|

市場調查報告書

商品編碼

1432578

汽車零件鎂壓鑄件:市場佔有率分析、產業趨勢、成長預測(2024-2029)Automotive Parts Magnesium Die Casting - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

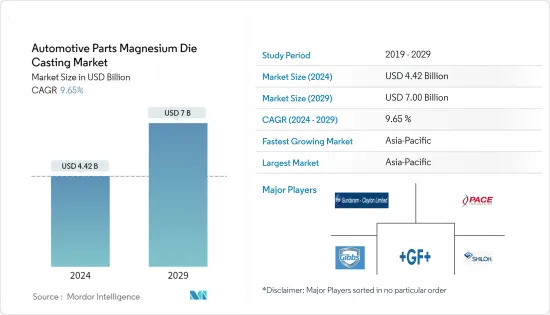

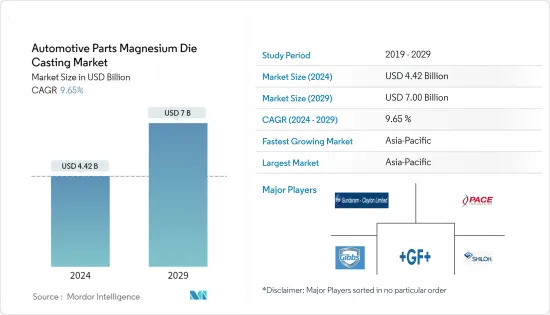

汽車零件鎂壓鑄件市場規模預計到2024年為44.2億美元,預計到2029年將達到70億美元,在預測期內(2024-2029年)複合年成長率為9.65%。 。

COVID-19大流行阻礙了2020年的重點市場,主要是由於汽車銷售和產量的下降。 2020年全球汽車銷量較2019年下降16%。各主要汽車生產國降幅均顯著,從11%降至近40%。歐洲產量幾乎佔全球產量的 22%。然而,疫情後的汽車產業在2020年卻呈現出顯著的成長。預計在預測期內,汽車銷售的整體成長和電動車銷售的成長將主要推動市場。

由於使用輕質汽車材料來製造關鍵零件,從而提高了車輛的燃油效率,輕量化汽車在汽車製造商中越來越受歡迎。此外,減輕汽車重量必須在不影響品質或性能之前安全性的前提下進行。

隨著世界各地嚴格廢氣法規的頒布,該市場預計將顯著成長。消費者對輕型汽車的趨勢日益成長,預計將推動鎂和碳纖維增強塑膠等輕質部件滲透到汽車零件中,從而提振市場。

主要製造業正在投資新型鎂合金和高效能製造技術的研發活動。例如,印度馬德拉斯理工學院、美國研究實驗室和北德克薩斯大學聯合開發了一種新型鎂合金,可在汽車工業中取代鋁和鋼合金,並提高汽車燃油效率。

增加對製造過程自動化的投資可能標誌著市場的顯著成長。鎂壓鑄製造流程的高成本很可能會阻礙汽車零件鎂壓鑄市場的發展。

汽車零件鎂壓鑄件市場趨勢

壓力壓鑄佔市場主導地位

對電動車的偏好不斷增加,消費者偏好不斷變化,迫使汽車製造商用鎂等合金製成的較輕零件取代較重的零件。

主要汽車製造商在後視鏡外殼、轉向柱、駕駛座安全氣囊外殼、座椅框架和儀表板蓋等應用中使用鎂合金。提高電池效率和燃料效率的不斷成長的趨勢以及對提高性能的需求正在推動人們對高壓壓鑄鎂合金的興趣。這些合金具有優異的機械性能和所有結構金屬中最高的強度重量比。

此外,製造電動車的公司也積極採購高壓壓鑄機並採用該技術來滿足不斷成長的消費者需求。

該地區提供汽車壓鑄件的一些主要企業包括 OEFORM Limited、CNM Tech、Dalian Yaming Automotive Parts 和 LC Rapid。一些公司專注於升級其產品組合,而另一些公司則專注於擴大其製造設施並透過合作來確立自己的市場主要企業。

預計亞太地區將在預測期內主導市場

亞太地區擁有大量的製造業,很可能為汽車零件鎂壓鑄市場提供良好的機會。該地區中小型製造業的快速擴張可能預示著市場的顯著成長。全部區域汽車產量的增加可能會增加對鎂壓鑄零件的需求,進而顯示市場的顯著成長。

由於更嚴格的排放法規,全部區域對電動車的需求不斷增加,汽車製造商正在尋求將輕質部件整合到車輛中。中國是壓鑄件主要生產國之一,佔亞太地區壓鑄件市場佔有率60%以上。中國金屬鑄造業擁有26,000多台設備,其中8,000多台生產有色鑄件。我國鑄造產量超過4,930萬噸。先進且高效的自動壓鑄機支撐著國家的金屬壓鑄需求。快速成長的國際汽車工業對中國鎂壓鑄市場有著巨大的需求。預計這將在預測期內推動中國市場的成長。

印度政府正專注於發展「印度製造」來發展汽車工業,嚴格的排放法規正在推動該國汽車零件鎂壓鑄市場的發展。汽車工業消耗的鑄件佔全國產量的35%。在印度,由於經濟放緩、燃油成本上漲和保險費上漲等多種原因,小客車銷售量正在下降。不過,儘管面臨油門法規審查、NBFC危機等諸多壓力,商用車整體銷售仍達到27.28%的穩健成長。

最新的法規結構「中國6」於2016年推出,第一階段「中國6a」將於2020年7月生效,第二階段計畫於2023年7月生效。監管標準的變化對於確定該地區汽車市場的動態至關重要。環境保護部 (MEP) 保存在中國註冊的每輛新車的排放氣體性能標準記錄。因此,在預測期內,亞太地區汽車零件鎂壓鑄市場可能會顯著成長。

汽車零件鎂壓鑄件產業概況

全球汽車零件鎂壓鑄市場由來自全球新興和已開發地區的中小型企業主導。 Georg Fischer Automotive、Ryobi Die Casting、Shiloh Industries、Pace Industries等大公司佔據全球市場30%以上的佔有率。

全球汽車製造商和汽車零件製造公司之間的併購數量不斷增加,顯示市場的顯著成長。主要產業正在投資輕量化零件的研發設施,以提高車輛的燃油效率。例如,2022 年 5 月,GF、沙夫豪森和 Bocar 集團旗下子公司 GF Casting Solutions 簽署了一項協議,在全球提供專業產品和服務。此次合作協助開發和投資新技術和服務,為北美、歐洲和亞洲的客戶提供支援。

其他福利

- Excel 格式的市場預測 (ME) 表

- 3 個月的分析師支持

目錄

第1章簡介

- 調查先決條件

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場動態

- 市場促進因素

- 市場限制因素

- 波特五力分析

- 新進入者的威脅

- 買家/消費者的議價能力

- 供應商的議價能力

- 替代品的威脅

- 競爭公司之間敵對關係的強度

第5章市場區隔

- 生產流程

- 壓力鑄造

- 真空壓鑄

- 重力鑄造

- 擠壓鑄造

- 目的

- 身體部位

- 引擎零件

- 傳動部件

- 其他用途

- 地區

- 北美洲

- 美國

- 加拿大

- 北美其他地區

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 其他歐洲國家

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他亞太地區

- 世界其他地區

- 南美洲

- 中東/非洲

- 北美洲

第6章 競爭形勢

- 供應商市場佔有率

- 公司簡介

- Chicago White Metal Casting Inc.

- Sandhar Group

- Georg Fischer AG

- Gibbs Die Casting Group

- Magic Precision Ltd.

- Meridian Lightweight Technologies Inc.

- Morimura Bros Ltd.

- Tadir-Gan Group(Ortal Ltd)

- Pace Industries

- Shiloh Industries Inc.

- Sundaram-Clayton Ltd.

- Twin City Die Castings Co.

- Dynacast(Form Technologies Inc.)

- Ryobi Limited

第7章 市場機會及未來趨勢

The Automotive Parts Magnesium Die Casting Market size is estimated at USD 4.42 billion in 2024, and is expected to reach USD 7 billion by 2029, growing at a CAGR of 9.65% during the forecast period (2024-2029).

The COVID-19 pandemic hampered the market in focus for the year 2020, primarily attributed to decline in vehicle sales and production. The global vehicle sale declined by 16% in 2020 as compared to the 2019 vehicle sales. All main vehicle-producing countries had major declines, ranging from 11% to almost 40%. Europe represented an almost 22% share of global production. However, post-pandemic the automotive industry witnessed significant growth for the year 2020. The overall increase in vehicle sales and expected increase in electric vehicle sales is anticipated to primarily drive the market during the forecast period.

Lightweight vehicles are gaining popularity among vehicle manufacturers owing to an enhanced fuel economy of automobiles with adoption of lightweight automotive materials manufacturing crucial parts. Additionally, the light-weighting of vehicles must be done without compromising on safety before quality and performance.

An enactment of stringent emission norms across the globe is liekly to witness significant growth for the market. Rising consumer trend towards light weight vehicle is likely to increase the penetration of light weight parts such as magnesium and carbon fiber reinforced plastic, to manufacture vehicle components, which in turn is anticipated to boost the market.

Major manufacturing industries are investing in research and development activities regarding new magnesium alloys and efficient manufacturing techniques. For instance, the Indian Institute of Technology, Madras, the US Army Research Laboratory, and the University of North Texas developed a new magnesium alloy that can replace aluminum and steel alloys in the automotive industry and increase the fuel efficiency of vehicles.

Growing investment in automation of manufacturing process is likely to witness major growth for the market. High cost of magnessium die casting manufacturing process is liekly to hamper the automotive parts magnesium die casting market.

Automotive Parts Magnesium Die Casting Market Trends

Pressure Die Casting dominating the market

Rise in demand for electric vehicles and a shift in consumer preferences have pushed vehicle manufacturer to replace heavier components with lightweight which are manufactured from alloys like Magnesium.

Major vehicle manufcturer use magnesium alloy for applications like mirror housings, steering columns, driver's airbag casings, seat frames, and dash encasings. Growing trend towards greater battery and fuel efficiency, along with demand for improved performance, has driven an increased interest in high-pressure die cast magnesium alloys. These alloys have an excellent combination of mechanical properties and the highest strength to weight ratio of any structural metal.

In addition, the companies manufacturing EV are also actively procuring pressure diecasting machines and are adopting this technology to make themselves ready for growing consumer demand.

Some of the key players offering automotive pressure die casting components in the region include OEFORM Limited, CNM Tech, Dalian Yaming Automotive Parts Co. Ltd, LC Rapid, and others. While some players focusing on upgrading their portfolio others focus on the manufacturing plants expansion, collaborations, etc. to pitch themselves as top players in the market. For instance,

- In February 2021, Nantong Jiangzhong Photoelectricity Co., Ltd. Installed its Italpresse gauss TF5700 high pressure die casting (HPDC) machine at the company's base in Jiangsu province, China. With its huge 3500 x 3500mm plates, the TF5700's closing force of 5700 tons making it the ideal solution for large part production. Jiangzhong has also purchased a Westomat 3100 from StrikoWestofen to integrate seamlessly with the machine.

Asia-Pacific Projected to Dominate the Market During the Forecast Period

Asia Pacific has major presence of manufacturing industries which is likely to create an opprtunity for automotive parts magnesium die casting market. Rapid expansion of small and medium manufacturing industries across the region is likely to witness major growth for the market. Rise in vehicle production across the region is likely to increase the demand for magnesium die casting parts which in turn is likely to witness major growth for the market.

Rise in demand for electric vehicle across the region owing to an enactment of stringent emission norms is prmpting vehicle manufacturer to integrate lightweight parts in vehicle. China is one of the major producers of die casting parts and accounts for more than 60% of the regional (Asia-Pacific) die casting market share. The metal casting industry in China has more than 26,000 facilities, out of which 8,000 facilities produce non-ferrous castings. The country produces over 49.3 million metric tons of castings. The advanced and efficient automatic die casting machines supported the demand for metal die castings in the country. The Chinese magnesium die casting market experiences high demand from the automotive industry, which is rapidly growing at the international level. This is expected to drive the Chinese market's growth over the forecast period.

The Government of India focus on Make in India, developing the automotive industry, and the stringent emission norms are driving the market for automotive parts magnesium die casting in the country. The castings consumed by the automotive sector accounted for 35% of the country's production. India witnessed a declining trend in passenger vehicle sales, owing to numerous reasons, such as economic slowdown, rise in fuel, and insurance costs. However, despite numerous pressures, such as revised axel norms and NBFC crisis, the overall commercial vehicle sales increased and showcased a robust 27.28% growth.

The latest regulatory framework, the China 6, which was introduced in 2016 and the first stage China 6a came into effect from July 2020 and the second stage is planned for July 2023. The change in the regulatory standards that have been crucial in determining the dynamics of the automotive market in the region. The Ministry of Environmental Protection (MEP), has been maintaining the record of emission performance standard for each new vehicle registered in. This is likely to witness major growth for the automotive part magnesium die casting market across the Asia-Pacific during the forecast period.

Automotive Parts Magnesium Die Casting Industry Overview

The global automotive parts magnesium die casting market isdomnaitng by regional small- and medium-scale players across both developing and developed countries around the world. Major recognized players, such as Georg Fischer Automotive, Ryobi Die Casting, Shiloh Industries, and Pace Industries, accounted for over 30% of the overall global market share.

Growing merger and acquisition between vehicle manufacturer and automotive parts manufacturing companies across the globe is witnessing major growth for the market. Major industries investing on research and development facilities on the light weight parts to enhance vehicle fuel efficiency. For instance,

- In May 2022, GF Casting Solutions, a division of GF, Schaffhausen and the Bocar Group have signed an agreement to offer a specialized range of products and services worldwide. The collabration helped to develop and invest in new technologies and services to support customers in North America, Europe and Asia.

- In January 2022, Koch Enterprises, Inc. has announced the acquisition of Amprod Holdings, LLC.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Market Drivers

- 4.2 Market Restraints

- 4.3 Porters Five Forces Analysis

- 4.3.1 Threat of New Entrants

- 4.3.2 Bargaining Power of Buyers/Consumers

- 4.3.3 Bargaining Power of Suppliers

- 4.3.4 Threat of Substitute Products

- 4.3.5 Intensity of Competitive Rivalry

5 MARKET SEGMENTATION

- 5.1 Production Process

- 5.1.1 Pressure Die Casting

- 5.1.2 Vacuum Die Casting

- 5.1.3 Gravity Die Casting

- 5.1.4 Squeeze Die Casting

- 5.2 Application

- 5.2.1 Body Parts

- 5.2.2 Engine Parts

- 5.2.3 Transmission Parts

- 5.2.4 Other Applications

- 5.3 Geography

- 5.3.1 North America

- 5.3.1.1 United States

- 5.3.1.2 Canada

- 5.3.1.3 Rest of North America

- 5.3.2 Europe

- 5.3.2.1 Germany

- 5.3.2.2 United Kingdom

- 5.3.2.3 France

- 5.3.2.4 Italy

- 5.3.2.5 Rest of the Europe

- 5.3.3 Asia-Pacific

- 5.3.3.1 China

- 5.3.3.2 India

- 5.3.3.3 Japan

- 5.3.3.4 South Korea

- 5.3.3.5 Rest of Asia-Pacific

- 5.3.4 Rest of World

- 5.3.4.1 South America

- 5.3.4.2 Middle-East and Africa

- 5.3.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Vendor Market Share

- 6.2 Company Profiles*

- 6.2.1 Chicago White Metal Casting Inc.

- 6.2.2 Sandhar Group

- 6.2.3 Georg Fischer AG

- 6.2.4 Gibbs Die Casting Group

- 6.2.5 Magic Precision Ltd.

- 6.2.6 Meridian Lightweight Technologies Inc.

- 6.2.7 Morimura Bros Ltd.

- 6.2.8 Tadir-Gan Group (Ortal Ltd)

- 6.2.9 Pace Industries

- 6.2.10 Shiloh Industries Inc.

- 6.2.11 Sundaram-Clayton Ltd.

- 6.2.12 Twin City Die Castings Co.

- 6.2.13 Dynacast (Form Technologies Inc.)

- 6.2.14 Ryobi Limited