|

市場調查報告書

商品編碼

1881284

汽車懸吊市場按驅動方式、零件、結構、系統、車輛類型、應用和地區分類-預測至2032年Automotive Suspension Market by Architecture, System, Actuation, Component, Vehicle, Aftermarket, & Region - Global Forecast to 2032 |

||||||

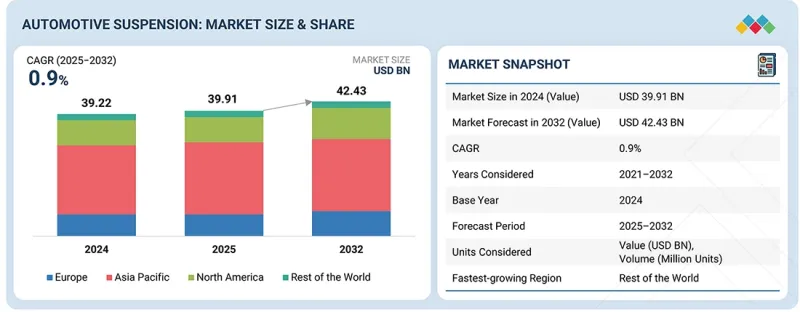

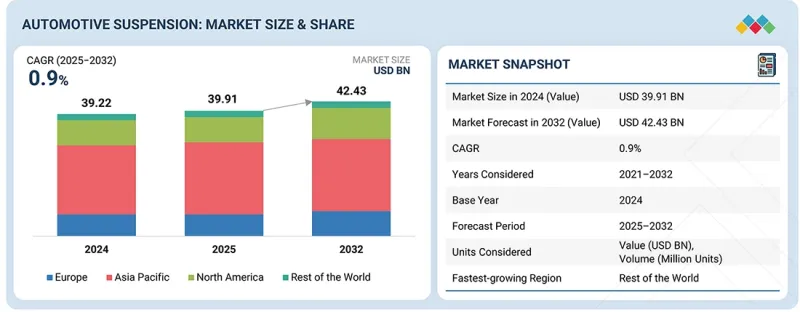

預計汽車懸吊市場規模將從 2025 年的 399.1 億美元成長到 2032 年的 424.3 億美元,預測期內複合年成長率為 0.9%。

全球SUV、電動車和豪華車的銷售量不斷成長,推動了懸吊市場的成長。

| 調查範圍 | |

|---|---|

| 調查期 | 2021-2032 |

| 基準年 | 2024 |

| 預測期 | 2025-2035 |

| 目標單元 | 金額(百萬美元) |

| 部分 | 按操作方法、部件、結構、系統、車輛類型、應用和區域分類 |

| 目標區域 | 亞太地區、歐洲、北美、世界其他地區 |

此外,公共汽車和卡車擴大採用空氣懸吊系統,這推動了先進懸吊系統市場的成長。

預計到2025年,空氣懸吊市場將持續擴張。這一成長主要得益於豪華巴士、高階客車、重型卡車和電動巴士的日益普及,尤其是在北美和歐洲。在這些地區,戴姆勒、沃爾沃和斯堪尼亞等汽車製造商優先考慮遠距運輸的乘坐舒適性、安全性和負載調節穩定性。沃爾沃FH和福萊納Cascadia等重型卡車正擴大整合式電子控制空氣懸架,以保護易損貨物並最佳化操控性能。儘管由於成本考慮,亞太地區的空氣懸吊普及率目前較低,但中國和印度正在快速將這些系統應用於高階城際巴士和先進物流車輛,這主要受消費者舒適性期望和都市區貨運需求的驅動。輕量化材料、模組化氣壓彈簧以及與電子穩定控制系統整合等技術創新不斷提升性能和耐久性,使空氣懸吊成為全球乘用車和商用車領域的關鍵差異化因素。

乘用車市場在全球汽車懸吊市場佔據最大佔有率,這主要得益於其高產量、SUV和豪華車的流行,以及消費者對乘坐舒適性和操控性日益成長的需求。大多數掀背車、轎車和中型SUV都採用麥花臣式前懸吊,因為其結構簡單、緊湊輕巧、成本效益高,並且易於整合到模組化平台中。另一方面,豪華SUV和小轎車採用雙橫臂,以獲得更優異的操控性和穩定性。這款雙橫臂懸吊廣泛應用於寶馬、Lexus和Mercedes-Benz等品牌的高性能和豪華車型。

在後懸吊方面,扭力樑式懸吊因其空間利用率高且成本績效。雖然空氣懸吊目前仍僅限於超豪華車型,但BMW、賓士、豐田和現代等品牌正在其旗艦車型中整合半主動和主動阻尼系統,以提升NVH性能和自適應操控性。總體而言,麥花臣式和扭力樑式懸吊系統在量產車型中佔據主導地位,而雙橫臂、多連桿式和氣壓懸吊則定義了高階車型。預計這一趨勢將在未來幾年持續下去。

預計到2025年,電動車(EV)細分市場將成為汽車懸吊系統市場中成長最快的細分市場之一。這主要得益於全球電動車普及率的加速提升、政府補貼政策以及排放氣體嚴格的排放法規。在各種動力傳動系統車型中,電動乘用車的需求量最大。在電動車領域,緊湊型和中型電動車主要採用麥花臣式前懸吊和扭力樑式或多連桿式後懸吊系統,類似於內燃機(ICE)汽車所使用的技術。同時,BMWi5、保時捷Taycan Cross Turismo、Lucid Air和特斯拉Model S/X等高階和高性能電動車擴大採用多連桿懸吊,以控制電池重量並最佳化乘坐舒適性。電動乘用車的關鍵懸吊技術包括輕量化多連桿結構,該結構整合複合複合材料控制臂和電子控制減震器,可在最佳化乘坐舒適性和操控性的同時,最大限度地降低能耗。特斯拉Model S和保時捷Taycan等車型上應用的電磁致動器和預測性懸吊控制等創新技術,透過提升車輛的動態響應性和電池續航里程,實現了差異化優勢。在電動巴士領域,空氣懸吊佔據主導地位(超過90%),透過模組化空氣彈簧系統與電子高度控制的整合,實現了卓越的乘客舒適性和負載適應性。在以Volvo電動FH系列為代表的電動卡車領域,傳統的重型拋物線形鋼板鋼板彈簧與新興的電液和半主動阻尼系統相結合,以平衡重載需求並提高動力傳動系統的效率。全球向電動車的轉型,以及消費者對乘坐舒適性和高階駕駛體驗日益成長的期望,正在推動電動車市場對先進、輕量化懸吊架構的強勁需求。

在北美,乘用車前懸吊主要採用麥花臣式獨立懸吊,後懸吊則採用多連桿式獨立懸吊,以提升乘坐舒適性和操控性。特斯拉Model 3和凱迪拉克CT4等車型就採用了這種設計。皮卡和輕型商用車(LCV)則傾向於使用雙橫臂和多連桿式前懸吊,以增強載重管理和越野性能。同時,扭力樑式和鋼板彈簧式後懸吊也較為常見。重型卡車主要採用拋物線形和半橢圓形鋼板彈簧。同樣,城際巴士也使用這些重型機械懸架,而空氣懸吊通常僅用於高階車型。各細分市場的電動車(EV)都在強調使用輕量化多連桿式懸吊、複合材料零件和電子控制阻尼系統,以有效平衡電池重量並最佳化效率。自適應和整合式懸吊技術在北美市場正迅速發展,為整車製造商(OEM)和售後市場供應商提供了開發專為電動車和商用車平台量身定做的智慧耐用解決方案的機會。

本報告分析了全球汽車懸吊市場,並按驅動方式、組件、結構、系統、車輛類型、應用、區域趨勢和公司概況提供了市場資訊。

目錄

第1章 引言

第2章調查方法

第3章執行摘要

第4章重要考察

第5章 市場概覽

- 介紹

- 市場動態

- 未滿足的需求和差距

- 相互關聯的市場與跨產業機遇

- 一級/二級/三級公司的策略性舉措

第6章:顧客狀況與購買行為

- 決策流程

- 主要相關人員和採購標準

- 採購過程中的關鍵相關人員

- 採購標準

- 招募障礙和內部挑戰

- 市場盈利

- 獲利潛力

- 成本動態

第7章 監理環境

- 監管狀態

- 監管機構、政府機構和其他組織

- 全球安全法規

第8章:科技、專利、數位化和人工智慧應用帶來的策略顛覆

- 專利分析

- 技術分析

- 技術/產品藍圖

- 未來應用

- 人工智慧/生成式人工智慧對汽車懸吊市場的影響

- 成功案例和實際應用

- 區域汽車懸吊熱點及本地化動態

- 汽車懸吊部件的供應鏈風險

- 政策塑造暫停採購

- 下一代懸吊系統的成本趨勢

- 電動車(EV)材料清單中汽車懸吊系統的佔有率(2025 年與 2032 年比較)

- 懸吊採購模式:多供應商模式與專屬式設計模式

- 未來車輛上市及對懸吊系統的未來需求

第9章 產業趨勢

- 總體經濟指標

- 生態系分析

- 供應鏈分析

- 定價分析

- 影響客戶業務的趨勢與干擾因素

- 投資和資金籌措方案

- 2025-2026 年主要會議和活動

- 貿易分析

- 案例研究分析

- 美國關稅的影響

第10章 主動懸吊市場(以驅動方式分類)

- 介紹

- 液壓驅動主動懸吊

- 電子控制主動懸吊

- 關鍵產業洞察

第11章 汽車懸吊售後市場(依零件分類)

- 介紹

- 避震器

- 支撐

- 球形關節

- 鋼板彈簧

- 控制臂

- 螺旋彈簧

- 關鍵產業洞察

第12章 汽車懸吊市場(依結構分類)

- 介紹

- 麥花臣式懸臂梁

- 雙橫臂

- 多鏈路

- 扭梁/扭轉梁

- 鋼板彈簧

- 氣壓懸吊

- 關鍵產業洞察

第13章 汽車懸吊市場(依系統分類)

- 介紹

- 被動的

- 半活性

- 積極的

- 關鍵產業洞察

第14章 汽車懸吊市場(依車輛類型分類)

- 介紹

- 搭乘用車

- LCVS

- 追蹤

- 公車

- 關鍵產業洞察

第15章 汽車懸吊原廠配套市場(按零件分類)

- 介紹

- 螺旋彈簧

- 空氣彈簧

- 避震器

- 支撐

- 控制臂

- 橡膠襯套

- 鋼板彈簧

- 連桿穩定器/穩定器

- 球形關節

- 關鍵產業洞察

第16章 電動和混合動力乘用車懸吊市場(按類型和地區分類)

- 介紹

- 電動車 (BEV)、插電式混合動力汽車(PHEV) 和燃料電池車 (FCEV) 的電動和混合動力懸吊市場(按架構分類)

- 按地區(按驅動方式)分類的電動和混合動力懸吊市場

第17章 電動車與混合動力重型商用車懸吊市場(依車輛類型分類)

- 介紹

- 按地區(按車輛類型)分類的電動車和混合動力HCV懸吊市場

- 電動車與混合動力HCV懸吊市場(按結構分類)

- 關鍵產業洞察

第18章非公路用車輛懸吊市場(依應用領域分類)

- 介紹

- 施工機械

- 農用曳引機

- 關鍵產業洞察

第19章 全地形車懸吊市場(按地區分類)

- 介紹

- 全地形車懸吊市場架構類型(按地區分類)

第20章 汽車懸吊市場(按地區分類)

- 介紹

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 其他

- 北美洲

- 美國

- 墨西哥

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 俄羅斯

- 其他

- 其他地區

- 巴西

- 南非

- 伊朗

第21章 競爭情勢

- 介紹

- 主要參與企業的策略/優勢

- 2024年市佔率分析

- 2020-2024年收入分析

- 估值和財務指標

- 品牌/產品對比

- 公司估值矩陣:主要參與企業,2024 年

- 公司估值矩陣:Start-Ups/中小企業,2024 年

- 競爭場景

第22章:公司簡介

- 主要參與企業

- ZF FRIEDRICHSHAFEN AG

- HYUNDAI MOBIS

- TENNECO INC.

- THYSSENKRUPP AG

- DANA LIMITED

- MAGNA INTERNATIONAL INC.

- CONTINENTAL AG

- BWI GROUP

- KYB CORPORATION

- HL MANDO CORPORATION

- MERITOR, INC.

- HENDRICKSON USA, LLC

- 其他公司

- ASTEMO, LTD

- SOGEFI

- EIBACH

- GESTAMP

- SIDEM

- PEDDERS SUSPENSION & BRAKES

- RTS

- YSS SUSPENSION

- BELLTECH

- SKYJACKER SUSPENSIONS

- MULTIMATIC INC

- KING SHOCKS

- FOX FACTORY, INC.

- RANCHO SUSPENSION

- TEIN USA.

- AIR LIFT COMPANY

- MOOG INC.

第23章:市場建議

第24章附錄

The automotive suspension market is expected to grow from USD 39.91 billion in 2025 to USD 42.43 billion by 2032, at a CAGR of 0.9% during the forecast period. Rising global sales of SUVs, electric vehicles, and luxury cars are driving the suspension market.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2021-2032 |

| Base Year | 2024 |

| Forecast Period | 2025-2035 |

| Units Considered | Value (USD Million) |

| Segments | Vehicle Type, Electric Vehicle, System, Architecture, Active Suspension Market, by Actuation, OE Market, by Component, Aftermarket, by Component, Off-highway Market, by Application, ATV Market, by Region, and Region |

| Regions covered | Asia Pacific, Europe, North America, and the Rest of the World |

Additionally, the increasing adoption of air suspension systems in buses and trucks is driving the growth of the advanced suspension systems market.

The air suspension market is expected to continue expanding in 2025. The growth is driven by the increased adoption of luxury buses, premium coaches, heavy-duty trucks, and electric buses, particularly in North America and Europe, where OEMs like Daimler, Volvo, and Scania prioritize ride quality, safety, and load adaptive stability for long-haul operations. Heavy-duty trucks, such as the Volvo FH and Freightliner Cascadia, increasingly integrate electronically controlled air suspensions to protect fragile cargo and optimize handling. Although Asia Pacific adoption is currently lower due to cost sensitivity, premium intercity buses and advanced logistics vehicles in China and India are rapidly adopting these systems, fueled by consumer expectations for comfort and urban freight demands. Innovations in lightweight materials, modular air springs, and integration with electronic stability systems continue to enhance performance and durability, establishing air suspension as a key differentiator in both the passenger and commercial segments globally.

"Passenger cars is the largest market for automotive suspension during the forecast period."

The passenger cars segment remains the largest in the global automotive suspension market, driven by high production volumes, the popularity of SUVs and premium vehicles, and growing demand for ride comfort and handling. Most hatchbacks, sedans, and mid-size SUVs utilize MacPherson strut front suspensions due to their simple design, compact & lightweight structure, cost efficiency, and ease of integration into modular platforms. Whereas high-end SUVs and coupes adopt double wishbone systems for superior handling and stability. The double wishbone suspension is commonly found in high-performance and luxury vehicle segments from brands like BMW, Lexus, and Mercedes-Benz, among others.

At the rear, torsion beams dominate compact and mid-range cars, offering space efficiency and affordability, especially in Asia, Europe, and the RoW markets. In contrast, multilink suspensions are common in premium and performance SUVs in North America, Europe, and luxury Asian markets, providing better comfort and control. Air suspensions, still limited to ultra-premium vehicles, enhance NVH and adaptive handling, with brands like BMW, Mercedes-Benz, Toyota, and Hyundai integrating semi-active and active damping in flagship models. Overall, MacPherson and torsion beam systems lead the mass-market segment, while double wishbone, multilink, and air suspensions define the premium category; this trend is expected to continue in the coming years.

"Growth in electric vehicle sales to drive the demand for suspension systems."

The EV segment is emerging as one of the fastest-growing markets for automotive suspension systems in 2025, driven by accelerating global EV adoption, government incentives, and stricter emissions regulations. Electric passenger vehicles account for the highest demand among alternative powertrain vehicles. For the electric cars segment, compact and mid-size EVs predominantly use MacPherson strut front suspensions with torsion beam or multilink rear setups, similar to the technologies adopted for ICE counterparts. Alternatively, premium EVs and performance models such as the BMW i5, Porsche Taycan Cross Turismo, Lucid Air, and Tesla Model S/X increasingly deploy multilink suspensions to manage battery weight and optimize ride comfort. In electric passenger cars, key suspension technologies include lightweight multilink setups with integrated composite control arms and electronically controlled dampers that optimize ride comfort and handling while minimizing energy consumption. Innovations such as electromagnetic actuators and predictive suspension control, featured in models like the Tesla Model S and Porsche Taycan, differentiate by enhancing dynamic response and battery range. For electric buses, air suspension dominates (>90%) due to its superior passenger comfort and load adaptability, which is achieved by integrating modular air spring systems with electronic height control. Electric trucks combine traditional robust parabolic leaf springs with emerging electrohydraulic and semi-active damping systems to balance heavy payload demands and improve drivetrain efficiency, as exemplified by Volvo's electric FH series. The global shift toward EVs, combined with rising consumer expectations for ride quality and premium driving experiences, is driving robust demand for advanced, weight-optimized suspension architectures across the EV market.

"North America is expected to be the second-largest market during the forecast period."

In North America, passenger cars primarily utilize MacPherson struts at the front and multilink suspensions at the rear to enhance ride quality and handling. This design is evident in models such as the Tesla Model 3 and Cadillac CT4. For pickups and light commercial vehicles (LCVs), double wishbone and multilink front suspensions are preferred for enhanced load management and improved off-road performance, while rear setups typically feature torsion beams and leaf springs. Heavy-duty trucks mainly depend on parabolic and semi-elliptical leaf springs. Similarly, intercity buses also employ these robust mechanical suspensions, although air suspension is typically reserved for premium models. EVs across various segments emphasize the use of lightweight multilink and composite components, along with electronic damping systems, to effectively balance battery weight and optimize efficiency. The North American market is rapidly advancing in adaptive and integrated suspension technologies, presenting opportunities for OEMs and aftermarket providers to develop smart, durable solutions specifically tailored for electrified and commercial vehicle platforms.

In-depth interviews were conducted with CEOs, marketing directors, other innovation and technology directors, and executives from various key organizations operating in this market.

- By Company Type: OEMs - 30% and Automotive Suspension Manufacturers - 70%

- By Designation: C-level - 35%, Director Level - 55%, and Others - 10%

- By Region: North America - 20%, Europe - 45%, Asia Pacific - 30%, and the Rest of the World - 5%

The automotive suspension market is dominated by established players, including Continental AG (Germany), ZF Friedrichshafen AG (Germany), ThyssenKrupp AG (Germany), KYB Corporation (Japan), and Tenneco Inc. (US). These companies actively manufacture and develop new and advanced rubber seals. They have set up R&D facilities and offer best-in-class products to their customers.

Research Coverage

The study segments the automotive suspension market and forecasts the market size based on system (passive suspension, semi-active suspension, and active suspension), active suspension market, actuation (hydraulically actuated and electronically actuated), architecture (MacPherson strut, double wishbone, multilink, twist beam/torsion beam, leaf spring suspension, air suspension), OE market, component (coil spring, air spring, shock dampener, strut, control arm, ball joint, rubber bushing, leaf spring, and sway bar/link stabilizer), aftermarket, component (shock absorber, strut, ball joint, leaf spring, control arm, coil spring), vehicle type (passenger cars, light commercial vehicles, trucks, and buses), electric & hybrid passenger car suspension, architecture (leaf spring suspension, air suspension, double wishbone, MacPherson strut, multilink, twist beam/torsion beam), electric & hybrid trucks and buses suspension, vehicle type (trucks and buses), off-highway application (construction & mining and agricultural tractors), all-terrain vehicles, and region (Asia Pacific, North America, Europe, and the Rest of the World).

Key Benefits of Purchasing this Report

The study provides a comprehensive competitive analysis of key market players, including their company profiles, key insights into product and business offerings, recent developments, and primary market strategies. The report will assist market leaders and new entrants with estimates of revenue figures for the overall automotive suspension market and its subsegments. It helps stakeholders understand the competitive landscape and gain additional insights to better position their businesses and develop effective go-to-market strategies. Additionally, the report provides information on key market drivers, restraints, challenges, and opportunities, enabling stakeholders to stay informed about market dynamics.

The report provides insights into the following points:

- Analysis of key drivers (strong premium SUV & pickup demand and regulatory pressure on vehicle & passenger safety & curb emissions), restraints (high system cost vs. ROI in non-premium segments), opportunities (integration of smart/connected suspensions with ADAS & SDVs and local manufacturing & supply chain opportunities), and challenges (balancing suspension weight and range efficiency in electric vehicles) influencing the growth of the automotive suspension market.

- Product Development/Innovation: Detailed insights on upcoming technologies, R&D activities, and product launches in the automotive suspension market.

- Market Development: Comprehensive information about lucrative markets - the report analyses the automotive suspension across various regions.

- Market Diversification: Exhaustive information about new products, untapped geographies, recent developments, and investments in the automotive suspension market.

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and service offerings of leading players like Continental AG (Germany), ZF Friedrichshafen AG (Germany), ThyssenKrupp AG (Germany), KYB Corporation (Japan), and Tenneco Inc. (US) in the market.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 MARKET SEGMENTATION

- 1.3.2 INCLUSIONS & EXCLUSIONS

- 1.4 YEARS CONSIDERED

- 1.5 CURRENCY CONSIDERED

- 1.6 UNIT CONSIDERED

- 1.7 STAKEHOLDERS

- 1.8 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 List of key secondary sources referred to for estimating vehicle production

- 2.1.1.2 List of key secondary sources referred to for estimating automotive suspension market

- 2.1.1.3 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Primary interviews: Demand and supply sides

- 2.1.2.2 Breakdown of primary interviews

- 2.1.2.3 Primary participants

- 2.1.1 SECONDARY DATA

- 2.2 MARKET SIZE ESTIMATION

- 2.2.1 BOTTOM-UP APPROACH

- 2.2.2 TOP-DOWN APPROACH

- 2.3 DATA TRIANGULATION

- 2.4 FACTOR ANALYSIS

- 2.4.1 DEMAND- AND SUPPLY-SIDE FACTOR ANALYSIS

- 2.5 RESEARCH LIMITATIONS

- 2.6 RESEARCH ASSUMPTIONS & RISK ASSESSMENT

3 EXECUTIVE SUMMARY

- 3.1 KEY INSIGHTS AND MARKET HIGHLIGHTS

- 3.2 KEY MARKET PARTICIPANTS: MAPPING OF STRATEGIC DEVELOPMENTS

- 3.3 DISRUPTIVE TRENDS IN THE AUTOMOTIVE SUSPENSION MARKET

- 3.4 HIGH-GROWTH SEGMENTS

- 3.5 SNAPSHOT: REGIONAL MARKET SIZE, GROWTH RATE, AND FORECAST

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN AUTOMOTIVE SUSPENSION MARKET

- 4.2 AUTOMOTIVE SUSPENSION MARKET, BY SYSTEM

- 4.3 AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE

- 4.4 AUTOMOTIVE SUSPENSION MARKET, BY VEHICLE TYPE

- 4.5 AUTOMOTIVE SUSPENSION OE MARKET, BY COMPONENT

- 4.6 AUTOMOTIVE SUSPENSION AFTERMARKET, BY COMPONENT

- 4.7 ELECTRIC & HYBRID PASSENGER CAR SUSPENSION MARKET, BY ARCHITECTURE

- 4.8 ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE

- 4.9 ACTIVE SUSPENSION MARKET, BY ACTUATION

- 4.10 OFF-HIGHWAY SUSPENSION MARKET, BY APPLICATION

- 4.11 ALL-TERRAIN VEHICLE SUSPENSION MARKET, BY REGION

- 4.12 AUTOMOTIVE SUSPENSION MARKET, BY REGION

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Rising demand for premium SUVs and pickup trucks

- 5.2.1.2 Regulatory pressure on vehicle and passenger safety and emissions

- 5.2.2 RESTRAINTS

- 5.2.2.1 High cost of suspension systems

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Integration of smart/connected suspension systems with ADAS and SDVs

- 5.2.3.2 Local manufacturing and supply chain opportunities

- 5.2.4 CHALLENGES

- 5.2.4.1 Balancing suspension weight and range efficiency in electric vehicles

- 5.2.1 DRIVERS

- 5.3 UNMET NEEDS AND WHITE SPACES

- 5.4 INTERCONNECTED MARKETS AND CROSS-SECTOR OPPORTUNITIES

- 5.5 STRATEGIC MOVES BY TIER 1/2/3 PLAYERS

6 CUSTOMER LANDSCAPE & BUYER BEHAVIOR

- 6.1 DECISION-MAKING PROCESS

- 6.2 KEY STAKEHOLDERS AND BUYING EVALUATION CRITERIA

- 6.2.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 6.2.2 BUYING CRITERIA

- 6.3 ADOPTION BARRIERS & INTERNAL CHALLENGES

- 6.4 MARKET PROFITABILITY

- 6.4.1 REVENUE POTENTIAL

- 6.4.2 COST DYNAMICS

7 REGULATORY LANDSCAPE

- 7.1 REGULATORY LANDSCAPE

- 7.1.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 7.1.2 GLOBAL SAFETY REGULATIONS

8 STRATEGIC DISRUPTION THROUGH TECHNOLOGY, PATENTS, DIGITAL, AND AI ADOPTION

- 8.1 PATENT ANALYSIS

- 8.1.1 INTRODUCTION

- 8.1.1.1 Methodology

- 8.1.1.2 Document type

- 8.1.1.3 Insights

- 8.1.1.4 Legal status of patents

- 8.1.1.5 Jurisdiction analysis

- 8.1.1.6 Top applicants

- 8.1.1.7 List of patents

- 8.1.1 INTRODUCTION

- 8.2 TECHNOLOGY ANALYSIS

- 8.2.1 KEY TECHNOLOGIES

- 8.2.1.1 Active and semi-active suspension systems

- 8.2.1.2 In-wheel suspension technology

- 8.2.2 COMPLEMENTARY TECHNOLOGIES

- 8.2.2.1 ADAS & sensor fusion integration

- 8.2.3 ADJACENT TECHNOLOGIES

- 8.2.3.1 Lightweight materials and additive manufacturing

- 8.2.3.2 Regenerative suspension systems

- 8.2.1 KEY TECHNOLOGIES

- 8.3 TECHNOLOGY/PRODUCT ROADMAP

- 8.4 FUTURE APPLICATIONS

- 8.5 IMPACT OF AI/GEN AI ON AUTOMOTIVE SUSPENSION MARKET

- 8.5.1 TOP USE CASES OF AI IMPLEMENTATION AND MARKET POTENTIAL

- 8.5.2 BEST PRACTICES IN AUTOMOTIVE SUSPENSION DEVELOPMENT

- 8.5.3 AUTOMOTIVE SUSPENSION MARKET: CASE STUDIES RELATED TO IMPLEMENTATION OF GEN AI

- 8.5.4 INTERCONNECTED ADJACENT MARKET ECOSYSTEM AND IMPACT ON MARKET PLAYERS

- 8.5.5 CLIENTS' READINESS TO ADOPT GENERATIVE AI IN AUTOMOTIVE SUSPENSION MARKET

- 8.6 SUCCESS STORIES AND REAL-WORLD APPLICATIONS

- 8.6.1 ZF FRIEDRICHSHAFEN: AI-DRIVEN ADAPTIVE DAMPER CALIBRATION

- 8.6.2 KYB CORPORATION: PREDICTIVE MAINTENANCE FOR ELECTRONIC DAMPERS

- 8.6.3 HITACHI ASTEMO: ELECTROHYDRAULIC ACTUATOR OPTIMIZATION

- 8.6.4 CONTINENTAL: SMART AIR SPRING WITH SENSOR INTEGRATION

- 8.7 REGIONAL AUTOMOTIVE SUSPENSION HOTSPOTS AND LOCALIZATION DYNAMICS

- 8.8 SUPPLY CHAIN RISKS IN AUTOMOTIVE SUSPENSION COMPONENTS

- 8.9 POLICY DRIVES SHAPING SUSPENSION SOURCING

- 8.10 COST TRAJECTORY FOR NEXT-GEN SUSPENSION SYSTEMS

- 8.11 SHARE OF AUTOMOTIVE SUSPENSION SYSTEMS IN BILL OF MATERIALS FOR EVS, 2025 VS. 2032

- 8.12 SUSPENSION SOURCING MODELS: MULTI-SUPPLIER VS. CAPTIVE DESIGN

- 8.13 UPCOMING VEHICLE LAUNCHES AND FUTURE DEMAND FOR SUSPENSION SYSTEMS

9 INDUSTRY TRENDS

- 9.1 MACROECONOMIC INDICATORS

- 9.1.1 INTRODUCTION

- 9.1.2 GDP TRENDS AND FORECAST

- 9.1.3 TRENDS IN GLOBAL ELECTRIC VEHICLE INDUSTRY

- 9.1.4 TRENDS IN GLOBAL AUTOMOTIVE & TRANSPORTATION INDUSTRY

- 9.2 ECOSYSTEM ANALYSIS

- 9.2.1 RAW MATERIAL SUPPLIERS

- 9.2.2 COMPONENT MANUFACTURERS

- 9.2.3 SYSTEM INTEGRATORS/SUSPENSION MANUFACTURERS

- 9.2.4 OEM ASSEMBLY

- 9.2.5 AFTERMARKET AND REPLACEMENT PART PROVIDERS

- 9.3 SUPPLY CHAIN ANALYSIS

- 9.4 PRICING ANALYSIS

- 9.4.1 AVERAGE SELLING PRICE OF LIGHT-DUTY VEHICLE SUSPENSION SYSTEMS, BY REGION

- 9.4.2 AVERAGE SELLING PRICE OF TRUCK SUSPENSION ARCHITECTURE TYPES, BY REGION

- 9.4.3 AVERAGE SELLING PRICE OF AUTOMOTIVE SUSPENSION OE COMPONENTS, BY REGION

- 9.5 TRENDS AND DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 9.6 INVESTMENT AND FUNDING SCENARIO

- 9.7 KEY CONFERENCES & EVENTS, 2025-2026

- 9.8 TRADE ANALYSIS

- 9.8.1 EXPORT SCENARIO

- 9.8.2 IMPORT SCENARIO

- 9.8.3 TRADE RESTRICTIONS

- 9.8.4 US-CHINA EXPORT BANS

- 9.8.5 EU SUBSIDY RACE

- 9.8.6 IMPACT OF LOCALIZATION POLICIES ON SOURCING

- 9.8.7 CXO PRIORITIES

- 9.9 CASE STUDY ANALYSIS

- 9.9.1 LINK AND VOLVO ENGINEERING TEAMS COLLABORATED TO DEVELOP PROPRIETARY APPLICATION AND VALIDATE FUEL SAVINGS

- 9.9.2 EMPLOYEES OF HENDRICKSON USA, L.L.C. IMPORTED CREO CAD GEOMETRY OF SUSPENSION SYSTEM

- 9.9.3 CONTINENTAL AG DEVELOPED HITEMP AIR SPRINGS, CAPABLE OF WITHSTANDING TEMPERATURES

- 9.10 IMPACT OF US TARIFF

- 9.10.1 INTRODUCTION

- 9.10.2 KEY TARIFF RATES

- 9.10.3 PRICE IMPACT ANALYSIS

- 9.10.4 IMPACT ON REGION/COUNTRY

- 9.10.5 IMPACT ON END-USE INDUSTRIES

10 ACTIVE SUSPENSION MARKET, BY ACTUATION

- 10.1 INTRODUCTION

- 10.2 HYDRAULICALLY ACTUATED ACTIVE SUSPENSION

- 10.2.1 HYDRAULIC SUSPENSION SYSTEMS REPLACE CONVENTIONAL COIL SPRINGS WITH AIR SPRINGS

- 10.3 ELECTRONICALLY ACTUATED ACTIVE SUSPENSION

- 10.3.1 TECHNOLOGICAL ADVANCEMENTS DRIVING NEED FOR ELECTRONICALLY ACTUATED ACTIVE SUSPENSION SYSTEM

- 10.4 KEY INDUSTRY INSIGHTS

11 AUTOMOTIVE SUSPENSION AFTERMARKET, BY COMPONENT

- 11.1 INTRODUCTION

- 11.2 SHOCK ABSORBERS

- 11.2.1 SHOCK ABSORBERS ARE AMONG MOST FREQUENTLY REPLACED SUSPENSION COMPONENTS DUE TO NATURAL WEAR FROM CONTINUOUS DAMPING CYCLES

- 11.3 STRUTS

- 11.3.1 GROWING VEHICLE SALES TO BOOST DEMAND FOR STRUTS

- 11.4 BALL JOINTS

- 11.4.1 BALL JOINTS ARE UNIVERSALLY USED IN FRONT SUSPENSION

- 11.5 LEAF SPRINGS

- 11.5.1 ABILITY OF LEAF SPRINGS TO HANDLE HEAVY LOAD TO DRIVE THEIR DEMAND

- 11.6 CONTROL ARMS

- 11.6.1 ALUMINUM AND HYBRID COMPOSITE CONTROL ARMS TO GAIN POPULARITY AS LIGHTWEIGHT REPLACEMENTS COMPATIBLE WITH OE SPECIFICATIONS

- 11.7 COIL SPRINGS

- 11.7.1 COIL SPRINGS ALLOW MAXIMUM RANGE OF MOVEMENT IN SUSPENSION SYSTEM

- 11.8 KEY INDUSTRY INSIGHTS

12 AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE

- 12.1 INTRODUCTION

- 12.2 MACPHERSON STRUT

- 12.2.1 COST-EFFECTIVENESS AND SIMPLE DESIGN MAKE MACPHERSON STRUT SUITABLE FOR PASSENGER CARS

- 12.3 DOUBLE WISHBONE

- 12.3.1 COMPLEX DESIGN AND HIGH COST MAKE DOUBLE WISHBONE SUITABLE FOR PREMIUM VEHICLES

- 12.4 MULTILINK

- 12.4.1 MULTILINK SUSPENSION PROVIDES BETTER RIDE QUALITY AND HANDLING

- 12.5 TWIST BEAM/TORSION BEAM

- 12.5.1 DEMAND FOR TWIST BEAM/TORSION BEAM SUSPENSION IS LIMITED TO ECONOMIC CARS

- 12.6 LEAF SPRING

- 12.6.1 LEAF SPRINGS ARE PREFERRED IN HEAVY TRUCKS DUE TO THEIR HIGH LOAD-CARRYING CAPACITY

- 12.7 AIR SUSPENSION

- 12.7.1 INCREASED DEMAND FOR CABIN COMFORT, BETTER CONTROL, AND STABILITY TO DRIVE MARKET

- 12.8 KEY INDUSTRY INSIGHTS

13 AUTOMOTIVE SUSPENSION MARKET, BY SYSTEM

- 13.1 INTRODUCTION

- 13.2 PASSIVE

- 13.2.1 MACPHERSON STRUT AND DOUBLE WISHBONE ARE MOST COMMONLY USED PASSIVE SYSTEMS IN PASSENGER CARS

- 13.3 SEMI-ACTIVE

- 13.3.1 INCREASING DEMAND FOR HIGH-PERFORMANCE CARS TO DRIVE MARKET FOR SEMI-ACTIVE SYSTEMS

- 13.4 ACTIVE

- 13.4.1 INCREASING DEMAND FOR ACTIVE AIR SUSPENSION SYSTEM IN BUSES TO DRIVE MARKET

- 13.5 KEY INDUSTRY INSIGHTS

14 AUTOMOTIVE SUSPENSION MARKET, BY VEHICLE TYPE

- 14.1 INTRODUCTION

- 14.2 PASSENGER CARS

- 14.2.1 USE OF MACPHERSON STRUT IN PASSENGER CARS TO DRIVE MARKET

- 14.3 LCVS

- 14.3.1 DEMAND FOR MULTILINK ARCHITECTURE TO DRIVE MARKET FOR LCV SUSPENSION

- 14.4 TRUCKS

- 14.4.1 INCREASED USE OF TRUCKS IN MAJOR REGIONS TO DRIVE NEED FOR LEAF SPRING SUSPENSION

- 14.5 BUSES

- 14.5.1 AIR SUSPENSION OFFERS MAXIMUM COMFORT TO PASSENGERS

- 14.6 KEY INDUSTRY INSIGHTS

15 AUTOMOTIVE SUSPENSION OE MARKET, BY COMPONENT

- 15.1 INTRODUCTION

- 15.2 COIL SPRINGS

- 15.3 AIR SPRINGS

- 15.4 SHOCK ABSORBERS

- 15.5 STRUTS

- 15.6 CONTROL ARMS

- 15.7 RUBBER BUSHINGS

- 15.8 LEAF SPRINGS

- 15.9 LINK STABILIZERS/SWAY BARS

- 15.10 BALL JOINTS

- 15.11 KEY INDUSTRY INSIGHTS

16 ELECTRIC & HYBRID PASSENGER CAR SUSPENSION MARKET, BY ARCHITECTURE & REGION

- 16.1 INTRODUCTION

- 16.2 ELECTRIC & HYBRID SUSPENSION MARKET FOR BEVS, PHEVS, AND FCEVS, BY ARCHITECTURE

- 16.2.1 BATTERY ELECTRIC VEHICLES (BEVS), BY ARCHITECTURE

- 16.2.1.1 Active suspension systems to enhance driving performance of BEVs

- 16.2.2 PLUG-IN HYBRID ELECTRIC VEHICLES (PHEVS), BY ARCHITECTURE

- 16.2.2.1 Demand for maximum comfort and safety in PHEVs to drive market for advanced suspension systems

- 16.2.3 FUEL CELL ELECTRIC VEHICLES (FCEVS), BY ARCHITECTURE

- 16.2.3.1 Limited demand for FCEVs due to infrastructure challenges

- 16.2.1 BATTERY ELECTRIC VEHICLES (BEVS), BY ARCHITECTURE

- 16.3 REGIONAL ELECTRIC & HYBRID SUSPENSION MARKET, BY PROPULSION

- 16.3.1 ASIA PACIFIC, BY PROPULSION

- 16.3.1.1 Advancements in battery technology and government support to drive BEV sales

- 16.3.2 EUROPE, BY PROPULSION

- 16.3.2.1 Demand for emission-free vehicles to drive electric & hybrid vehicle suspension market

- 16.3.3 NORTH AMERICA, BY PROPULSION

- 16.3.3.1 Technological advancements to fuel demand for advanced suspension systems

- 16.3.4 INDUSTRY INSIGHTS

- 16.3.1 ASIA PACIFIC, BY PROPULSION

17 ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE

- 17.1 INTRODUCTION

- 17.2 REGIONAL ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE

- 17.2.1 ASIA PACIFIC, BY VEHICLE TYPE

- 17.2.1.1 Need to scale zero-emission bus deployment in urban mega-cities through policy and charging integration to drive market

- 17.2.2 EUROPE, BY VEHICLE TYPE

- 17.2.2.1 Need to expand zero-emission urban freight and public transit zones to drive fleet conversion

- 17.2.3 NORTH AMERICA, BY VEHICLE TYPE

- 17.2.3.1 Need for leveraging federal incentives to scale zero-emission freight corridors and transit fleets to drive market

- 17.2.1 ASIA PACIFIC, BY VEHICLE TYPE

- 17.3 ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY ARCHITECTURE

- 17.3.1 ELECTRIC & HYBRID TRUCKS

- 17.3.2 ELECTRIC & HYBRID BUSES

- 17.4 KEY INDUSTRY INSIGHTS

18 OFF-HIGHWAY VEHICLE SUSPENSION MARKET, BY APPLICATION

- 18.1 INTRODUCTION

- 18.2 CONSTRUCTION EQUIPMENT

- 18.2.1 INCREASED DEMAND FOR OPERATOR COMFORT AND EQUIPMENT STABILITY TO DRIVE MARKET

- 18.3 AGRICULTURAL TRACTORS

- 18.3.1 RISING FARM MECHANIZATION ACTIVITIES TO DRIVE DEMAND FOR SUSPENSION IN TRACTORS

- 18.4 KEY INDUSTRY INSIGHTS

19 ALL-TERRAIN VEHICLE SUSPENSION MARKET, BY REGION

- 19.1 INTRODUCTION

- 19.2 ALL-TERRAIN VEHICLE SUSPENSION MARKET ARCHITECTURE TYPES, BY REGION

- 19.2.1 MACPHERSON STRUT

- 19.2.1.1 Growing penetration of ATVs in agricultural practices and sports activities to drive market

- 19.2.2 DOUBLE WISHBONE

- 19.2.2.1 Double wishbone suspension systems offer maximum comfort while traveling

- 19.2.3 KEY INDUSTRY INSIGHTS

- 19.2.1 MACPHERSON STRUT

20 AUTOMOTIVE SUSPENSION MARKET, BY REGION

- 20.1 INTRODUCTION

- 20.2 ASIA PACIFIC

- 20.2.1 CHINA

- 20.2.1.1 Demand for MacPherson strut architecture to drive growth

- 20.2.2 INDIA

- 20.2.2.1 Growing vehicle production and expanding domestic demand for comfort and safety to drive market

- 20.2.3 JAPAN

- 20.2.3.1 Need for electrification and premium vehicle development to drive market

- 20.2.4 SOUTH KOREA

- 20.2.4.1 Strong push toward independent suspension architecture to drive market

- 20.2.5 REST OF ASIA PACIFIC

- 20.2.1 CHINA

- 20.3 NORTH AMERICA

- 20.3.1 US

- 20.3.1.1 Preference for SUVs and light trucks to boost growth

- 20.3.2 MEXICO

- 20.3.2.1 Strong vehicle production and export base to lead market

- 20.3.3 CANADA

- 20.3.3.1 Increasing adoption of advanced suspension technologies to boost growth

- 20.3.1 US

- 20.4 EUROPE

- 20.4.1 GERMANY

- 20.4.1.1 Rapid technological advancements to drive market

- 20.4.2 UK

- 20.4.2.1 Strong base of premium and performance vehicle manufacturers to boost market

- 20.4.3 FRANCE

- 20.4.3.1 Notable transition toward electrified and comfort-oriented vehicle platforms to boost growth

- 20.4.4 SPAIN

- 20.4.4.1 Increasing production of compact cars, SUVs, and light commercial vehicles to drive market

- 20.4.5 ITALY

- 20.4.5.1 Increased demand for air suspension architecture in special application trucks to drive market

- 20.4.6 RUSSIA

- 20.4.6.1 Rise in production of SUVs, LCVs, and off-road vehicles to boost market

- 20.4.7 REST OF EUROPE

- 20.4.1 GERMANY

- 20.5 REST OF THE WORLD (ROW)

- 20.5.1 BRAZIL

- 20.5.1.1 Well-established automotive manufacturing base and strong domestic demand to drive market

- 20.5.2 SOUTH AFRICA

- 20.5.2.1 Country's expanding and aging vehicle fleet to drive market

- 20.5.3 IRAN

- 20.5.1 BRAZIL

21 COMPETITIVE LANDSCAPE

- 21.1 INTRODUCTION

- 21.2 KEY PLAYER STRATEGIES/RIGHT TO WIN

- 21.3 MARKET SHARE ANALYSIS, 2024

- 21.4 REVENUE ANALYSIS, 2020-2024

- 21.5 COMPANY VALUATION AND FINANCIAL METRICS

- 21.6 BRAND/PRODUCT COMPARISON

- 21.7 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 21.7.1 STARS

- 21.7.2 EMERGING LEADERS

- 21.7.3 PERVASIVE PLAYERS

- 21.7.4 PARTICIPANTS

- 21.7.5 COMPANY FOOTPRINT

- 21.7.5.1 Company footprint

- 21.7.5.2 Region footprint

- 21.7.5.3 System footprint

- 21.7.5.4 Actuation footprint

- 21.7.5.5 Vehicle type footprint

- 21.8 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 21.8.1 PROGRESSIVE COMPANIES

- 21.8.2 RESPONSIVE COMPANIES

- 21.8.3 DYNAMIC COMPANIES

- 21.8.4 STARTING BLOCKS

- 21.8.5 COMPETITIVE BENCHMARKING

- 21.8.5.1 List of startups/SMEs

- 21.8.5.2 Competitive benchmarking of SMEs

- 21.9 COMPETITIVE SCENARIO

- 21.9.1 PRODUCT LAUNCHES

- 21.9.2 DEALS

- 21.9.3 EXPANSIONS

- 21.9.4 OTHER DEVELOPMENTS

22 COMPANY PROFILES

- 22.1 KEY PLAYERS

- 22.1.1 ZF FRIEDRICHSHAFEN AG

- 22.1.1.1 Business overview

- 22.1.1.2 Products offered

- 22.1.1.3 Recent developments

- 22.1.1.3.1 Product launches/developments

- 22.1.1.3.2 Expansions

- 22.1.1.4 MnM view

- 22.1.1.4.1 Key strengths

- 22.1.1.4.2 Strategic choices

- 22.1.1.4.3 Weaknesses and competitive threats

- 22.1.2 HYUNDAI MOBIS

- 22.1.2.1 Business overview

- 22.1.2.2 Products offered

- 22.1.2.3 Recent developments

- 22.1.2.3.1 Product launches/developments

- 22.1.2.4 MnM view

- 22.1.2.4.1 Key strengths

- 22.1.2.4.2 Weaknesses and competitive threats

- 22.1.2.4.3 Strategic choices

- 22.1.3 TENNECO INC.

- 22.1.3.1 Business overview

- 22.1.3.2 Products offered

- 22.1.3.3 Recent developments

- 22.1.3.3.1 Product launches/developments

- 22.1.3.4 MnM view

- 22.1.3.4.1 Key strengths

- 22.1.3.4.2 Weaknesses and competitive threats

- 22.1.3.4.3 Strategic choices

- 22.1.4 THYSSENKRUPP AG

- 22.1.4.1 Business overview

- 22.1.4.2 Products offered

- 22.1.4.3 Recent developments

- 22.1.4.3.1 Deals

- 22.1.4.4 MnM view

- 22.1.4.4.1 Key strengths

- 22.1.4.4.2 Weaknesses and competitive threats

- 22.1.4.4.3 Strategic choices

- 22.1.5 DANA LIMITED

- 22.1.5.1 Business overview

- 22.1.5.2 Products offered

- 22.1.5.3 Recent developments

- 22.1.5.3.1 Product launches/developments

- 22.1.5.4 MnM view

- 22.1.5.4.1 Key strengths

- 22.1.5.4.2 Weaknesses and competitive threats

- 22.1.5.4.3 Strategic choices

- 22.1.6 MAGNA INTERNATIONAL INC.

- 22.1.6.1 Business overview

- 22.1.6.2 Products offered

- 22.1.6.3 MnM view

- 22.1.6.3.1 Key strengths

- 22.1.6.3.2 Strategic choices

- 22.1.6.3.3 Weaknesses and competitive threats

- 22.1.7 CONTINENTAL AG

- 22.1.7.1 Business overview

- 22.1.7.2 Products offered

- 22.1.8 BWI GROUP

- 22.1.8.1 Business overview

- 22.1.8.2 Products offered

- 22.1.8.3 Recent developments

- 22.1.8.3.1 Expansions

- 22.1.8.3.2 Deals

- 22.1.9 KYB CORPORATION

- 22.1.9.1 Business overview

- 22.1.9.2 Products offered

- 22.1.9.3 MnM view

- 22.1.9.3.1 Key strengths

- 22.1.9.3.2 Strategic choices

- 22.1.9.3.3 Weaknesses and competitive threats

- 22.1.10 HL MANDO CORPORATION

- 22.1.10.1 Business overview

- 22.1.10.2 Products offered

- 22.1.11 MERITOR, INC.

- 22.1.11.1 Business overview

- 22.1.11.2 Products offered

- 22.1.12 HENDRICKSON USA, L.L.C.

- 22.1.12.1 Business overview

- 22.1.12.2 Products offered

- 22.1.12.3 Recent developments

- 22.1.12.3.1 Product launches/developments

- 22.1.12.3.2 Deals

- 22.1.1 ZF FRIEDRICHSHAFEN AG

- 22.2 OTHER KEY PLAYERS

- 22.2.1 ASTEMO, LTD

- 22.2.2 SOGEFI

- 22.2.3 EIBACH

- 22.2.4 GESTAMP

- 22.2.5 SIDEM

- 22.2.6 PEDDERS SUSPENSION & BRAKES

- 22.2.7 RTS

- 22.2.8 YSS SUSPENSION

- 22.2.9 BELLTECH

- 22.2.10 SKYJACKER SUSPENSIONS

- 22.2.11 MULTIMATIC INC

- 22.2.12 KING SHOCKS

- 22.2.13 FOX FACTORY, INC.

- 22.2.14 RANCHO SUSPENSION

- 22.2.15 TEIN USA.

- 22.2.16 AIR LIFT COMPANY

- 22.2.17 MOOG INC.

23 RECOMMENDATIONS BY MARKETSANDMARKETS

- 23.1 ASIA PACIFIC TO LEAD AUTOMOTIVE SUSPENSION MARKET

- 23.2 GROWING DEMAND FOR AIR SUSPENSION SYSTEMS: KEY FOCUS AREAS

- 23.3 CONCLUSION

24 APPENDIX

- 24.1 INSIGHTS FROM INDUSTRY EXPERTS

- 24.2 DISCUSSION GUIDE

- 24.3 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 24.4 CUSTOMIZATION OPTIONS

- 24.4.1 AUTOMOTIVE SUSPENSION MARKET, BY ICE VEHICLE TYPE (COUNTRY LEVEL)

- 24.4.1.1 Passenger cars

- 24.4.1.1.1 Front suspension, by architecture

- 24.4.1.1.1.1 Macpherson strut

- 24.4.1.1.1.2 Double wishbone

- 24.4.1.1.1.3 Multilink

- 24.4.1.1.1.4 Twist beam/torsion beam

- 24.4.1.1.1.5 Air suspension

- 24.4.1.1.2 Rear suspension, by architecture

- 24.4.1.1.2.1 Macpherson strut

- 24.4.1.1.2.2 Double wishbone

- 24.4.1.1.2.3 Multilink

- 24.4.1.1.2.4 Twist beam/torsion beam

- 24.4.1.1.2.5 Air suspension

- 24.4.1.1.1 Front suspension, by architecture

- 24.4.1.2 LCVs

- 24.4.1.2.1 Front suspension, by architecture

- 24.4.1.2.1.1 Macpherson strut

- 24.4.1.2.1.2 Double wishbone

- 24.4.1.2.1.3 Multilink

- 24.4.1.2.1.4 Twist beam/torsion beam

- 24.4.1.2.1.5 Leaf spring

- 24.4.1.2.1.6 Air suspension

- 24.4.1.2.2 Rear suspension, by architecture

- 24.4.1.2.2.1 Macpherson strut

- 24.4.1.2.2.2 Double wishbone

- 24.4.1.2.2.3 Multilink

- 24.4.1.2.2.4 Twist beam/torsion beam

- 24.4.1.2.2.5 Leaf spring

- 24.4.1.2.2.6 Air suspension

- 24.4.1.2.1 Front suspension, by architecture

- 24.4.1.3 HCVs

- 24.4.1.1 Passenger cars

- 24.4.2 PASSIVE, SEMI-ACTIVE, AND ACTIVE SUSPENSION MARKET, BY ARCHITECTURE (COUNTRY LEVEL)

- 24.4.2.1 Macpherson strut

- 24.4.2.2 Double wishbone

- 24.4.2.3 Multilink

- 24.4.2.4 Twist beam/torsion beam

- 24.4.2.5 Leaf spring suspension

- 24.4.2.6 Air suspension

- 24.4.3 AUTOMOTIVE SUSPENSION MARKET, ELECTRIC & HYBRID VEHICLE (REGIONAL LEVEL), BY PROPULSION

- 24.4.3.1 BEV

- 24.4.3.1.1 Front suspension, by architecture

- 24.4.3.1.2 Rear suspension, by architecture

- 24.4.3.2 PHEV

- 24.4.3.2.1 Front suspension, by architecture

- 24.4.3.2.2 Rear suspension, by architecture

- 24.4.3.3 FCEV

- 24.4.3.3.1 Front suspension, by architecture

- 24.4.3.3.2 Rear suspension, by architecture

- 24.4.3.1 BEV

- 24.4.4 OFF-HIGHWAY SUSPENSION MARKET, BY APPLICATION (REGIONAL LEVEL)

- 24.4.4.1 Construction equipment

- 24.4.4.1.1 Mechanical

- 24.4.4.1.2 Pneumatic

- 24.4.4.1.3 Hydropneumatics

- 24.4.4.2 Agricultural tractors

- 24.4.4.2.1 Mechanical

- 24.4.4.2.2 Pneumatic

- 24.4.4.2.3 Hydropneumatics

- 24.4.4.1 Construction equipment

- 24.4.1 AUTOMOTIVE SUSPENSION MARKET, BY ICE VEHICLE TYPE (COUNTRY LEVEL)

- 24.5 RELATED REPORTS

- 24.6 AUTHOR DETAILS

List of Tables

- TABLE 1 USD EXCHANGE RATES, BY COUNTRY, 2019-2024

- TABLE 2 RESEARCH ASSUMPTIONS: ARCHITECTURE

- TABLE 3 NORTH AMERICA: REGULATIONS & STANDARDS FOR AUTOMOTIVE SUSPENSION SYSTEMS AND THEIR IMPACT, 2012-2027

- TABLE 4 STRATEGIC MOVES BY KEY PLAYERS

- TABLE 5 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS, BY VEHICLE TYPE

- TABLE 6 KEY BUYING CRITERIA, BY KEY ARCHITECTURE

- TABLE 7 PROFITABILITY OF AUTOMOTIVE SUSPENSION COMPONENTS

- TABLE 8 NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 9 EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 10 ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 11 SAFETY REGULATIONS, BY COUNTRY/REGION

- TABLE 12 AUTOMOTIVE SUSPENSION MARKET: TOTAL NUMBER OF PATENTS, JANUARY 2015-DECEMBER 2024

- TABLE 13 IMPORTANT PATENT REGISTRATIONS RELATED TO AUTOMOTIVE SUSPENSION MARKET

- TABLE 14 AUTOMOTIVE SUSPENSION MARKET: CURRENT STATUS AND SHORT-/MID-/ LONG-TERM PROSPECTS OF KEY TECHNOLOGIES

- TABLE 15 FUTURE APPLICATION AREAS FOR AUTOMOTIVE SUSPENSION

- TABLE 16 TOP USE CASES OF AI IMPLEMENTATION AND MARKET POTENTIAL

- TABLE 17 COMPANIES IMPLEMENTING BEST PRACTICES IN AUTOMOTIVE SUSPENSION DEVELOPMENT

- TABLE 18 AUTOMOTIVE SUSPENSION MARKET: CASE STUDIES RELATED TO IMPLEMENTATION OF GEN AI

- TABLE 19 INTERCONNECTED ADJACENT MARKET ECOSYSTEM AND IMPACT ON MARKET PLAYERS

- TABLE 20 REGIONAL LOCALIZATION DYNAMICS FOR AUTOMOTIVE SUSPENSION PRODUCTION

- TABLE 21 EXISTING AND UPCOMING PLANTS FOR AUTOMOTIVE SUSPENSION

- TABLE 22 AUTOMOTIVE SUSPENSION MARKET: RISKS AND STRATEGIC RESPONSES

- TABLE 23 KEY POLICIES AFFECTING AUTOMOTIVE SUSPENSION MARKET, BY KEY ECONOMY

- TABLE 24 PROJECTED GROWTH OF SHARE OF SUSPENSION SYSTEMS IN BILL OF MATERIALS FOR EVS, 2025 VS. 2032

- TABLE 25 ANALYSIS OF SUSPENSION SOURCING MODELS

- TABLE 26 VEHICLE LAUNCH PIPELINE AND SUSPENSION DEMAND

- TABLE 27 GDP PERCENTAGE CHANGE, BY KEY COUNTRY, 2021-2030

- TABLE 28 ROLE OF COMPANIES IN MARKET ECOSYSTEM

- TABLE 29 AVERAGE SELLING PRICE OF LIGHT-DUTY VEHICLE SUSPENSION SYSTEMS, BY REGION, 2024 (USD/UNIT)

- TABLE 30 AVERAGE SELLING PRICE OF TRUCK SUSPENSION ARCHITECTURE TYPES, BY REGION, 2024 (USD/UNIT)

- TABLE 31 AVERAGE SELLING PRICE OF AUTOMOTIVE SUSPENSION OE COMPONENTS, BY REGION, 2024 (US/UNIT)

- TABLE 32 AUTOMOTIVE SUSPENSION MARKET: KEY CONFERENCES & EVENTS, 2025-2026

- TABLE 33 US: EXPORT DATA FOR HS CODE 870880-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 34 CHINA: EXPORT DATA FOR HS CODE 870880-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 35 GERMANY: EXPORT DATA FOR HS CODE 870880-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 36 MEXICO: EXPORT DATA FOR HS CODE 870880-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 37 US: IMPORT DATA FOR HS CODE 870880-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 38 CANADA: IMPORT DATA FOR HS CODE 870880-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 39 GERMANY: IMPORT DATA FOR HS CODE 870880-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 40 CHINA: IMPORT DATA FOR HS CODE 870880-COMPLIANT PRODUCTS, BY COUNTRY, 2020-2024 (USD THOUSAND)

- TABLE 41 TYPES OF TRADE RESTRICTIONS AND SHORT-TERM EFFECT ON AUTOMOTIVE SUSPENSION SUPPLY

- TABLE 42 US-CHINA EXPORT BANS: TIMELINE AND EFFECT ON AUTOMOTIVE SEMICONDUCTORS

- TABLE 43 MAJOR EU SUBSIDIES AND EXPECTED EFFECT ON AUTOMOTIVE SUPPLY CHAIN

- TABLE 44 IMPACT OF LOCALIZATION POLICIES ON OEM SOURCING, BY AUTOMOTIVE SUSPENSION COMPONENT

- TABLE 45 TARIFF RATES FOR SEMICONDUCTOR-RELATED GOODS, 2025

- TABLE 46 EXPECTED CHANGE IN PRICES AND LIKELY IMPACT

- TABLE 47 REGIONAL TARIFF IMPACT, 2025

- TABLE 48 KEY PRODUCT-RELATED TARIFF FOR END USE INDUSTRIES

- TABLE 49 HYDRAULICALLY ACTUATED VS. ELECTRONICALLY ACTUATED SUSPENSION SYSTEMS

- TABLE 50 ACTIVE SUSPENSION MARKET, BY ACTUATION, 2021-2024 (THOUSAND UNITS)

- TABLE 51 ACTIVE SUSPENSION MARKET, BY ACTUATION, 2025-2032 (THOUSAND UNITS)

- TABLE 52 ACTIVE SUSPENSION MARKET, BY ACTUATION, 2021-2024 (USD MILLION)

- TABLE 53 ACTIVE SUSPENSION MARKET, BY ACTUATION, 2025-2032 (USD MILLION)

- TABLE 54 HYDRAULICALLY ACTUATED ACTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 55 HYDRAULICALLY ACTUATED ACTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 56 HYDRAULICALLY ACTUATED ACTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 57 HYDRAULICALLY ACTUATED ACTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 58 ELECTRONICALLY ACTUATED ACTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 59 ELECTRONICALLY ACTUATED ACTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 60 ELECTRONICALLY ACTUATED ACTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 61 ELECTRONICALLY ACTUATED ACTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 62 AUTOMOTIVE SUSPENSION AFTERMARKET, BY COMPONENT, 2021-2024 (MILLION UNITS)

- TABLE 63 AUTOMOTIVE SUSPENSION AFTERMARKET, BY COMPONENT, 2025-2032 (MILLION UNITS)

- TABLE 64 AUTOMOTIVE SUSPENSION AFTERMARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 65 AUTOMOTIVE SUSPENSION AFTERMARKET, BY COMPONENT, 2025-2032 (USD MILLION)

- TABLE 66 SHOCK ABSORBERS AFTERMARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 67 SHOCK ABSORBERS AFTERMARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 68 SHOCK ABSORBERS AFTERMARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 69 SHOCK ABSORBERS AFTERMARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 70 STRUTS AFTERMARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 71 STRUTS AFTERMARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 72 STRUTS AFTERMARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 73 STRUTS AFTERMARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 74 BALL JOINTS AFTERMARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 75 BALL JOINTS AFTERMARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 76 BALL JOINTS AFTERMARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 77 BALL JOINTS AFTERMARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 78 LEAF SPRINGS AFTERMARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 79 LEAF SPRINGS AFTERMARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 80 LEAF SPRINGS AFTERMARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 81 LEAF SPRINGS AFTERMARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 82 CONTROL ARMS AFTERMARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 83 CONTROL ARMS AFTERMARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 84 CONTROL ARMS AFTERMARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 85 CONTROL ARMS AFTERMARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 86 COIL SPRINGS AFTERMARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 87 COIL SPRINGS AFTERMARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 88 COIL SPRINGS AFTERMARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 89 COIL SPRINGS AFTERMARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 90 AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 91 AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 92 AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 93 AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 94 PASSENGER CAR MODELS WITH MACPHERSON STRUT AT FRONT/REAR AXLE, BY KEY COUNTRY, 2025

- TABLE 95 MACPHERSON STRUT: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 96 MACPHERSON STRUT: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 97 MACPHERSON STRUT: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 98 MACPHERSON STRUT: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 99 PASSENGER CAR MODELS WITH DOUBLE WISHBONE AT FRONT/REAR AXLE, BY KEY COUNTRY, 2025

- TABLE 100 DOUBLE WISHBONE: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 101 DOUBLE WISHBONE: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 102 DOUBLE WISHBONE: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 103 DOUBLE WISHBONE: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 104 PASSENGER CAR MODELS WITH MULTILINK SUSPENSION AT FRONT/REAR AXLE, BY KEY COUNTRY, 2025

- TABLE 105 MULTILINK: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 106 MULTILINK: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 107 MULTILINK: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 108 MULTILINK: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 109 PASSENGER CAR MODELS WITH TWIST BEAM/TORSION BEAM SUSPENSION AT FRONT/REAR AXLE, BY KEY COUNTRY, 2025

- TABLE 110 TWIST BEAM/TORSION BEAM: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 111 TWIST BEAM/TORSION BEAM: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 112 TWIST BEAM/TORSION BEAM: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 113 TWIST BEAM/TORSION BEAM: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 114 LEAF SPRING: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 115 LEAF SPRING: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 116 LEAF SPRING: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 117 LEAF SPRING: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 118 PASSENGER CAR MODELS WITH AIR SUSPENSION AT FRONT/REAR AXLE, BY KEY COUNTRY, 2025

- TABLE 119 AIR SUSPENSION: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 120 AIR SUSPENSION: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 121 AIR SUSPENSION: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 122 AIR SUSPENSION: AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 123 AUTOMOTIVE SUSPENSION MARKET, BY SYSTEM, 2021-2024 (THOUSAND UNITS)

- TABLE 124 AUTOMOTIVE SUSPENSION MARKET, BY SYSTEM, 2025-2032 (THOUSAND UNITS)

- TABLE 125 AUTOMOTIVE SUSPENSION MARKET, BY SYSTEM, 2021-2024 (USD MILLION)

- TABLE 126 AUTOMOTIVE SUSPENSION MARKET, BY SYSTEM, 2025-2032 (USD MILLION)

- TABLE 127 PASSIVE SYSTEM MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 128 PASSIVE SYSTEM MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 129 PASSIVE SYSTEM MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 130 PASSIVE SYSTEM MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 131 SEMI-ACTIVE SYSTEM MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 132 SEMI-ACTIVE SYSTEM MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 133 SEMI-ACTIVE SYSTEM MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 134 SEMI-ACTIVE SYSTEM MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 135 ACTIVE SYSTEM MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 136 ACTIVE SYSTEM MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 137 ACTIVE SYSTEM MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 138 ACTIVE SYSTEM MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 139 AUTOMOTIVE SUSPENSION MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 140 AUTOMOTIVE SUSPENSION MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 141 AUTOMOTIVE SUSPENSION MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 142 AUTOMOTIVE SUSPENSION MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 143 PASSENGER CAR SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 144 PASSENGER CAR SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 145 PASSENGER CAR SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 146 PASSENGER CAR SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 147 LCV SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 148 LCV SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 149 LCV SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 150 LCV SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 151 TRUCK SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 152 TRUCK SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 153 TRUCK SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 154 TRUCK SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 155 BUS SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 156 BUS SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 157 BUS SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 158 BUS SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 159 AUTOMOTIVE SUSPENSION OE MARKET, BY COMPONENT, 2021-2024 (MILLION UNITS)

- TABLE 160 AUTOMOTIVE SUSPENSION OE MARKET, BY COMPONENT, 2025-2032 (MILLION UNITS)

- TABLE 161 AUTOMOTIVE SUSPENSION OE MARKET, BY COMPONENT, 2021-2024 (USD MILLION)

- TABLE 162 AUTOMOTIVE SUSPENSION OE MARKET, BY COMPONENT, 2025-2032 (USD MILLION)

- TABLE 163 COIL SPRING OE MARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 164 COIL SPRING OE MARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 165 COIL SPRING OE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 166 COIL SPRING OE MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 167 AIR SPRING OE MARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 168 AIR SPRING OE MARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 169 AIR SPRING OE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 170 AIR SPRING OE MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 171 SHOCK ABSORBER OE MARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 172 SHOCK ABSORBER OE MARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 173 SHOCK ABSORBER OE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 174 SHOCK ABSORBER OE MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 175 STRUT OE MARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 176 STRUT OE MARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 177 STRUT OE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 178 STRUT OE MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 179 CONTROL ARM OE MARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 180 CONTROL ARM OE MARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 181 CONTROL ARM OE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 182 CONTROL ARM OE MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 183 RUBBER BUSHING OE MARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 184 RUBBER BUSHING OE MARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 185 RUBBER BUSHING OE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 186 RUBBER BUSHING OE MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 187 LEAF SPRING OE MARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 188 LEAF SPRING OE MARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 189 LEAF SPRING OE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 190 LEAF SPRING OE MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 191 LINK STABILIZER/SWAY BAR OE MARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 192 LINK STABILIZER/SWAY BAR OE MARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 193 LINK STABILIZER/SWAY BAR OE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 194 LINK STABILIZER/SWAY BAR OE MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 195 BALL JOINT OE MARKET, BY REGION, 2021-2024 (MILLION UNITS)

- TABLE 196 BALL JOINT OE MARKET, BY REGION, 2025-2032 (MILLION UNITS)

- TABLE 197 BALL JOINT OE MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 198 BALL JOINT OE MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 199 ELECTRIC & HYBRID PASSENGER CAR SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 200 ELECTRIC & HYBRID PASSENGER CAR SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 201 ELECTRIC & HYBRID PASSENGER CAR SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 202 ELECTRIC & HYBRID PASSENGER CAR SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 203 BEV SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 204 BEV SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 205 BEV SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 206 BEV SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 207 PHEV SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 208 PHEV SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 209 PHEV SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 210 PHEV SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 211 FCEV SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 212 FCEV SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 213 FCEV SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 214 FCEV SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 215 ASIA PACIFIC: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2021-2024 (THOUSAND UNITS)

- TABLE 216 ASIA PACIFIC: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2025-2032 (THOUSAND UNITS)

- TABLE 217 ASIA PACIFIC: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2021-2024 (USD MILLION)

- TABLE 218 ASIA PACIFIC: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2025-2032 (USD MILLION)

- TABLE 219 EUROPE: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2021-2024 (THOUSAND UNITS)

- TABLE 220 EUROPE: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2025-2032 (THOUSAND UNITS)

- TABLE 221 EUROPE: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2021-2024 (USD MILLION)

- TABLE 222 EUROPE: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2025-2032 (USD MILLION)

- TABLE 223 NORTH AMERICA: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2021-2024 (THOUSAND UNITS)

- TABLE 224 NORTH AMERICA: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2025-2032 (THOUSAND UNITS)

- TABLE 225 NORTH AMERICA: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2021-2024 (USD MILLION)

- TABLE 226 NORTH AMERICA: ELECTRIC & HYBRID VEHICLE SUSPENSION MARKET, BY PROPULSION, 2025-2032 (USD MILLION)

- TABLE 227 ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 228 ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 229 ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 230 ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 231 ASIA PACIFIC: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 232 ASIA PACIFIC: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 233 ASIA PACIFIC: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 234 ASIA PACIFIC: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 235 EUROPE: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 236 EUROPE: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 237 EUROPE: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 238 EUROPE: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 239 NORTH AMERICA: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2021-2024 (THOUSAND UNITS)

- TABLE 240 NORTH AMERICA: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2025-2032 (THOUSAND UNITS)

- TABLE 241 NORTH AMERICA: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2021-2024 (USD MILLION)

- TABLE 242 NORTH AMERICA: ELECTRIC & HYBRID HCV SUSPENSION MARKET, BY VEHICLE TYPE, 2025-2032 (USD MILLION)

- TABLE 243 ELECTRIC & HYBRID TRUCK SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 244 ELECTRIC & HYBRID TRUCK SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 245 ELECTRIC & HYBRID TRUCK SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 246 ELECTRIC & HYBRID TRUCK SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 247 ELECTRIC & HYBRID BUS SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 248 ELECTRIC & HYBRID BUS SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 249 ELECTRIC & HYBRID BUS SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 250 ELECTRIC & HYBRID BUS SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 251 OFF-HIGHWAY VEHICLE SUSPENSION MARKET, BY APPLICATION, 2021-2024 (THOUSAND UNITS)

- TABLE 252 OFF-HIGHWAY VEHICLE SUSPENSION MARKET, BY APPLICATION, 2025-2032 (THOUSAND UNITS)

- TABLE 253 CONSTRUCTION EQUIPMENT SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 254 CONSTRUCTION EQUIPMENT SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 255 AGRICULTURAL TRACTOR SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 256 AGRICULTURAL TRACTOR SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 257 ALL-TERRAIN VEHICLE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 258 ALL-TERRAIN VEHICLE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 259 ALL-TERRAIN VEHICLE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 260 ALL-TERRAIN VEHICLE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 261 MACPHERSON STRUT SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 262 MACPHERSON STRUT SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 263 MACPHERSON STRUT SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 264 MACPHERSON STRUT SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 265 DOUBLE WISHBONE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 266 DOUBLE WISHBONE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 267 DOUBLE WISHBONE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 268 DOUBLE WISHBONE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 269 AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 270 AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 271 AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2021-2024 (USD MILLION)

- TABLE 272 AUTOMOTIVE SUSPENSION MARKET, BY REGION, 2025-2032 (USD MILLION)

- TABLE 273 ASIA PACIFIC: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY/REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 274 ASIA PACIFIC: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY/REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 275 ASIA PACIFIC: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY/REGION, 2021-2024 (USD MILLION)

- TABLE 276 ASIA PACIFIC: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY/REGION, 2025-2032 (USD MILLION)

- TABLE 277 CHINA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 278 CHINA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 279 CHINA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 280 CHINA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 281 INDIA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 282 INDIA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 283 INDIA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 284 INDIA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 285 JAPAN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 286 JAPAN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 287 JAPAN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 288 JAPAN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 289 SOUTH KOREA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 290 SOUTH KOREA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 291 SOUTH KOREA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 292 SOUTH KOREA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 293 REST OF ASIA PACIFIC: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 294 REST OF ASIA PACIFIC: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 295 REST OF ASIA PACIFIC: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 296 REST OF ASIA PACIFIC: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 297 NORTH AMERICA: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY, 2021-2024 (THOUSAND UNITS)

- TABLE 298 NORTH AMERICA: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY, 2025-2032 (THOUSAND UNITS)

- TABLE 299 NORTH AMERICA: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 300 NORTH AMERICA: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY, 2025-2032 (USD MILLION)

- TABLE 301 US: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 302 US: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 303 US: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 304 US: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 305 MEXICO: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 306 MEXICO: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 307 MEXICO: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 308 MEXICO: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 309 CANADA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 310 CANADA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 311 CANADA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 312 CANADA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 313 EUROPE: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY/REGION, 2021-2024 (THOUSAND UNITS)

- TABLE 314 EUROPE: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY/REGION, 2025-2032 (THOUSAND UNITS)

- TABLE 315 EUROPE: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY/REGION, 2021-2024 (USD MILLION)

- TABLE 316 EUROPE: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY/REGION, 2025-2032 (USD MILLION)

- TABLE 317 GERMANY: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 318 GERMANY: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 319 GERMANY: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 320 GERMANY: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 321 UK: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 322 UK: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 323 UK: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 324 UK: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 325 FRANCE: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 326 FRANCE: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 327 FRANCE: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 328 FRANCE: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 329 SPAIN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 330 SPAIN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 331 SPAIN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 332 SPAIN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 333 ITALY: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 334 ITALY: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 335 ITALY: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 336 ITALY: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 337 RUSSIA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 338 RUSSIA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 339 RUSSIA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 340 RUSSIA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 341 REST OF EUROPE: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 342 REST OF EUROPE: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 343 REST OF EUROPE: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 344 REST OF EUROPE: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 345 ROW: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY, 2021-2024 (THOUSAND UNITS)

- TABLE 346 ROW: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY, 2025-2032 (THOUSAND UNITS)

- TABLE 347 ROW: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY, 2021-2024 (USD MILLION)

- TABLE 348 ROW: AUTOMOTIVE SUSPENSION MARKET, BY COUNTRY, 2025-2032 (USD MILLION)

- TABLE 349 BRAZIL: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 350 BRAZIL: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 351 BRAZIL: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 352 BRAZIL: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 353 SOUTH AFRICA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 354 SOUTH AFRICA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 355 SOUTH AFRICA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 356 SOUTH AFRICA: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 357 IRAN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (THOUSAND UNITS)

- TABLE 358 IRAN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (THOUSAND UNITS)

- TABLE 359 IRAN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2021-2024 (USD MILLION)

- TABLE 360 IRAN: AUTOMOTIVE SUSPENSION MARKET, BY ARCHITECTURE, 2025-2032 (USD MILLION)

- TABLE 361 KEY PLAYER STRATEGIES/RIGHT TO WIN, JANUARY 2023-2025

- TABLE 362 AUTOMOTIVE SUSPENSION MARKET: DEGREE OF COMPETITION, 2024

- TABLE 363 REGION FOOTPRINT

- TABLE 364 SYSTEM FOOTPRINT

- TABLE 365 ACTUATION FOOTPRINT

- TABLE 366 VEHICLE TYPE FOOTPRINT

- TABLE 367 LIST OF STARTUPS/SMES

- TABLE 368 COMPETITIVE BENCHMARKING OF SMES (1/2)

- TABLE 369 COMPETITIVE BENCHMARKING OF SMES (2/2)

- TABLE 370 AUTOMOTIVE SUSPENSION MARKET: PRODUCT LAUNCHES/DEVELOPMENTS, JANUARY 2024- SEPTEMBER 2025

- TABLE 371 AUTOMOTIVE SUSPENSION MARKET: DEALS, JANUARY 2024-OCTOBER 2025

- TABLE 372 AUTOMOTIVE SUSPENSION MARKET: EXPANSIONS, JANUARY 2024-OCTOBER 2025

- TABLE 373 AUTOMOTIVE SUSPENSION MARKET: OTHER DEVELOPMENTS, JANUARY 2024-OCTOBER 2025

- TABLE 374 ZF FRIEDRICHSHAFEN AG: COMPANY OVERVIEW

- TABLE 375 ZF FRIEDRICHSHAFEN AG: PRODUCTS OFFERED

- TABLE 376 ZF FRIEDRICHSHAFEN AG: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 377 ZF FRIEDRICHSHAFEN AG: EXPANSIONS

- TABLE 378 HYUNDAI MOBIS: COMPANY OVERVIEW

- TABLE 379 HYUNDAI MOBIS: PRODUCTS OFFERED

- TABLE 380 HYUNDAI MOBIS: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 381 TENNECO INC.: COMPANY OVERVIEW

- TABLE 382 TENNECO INC.: PRODUCTS OFFERED

- TABLE 383 TENNECO INC.: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 384 THYSSENKRUPP AG: COMPANY OVERVIEW

- TABLE 385 THYSSENKRUPP AG: PRODUCTS OFFERED

- TABLE 386 THYSSENKRUPP AG: DEALS

- TABLE 387 DANA LIMITED: COMPANY OVERVIEW

- TABLE 388 DANA LIMITED: PRODUCTS OFFERED

- TABLE 389 DANA LIMITED: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 390 MAGNA INTERNATIONAL INC.: COMPANY OVERVIEW

- TABLE 391 MAGNA INTERNATIONAL INC.: PRODUCTS OFFERED

- TABLE 392 CONTINENTAL AG: COMPANY OVERVIEW

- TABLE 393 CONTINENTAL AG: PRODUCTS OFFERED

- TABLE 394 BWI GROUP: COMPANY OVERVIEW

- TABLE 395 BWI GROUP: PRODUCTS OFFERED

- TABLE 396 BWI GROUP: EXPANSIONS

- TABLE 397 BWI GROUP: DEALS

- TABLE 398 KYB CORPORATION: COMPANY OVERVIEW

- TABLE 399 KYB CORPORATION: PRODUCTS OFFERED

- TABLE 400 HL MANDO CORPORATION: COMPANY OVERVIEW

- TABLE 401 HL MANDO CORPORATION: PRODUCTS OFFERED

- TABLE 402 MERITOR, INC.: COMPANY OVERVIEW

- TABLE 403 MERITOR, INC.: PRODUCTS OFFERED

- TABLE 404 HENDRICKSON USA, L.L.C.: COMPANY OVERVIEW

- TABLE 405 HENDRICKSON USA, L.L.C.: PRODUCTS OFFERED

- TABLE 406 HENDRICKSON USA, L.L.C.: PRODUCT LAUNCHES/DEVELOPMENTS

- TABLE 407 HENDRICKSON USA, L.L.C.: DEALS

- TABLE 408 ASTEMO, LTD: COMPANY OVERVIEW

- TABLE 409 SOGEFI: COMPANY OVERVIEW

- TABLE 410 EIBACH: COMPANY OVERVIEW

- TABLE 411 GESTAMP: COMPANY OVERVIEW

- TABLE 412 SIDEM: COMPANY OVERVIEW

- TABLE 413 PEDDERS SUSPENSION & BRAKES: COMPANY OVERVIEW

- TABLE 414 RTS: COMPANY OVERVIEW

- TABLE 415 YSS SUSPENSION: COMPANY OVERVIEW

- TABLE 416 BELLTECH: COMPANY OVERVIEW

- TABLE 417 SKYJACKER SUSPENSIONS: COMPANY OVERVIEW

- TABLE 418 MULTIMATIC INC.: COMPANY OVERVIEW

- TABLE 419 KING SHOCKS: COMPANY OVERVIEW

- TABLE 420 FOX FACTORY, INC.: COMPANY OVERVIEW

- TABLE 421 RANCHO SUSPENSION: COMPANY OVERVIEW

- TABLE 422 TEIN USA.: COMPANY OVERVIEW

- TABLE 423 AIR LIFT COMPANY: COMPANY OVERVIEW

- TABLE 424 MOOG INC.: COMPANY OVERVIEW

List of Figures

- FIGURE 1 RESEARCH DESIGN

- FIGURE 2 RESEARCH PROCESS FLOW

- FIGURE 3 MARKET SIZE ESTIMATION METHODOLOGY

- FIGURE 4 AUTOMOTIVE SUSPENSION MARKET SIZE: BOTTOM-UP APPROACH (ARCHITECTURE AND REGION)

- FIGURE 5 AUTOMOTIVE SUSPENSION MARKET SIZE: BOTTOM-UP APPROACH (AFTERMARKET, BY COMPONENT)

- FIGURE 6 TOP-DOWN APPROACH

- FIGURE 7 DATA TRIANGULATION

- FIGURE 8 MARKET GROWTH PROJECTIONS FROM DEMAND-SIDE DRIVERS

- FIGURE 9 MARKET SCENARIO

- FIGURE 10 GLOBAL AUTOMOTIVE SUSPENSION MARKET, 2021-2032

- FIGURE 11 MAJOR STRATEGIES ADOPTED BY KEY PLAYERS IN THE AUTOMOTIVE SUSPENSION MARKET, 2021-2025

- FIGURE 12 DISRUPTIONS INFLUENCING THE GROWTH OF THE AUTOMOTIVE SUSPENSION MARKET

- FIGURE 13 HIGH-GROWTH SEGMENTS IN AUTOMOTIVE SUSPENSION MARKET, 2025-2032

- FIGURE 14 ASIA PACIFIC TO DOMINATE IN THE AUTOMOTIVE SUSPENSION MARKET, IN TERMS OF VALUE, DURING THE FORECAST PERIOD

- FIGURE 15 RISING AWARENESS REGARDING PASSENGER COMFORT TO DRIVE AUTOMOTIVE SUSPENSION MARKET

- FIGURE 16 PASSIVE SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 17 AIR SUSPENSION SEGMENT TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 18 BUSES SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 19 RUBBER BUSHINGS SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 20 SHOCK ABSORBERS SEGMENT TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 21 MULTILINK SEGMENT TO ACCOUNT FOR LARGEST MARKET IN 2025

- FIGURE 22 TRUCKS SEGMENT TO LEAD MARKET BY 2032

- FIGURE 23 ELECTRONICALLY ACTUATED SEGMENT TO ACHIEVE SIGNIFICANT GROWTH DURING FORECAST PERIOD

- FIGURE 24 AGRICULTURE TRACTORS SEGMENT TO LEAD MARKET IN 2025

- FIGURE 25 ASIA PACIFIC TO REGISTER HIGHEST GROWTH DURING FORECAST PERIOD

- FIGURE 26 ASIA PACIFIC TO ACCOUNT FOR LARGEST SHARE IN 2025

- FIGURE 27 AUTOMOTIVE SUSPENSION MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 28 SUV PRODUCTION IN NORTH AMERICA, 2020-2024 ('000 UNITS)

- FIGURE 29 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS, BY VEHICLE TYPE

- FIGURE 30 KEY BUYING CRITERIA, BY KEY ARCHITECTURE

- FIGURE 31 PATENT ANALYSIS, BY DOCUMENT TYPE, JANUARY 2015-DECEMBER 2024

- FIGURE 32 PATENT PUBLICATION TRENDS, 2015-2025

- FIGURE 33 AUTOMOTIVE SUSPENSION MARKET: LEGAL STATUS OF PATENTS, JANUARY 2015-DECEMBER 2024

- FIGURE 34 US WITNESSED HIGHEST REGISTRATION OF PATENTS BETWEEN 2015 AND 2024

- FIGURE 35 TOP PATENT APPLICANTS, JANUARY 2015-DECEMBER 2024

- FIGURE 36 ECOSYSTEM ANALYSIS

- FIGURE 37 SUPPLY CHAIN ANALYSIS