|

市場調查報告書

商品編碼

1431449

塑膠薄膜電容器的全球市場:市場佔有率分析、產業趨勢/統計、成長預測(2024-2029)Plastic Film Capacitors - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2024 - 2029) |

||||||

※ 本網頁內容可能與最新版本有所差異。詳細情況請與我們聯繫。

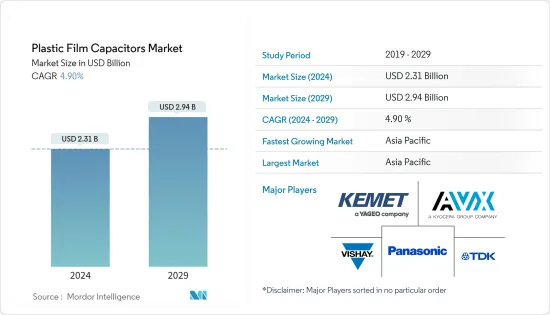

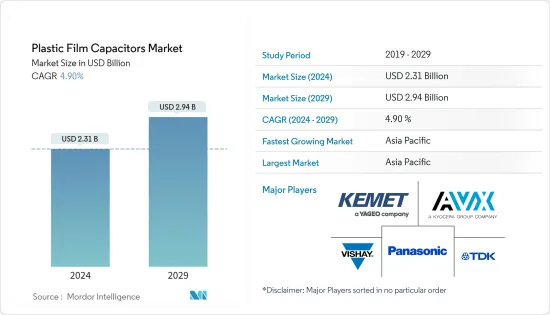

2024年全球塑膠薄膜電容器市場規模估計為23.1億美元,預計到2029年將達到29.4億美元,在預測期間(2024~2029年)以4.90%的複合年增長率增長。

塑膠薄膜電容器包括多個主要使用不同塑膠作為介電材料的電容器系列。它們在音訊和無線電電路以及低至中壓電路等應用中很大程度上取代了紙質電容器。電容器中常用的塑膠包括聚碳酸酯、聚丙烯(PP)、聚酯(PET)、聚苯乙烯、聚碸、 聚亞醯胺膜聚醯亞胺、鐵氟隆(PTFE含氟聚合物)和金屬化聚酯(金屬化塑膠)。

主要亮點

- 使用塑膠薄膜電容器的一大優點是失真度低且頻率響應出色。此外,這些電容器使用的塑膠薄膜種類繁多,使其用途廣泛。這些電容器不會很快磨損,因此適用於高電壓、高頻應用,例如耦合和去耦電路以及音訊電路中的 ADC。

- 隨著各行業日益關注永續發電解決方案,對太陽能和風能逆變器的需求不斷增加。為了解決這個問題,供應商正在推出新的塑膠薄膜電容器。例如,2021 年 5 月,New Yorker Electronics 宣布推出 CDE-Illinois 電容器(33 至 220 uF,高達 1,440 WVDC,-40 至 +85 C)。該產品專為直流母線、電暖器、馬達驅動器、感應加熱器、UPS 系統以及太陽能和風能逆變器等應用而設計。

- 此外,過去幾年,穿戴式裝置在醫療保健領域的採用越來越受到關注,使其成為影響研究市場的關鍵因素之一。穿戴式連接裝置的主要趨勢包括對疼痛管理穿戴式裝置的需求增加以及穿戴式裝置在心血管疾病管理的使用增加。

- 此外,2022 年 4 月,Electroninx 宣佈其全套專有的有機金屬金屬金屬油墨解決方案現已投入生產規模。 除了將單個油墨產品推向市場外,Electroninx 還為客戶提供了一套油墨產品的整體解決方案,包括用於按需印刷電路板 (PCB) 列印和維修的獨特緊湊型桌面原型增材製造解決方案,稱為 CircuitJet。 這些新興市場的發展也可能推動研究市場的發展。

- COVID-19 大流行對全球各行業的供應鏈造成了嚴重破壞。為了對抗病毒的傳播,全球許多公司已暫停或減少業務。然而,在疫情後的情況下,電子元件市場促使整個供應鏈在原料和元件生產層面的營運水準提高。這增加了各個地區和國家的銷售額。

- 此外,電子元件是資源密集型的。大規模生產表面黏著技術電子元件所消耗的材料(通常以工程粉末或糊劑的形式提供)構成了與電容器等被動元件的生產相關的最大「可變成本」。

塑膜電容器市場趨勢

家電預計將佔據較大市場佔有率

- 家電需求的激增正在提振市場。智慧型手機和平板電腦等設備需要能夠提供高效能的小型天線。這些天線系統需要具有特定性能特徵的電容器。電容器是天線系統中的重要元件。電容器在天線系統中最常見的用途包括頻率調諧、電阻和濾波。這些應用中使用的電容器需要優異的性能特性,例如低漏電流、高品質因數和高線性度。

- 電容器技術取得了許多進步,生產的電容器能夠滿足智慧型手機天線系統嚴格的效能要求。例如,電容器製造商正在使用電子機械系統 (MEMS) 技術為智慧型手機天線系統製造超小型、薄型電容器。

- 根據消費者科技協會的數據,2012 年至 2021 年美國消費性電子市場的零售額持續成長。根據2023年零售額預測,美國消費性電子零售額預計將達4,850億美元。

- 此外,電容器通常內建於相機的閃光燈模組中。相機閃光燈電容器採用低電阻和極低電感構造,可盡快將能量傳輸至閃光燈管,從而實現電流脈衝的快速上升時間。此外,內部連接更加堅固,以避免因高電流而產生局部熱量。如果沒有閃光燈電容器,數位相機中的電池將很快耗盡。

- 此外,智慧型手錶、頭戴式顯示器、佩戴式攝影機、耳掛型設備和健身追蹤器等穿戴式電子產品的進步正在推動塑膠薄膜電容器的創新和採用。例如,電容器因其耐磨性而被廣泛應用於穿戴式家用電器中,在10,000次充放電循環後,其能源性能會下降幾個百分點。

亞太地區預計將佔據主要市場佔有率

- 亞太地區是電容器最重要的市場之一。中國汽車工業正在崛起,在全球汽車市場中發揮越來越重要的作用。政府認為汽車工業,包括汽車零件產業,是國家的支柱產業之一。中國政府預計,2020年中國汽車產量將達3,000萬輛,到2025年將達到3,500萬輛。預計這將推動研究電容器的需求。

- 電動車越來越受歡迎,中國被認為是採用電動車的主要國家之一。中國的「十三五」規劃促進了混合動力汽車和電動車等環保交通解決方案的發展,預計將發展該國的交通運輸業。

- 中國小客車協會資料顯示,2021年11月至12月,新能源汽車銷量成長一倍多,總計299萬輛,較去年同期成長169%,成為全球銷量第一的新能源汽車。銷量最大,佔主要汽車市場中國新車銷量的14.8%。預計這將促進塑膠薄膜電容器在該國的採用。

- 根據 IEA 的數據,中國是可再生能源成長領域標語的領導者,預計到 2022 年將佔清潔能源總量的 40% 左右。該國還超額完成了 2020 年太陽能電池板目標。

- 此外,為了加速零排放汽車的普及,澳洲新南威爾斯(NSW)政府於2021年推出了電動車策略,提供總計約5億澳元的資金。 2021年上半年澳洲銷售了8,688輛電動車。該國還在擴大其電動車支援基礎設施。澳洲有超過3000個電動車公共充電器。中國電動車市場現有電動車車型31款,預計2022年終電動車車型將達58款。

塑膜電容器產業概況

塑膠薄膜電容器市場較為分散,有幾家主要公司。這些擁有大量市場佔有率的大公司正專注於擴大海外基本客群。 Panasonic Corporation、Vishay Intertechnology Inc.、TDK Corporation、AVX Corporation、KEMET Corporation 等許多公司都參與了這個市場。這些公司正在利用策略合作措施來提高市場佔有率和盈利。

- 2023 年 11 月 Electrocube 開發了一種金屬化聚丙烯薄膜電容器,專為各種軍事、商業、陸地和海洋應用中使用的高功率逆變器量身定做。這些電容器經過精心設計和最佳化,可在具有交流和脈衝訊號的高溫、高電流環境中表現良好。此外,它們具有承受高突波電流而不劣化的卓越能力,使其成為電解電容器的絕佳替代品。

- 2023年5月,Sabic旗下的Hercules推出了以聚碳酸酯共聚物為基礎的HTV150A薄膜。當暴露在高達 150°C 的溫度和高達 100kHz 的頻率下時,該薄膜可將耗散損耗降低高達 40%。這種材料已經在薄壁電容器薄膜中展示了其有效性。透過利用具有低耗散損耗的 Elcres HTV150A 介電薄膜,工程師可以受益於提高工作效率、減少內部熱量產生以及穩定熱點溫度,從而提高電容器設計的彈性。該薄膜預計將有助於減少電容器的損耗。

其他福利:

- Excel 格式的市場預測 (ME) 表

- 3 個月分析師支持

目錄

第1章 簡介

- 研究假設和市場定義

- 調查範圍

第2章調查方法

第3章執行摘要

第4章市場洞察

- 市場概況

- 產業吸引力-波特五力分析

- 買方議價能力

- 供應商的議價能力

- 替代品的威脅

- 新進入者的威脅

- 競爭公司之間的敵對關係

- 產業價值鏈分析

- 評估宏觀經濟趨勢對產業的影響

第5章市場動態

- 市場促進因素

- 由於電動車的出現,汽車產業的需求增加

- 電子產品的複雜度不斷增加

- 市場限制因素

- 金屬價格上漲影響零件製造成本

第6章市場區隔

- 類型

- 聚丙烯

- 聚乙烯

- 其他類型(PTFE、PPS等)

- 目的

- 車

- 通訊

- 工業的

- 航太/國防

- 家用電器

- 醫療保健

- 其他用途

- 地區

- 美洲

- 歐洲、中東/非洲

- 亞太地區(不包括日本和韓國)

- 日本、韓國

第7章 競爭形勢

- 公司簡介

- KEMET Corporation(Yageo company)

- Panasonic Corporation

- Vishay Intertechnology Inc.

- TDK Corporation

- AVX Corporation(Kyocera Corp)

- Murata Manufacturing Co. Ltd.

- Cornell Dubilier Electronics Inc.

- Desai Electronics

- Shanghai Yinyan Electronic

- Rubycon Corporation

- Nantong Jianghai Capacitor Co. Ltd.

- Nichicon Corporation

- Wima GmBH & Co. KG

第8章投資分析

第9章 市場未來展望

The Plastic Film Capacitors Market size is estimated at USD 2.31 billion in 2024, and is expected to reach USD 2.94 billion by 2029, growing at a CAGR of 4.90% during the forecast period (2024-2029).

Plastic Film capacitors primarily include multiple families of capacitors that use different plastics as dielectric materials. They significantly replace paper-type capacitors in applications such as audio, radio circuits, and circuits operating at low to moderate voltages. Some of the commonly used plastics in these capacitors include polycarbonate, polypropylene (PP), polyester (PET), polystyrene, polysulfone, Kapton polyimide, Teflon (PTFE fluorocarbon), and metalized polyester (metalized plastic).

Key Highlights

- The significant advantage of using a plastic film capacitor is that it has a low distortion factor and exceptional frequency characteristics. Also, the wide range of plastic films that are used for these capacitors makes them versatile. These capacitors do not wear off quickly and are suited for high-voltage and high-frequency applications such as coupling and decoupling circuits and audio circuit ADCs.

- With a rising focus on sustainable solutions across various industries for power generation, the demand for solar and wind power inverters has increased. To cater to this, vendors are introducing new plastic-film capacitors. For instance, in May 2021, New Yorker Electronics introduced CDE-Illinois capacitors (33 to 220 uF and up to 1,440 WVDC, -40°C to +85°C) that are manufactured with low-profile metalized polypropylene film and offer high capacitance. The product is designed for applications such as DC links, electric heaters, motor drives, induction heaters, UPS systems, and solar and wind power inverters.

- Moreover, the adoption of wearables in the healthcare sector has been gaining traction in recent times, which, in turn, has been one of the significant factors influencing the market studied. The major trends in wearable connected devices include the increasing demand for pain management wearable devices and the increased use of wearables for cardiovascular disease management, among others.

- Further, in April 2022, Electroninks, Inc. announced the production-scale availability of its full suite of proprietary metal-organic decomposition (MOD) conductive metal ink solutions. In addition to bringing standalone ink products to market, Electroninks is also bringing total solutions to the customer with its line of ink products, including its own small desktop prototype additive manufacturing solution for rapid on-demand printed circuit board (PCB) printing and repair, called CircuitJet. These developments will also drive the study market.

- The COVID-19 pandemic led to immense disruptions in supply chains across industries globally. Many businesses globally halted or reduced operations to help combat the spread of the virus. However, in post pandemic scenario, the electronic components market, leading to increased operation levels across the supply chain for raw materials and component production levels. This denoted a rise in sales among a range of regions and countries.

- Moreover, electronic components are resource-intensive. The materials consumed in the mass production of surface-mount electronic components usually come in the form of engineered powders and pastes, making up the largest "variable cost" associated with producing passive components like capacitors.

Plastic Film Capacitors Market Trends

Consumer Electronics is Expected to Hold Significant Market Share

- The rapid surge in demand for consumer electronics products has boosted the market. Devices such as smartphones and tablets need small antennas capable of delivering high performance. These antenna systems demand capacitors with specific performance characteristics. Capacitors are critical components in antenna systems. The most general applications of capacitors in antenna systems include frequency tuning, impedance matching, and filtering. Capacitors for use in these applications must have prominent performance characteristics, including low leakage current, a high quality factor, and high linearity.

- Numerous advancements in capacitor technology have been made to produce capacitors that meet the strict performance requirements of smartphone antenna systems. For instance, capacitor manufacturers use microelectromechanical systems (MEMS) technology to make ultra-small and thin capacitors for smartphone antenna systems.

- According to the Consumer Technology Association, the retail revenue of the consumer electronics market in the United States constantly increased during the period from 2012 to 2021. Based on the projected retail sales for 2023, consumer electronics retail sales in the United States is expected to reach USD 485 billion.

- Moreover, capacitors are commonly incorporated in the flash module of cameras. Camera flash capacitors are constructed to have low resistance and significantly low inductance to deliver their energy to the flash tube as fast as possible, achieving a fast rise time on the pulse of current. The internal connections are also made more robust to avoid localized heating due to the high current. Without the flash capacitor, the batteries located inside the digital cameras would drain quickly.

- Furthermore, developments in wearable electronics, such as smartwatches, head-mounted displays, body-worn cameras, ear-worn devices, and fitness trackers, among others, drive innovations and the adoption of plastic film capacitors. For instance, capacitors are being widely used in wearable consumer electronics due to their wear and tear capability, which exhibits a loss of a few percentage points of energy performance after 10,000 cycles of charging and discharging.

Asia-Pacific is Expected to Hold Significant Market Share

- The Asia-Pacific region is one of the most important markets for capacitors. The automotive industry is increasing in China, and the country plays an increasingly important role in the global automotive market. The government views its automotive industry, including the auto parts sector, as one of the country's pillar industries. The government of China estimates that China's automobile output is expected to reach 30 million units by 2020 and 35 million units by 2025. This is expected to drive the studied capacitors' demand.

- The popularity of EVs is growing, and China is regarded as one of the dominant adopters of electric vehicles. The country's 13th Five-Year Plan promotes the development of green transportation solutions, such as hybrid and electric vehicles, for advancements in the country's transportation sector.

- According to data by the China Passenger Car Association (CPCA), sales of these new energy vehicles (NEVs) more than doubled in November and December of 2021, increasing full-year deliveries by 169% to a record 2.99 million units, or 14.8% of new sales in China, the world's largest vehicle market. This is anticipated to boost the country's adoption of plastic film capacitors.

- According to the IEA, China was the undisputed leader in renewable growth, estimated to account for around 40% of its total clean energy mix by 2022. The country also surpassed its 2020 solar panel target.

- Additionally, to promote the adoption of zero-emission vehicles, the New South Wales (NSW) state government in Australia introduced an Electric Vehicle Strategy in 2021 with funding totaling almost AUD 500 million. 8,688 electric vehicles were sold during the first half of 2021 in Australia. The country is witnessing a growing electric vehicle support infrastructure as well. Australia has more than 3,000 public chargers for electric vehicles. The country's EV market had 31 electric vehicle models, and by the end of 2022, it was estimated that there would be 58 electric vehicle models in the country.

Plastic Film Capacitors Industry Overview

The plastic film capacitors market is fragmented and has several major players. These major players with prominent shares in the market are focusing on expanding their customer base across foreign countries. The market comprises Panasonic Corporation, Vishay Intertechnology Inc., TDK Corporation, AVX Corporation, KEMET Corporation, and many others. These companies leverage strategic collaborative initiatives to increase their market shares and profitability.

- November 2023: Electrocube has developed a range of metalized polypropylene film capacitors specifically tailored for high-power inverters used in various military, commercial, land, and sea applications. These capacitors have been carefully designed and optimized to function exceptionally well in high temperature and high current scenarios with AC and pulsing signals. Furthermore, their remarkable capability to withstand high surge currents without deterioration makes them an outstanding alternative to electrolytic capacitors.

- May 2023: Sabic's Elcres introduced its polycarbonate copolymer-based HTV150A films, which can potentially decrease dissipation losses by up to 40% when exposed to temperatures up to 150°C and frequencies up to 100 kHz. This material has already demonstrated its effectiveness in thin-wall capacitor films. By utilizing Elcres HTV150A dielectric films with lower dissipation losses, engineers can benefit from improved operating efficiency, reduced internal heat generation, and more stable hot spot temperatures, resulting in increased flexibility when designing capacitors. It is anticipated that these films will lead to reduced dissipation losses in capacitors.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Buyers

- 4.2.2 Bargaining Power of Suppliers

- 4.2.3 Threat of Substitute Products

- 4.2.4 Threat of New Entrants

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Industry Value Chain Analysis

- 4.4 Assessment of Impact of Macro Economic Trends on the Industry

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Growing Demand from the Automotive Industry due to the Advent of EVs

- 5.1.2 Increasing Complexity of Electronics

- 5.2 Market Restraints

- 5.2.1 Rising Metal Prices Impacting Component Production Costs

6 MARKET SEGMENTATION

- 6.1 Type

- 6.1.1 Polypropylene

- 6.1.2 Polyethylene

- 6.1.3 Other Types (PTFE, PPS, etc.)

- 6.2 Applications

- 6.2.1 Automotive

- 6.2.2 Telecommunications

- 6.2.3 Industrial

- 6.2.4 Aerospace & Defense

- 6.2.5 Consumer Electronics

- 6.2.6 Medical

- 6.2.7 Other Applications

- 6.3 Geography

- 6.3.1 Americas

- 6.3.2 Europe, Middle East & Africa

- 6.3.3 Asia-Pacific (Excl. Japan and Korea)

- 6.3.4 Japan and Korea

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 KEMET Corporation (Yageo company)

- 7.1.2 Panasonic Corporation

- 7.1.3 Vishay Intertechnology Inc.

- 7.1.4 TDK Corporation

- 7.1.5 AVX Corporation (Kyocera Corp)

- 7.1.6 Murata Manufacturing Co. Ltd.

- 7.1.7 Cornell Dubilier Electronics Inc.

- 7.1.8 Desai Electronics

- 7.1.9 Shanghai Yinyan Electronic

- 7.1.10 Rubycon Corporation

- 7.1.11 Nantong Jianghai Capacitor Co. Ltd.

- 7.1.12 Nichicon Corporation

- 7.1.13 Wima GmBH & Co. KG