advancements.

- Shopify's Strategic Acquisition: Shopify's USD 450 million acquisition of 6 River Systems in 2019 expanded its fulfillment capabilities, incorporating cloud-based software and collaborative mobile robots.

- E-commerce Boom Accelerates Adoption: The rapid growth of e-commerce continues to drive the adoption of warehouse robotics. Efficient inventory management and fulfillment operations are becoming critical as online retail surges.

- Projected Market Value: Cowen projects that the U.S. market for warehouse and logistics robots in e-commerce will reach nearly USD 8 billion by 2024.

- New Fulfillment Models: Albertsons and Takeoff Technologies have collaborated to pilot urban fulfillment centers powered by AI and robotics to streamline small urban warehouse operations.

- Kroger's Expansion: Kroger is planning to open up to 20 customer fulfillment centers in partnership with Ocado, featuring large-scale robot-driven facilities.

- Labor Shortages and Cost Reduction Drive Innovation: Warehouse robotics are being increasingly used to tackle labor shortages and reduce operational costs. Automation helps improve efficiency by reducing unnecessary labor movement and streamlining operations.

- Wasted Motion Costs: U.S. warehouses lose USD 4.3 billion annually due to wasted motion, emphasizing the importance of robotic solutions.

- Industrial Robots Growth: The operational stock of industrial robots is projected to grow from 2,408 thousand units in 2018 to 3,788 thousand units by 2021.

- Alibaba's Workforce Reduction: By deploying robotic labor, Alibaba reduced its warehouse workforce by 70%, while creating more opportunities for skilled labor.

Warehouse Robotics Market Trends

Mobile Robots (AGVs and AMRs) Largest Segment by Type

Mobile robots, particularly Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), dominate the warehouse robotics market. This segment captured 22.80% of global revenue in 2021, making it a pivotal driver of automation.

- Strong Growth: Mobile robots are the fastest-growing segment, with a CAGR of 16.64% forecasted, indicating a clear market preference for adaptable robotic solutions.

- Revenue Projections: The segment generated USD 2.25 billion in revenue in 2021 and is expected to grow to USD 5.63 billion by 2027, underlining the increased adoption in warehouses.

- Technological Advancements: Investments in sensor technology, AI, and computer vision are enhancing the capabilities of mobile robots. Amazon's acquisition of Canvas Technology for advanced autonomous robots is a notable example.

- Industry Applications: Mobile robots are widely used across industries, particularly in retail (27.46% market share in 2021) and food and beverage sectors, where they enhance efficiency in product handling and temperature-controlled environments.

Asia Pacific is Expected to Hold Significant Market Share

Asia-Pacific is the dominant and fastest-growing region in the warehouse robotics market, capturing 46.72% of the global share in 2021.

- CAGR Projections: The region is expected to maintain its leadership with a CAGR of 16.06%, driven by the rapid adoption of robotics technologies in countries like China and India.

- Market Size: The Asia-Pacific warehouse robotics market generated USD 4.62 billion in revenue in 2021, with forecasts estimating growth to USD 11.20 billion by 2027.

- E-commerce Expansion: The booming e-commerce market in India and China is a significant driver, with India's market expected to grow from USD 46.2 billion in 2020 to USD 350 billion by 2030.

- Manufacturing Leadership: Asia-Pacific's status as a global manufacturing hub is propelling the adoption of warehouse automation technologies, especially in China, Japan, and South Korea.

- Technological Innovation: Companies in Asia are investing in AI-powered robotics solutions. Geek+, a Chinese robotics company, has made significant advancements with its AI-powered logistics robots, competing with established global players.

Warehouse Robotics Industry Overview

The warehouse robotics market is dominated by global players, with a consolidated market structure. Established automation companies and specialized robotics firms are at the forefront of the industry, leveraging research, partnerships, and acquisitions to maintain their market positions.

Honeywell's Robotics Hub: Honeywell's USD 50 million investment in a Robotics Innovation Hub showcases the company's commitment to leading the warehouse automation sector.

Investor Confidence: Emerging players such as GreyOrange and Vecna Robotics have raised substantial funds, indicating strong confidence in the growth potential of warehouse robotics.

Technology Leaders Shape Market Dynamics: Key players like ABB Limited, Fanuc Corporation, Honeywell International Inc., KUKA AG, and Yaskawa Electric Corporation lead the market. These companies are developing advanced solutions, including AMRs, AS/RS, and AI-powered systems.

Innovative Solutions: Swisslog's KR SCARA robots and Locus Robotics' RaaS (robots-as-a-service) subscription model are disrupting traditional market approaches, providing cost-effective and accessible automation solutions.

Strategic Partnerships: Collaboration with e-commerce platforms and logistics providers, such as Berkshire Grey's USD 23 million contract with a global retailer for same-day grocery fulfillment, is a key strategy for market expansion.

Factors Driving Future Success in the Market: To succeed, companies need to focus on AI and machine learning advancements to enhance robotic capabilities. Flexible solutions that adapt to various warehouse configurations, partnerships with retailers, and scalable automation platforms will be critical. Addressing high implementation costs and regulatory challenges will also be essential to ensure wider adoption across industries.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Buyers

- 4.2.2 Bargaining Power of Suppliers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitute Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of the Impact of COVID-19 on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Increasing Number of SKUs

- 5.1.2 Increasing Investments in Technology and Robotics

- 5.2 Market Challenges

- 5.2.1 Stringent Regulatory Requirements

- 5.2.2 High Cost

6 MARKET SEGMENTATION

- 6.1 By Type

- 6.1.1 Industrial Robots

- 6.1.2 Sortation Systems

- 6.1.3 Conveyors

- 6.1.4 Palletizers

- 6.1.5 Automated Storage and Retrieval System (ASRS)

- 6.1.6 Mobile Robots (AGVs and AMRs)

- 6.2 By Function

- 6.2.1 Storage

- 6.2.2 Packaging

- 6.2.3 Trans-shipment

- 6.2.4 Other Functions

- 6.3 By End-user Industry

- 6.3.1 Food and Beverage

- 6.3.2 Automotive

- 6.3.3 Retail

- 6.3.4 Electrical and Electronics

- 6.3.5 Pharmaceutical

- 6.3.6 Other End-user Industries

- 6.4 By Geography

- 6.4.1 North America

- 6.4.1.1 United States

- 6.4.1.2 Canada

- 6.4.2 Europe

- 6.4.2.1 United Kingdom

- 6.4.2.2 Germany

- 6.4.2.3 France

- 6.4.3 Asia

- 6.4.3.1 China

- 6.4.3.2 South Korea

- 6.4.3.3 Japan

- 6.4.4 Australia and New Zealand

- 6.4.5 Latin America

- 6.4.6 Middle East and Africa

- 6.4.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 ABB Limited

- 7.1.2 Kiva Systems (Amazon Robotics LLC)

- 7.1.3 TGW Logistics Group GMBH

- 7.1.4 Singapore Technologies Engineering Ltd (Aethon Incorporation)

- 7.1.5 InVia Robotics Inc.

- 7.1.6 Fanuc Corporation

- 7.1.7 Honeywell International Incorporation

- 7.1.8 Toshiba Corporation

- 7.1.9 Omron Adept Technologies

- 7.1.10 Yaskawa Electric Corporation (Yaskawa Motoman)

- 7.1.11 Kuka AG

- 7.1.12 Fetch Robotics Inc.

- 7.1.13 Geek+ Inc.

- 7.1.14 Grey Orange Pte Ltd

- 7.1.15 Hangzhou Hikrobot Technology Co. Ltd

- 7.1.16 Syrius Robotics

- 7.1.17 Locus Robotics