|

市場調查報告書

商品編碼

1439876

3D 列印長絲:市場佔有率分析、產業趨勢與統計、成長預測(2024-2029 年)3D Printing Filament - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

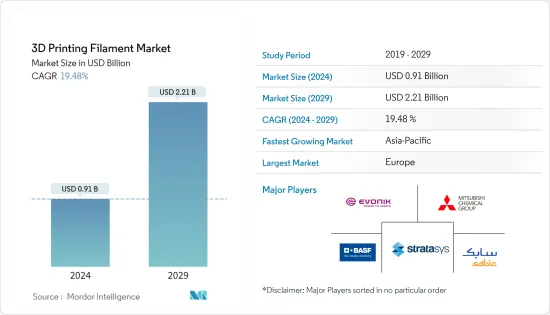

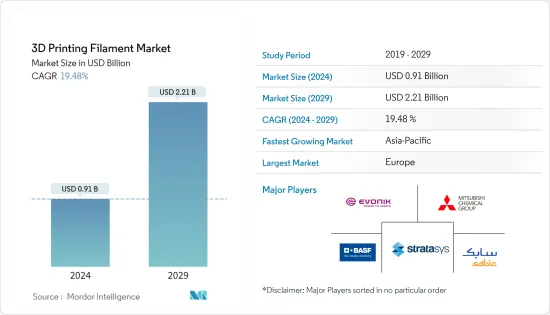

3D列印耗材市場規模預估至2024年為9.1億美元,預估至2029年將達22.1億美元,預測期間(2024-2029年)複合年成長率為19.48%

COVID-19 大流行導致全球全國範圍內的封鎖、製造活動和供應鏈中斷以及生產停工,所有這些都對2020年的市場產生了負面影響。 然而,在2021-2022年,情況開始好轉。 預計它將在預測期內推動市場增長。

主要亮點

- 短期內,3D列印耗材在製造應用中的使用增加以及與3D列印相關的大規模客製化將成為預測期內推動市場需求的因素。

- 另一方面,3D列印過程中的高資本投資要求阻礙了市場成長。

- 醫療領域3D列印的創新和3D列印材料的進步可能為未來3D列印耗材市場提供成長機會。

- 預計歐洲將在預測期內獲得最大的市場佔有率,從而主導市場。

3D列印耗材市場趨勢

醫療和牙科行業的需求增加

- 醫療和牙科行業是使用3D列印耗材的主要行業。該產業約佔所有 3D 列印耗材應用的 30-35%。

- 使用各種細絲的 3D 列印技術可以創建組織和類器官、手術器械、患者特定手術模型以及用於醫療和牙科行業的自訂義肢。這些3D列印物件為產業的進步和發展做出了巨大貢獻。

- 透過 3D 列印製造的醫療設備包括整形外科和顱骨植入、手術器械、牙冠等牙科修復體以及外部假體。

- 2022 年 8 月,工業 3D 列印解決方案公司 Nexa3D 宣布了一項舉措,透過針對牙科行業應用的 3D 列印流程的新擴展和安裝來發展其數位牙科產品組合。

- 2022年8月,3D陶瓷列印公司Lithoz報告稱,由於其產品訂單增加,今年上半年是該公司歷史上最成功的上半年。該公司提供廣泛的陶瓷 3D 列印機,用於各種應用,包括醫療、牙科和工業應用。

- 由於3D列印耗材的上述所有因素,預計其市場在預測期內將快速成長。

歐洲地區主導市場

- 預計歐洲地區將主導市場。在該地區,以國內生產毛額計算,德國是最大的經濟體。德國、英國和法國是世界上發展最快的新興國家之一。

- 截至 2021 年 6 月,歐洲人均衛生技術支出為 265 歐元(約 278.47 美元)。此外,截至 2021 年 6 月,歐洲平均將國內生產總值(GDP) 的約 11% 用於醫療保健。

- 根據 MedTech Europe 的數據,歐洲有超過 33,000 家醫療科技公司。其中大多數在德國,其次是義大利、英國、法國和瑞士。大約 95% 的醫療科技產業由中小企業 (SME) 組成。

- 德國航太全國有2,300多家公司,其中最集中在德國北部。該國擁有多個飛機內裝零件和材料生產基地,主要位於巴伐利亞州、不來梅州、巴登-符騰堡州和梅克倫堡-前波莫瑞州。

- 根據英國國際貿易部統計,英國電子業每年為當地經濟貢獻160億英鎊(約195.3億美元)。目前,該國擁有歐洲電子設計業40%的佔有率。目前該行業的專業知識主要集中在積體電路 (IC)、RFID、光電子學和電子元件。

- 近年來,法國的飛機製造和組裝業務有所增加,因為它是空中巴士、賽峰、巴西航空工業公司和 Daher Socata 等製造商的主要製造地。

- 法國繼續計劃從2019年到2025年每年增加17億歐元(約合20.8億美元)的國防預算,並正在履行其到2025年將國防預算提高到GDP的2%的承諾。

- 所有上述因素預計將增加該地區對 3D 列印耗材的需求。

3D列印耗材產業概況

全球 3D 列印耗材市場本質上高度分散,少數大型企業控制著很大一部分市場。主要企業包括(排名不分先後)Stratasys Ltd、SABIC、 BASF SE、Evonik Industries AG 和 Mitsubishi Chemical Corporation。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章簡介

- 調查先決條件

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 促進因素

- 增加在製造應用的使用

- 與3D列印相關的大規模客製化

- 抑制因素

- 3D列印過程需要大量資金投入

- 產業價值鏈分析

- 波特五力分析

- 供應商的議價能力

- 買方議價能力

- 新進入者的威脅

- 替代產品和服務的威脅

- 競爭程度

第5章市場區隔(以金額為準的市場規模)

- 類型

- 金屬

- 鈦

- 不銹鋼

- 其他金屬

- 塑膠

- 聚對苯二甲酸乙二酯(PET)

- 聚乳酸(PLA)

- 丙烯腈丁二烯苯乙烯 (ABS)

- 尼龍

- 其他塑膠

- 陶瓷

- 其他類型

- 金屬

- 目的

- 航太和國防

- 車

- 醫療和牙科

- 電子產品

- 其他用途

- 地區

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 南美洲

- 巴西

- 阿根廷

- 南美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 中東和非洲其他地區

- 亞太地區

第6章 競爭形勢

- 併購、合資、合作與協議

- 市場排名分析

- 主要企業採取的策略

- 公司簡介

- BASF SE

- Covestro Ag

- DOW

- DSM

- Evonik Industries Ag

- Keene Village Plastics

- Mitsubishi Chemical Corporation

- SABIC

- Solvay

- Shenzhen Esun Industrial Co. Ltd

- Stratasys

第7章市場機會與未來趨勢

The 3D Printing Filament Market size is estimated at USD 0.91 billion in 2024, and is expected to reach USD 2.21 billion by 2029, growing at a CAGR of 19.48% during the forecast period (2024-2029).

The COVID-19 outbreak caused nationwide lockdowns around the world, disruption in manufacturing activities and supply chains, and production halts, all of which had a negative impact on the market in 2020. However, conditions began to improve in 2021-2022, which is expected to boost market growth during the forecast period.

Key Highlights

- Over the short term, the growing usage of 3D printing filament in manufacturing applications along with mass customization associated with 3D printing are the factors driving the market demand during the forecast period.

- On the flip side, high capital investment requirements in the 3D printing process is hindering the market's growth.

- 3D printing innovation in the medical sector and advancements in 3D printing materials may likely act as growth opportunities for the 3D printing filament market in the future.

- Europe is expected to dominate the market with largest market share in the forecast period.

3D Printing Filament Market Trends

Increased Demand from the Medical and Dental Segment

- The Medical and Dental Industry is the leading industry that uses 3D printing filaments. The industry contributes to around 30-35% of the total applications of 3D printing filaments.

- 3D printing technology using different filaments allowed the creation of tissues and organoids, surgical tools, patient-specific surgical models, and custom-made prosthetics as applications in the medical and dental industry. These 3D printed objects are significantly contributing to the advancement and development of the industry.

- Medical devices produced by 3D printing include orthopedic and cranial implants, surgical instruments, dental restorations such as crowns, and external prosthetics.

- In August 2022, Nexa3D, an industrial 3D printing solution company, announced its work on advancing its digital dentistry portfolio by making new expansions and installations for the 3D printing processes for applications in the dental industry.

- In August of 2022, Lithoz, a 3D ceramic printing reported the first half of the year as the most successful first half in its history due to the increased order of its products. The company offers a wide range of ceramic 3D printers used for various applications, including medical, dental, and industrial applications.

- Owing to all the above-mentioned factors for 3D printing filaments, its market is expected to grow rapidly over the forecast period.

Europe Region to Dominate the Market

- The European region is expected to dominate the market. In the region, Germany is the largest economy in terms of GDP. Germany, United Kingdom and France are among the fastest emerging economies globally.

- As of June 2021, in Europe, expenditure on medical technology per capita accounted for EUR 265 (~USD 278.47). Moreover, as of June 2021, an average of ~11% of gross domestic product (GDP) is spent on healthcare in Europe.

- According to MedTech Europe, over 33,000 medical technology companies are present in Europe. Most of them are located in Germany, followed by Italy, the United Kingdom, France, and Switzerland. Small and medium-sized companies (SMEs) make up around 95% of the medical technology industry.

- The German aerospace industry includes more than 2,300 firms located across the country, with northern Germany recording the highest concentration of firms. The country hosts many production bases for aircraft interior components and materials, largely in Bavaria, Bremen, Baden-Wurttemberg, and Mecklenburg-Vorpommern.

- According to the Department for International Trade, the electronics sector in the United Kingdom contributes GBP 16 billion (~USD 19.53 billion) each year to the local economy. The country currently holds 40% of the share in the available electronics design industry in Europe. Current expertise within the industry is focused on integrated circuits (ICs), RFIDs, optoelectronics, and electronic components.

- France has been witnessing an increase in aircraft manufacturing and assembly operations in recent times as it is a major manufacturing base for manufacturers such as Airbus, Safran, Embraer, and Daher-Socata.

- France is continuing with its plan to increase its defense budget by EUR 1.7 billion (~ USD 2.08 billion) per year between 2019-2025 and to fulfill its commitment to increase the defense budget to 2% of its GDP by 2025.

- All the factors mentioned above are expected to boost the demand for 3D printing filament in the region.

3D Printing Filament Industry Overview

The global 3D printing filament market is highly fragmented in nature with a few major players dominating a significant portion of the market. Some of the major companies are Stratasys Ltd, SABIC, BASF SE, Evonik Industries AG, and Mitsubishi Chemical Corporation, among others (not in any particular order).

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Growing Usage in Manufacturing Applications

- 4.1.2 Mass Customization Associated with 3D Printing

- 4.2 Restraints

- 4.2.1 High Capital Investment Requirement in 3D Printing Process

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Buyers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Type

- 5.1.1 Metals

- 5.1.1.1 Titanium

- 5.1.1.2 Stainless Steel

- 5.1.1.3 Other Metals

- 5.1.2 Plastics

- 5.1.2.1 Polyethylene Terephthalate (PET)

- 5.1.2.2 Polylactic Acid (PLA)

- 5.1.2.3 Acrylonitrile Butadiene Styrene (ABS)

- 5.1.2.4 Nylon

- 5.1.2.5 Other Plastics

- 5.1.3 Ceramics

- 5.1.4 Other Types

- 5.1.1 Metals

- 5.2 Application

- 5.2.1 Aerospace and Defense

- 5.2.2 Automotive

- 5.2.3 Medical and Dental

- 5.2.4 Electronics

- 5.2.5 Other Applications

- 5.3 Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers and Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 BASF SE

- 6.4.2 Covestro Ag

- 6.4.3 DOW

- 6.4.4 DSM

- 6.4.5 Evonik Industries Ag

- 6.4.6 Keene Village Plastics

- 6.4.7 Mitsubishi Chemical Corporation

- 6.4.8 SABIC

- 6.4.9 Solvay

- 6.4.10 Shenzhen Esun Industrial Co. Ltd

- 6.4.11 Stratasys