|

市場調查報告書

商品編碼

1432581

軟包裝:市場佔有率分析、產業趨勢與統計、成長預測(2024-2029)Flexible Packaging - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

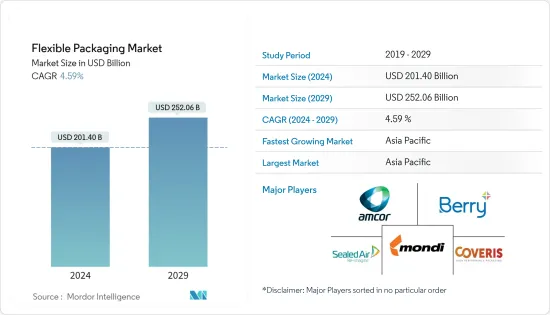

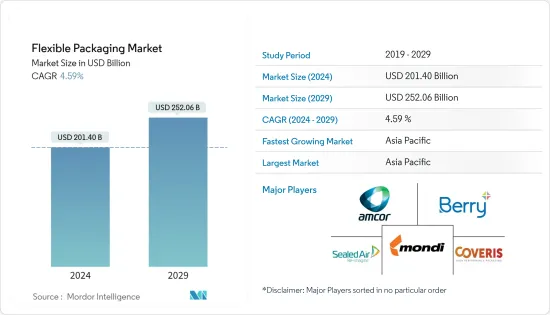

軟包裝市場規模預計到2024年為2014億美元,預計到2029年將達到2520.6億美元,在預測期內(2024-2029年)複合年成長率為4.59%。

由於顯著的能源和環境效益,包裝產業正在轉向採用軟包裝解決方案。

主要亮點

- 此外,人們對軟包裝中生物分解性聚合物的使用及其對環境的影響越來越關注,這促使製造商提供安全、可靠和環保的包裝。製造商在生產過程中使用更少的資源和能源,匹配最終用戶的產品和品牌名稱,更少的運輸支出,更長的產品保存期限,減輕成本壓力,並改進產品包裝。我們繼續專注於提供永續的包裝選擇,以保護正直。

- 多種最終用途對軟包裝的需求不斷成長。這包括電子商務、數位印刷和永續性趨勢,這些趨勢正在推動市場的開拓和成長。客戶越來越願意為軟包裝增強的某些產品屬性支付額外費用。消費者願意為採用永續包裝的產品支付更多費用,這將有助於產業吸收因轉向永續包裝而增加的成本。

- 食品企業對肉類、家禽和魚貝類的軟包裝的選擇受到便利性以外的因素的影響,例如永續性、透明度、食品安全和減少食品廢棄物。永續性是企業對使用可回收和再生材料的軟包裝解決方案越來越感興趣的原因之一。這方面的解決方案不斷湧現,其中包括可塑紙,它具有優異的阻隔性,適用於份量包裝和午餐肉,並且根據行業估計,可以減少高達 80% 的塑膠使用量。

- 世界上許多公司都傾向於借助單一材料來製造基於 PE 的包裝。例如,2022 年 8 月,Mondi 和漢高透過開發全新的可重複使用包裝概念,幫助消費者更環保地洗碗。兩家公司合作開發了適用於漢高手洗餐具解決方案的包裝解決方案,實現從軟袋到寶特瓶的再填充。此次合作將有助於漢高實現其永續發展目標,即在 2025 年實現 100% 可回收或可重複使用包裝以及將由石化燃料製成的原生塑膠減少 50%。替代硬質寶特瓶時,軟性立式袋可減少 70% 的塑膠用量,而且在擁有成熟回收基礎設施的地區也易於回收。

- 此外,AR Packaging 於 2021 年 7 月推出了 Ecoflex,這是一種熱成型單聚乙烯薄膜,100% 可回收,提供比 PA 材料更環保的選擇,同時完全符合 OPRL 標準。推出 Ecoflex,零售商現在可以選擇永續材料。 Ecoflex 提供可比較的機械強度和衝擊強度,可作為軟性熱成型應用中 PA/PE 材料的替代品。例如,在英國,回收設施可以在商店回收軟性聚烯包裝。

- 大多數回收設施都已經過時,因此效率低下,無法跟上不斷變化的廢棄物流。例如,目前的設備不足以跟上包裝廢棄物的變化趨勢,即使紙張廢物量減少且塑膠廢物量增加。

- 軟包裝製造商越來越擔心通膨。人事費用、能源和運輸成本造就了一個營運成本高且競爭激烈的產業。原物料價格進一步上漲受到俄烏危機、俄羅斯制裁以及東西方地緣政治領域重新佈局的影響。

- 最近的 COVID-19 疫情為軟包裝製造商帶來了許多問題,包括非製藥應用的需求下降,而且這些問題可能會持續一段時間。供應鏈中斷、製造原料短缺、勞動力短缺、可能推高生產成本並超出預算的價格波動以及出貨問題只是封鎖造成的一些後果。隨著封鎖放鬆和解除,市場開始復甦,COVID-19 的影響現已開始消退。

軟包裝市場趨勢

乳製品預計將在食品領域佔據較大市場佔有率

- 當前的市場狀況表明,隨著乳製品消費的健康成長,乳製品的需求激增。例如,根據美國農業部 (USDA) 的數據,歐洲的人均起司消費量最高。 2021年歐盟(EU)平均起司消費量為20.44公斤。美國和加拿大同年分居第二和第三位,人均起司消費量分別約為17.9公斤和15公斤。 2021年,歐盟(EU)27個國家生產了1,035萬噸乳酪,大約是第二大生產國的兩倍。

- 牛奶是主要的乳製品食品,是均衡飲食的重要組成部分,富含鈣和其他重要營養素。根據聯合國糧食及農業組織及美國農業部統計,印度2021年的牛奶消費量量約8,300萬噸,是全球最大的消費國。第二大國家是歐盟 (EU),擁有 2,390 萬噸。軟包裝袋是迄今為止最受歡迎的牛奶包裝類型,其次是無菌包裝,且使用量正在上升。軟包裝袋已成為快速、廉價且安全的包裝選擇。由於國內分銷網路廣泛,這種包裝類型易於包裝和處理。消費者對奶袋的正面反應鼓勵了新技術的採用。

- 液體盒包裝傳統上與牛奶聯繫在一起,因為它可以保護食品並且有利於環境。紙板是一種經常用於製作牛奶包裝液體盒的材料。牛奶紙盒,也稱為山形蓋頂紙盒,是一種由聚乙烯塗層紙製成的型態。以重量計算,牛奶盒的材質為 80% 紙張和 20% 聚乙烯。 20 世紀 50 年代,紙盒牛奶取代了可再填充的玻璃瓶,為消費者提供了方便、輕巧的替代品。

- 許多起司品牌和生產商已經採用軟包裝來提供價值和便利。軟包裝透過緊密的供應鏈為產品提供強度和保護,但可能會損壞其他包裝類型並導致不良結果。

- 例如,GOOD PLANeT Foods 於 2022 年 4 月重新設計了其全系列植物性乳酪,預計 2022 年將大幅成長,並且近期擴大了在超級市場的分銷,Sprouts 也增加了全國範圍內的分銷。 GOOD PLANeT 為該產品選擇了 Bellmark 的可回收軟包裝袋,以增強配方和包裝。

- 具有中等阻隔性(PA/PE)或阻隔性(PA/EVOH/PE)的真空袋被廣泛接受。這些以薄膜為基礎的真空袋被涵蓋調氣包裝(MAP) 應用中,主要用於乳製品和蛋白質包裝。

亞太地區預計將出現顯著成長

- 在食品業,不僅是便利性,永續性、透明度、食品安全和減少食品廢棄物等其他特性也在影響肉類、家禽和魚貝類軟包裝的選擇。根據中國工業與資訊化部、國家統計局統計,2021年,中國食品工業獲利約6,187億元。

- 根據厚生勞動省的數據,截至 2021 年 9 月,學名藥在日本倫理藥品市場的銷售佔有率約為 79%。根據聯合國COMTRADE國際貿易資料庫,2021年日本將進口372.9億美元的藥品。隨著日本人口迅速老化,需要治療相關疾病的新藥,這項需求預計將會增加。因此,這些趨勢預計將對市場成長產生正面影響。

- 根據美國農業部對外農業局統計,2021年印度包裝食品市場乳製品銷售達2,381萬噸。這比 2017 年的約 1,974 萬噸大幅增加。印度食品零售的擴張和多元化預計將成為乳製品包裝食品的催化劑,其中都市區佔銷售額的75%以上。

- 印度品牌股權基金會的報告顯示,印度政府最近在FMCG(快速消費品)領域進行了良好的投資和支持。 2000年4月至2022年3月,快消品產業吸收FDI健康流入201.1億美元。此外,2022-23 年聯邦預算向消費者事務局撥款 2.2219 億美元,向食品和公共分配部撥款 278.2 億美元。增加對分銷的投資可以提高全部區域進出口中永續包裝的採用。

軟包裝產業概況

由於少數佔據重要市場佔有率的供應商,軟包裝市場得到適度整合。市場似乎有些集中,主要企業採取產品創新、併購等策略來保持競爭力。該行業的主要企業包括 Amcor PLC、Mondi Group、Berry Global Inc 和 Sealed Air Corporation。

- 2022 年 4 月 - Mondi 與法國機械製造商 Thimonnier 合作開發可回收包裝,以減少塑膠廢棄物。兩家公司開發了一種可以完全清空的新型液體填充用包裝。共擠聚乙烯是一種單一可回收材料,用於生產 Barlingo小袋。與硬質塑膠瓶相比,該產品重量更輕,塑膠用量減少 75% 以上。此再填充解決方案可取代目前業界標準但不可回收的多層 PVC 再填充容器。

- 2021 年 10 月 - Berry World 和利安德巴塞爾聯手推進到 2026 年 100%永續採購客戶包裝的目標。此次合作將幫助更多消費者從可回收的塑膠內襯基板中選擇可回收的透明塑膠飲水杯。

- 2021 年 6 月 - Coveris 憑藉其技術力開發了一種新的串行班輪解決方案。 Cereal+ 內襯的開發旨在提高包裝機性能並延長保存期限。 Coveris 的 Cereal+ 內襯由完全可回收的聚乙烯製成,為盒中袋薄膜包裝的穀物和乾食品提供產品保護、新鮮度和保存期限。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 市場概況

- 產業吸引力-波特五力分析

- 買方議價能力

- 供應商的議價能力

- 替代品的威脅

- 新進入者的威脅

- 競爭公司之間的敵對關係

- 產業價值鏈分析

- 評估 COVID-19 對產業的影響

- 市場促進因素

- 對便捷包裝的需求不斷成長

- 長期儲存的需求和生活方式的改變

- 市場限制因素

- 環境和回收問題

第5章市場區隔

- 材料種類

- 塑膠

- 聚乙烯(PE)

- 雙軸延伸聚丙烯(BOPP)

- 流延聚丙烯 (CPP)

- 聚氯乙烯(PVC)

- 乙烯 - 乙烯醇(EVOH)

- 紙

- 鋁箔

- 塑膠

- 產品類別

- 小袋

- 包包

- 薄膜和包裝

- 其他產品類型

- 最終用戶產業

- 食品

- 冷凍食品

- 乳製品

- 水果和蔬菜

- 肉類、家禽、魚貝類

- 烘焙點心/零嘴零食

- 糖果/糖果零食

- 其他食品

- 飲料

- 藥品和醫療用品

- 家居用品/個人護理

- 其他最終用戶產業

- 食品

- 地區

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 土耳其

- 波蘭

- 俄羅斯

- 其他歐洲國家

- 亞太地區

- 中國

- 日本

- 印度

- 澳洲

- 其他亞太地區

- 拉丁美洲

- 巴西

- 阿根廷

- 墨西哥

- 其他拉丁美洲

- 中東/非洲

- 沙烏地阿拉伯

- 南非

- 埃及

- 伊朗

- 奈及利亞

- 其他中東和非洲

- 北美洲

第6章 競爭形勢

- 公司簡介

- Amcor Plc

- Berry Global Inc.

- Mondi Group

- Sealed Air Corporation

- Coveris Holdings SA

- UFlex Limited

- Huhtamaki Group

- Proampac LLC

- WIPF Doypak(Wipf AG)

- FlexPak Services LLC

- Laser Packaging Manufacturing PTE Limited

- KM Packaging Services Ltd

- Sonoco Products Company

第7章 投資分析

第8章 市場機會及未來趨勢

The Flexible Packaging Market size is estimated at USD 201.40 billion in 2024, and is expected to reach USD 252.06 billion by 2029, growing at a CAGR of 4.59% during the forecast period (2024-2029).

The packaging industry has been shifting toward adopting flexible packaging solutions owing to its considerable energy and environmental benefits.

Key Highlights

- Additionally, manufacturers have been prompted to provide environmentally friendly packaging choices that are safe and secure, owing to growing worries about the usage of biodegradable polymers for flexible packaging and its effects on the environment. Manufacturers continue to look toward providing sustainable packaging options that use fewer resources and energy during production, fit with the product and brand name of the end-user, need less money for transportation, and provide products with a longer shelf life to ease cost pressure and preserve the integrity of product packages.

- The demand for flexible packaging is growing across multiple end-use applications. It includes e-commerce, digital printing, and sustainability trends, which can drive market development and growth. Customers are increasingly eager to pay extra for specific product attributes boosted by flexible packaging. Consumers' willingness to pay more for products with sustainable packaging could help the industry absorb the increased costs of switching to sustainable packaging.

- The choice of flexible packaging for meat, poultry, and seafood in the food business is influenced by factors beyond convenience, such as sustainability, transparency, food safety, and a reduction in food waste. Companies are becoming increaslngly interested in flexible packaging solutions that uses recyclable and recycled content for obvious reasons, one of which is sustainability. Solutions, including formable paper, which offers good barrier qualities, is suited for portion packs and lunchmeat, and according to some industry estimates it reduces plastic use by up to 80%, are gaining ground in this regard.

- Many companies worldwide are following a trend of building PE-based packages with the help of mono materials. For instance, in August 2022, Mondi and Henkel assisted consumers in more environmentally friendly dishwashing by developing an entirely new reusable packaging idea. The two businesses collaborated on a packaging solution for Henkel's hand dishwashing solutions in allowing the refilling of plastic bottles from flexible pouches. The collaboration helps Henkel achieve its sustainability goals of 100% recyclable or reusable packaging by 2025 and a 50% decrease in virgin plastic made from fossil fuels. When rigid plastic bottles are replaced, the flexible stand-up pouch eliminates plastic by 70% and is simple to recycle in areas with established recycling infrastructure.

- Furthermore, in July 2021, Ecoflex, a thermoforming mono polyethylene film that is 100% recyclable and offers a greener option to PA-based materials while completely adhering to OPRL criteria, was launched by the AR Packaging. Retailers now have a sustainable material of choice with the introduction of Ecoflex. Ecoflex provides comparable mechanical and impact strength for its flexible thermoformed applications instead of PA/PE material. For instance, recycling facilities can recycle flexible polyolefin packaging at the front-of-store in the United Kingdom.

- Most recycling facilities are inefficient in handling changes in waste streams because they are outdated. The current device, for instance, is inadequate to address such shifts in packaging waste trends, even while the amount of paper trash has declined and the amount of plastic waste has increased.

- Manufacturers of flexible packaging are getting increasingly concerned about inflation. Labor, energy and transportation costs have created a competitive industry with high operational expenses. Additional raw material price hikes are influenced by the crisis between Russia and Ukraine, Russian sanctions, and the realignment of western and eastern countries in the geopolitical arena.

- The recent COVID-19 outbreak has caused many problems for flexible packaging makers, including demand decline in the sectors that were not relted to pharmaceutical applications, although these are only likely to last for a short while. Supply chain interruptions, a lack of raw materials for manufacture, workforce shortages, pricing fluctuations that could drive up production costs and push them beyond budget, and shipping issues are just a few consequences of a lockdown. The COVID-19 impact has now started to wear-off with market recovering post easing and lifting of lockdown.

Flexible Packaging Market Trends

Dairy Products are Expected to Hold a Significant Market Share in the Food Segment

- The current market scenario indicates an upsurge in demand for dairy products, as the consumption of dairy products is increasing at a healthy rate. For instance, according to the United States Department of Agriculture (USDA), cheese consumption per capita is the highest in Europe. The average cheese consumed in the European Union in 2021 was 20.44 kilos. With around 17.9 and 15 kg of cheese per person, the United States and Canada placed second and third in the year. In 2021, the 27 countries that make up the European Union produced 10.35 million metric tonnes of cheese, nearly twice as much as the second-largest producer.

- Among all dairy products, milk is a primary staple food and an essential part of a balanced diet containing a high percentage of calcium and other vital nutrients. According to the FAO (Food and Agriculture Organization of the United Nations) and the US department of agriculture, India consumed roughly 83 million metric tonnes of cow milk in 2021, the world's largest. With 23.9 million metric tons, the European Union utilized the next-highest amount of milk. Flexible pouches, which predominate in total milk packaging, are followed by aseptic packaging, whose use is on the rise. Flexible pouches have established themselves as a rapid, inexpensive, and secure packing option. The packaging type is also simple to package and handle due to the nation's vast distribution network. The positive consumer reaction to milk pouches made the adoption of new technology.

- Liquidbox packaging has conventionally been associated with milk, as it protects food and is also good for the environment. Paperboard is a frequently used material for making liquidbox for milk packaging. Also known as gable-top cartons, milk cartons is a common form of poly-coated paper packaging. By weight, milk cartons are 80% paper and 20% polyethylene. Paper milk cartons substituted refillable glass bottles in the 1950s, offering consumers a convenient, lightweight alternative.

- Numerous cheese brands and producers have already adopted flexible packaging to provide value and convenience. Flexible packaging delivers strength and protection for the product throughout the demanding supply chain, which can damage other packaging types and lead to poor outcomes.

- For instance, GOOD PLANeT Foods redesigned its whole range of plant-based cheeses in April 2022 in anticipation of a significant growth prediction in 2022, with recent distribution gains at supermarkets like Giant Martin, Giant Eagle, and Hy-Vee, as well as increasing distribution nationally in Sprouts. GOOD PLANeT chose Belmark's recyclable flexible pouches for the product to enhance formulation and packaging.

- Vacuum pouches with moderate (PA/PE) or high barrier (PA/EVOH/PE) properties have gained widespread acceptance. These film-based vacuum pouches are incorporated in Modified Atmosphere Packaging (MAP) applications and utilized mainly for dairy and protein packaging.

Asia Pacific is Expected to Witness Significant Growth

- In the food industry, beyond convenience, other characteristics, such as sustainability, transparency, food safety, and reduction in food waste, influence the flexible packaging choice for meat, poultry, and seafood. According to the Ministry of Industry and Information Technology and the National Bureau of Statistics of China, in 2021, the food industry in the country generated total profits of around CNY 618.7 billion.

- According to the Ministry of Health, Labor and Welfare (MHLW Japan), the volume share of generics in the Japanese prescription drugs market stood at around 79% as of September 2021. According to the United Nations COMTRADE database on international trade, Japan imported pharmaceutical products worth USD 37.29 billion in 2021. This demand is anticipated to increase as the country's rapidly aging population demands new medicines for associated conditions. Hence, such trends are expected to positively contribute to the market's growth.

- According to the USDA Foreign Agricultural Service, the sales volume of dairy food in the Indian packaged foods market amounted to 23.81 million metric tons in 2021. A significant increase from about 19.74 million metric tons in 2017 was recorded. India's food retail expansion and diversification are expected to act as catalysts for dairy packaged foods, with urban areas accounting for more than 75% of the sales.

- The government of India has recently provided the Fast Moving Consumer Goods (FMCG) sector with good investments and support, according to India Brand Equity Foundation reports. From April 2000 to March 2022, the industry saw healthy FDI inflows of USD 20.11 billion. Additionally, the Department of Consumer Affairs has been allocated USD 222.19 million, while the Department of Food and Public Distribution has been allocated USD 27.82 billion under the Union Budget 2022-23. The increased investments in distribution could improve sustainable packaging adoption for imports and exports across the region.

Flexible Packaging Industry Overview

The Flexible Packaging Market is moderately consolidated owing to the presence of a few vendors in the market with significant market share. The market appears to be slightly concentrated, with the major players adopting strategies such as product innovation, mergers, and acquisitions to stay competitive. Some of the major players in the industry are Amcor PLC, Mondi Group, Berry Global Inc, and Sealed Air Corporation, among others.

- April 2022 - Mondi teamed up with French machine producer Thimonnier to create a recyclable package that cuts down on plastic waste. The businesses have developed new liquid refill packaging that can be completely emptied. Coextruded polyethylene, a recyclable mono-material, is used to make the berlingot sachet. Compared to rigid plastic bottles, the product weighs less and employs more than 75% less plastic. The refill solution can replace the multilayer PVC refill containers, which are currently the industry standard but aren't recyclable.

- October 2021 - Berry Global and LyondellBasell collaborated to advance the goal of sourcing 100% of its customer-facing packaging sustainably by 2026. The collaboration supports the selection of plastic-lined paper cups with limited recyclability to single-substrate, clear plastic drink cups that more consumers will be able to recycle.

- June 2021 -Coveris, with its technical capabilities, developed a new cereal liner solution. The Cereal+ liner has been created to deliver packer performance and improved shelf life. Coveris Cereal+ liner is made from fully recyclable polyethylene and provides product protection, freshness, and shelf life for cereals and dry foods packed in bag-in-box films.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Buyers

- 4.2.2 Bargaining Power of Suppliers

- 4.2.3 Threat of Substitutes

- 4.2.4 Threat of New Entrants

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of Impact of COVID-19 on the Industry

- 4.5 Market Drivers

- 4.5.1 Increased Demand for Convenient Packaging

- 4.5.2 Demand for Longer Shelf Life and Changing Lifestyles

- 4.6 Market Restraints

- 4.6.1 Concerns Regarding the Environment and Recycling

5 MARKET SEGMENTATION

- 5.1 Material Type

- 5.1.1 Plastic

- 5.1.1.1 Polyethene (PE)

- 5.1.1.2 Bi-orientated Polypropylene (BOPP)

- 5.1.1.3 Cast polypropylene (CPP)

- 5.1.1.4 Polyvinyl Chloride (PVC)

- 5.1.1.5 Ethylene Vinyl Alcohol (EVOH)

- 5.1.2 Paper

- 5.1.3 Aluminum Foil

- 5.1.1 Plastic

- 5.2 Product Type

- 5.2.1 Pouches

- 5.2.2 Bags

- 5.2.3 Films & Wraps

- 5.2.4 Other Product Types

- 5.3 End-User Industry

- 5.3.1 Food

- 5.3.1.1 Frozen Food

- 5.3.1.2 Dairy Products

- 5.3.1.3 Fruits and Vegetables

- 5.3.1.4 Meat, Poultry, and Seafood

- 5.3.1.5 Baked Goods and Snack Foods

- 5.3.1.6 Candy and Confections

- 5.3.1.7 Other Food Products

- 5.3.2 Beverage

- 5.3.3 Pharmaceutical and Medical

- 5.3.4 Household and Personal Care

- 5.3.5 Other End-User Industries

- 5.3.1 Food

- 5.4 Geography

- 5.4.1 North America

- 5.4.1.1 United States

- 5.4.1.2 Canada

- 5.4.2 Europe

- 5.4.2.1 United Kingdom

- 5.4.2.2 Germany

- 5.4.2.3 France

- 5.4.2.4 Italy

- 5.4.2.5 Spain

- 5.4.2.6 Turkey

- 5.4.2.7 Poland

- 5.4.2.8 Russia

- 5.4.2.9 Rest of Europe

- 5.4.3 Asia Pacific

- 5.4.3.1 China

- 5.4.3.2 Japan

- 5.4.3.3 India

- 5.4.3.4 Australia

- 5.4.3.5 Rest of Asia Pacific

- 5.4.4 Latin America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Mexico

- 5.4.4.4 Rest of Latin America

- 5.4.5 Middle East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Egypt

- 5.4.5.4 Iran

- 5.4.5.5 Nigeria

- 5.4.5.6 Rest of Middle East and Africa

- 5.4.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Company Profiles

- 6.1.1 Amcor Plc

- 6.1.2 Berry Global Inc.

- 6.1.3 Mondi Group

- 6.1.4 Sealed Air Corporation

- 6.1.5 Coveris Holdings SA

- 6.1.6 UFlex Limited

- 6.1.7 Huhtamaki Group

- 6.1.8 Proampac LLC

- 6.1.9 WIPF Doypak (Wipf AG)

- 6.1.10 FlexPak Services LLC

- 6.1.11 Laser Packaging Manufacturing PTE Limited

- 6.1.12 KM Packaging Services Ltd

- 6.1.13 Sonoco Products Company