|

市場調查報告書

商品編碼

1807079

顏料分散劑市場:按顏料類型、分散劑類型、應用、最終用途行業和地區分類的全球市場 - 預測至 2030 年Pigment Dispersion Market by Dispersion Type (Water-based, Solvent-based), Application (Automotive Paint & Coatings, Decorative Paints & Coatings), Pigment Type, End-use Industry (Building & Construction, Packaging), and Region - Global Forecast to 2030 |

||||||

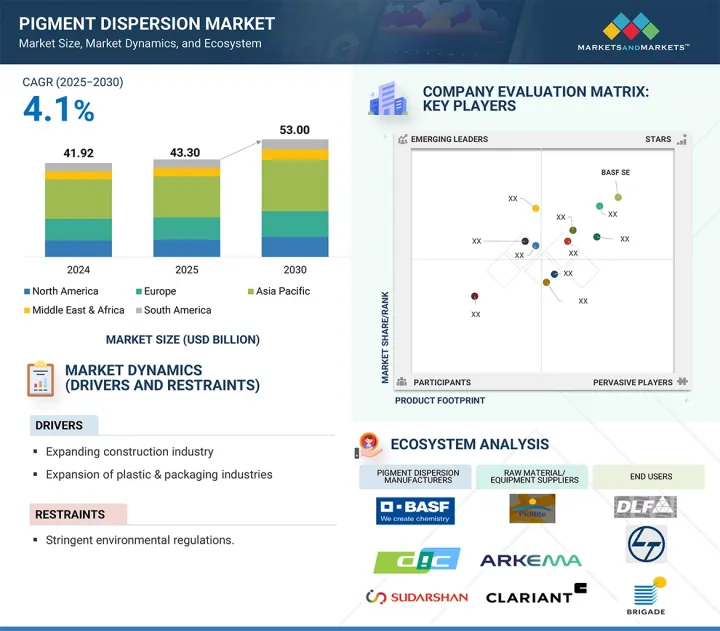

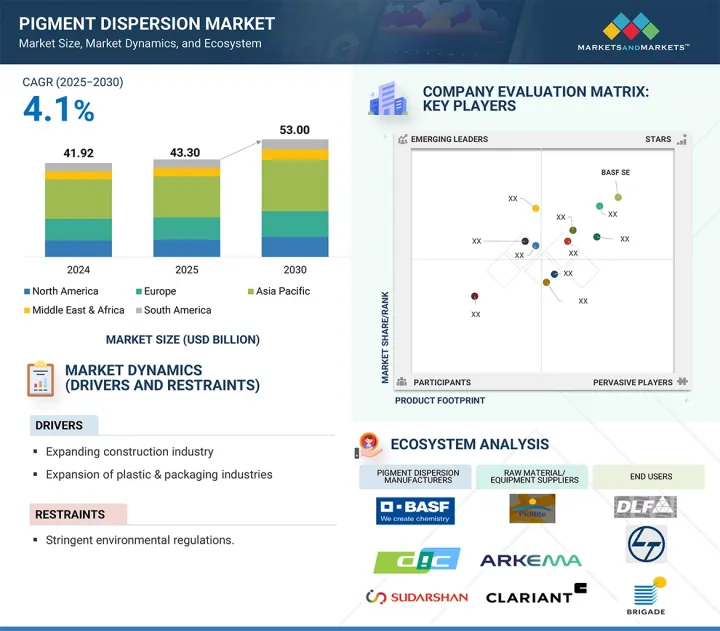

顏料分散劑市場預計將從 2025 年的 433 億美元成長到 2030 年的 530 億美元,預測期內的複合年成長率為 4.1%。

| 調查範圍 | |

|---|---|

| 調查年份 | 2022-2030 |

| 基準年 | 2024 |

| 預測期 | 2025-2030 |

| 對價單位 | 金額(百萬美元)、數量(千噸) |

| 部分 | 按顏料類型、分散類型、應用、最終用途行業和地區 |

| 目標區域 | 北美、歐洲、亞太地區、南美、中東和非洲 |

顏料分散劑涉及顏料在介質中的穩定、均勻分散,確保油漆、被覆劑、塑膠、油墨、紡織品等最終應用具有一致的顏色、不透明度和性能。這些分散劑確保顏料分散均勻,不會結塊,從而使最終產品具有鮮豔的色彩和耐用性。

顏料分散劑有水基、溶劑基和其他配方,對於外觀和性能至關重要的多種行業而言都是必不可少的。顏料分散劑市場的成長由幾個關鍵因素所驅動。快速的都市化和基礎設施發展,尤其是在亞太地區,正在推動對油漆和塗料的需求,從而刺激顏料分散劑的使用。由於更嚴格的環境法規和對揮發性有機化合物 (VOC)排放的認知不斷提高,全球向永續解決方案的轉變正在加速水基分散體的應用。由於消費者需求和工業生產的成長,包裝、汽車和紡織等終端使用產業的擴張也促進了市場成長。此外,分散技術的改進正在提高產品品質並擴大應用選擇,而政府的支持性政策,尤其是在新興經濟體,正在為本地生產和創新創造有利條件。這些因素加在一起,使顏料分散劑成為傳統和新興工業領域的重要組成部分。

工業塗料和塗層是顏料分散劑的重要應用領域,服務於汽車、機械、船舶、航太和建築等行業。這些塗層兼具美觀和功能性保護,能夠抵抗腐蝕、化學物質、紫外線和磨損。顏料分散劑對於確保顏色均勻一致、不透明度和穩定性至關重要,同時還能提高耐熱性和耐久性等性能。隨著越來越多的行業對高性能、持久耐用的塗料的需求,顏料分散劑也在不斷發展,以滿足更嚴格的品質、環境和安全標準。尤其是在歐洲和北美等已開發地區,人們正在轉向環保、低揮發性有機化合物 (VOC) 配方,加速了先進水性分散劑的採用。同時,亞太地區(尤其是印度、中國和東南亞)的快速工業成長正在推動大規模基礎設施建設和製造計劃,從而增加對工業塗料的需求。此外,奈米顏料分散劑和混合配方等技術創新正在拓展其在航太和電子等先進領域的應用選擇。

汽車產業是推動顏料分散劑需求的主要終端使用產業,因為它們在汽車塗料的美觀和保護方面發揮關鍵作用。顏料分散劑用於車身外漆、內裝件和塑膠裝飾,以確保鮮豔的色彩、紫外線穩定性、耐腐蝕性和持久的光潔度。隨著消費者偏好轉向外觀吸引人和耐用的汽車,尤其是鮮豔的金屬色調,對高品質顏料分散劑的需求持續成長。此外,全球向電動車 (EV) 和輕量化材料的轉變進一步推動了對可提高能源效率和表面耐久性的先進塗料的需求。受可支配收入增加、城市都市化和政府對電動車的激勵措施的推動,亞太地區,尤其是印度和中國等地區的汽車產銷量正在強勁成長。汽車產量的成長直接轉化為油漆和被覆劑消費量的增加,並最終轉化為顏料分散劑消費量的增加。

亞太地區佔據全球顏料分散劑市場的最大佔有率,這得益於快速的工業化、城市擴張以及建築、汽車、包裝和紡織等終端使用產業的蓬勃發展。中國、印度、日本和韓國等國家憑藉其強大的製造業基礎、不斷成長的消費需求以及政府的支持性政策引領著這一成長。中國作為全球製造地,在油漆、被覆劑和塑膠產業中佔據主導地位,導致顏料分散劑的消費量龐大。印度的建築和基礎設施建設正經歷前所未有的成長,這得益於「智慧城市計畫」和房地產開發的增加,從而推動了對裝飾塗料和工業塗料的需求。此外,印度不斷擴張的紡織業和不斷成長的包裝業進一步推動了對高性能顏料的需求。日本和韓國透過先進的應用和技術進步做出了貢獻。日本專注於基礎設施維修和智慧城市計劃,而韓國正在進行大型建設項目,如三星半導體叢集和國際金融中心的重建。總體而言,亞太地區人口眾多、中階不斷壯大、汽車產量不斷上升以及都市化迅速,使其成為顏料分散劑製造商成長最快、最具前景的市場,為創新和業務擴展提供了充足的機會。

本報告研究了全球顏料分散劑市場,並按顏料類型、分散類型、應用、最終用途行業、區域趨勢和參與市場的公司概況進行細分。

目錄

第1章 引言

第2章調查方法

第3章執行摘要

第4章重要考察

第5章市場概述

- 介紹

- 市場動態

第6章 產業趨勢

- 波特五力分析

- 價值鏈分析

- 總體經濟指標

- 定價分析

- 貿易分析

- 生態系分析

- 影響客戶業務的趨勢/中斷

- 技術分析

- 2025-2026年主要會議和活動

第7章顏料分散劑市場(依顏料類型)

- 介紹

- 有機顏料

- 無機顏料

第8章顏料分散劑市場(依分散劑類型)

- 介紹

- 水性分散劑

- 溶劑型分散劑

第9章顏料分散劑市場(依應用)

- 介紹

- 汽車油漆和塗料

- 裝飾油漆和塗料

- 工業油漆和塗料

- 墨水

- 塑膠

- 其他

第10章顏料分散劑市場(依最終用途產業)

- 介紹

- 建築/施工

- 車

- 包裝

- 紙張/印刷

- 纖維

- 其他

第 11 章顏料分散劑市場(按地區)

- 介紹

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 印尼

- 其他

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 德國

- 法國

- 英國

- 義大利

- 西班牙

- 其他

- 中東和非洲

- 海灣合作理事會國家

- 南非

- 其他

- 南美洲

- 巴西

- 阿根廷

- 其他

第12章競爭格局

- 介紹

- 收益分析

- 市場佔有率分析

- 公司估值矩陣:2024 年關鍵參與企業

- 公司估值矩陣:Start-Ups/中小企業,2024 年

- 競爭情境和趨勢

第13章:公司簡介

- 主要參與企業

- BASF SE

- DIC CORPORATION

- SUDARSHAN CHEMICAL INDUSTRIES LIMITED

- VIBRANTZ

- CABOT CORPORATION

- DYSTAR SINGAPORE PTE LTD

- LANXESS

- PENN COLOR INC.

- PIDILITE PIGMENT

- ARALON COLOR GMBH

- 其他公司

- AUM FARBENCHEM

- ACHITEX MINERVA SPA

- CHROMATECH INCORPORATED

- DCL CORPORATION

- DECORATIVE COLOR & CHEMICAL, INC.

- DCC GROUP COMPANY LIMITED

- KEMITEKS

- MANALI PIGMENTS PVT. LTD.

- MIKUNI-COLOR LTD.

- RPM INTERNATIONAL INC.

- SYNTHESIA, AS

- TIARCO CHEMICALS

- TENNANTS TEXTILE COLOURS LTD.

- VIPUL ORGANICS LTD.

- QUAKER COLOR

第14章 附錄

The pigment dispersion market is expected to reach USD 53.00 billion by 2030, up from USD 43.30 billion in 2025, growing at a CAGR of 4.1% during the forecast period.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2022-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million), Volume (Kiloton) |

| Segments | Type, Pigment Type, Application, End-use Industry, and Region |

| Regions covered | North America, Europe, Asia Pacific, South America, and Middle East & Africa |

Pigment dispersion involves the stable and uniform spread of pigments in a medium, ensuring consistent color, opacity, and performance in end-use applications like paints, coatings, plastics, inks, and textiles. These dispersions guarantee that pigments are evenly distributed without clumping, resulting in vibrant color and durability in finished products.

Available in water-based, solvent-based, and other formulations, pigment dispersions are vital to various industries where appearance and function matter. The growth of the pigment dispersion market is driven by several key factors. Rapid urbanization and infrastructure development, especially in Asia-Pacific, are increasing demand for paints and coatings, thereby boosting pigment dispersion use. The global shift toward sustainable solutions is speeding up the adoption of water-based dispersions due to stricter environmental regulations and rising awareness of VOC emissions. Expanding end-use industries such as packaging, automotive, and textiles are also contributing to market growth, supported by growing consumer demand and industrial production. Furthermore, improvements in dispersion technologies have enhanced product quality and expanded application options, while supportive government policies, particularly in emerging economies, are creating favorable conditions for local manufacturing and innovation. Collectively, these factors position pigment dispersions as crucial components in both traditional and emerging industrial sectors.

"Industrial paint & coating segment is the second fastest-growing segment in the pigment dispersion market during the forecast period."

Industrial paints and coatings are a key application area for pigment dispersions, serving industries such as automotive, machinery, marine, aerospace, and construction. These coatings are made for both aesthetic appeal and functional protection-resisting corrosion, chemicals, UV rays, and wear. Pigment dispersions are essential because they ensure consistent color, opacity, and stability, while also improving performance features like heat resistance and durability. As industries increasingly require high-performance, long-lasting coatings, pigment dispersions are evolving to meet stricter quality, environmental, and safety standards. The move toward eco-friendly, low-VOC formulations-particularly in developed regions like Europe and North America-is accelerating the adoption of advanced water-based dispersions. At the same time, rapid industrial growth in Asia-Pacific, especially in India, China, and Southeast Asia, is driving large-scale infrastructure and manufacturing projects, increasing demand for industrial coatings. Additionally, technological innovations such as nano-pigment dispersions and hybrid formulations are broadening application options in advanced sectors like aerospace and electronics.

"The automotive segment is the second-largest in the pigment dispersion market."

The automotive industry is a major end-use sector driving demand for pigment dispersions, due to their vital role in vehicle coatings for both aesthetics and protection. Pigment dispersions are used in exterior body paints, interior components, and plastic trims to ensure vibrant color, UV stability, corrosion resistance, and long-lasting finishes. As consumer preference shifts toward visually appealing and durable vehicles, especially in vibrant and metallic shades, the demand for high-quality pigment dispersions continues to increase. Additionally, the global move toward electric vehicles (EVs) and lightweight materials further boosts the need for advanced coatings that improve energy efficiency and surface durability. Regions like Asia-Pacific, especially India and China, are experiencing strong growth in automotive production and sales, supported by rising disposable incomes, urbanization, and government incentives for EVs. This increase in automotive output directly leads to higher consumption of paints, coatings, and consequently, pigment dispersions.

.

.

The Asia Pacific region is projected to be the largest market for pigment dispersion during the forecast period.

Asia Pacific holds the largest share in the global pigment dispersion market, driven by rapid industrialization, urban expansion, and thriving end-use industries such as construction, automotive, packaging, and textiles. Countries like China, India, Japan, and South Korea are leading this growth due to strong manufacturing bases, rising consumer demand, and supportive government policies. China, as the world's manufacturing hub, continues to dominate the paints, coatings, and plastics industries, resulting in significant consumption of pigment dispersions. India is experiencing unprecedented growth in construction and infrastructure, supported by initiatives like the Smart Cities Mission and increasing real estate development, which boost demand for decorative and industrial coatings. Additionally, India's expanding textile sector and growing packaging industry are further increasing the need for high-performance pigments. Japan and South Korea contribute through advanced applications and technological progress. Japan's focus on infrastructure renovation and smart city projects, along with large-scale construction efforts in South Korea-such as the Samsung semiconductor cluster and international finance center redevelopment-are driving demand for specialized coatings and dispersions. Overall, the region's large population, growing middle class, rising automotive production, and rapid urbanization make Asia-Pacific the fastest-growing and most promising market for pigment dispersion manufacturers, offering ample opportunities for innovation and expansion.

Extensive primary interviews were conducted to determine and verify the market size for several segments and subsegments and the information gathered through secondary research.

The break-up of primary interviews is given below:

- By Department: Tier 1: 40%, Tier 2: 25%, and Tier 3: 35%

- By Designation: C Level: 35%, Director Level: 30%, and Executives: 35%

- By Region: North America: 25%, Europe: 35%, Asia Pacific: 30%, South America: 5%, Middle East & Africa 5%

BASF SE (Germany), DIC Corporation (Japan), Sudarshan Chemical (India), Vibrantz (US), Cabot Corporation (US), Heubach GmbH (Germany), Penn Colors (US), Pidilite (India), Lanxess (Germany), DyStar Industries (Singapore), Achitex Minerva S.p.A (Italy), Aralon Color GmbH (Germany), Chromatech Inc. (US), DCL Corporation (Canada), and AUM Farbenchem (India), among others, are some of the key players in the pigment dispersion market.

The study includes an in-depth competitive analysis of these players in the market, with their company profiles, recent developments, and key strategies.

Research Coverage

The market study covers the pigment dispersion market across various segments. It aims to estimate the market size and growth potential in different segments based on type, pigment type, end-use industry, and region. The study also includes an in-depth competitive analysis of key players in the market, their company profiles, important observations about their products and offerings, recent developments, and key growth strategies they are using to enhance their position in the pigment dispersion market.

Key Benefits of Buying the Report

The report aims to assist market leaders and new entrants in approximating the revenue figures of the overall pigment dispersion market and its segments. It is designed to help stakeholders understand the competitive landscape, gain insights to strengthen their business positions, and develop effective go-to-market strategies. Additionally, the report provides insights into the market's current pulse, including key drivers, restraints, challenges, and opportunities.

The report provides insights into the following points:

- Analysis of key drivers (growing construction industry, expansion of plastic and packaging sectors), restraints (strict environmental regulations, fluctuations in raw material costs), opportunities (growth in emerging markets, increasing importance of aesthetics in packaging), challenges (disposal and waste management concerns)

- Market Development: Comprehensive information about lucrative markets - the report analyzes the pigment dispersion market across varied regions

Market Diversification: Exhaustive information about new products & services, untapped geographies, recent developments, and investments in pigment dispersion market

- Competitive Assessment: In-depth assessment of market share, growth strategies, product and service offerings of leading players like BASF SE (Germany), DIC Corporation (Japan), Sudarshan Chemical (India), Vibrantz (US), Cabot Corporation (US), Heubach GmbH (Germany), Penn Colors (US), Pidilite (India), Lanxess (Germany), DyStar Industries (Singapore), Achitex Minerva S.p.A (Italy), Aralon Color GmbH (Germany), Chromatech Inc. (US), DCL Corporation (Canada), and AUM Farbenchem (India), among others, are the top manufacturers covered in the pigment dispersion market.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 MARKET SCOPE

- 1.3.1 PIGMENT DISPERSIONS MARKET SEGMENTATION

- 1.3.2 YEARS CONSIDERED

- 1.4 CURRENCY CONSIDERED

- 1.5 UNITS CONSIDERED

- 1.6 STAKEHOLDERS

- 1.7 LIMITATIONS

- 1.8 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Key data from primary sources

- 2.1.2.2 Key industry insights

- 2.1.2.3 Breakdown of interviews with experts

- 2.1.1 SECONDARY DATA

- 2.2 MARKET SIZE ESTIMATION

- 2.2.1 BOTTOM-UP APPROACH

- 2.2.2 TOP-DOWN APPROACH

- 2.3 DATA TRIANGULATION

- 2.4 ASSUMPTIONS

- 2.5 LIMITATIONS & RISKS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN PIGMENT DISPERSIONS MARKET

- 4.2 PIGMENT DISPERSIONS MARKET, BY DISPERSION TYPE

- 4.3 PIGMENT DISPERSIONS MARKET, BY APPLICATION TYPE

- 4.4 PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY

- 4.5 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY AND COUNTRY

- 4.6 PIGMENT DISPERSIONS MARKET, BY MAJOR COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Expanding construction industry

- 5.2.1.2 Growing plastics and packaging industries

- 5.2.1.3 Urbanization and industrialization in emerging economies

- 5.2.2 RESTRAINTS

- 5.2.2.1 Stringent environmental regulations

- 5.2.2.2 Volatility in raw material prices

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Growing global emphasis on sustainability and environmental compliance

- 5.2.3.2 Increasing importance of esthetics in packaging

- 5.2.3.3 Innovation in nano-pigment and high-performance dispersion technologies

- 5.2.4 CHALLENGES

- 5.2.4.1 Disposal and waste management concerns

- 5.2.1 DRIVERS

6 INDUSTRY TRENDS

- 6.1 PORTER'S FIVE FORCE ANALYSIS

- 6.1.1 BARGAINING POWER OF BUYERS

- 6.1.2 BARGAINING POWER OF SUPPLIERS

- 6.1.3 THREAT OF NEW ENTRANTS

- 6.1.4 THREAT OF SUBSTITUTES

- 6.1.5 INTENSITY OF COMPETITIVE RIVALRY

- 6.2 VALUE CHAIN ANALYSIS

- 6.2.1 RAW MATERIAL SUPPLIERS

- 6.2.2 MANUFACTURERS

- 6.2.3 DISTRIBUTORS

- 6.2.4 END USERS

- 6.3 MACROECONOMIC INDICATORS

- 6.3.1 GLOBAL GDP TRENDS

- 6.4 PRICING ANALYSIS

- 6.4.1 AVERAGE SELLING PRICE TREND, BY REGION

- 6.5 TRADE ANALYSIS

- 6.5.1 IMPORT SCENARIO (HS CODE 321290)

- 6.5.2 EXPORT SCENARIO (HS CODE 321290)

- 6.6 ECOSYSTEM ANALYSIS

- 6.7 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 6.8 TECHNOLOGY ANALYSIS

- 6.8.1 KEY TECHNOLOGIES

- 6.8.1.1 High-speed dispersions

- 6.8.1.2 Ultrasonic dispersion

- 6.8.1 KEY TECHNOLOGIES

- 6.9 KEY CONFERENCES & EVENTS IN 2025-2026

7 PIGMENT DISPERSIONS MARKET, BY PIGMENT TYPE

- 7.1 INTRODUCTION

- 7.2 ORGANIC PIGMENTS

- 7.2.1 AZO PIGMENTS

- 7.2.1.1 Rising demand in paints, printing inks, plastics, and textiles to drive market

- 7.2.2 PHTHALOCYANINE PIGMENTS

- 7.2.2.1 Outstanding color fastness, strong chromatic strength, and excellent durability to boost market

- 7.2.3 HIGH-PERFORMANCE PIGMENTS

- 7.2.3.1 Excellent lightfastness and heat stability properties to fuel demand

- 7.2.4 OTHER ORGANIC PIGMENTS

- 7.2.1 AZO PIGMENTS

- 7.3 INORGANIC PIGMENTS

- 7.3.1 TITANIUM DIOXIDE

- 7.3.1.1 Cost-effectiveness to propel market growth

- 7.3.2 IRON OXIDE

- 7.3.2.1 Rising infrastructure developments to drive demand

- 7.3.3 CARBON BLACK

- 7.3.3.1 Wide demand in rubber and plastic applications to support growth

- 7.3.4 OTHER INORGANIC PIGMENTS

- 7.3.1 TITANIUM DIOXIDE

8 PIGMENT DISPERSIONS MARKET, BY DISPERSION TYPE

- 8.1 INTRODUCTION

- 8.2 WATER-BASED DISPERSIONS

- 8.2.1 LOW VOC PROPERTY TO FUEL MARKET GROWTH

- 8.3 SOLVENT-BASED DISPERSIONS

- 8.3.1 OUTSTANDING DURABILITY WITH ENHANCED RESISTANCE TO PROPEL GROWTH

9 PIGMENT DISPERSIONS MARKET, BY APPLICATION

- 9.1 INTRODUCTION

- 9.2 AUTOMOTIVE PAINTS & COATINGS

- 9.2.1 GROWTH OF AUTOMOTIVE INDUSTRY TO BOOST DEMAND

- 9.3 DECORATIVE PAINTS & COATINGS

- 9.3.1 RAPID GROWTH IN RESIDENTIAL CONSTRUCTION TO PROPEL MARKET

- 9.4 INDUSTRIAL PAINTS & COATINGS

- 9.4.1 INDUSTRIALIZATION TO SUPPORT MARKET GROWTH

- 9.5 INKS

- 9.5.1 GROWING DIGITAL PRINTING INDUSTRY TO DRIVE MARKET

- 9.6 PLASTICS

- 9.6.1 OUTSTANDING WEATHER AND UV RESISTANCE AND HIGH LEVEL OF LIGHTFASTNESS TO BOOST MARKET

- 9.7 OTHER APPLICATIONS

10 PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY

- 10.1 INTRODUCTION

- 10.2 BUILDING & CONSTRUCTION

- 10.2.1 STRONG GROWTH IN CONSTRUCTION SECTOR TO PROPEL GROWTH

- 10.3 AUTOMOTIVE

- 10.3.1 GROWING CONSUMER DEMAND AND GLOBAL SHIFT TOWARD ELECTRIC MOBILITY TO DRIVE MARKET GROWTH

- 10.4 PACKAGING

- 10.4.1 PROTECTION OF GOODS DURING DISTRIBUTION, TRANSPORTATION, AND STORAGE TO PROPEL MARKET

- 10.5 PAPER & PRINTING

- 10.5.1 INCREASING DEMAND IN EMERGING COUNTRIES TO FUEL MARKET

- 10.6 TEXTILE

- 10.6.1 UNIFORM COLORATION, EXCELLENT WASH FASTNESS, AND VIBRANT SHADES TO SPUR DEMAND

- 10.7 OTHER END-USE INDUSTRIES

11 PIGMENT DISPERSIONS MARKET, BY REGION

- 11.1 INTRODUCTION

- 11.2 ASIA PACIFIC

- 11.2.1 CHINA

- 11.2.1.1 Cost-effective labor and low-cost raw materials to drive market

- 11.2.2 INDIA

- 11.2.2.1 Rising disposable income to propel market

- 11.2.3 JAPAN

- 11.2.3.1 Presence of multinational automobile companies to boost market growth

- 11.2.4 SOUTH KOREA

- 11.2.4.1 Strong construction industry to drive market

- 11.2.5 INDONESIA

- 11.2.5.1 Government focus on renovation of existing infrastructure and investment in residential development to drive market

- 11.2.6 REST OF ASIA PACIFIC

- 11.2.1 CHINA

- 11.3 NORTH AMERICA

- 11.3.1 US

- 11.3.1.1 Strong investments in R&D and technological advancements to drive market

- 11.3.2 CANADA

- 11.3.2.1 Strong construction and automotive industry to propel market

- 11.3.3 MEXICO

- 11.3.3.1 Growing investment in construction sector to drive market

- 11.3.1 US

- 11.4 EUROPE

- 11.4.1 GERMANY

- 11.4.1.1 Presence of large industrial base to propel market

- 11.4.2 FRANCE

- 11.4.2.1 Growth in paints & coatings sector to boost market

- 11.4.3 UK

- 11.4.3.1 Government initiatives for construction sector to boost market

- 11.4.4 ITALY

- 11.4.4.1 Increasing construction activities to propel market growth

- 11.4.5 SPAIN

- 11.4.5.1 Increasing capital spending on construction projects to drive market

- 11.4.6 REST OF EUROPE

- 11.4.1 GERMANY

- 11.5 MIDDLE EAST & AFRICA

- 11.5.1 GCC COUNTRIES

- 11.5.1.1 Saudi Arabia

- 11.5.1.1.1 Rapid infrastructural development to propel demand

- 11.5.1.2 UAE

- 11.5.1.2.1 Robust construction industry and strong consumer demand for luxury vehicles to boost market

- 11.5.1.3 Rest of GCC Countries

- 11.5.1.1 Saudi Arabia

- 11.5.2 SOUTH AFRICA

- 11.5.2.1 Ongoing infrastructure developments to boost consumption

- 11.5.3 REST OF MIDDLE EAST & AFRICA

- 11.5.1 GCC COUNTRIES

- 11.6 SOUTH AMERICA

- 11.6.1 BRAZIL

- 11.6.1.1 Growth in automotive sector to drive market

- 11.6.2 ARGENTINA

- 11.6.2.1 Growth of building & construction industry to propel market

- 11.6.3 REST OF SOUTH AMERICA

- 11.6.1 BRAZIL

12 COMPETITIVE LANDSCAPE

- 12.1 INTRODUCTION

- 12.1.1 STRATEGIES ADOPTED BY KEY PIGMENT DISPERSION MANUFACTURERS, JANUARY 2020-JUNE 2025

- 12.2 REVENUE ANALYSIS

- 12.3 MARKET SHARE ANALYSIS

- 12.4 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 12.4.1 STARS

- 12.4.2 PERVASIVE PLAYERS

- 12.4.3 EMERGING LEADERS

- 12.4.4 PARTICIPANTS

- 12.4.5 STRENGTH OF PRODUCT PORTFOLIO

- 12.4.6 BUSINESS STRATEGY EXCELLENCE

- 12.5 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 12.5.1 PROGRESSIVE COMPANIES

- 12.5.2 RESPONSIVE COMPANIES

- 12.5.3 DYNAMIC COMPANIES

- 12.5.4 STARTING BLOCKS

- 12.5.5 STRENGTH OF PRODUCT PORTFOLIO

- 12.5.6 BUSINESS STRATEGY EXCELLENCE

- 12.6 COMPETITIVE SCENARIO AND TRENDS

- 12.6.1 PRODUCT LAUNCHES

- 12.6.2 DEALS

- 12.6.3 EXPANSIONS

13 COMPANY PROFILES

- 13.1 KEY PLAYERS

- 13.1.1 BASF SE

- 13.1.1.1 Business overview

- 13.1.1.2 Products/Solutions/Services offered

- 13.1.1.3 Recent developments

- 13.1.1.3.1 Expansions

- 13.1.1.4 MnM view

- 13.1.1.4.1 Key strengths

- 13.1.1.4.2 Strategic choices

- 13.1.1.4.3 Weaknesses and competitive threats

- 13.1.2 DIC CORPORATION

- 13.1.2.1 Business overview

- 13.1.2.2 Products/Solutions/Services offered

- 13.1.2.3 Recent developments

- 13.1.2.3.1 Deals

- 13.1.2.4 MnM view

- 13.1.2.4.1 Key strengths

- 13.1.2.4.2 Strategic choices

- 13.1.2.4.3 Weaknesses and competitive threats

- 13.1.3 SUDARSHAN CHEMICAL INDUSTRIES LIMITED

- 13.1.3.1 Business overview

- 13.1.3.2 Products/Solutions/Services offered

- 13.1.3.3 Recent developments

- 13.1.3.3.1 Deals

- 13.1.3.4 MnM view

- 13.1.3.4.1 Key strengths

- 13.1.3.4.2 Strategic choices

- 13.1.3.4.3 Weaknesses and competitive threats

- 13.1.4 VIBRANTZ

- 13.1.4.1 Business overview

- 13.1.4.2 Products/Solutions/Services offered

- 13.1.4.3 Recent developments

- 13.1.4.3.1 Deals

- 13.1.4.4 MnM view

- 13.1.4.4.1 Key strengths

- 13.1.4.4.2 Strategic choices

- 13.1.4.4.3 Weaknesses and competitive threats

- 13.1.5 CABOT CORPORATION

- 13.1.5.1 Business overview

- 13.1.5.2 Products/Solutions/Services offered

- 13.1.5.3 Recent developments

- 13.1.5.3.1 Expansions

- 13.1.5.4 MnM view

- 13.1.5.4.1 Key strengths

- 13.1.5.4.2 Strategic choices

- 13.1.5.4.3 Weaknesses and competitive threats

- 13.1.6 DYSTAR SINGAPORE PTE LTD

- 13.1.6.1 Business overview

- 13.1.6.2 Products/Solutions/Services offered

- 13.1.6.3 MnM view

- 13.1.7 LANXESS

- 13.1.7.1 Business overview

- 13.1.7.2 Products/Solutions/Services offered

- 13.1.7.3 Recent developments

- 13.1.7.3.1 Deals

- 13.1.7.4 MnM view

- 13.1.8 PENN COLOR INC.

- 13.1.8.1 Business overview

- 13.1.8.2 Products/Solutions/Services offered

- 13.1.8.3 Recent developments

- 13.1.8.3.1 Product launches

- 13.1.8.3.2 Deals

- 13.1.8.3.3 Expansions

- 13.1.8.4 MnM view

- 13.1.9 PIDILITE PIGMENT

- 13.1.9.1 Business overview

- 13.1.9.2 Products/Solutions/Services offered

- 13.1.9.3 MnM view

- 13.1.10 ARALON COLOR GMBH

- 13.1.10.1 Business overview

- 13.1.10.2 Products/Solutions/Services offered

- 13.1.10.3 MnM view

- 13.1.1 BASF SE

- 13.2 OTHER PLAYERS

- 13.2.1 AUM FARBENCHEM

- 13.2.2 ACHITEX MINERVA S.P.A

- 13.2.3 CHROMATECH INCORPORATED

- 13.2.4 DCL CORPORATION

- 13.2.5 DECORATIVE COLOR & CHEMICAL, INC.

- 13.2.6 DCC GROUP COMPANY LIMITED

- 13.2.7 KEMITEKS

- 13.2.8 MANALI PIGMENTS PVT. LTD.

- 13.2.9 MIKUNI-COLOR LTD.

- 13.2.10 RPM INTERNATIONAL INC.

- 13.2.11 SYNTHESIA, A.S.

- 13.2.12 TIARCO CHEMICALS

- 13.2.13 TENNANTS TEXTILE COLOURS LTD.

- 13.2.14 VIPUL ORGANICS LTD.

- 13.2.15 QUAKER COLOR

14 APPENDIX

- 14.1 DISCUSSION GUIDE

- 14.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 14.3 CUSTOMIZATION OPTIONS

- 14.4 RELATED REPORTS

- 14.5 AUTHOR DETAILS

List of Tables

- TABLE 1 REGULATIONS IN PIGMENTS MARKET

- TABLE 2 PER CAPITA GDP TRENDS, 2020-2023 (USD)

- TABLE 3 GDP GROWTH ESTIMATE AND PROJECTION FOR KEY COUNTRIES, 2024-2027 (USD)

- TABLE 4 INDUSTRY (INCLUDING CONSTRUCTION) VALUE-ADDED STATISTICS, BY COUNTRY, 2023 (USD MILLION)

- TABLE 5 PIGMENT DISPERSIONS MARKET: ROLE OF COMPANIES IN ECOSYSTEM

- TABLE 6 PIGMENT DISPERSIONS MARKET: KEY CONFERENCES & EVENTS, 2025-2026

- TABLE 7 PIGMENT DISPERSIONS MARKET, BY DISPERSION TYPE, 2022-2024 (USD MILLION)

- TABLE 8 PIGMENT DISPERSIONS MARKET, BY DISPERSION TYPE, 2025-2030 (USD MILLION)

- TABLE 9 PIGMENT DISPERSIONS MARKET, BY DISPERSION TYPE, 2022-2024 (KILOTON)

- TABLE 10 PIGMENT DISPERSIONS MARKET, BY DISPERSION TYPE, 2025-2030 (KILOTON)

- TABLE 11 PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 12 PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 13 PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (KILOTON)

- TABLE 14 PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (KILOTON)

- TABLE 15 PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 16 PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 17 PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 18 PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 19 PIGMENT DISPERSIONS MARKET, BY REGION, 2022-2024 (USD MILLION)

- TABLE 20 PIGMENT DISPERSIONS MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 21 PIGMENT DISPERSIONS MARKET, BY REGION, 2022-2024 (KILOTON)

- TABLE 22 PIGMENT DISPERSIONS MARKET, BY REGION, 2025-2030 (KILOTON)

- TABLE 23 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 24 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 25 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 26 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 27 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 28 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 29 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (KILOTON)

- TABLE 30 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (KILOTON)

- TABLE 31 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 32 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 33 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 34 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 35 CHINA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 36 CHINA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 37 CHINA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 38 CHINA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 39 INDIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 40 INDIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 41 INDIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 42 INDIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 43 JAPAN: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 44 JAPAN: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 45 JAPAN: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 46 JAPAN: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 47 SOUTH KOREA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 48 SOUTH KOREA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 49 SOUTH KOREA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 50 SOUTH KOREA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 51 INDONESIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 52 INDONESIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 53 INDONESIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 54 INDONESIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 55 REST OF ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 56 REST OF ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 57 REST OF ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 58 REST OF ASIA PACIFIC: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 59 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 60 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 61 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 62 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 63 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 64 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 65 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (KILOTON)

- TABLE 66 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (KILOTON)

- TABLE 67 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 68 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 69 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 70 NORTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 71 US: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 72 US: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 73 US: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 74 US: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 75 CANADA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 76 CANADA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 77 CANADA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 78 CANADA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 79 MEXICO: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 80 MEXICO: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 81 MEXICO: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 82 MEXICO: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 83 EUROPE: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 84 EUROPE: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 85 EUROPE: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 86 EUROPE: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 87 EUROPE: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 88 EUROPE: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 89 EUROPE: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (KILOTON)

- TABLE 90 EUROPE: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (KILOTON)

- TABLE 91 EUROPE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 92 EUROPE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 93 EUROPE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 94 EUROPE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 95 GERMANY: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 96 GERMANY: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 97 GERMANY: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 98 GERMANY: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 99 FRANCE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 100 FRANCE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 101 FRANCE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 102 FRANCE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 103 UK: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 104 UK: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 105 UK: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 106 UK: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 107 ITALY: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 108 ITALY: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 109 ITALY: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 110 ITALY: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 111 SPAIN: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 112 SPAIN: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 113 SPAIN: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 114 SPAIN: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 115 REST OF EUROPE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 116 REST OF EUROPE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 117 REST OF EUROPE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 118 REST OF EUROPE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 119 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 120 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 121 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 122 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 123 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 124 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 125 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (KILOTON)

- TABLE 126 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (KILOTON)

- TABLE 127 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 128 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 129 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 130 MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 131 SAUDI ARABIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 132 SAUDI ARABIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 133 SAUDI ARABIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 134 SAUDI ARABIA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 135 UAE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 136 UAE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 137 UAE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 138 UAE: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 139 REST OF GCC COUNTRIES: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 140 REST OF GCC COUNTRIES: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 141 REST OF GCC COUNTRIES: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 142 REST OF GCC COUNTRIES: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 143 SOUTH AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 144 SOUTH AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 145 SOUTH AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 146 SOUTH AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 147 REST OF MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 148 REST OF MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 149 REST OF MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 150 REST OF MIDDLE EAST & AFRICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 151 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 152 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 153 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2022-2024 (KILOTON)

- TABLE 154 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY COUNTRY, 2025-2030 (KILOTON)

- TABLE 155 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 156 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 157 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2022-2024 (KILOTON)

- TABLE 158 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY APPLICATION, 2025-2030 (KILOTON)

- TABLE 159 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 160 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 161 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 162 SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 163 BRAZIL: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 164 BRAZIL: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 165 BRAZIL: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 166 BRAZIL: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 167 ARGENTINA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 168 ARGENTINA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 169 ARGENTINA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 170 ARGENTINA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 171 REST OF SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 172 REST OF SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 173 REST OF SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2022-2024 (KILOTON)

- TABLE 174 REST OF SOUTH AMERICA: PIGMENT DISPERSIONS MARKET, BY END-USE INDUSTRY, 2025-2030 (KILOTON)

- TABLE 175 PIGMENT DISPERSIONS MARKET: DEGREE OF COMPETITION

- TABLE 176 PIGMENT DISPERSIONS MARKET: PRODUCT LAUNCHES, JANUARY 2020-JULY 2025

- TABLE 177 PIGMENT DISPERSIONS MARKET: DEALS, JANUARY 2020-JULY 2025

- TABLE 178 PIGMENT DISPERSIONS MARKET: EXPANSIONS, JANUARY 2020-JULY 2025

- TABLE 179 BASF SE: COMPANY OVERVIEW

- TABLE 180 BASF SE: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 181 BASF SE: EXPANSIONS

- TABLE 182 DIC CORPORATION: COMPANY OVERVIEW

- TABLE 183 DIC CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 184 DIC CORPORATION: DEALS

- TABLE 185 SUDARSHAN CHEMICAL INDUSTRIES LIMITED: COMPANY OVERVIEW

- TABLE 186 SUDARSHAN CHEMICAL INDUSTRIES LIMITED: PRODUCTS/SOLUTIONS/ SERVICES OFFERED

- TABLE 187 SUDARSHAN CHEMICAL INDUSTRIES LIMITED: DEALS

- TABLE 188 VIBRANTZ: COMPANY OVERVIEW

- TABLE 189 VIBRANTZ: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 190 VIBRANTZ: DEALS

- TABLE 191 CABOT CORPORATION: COMPANY OVERVIEW

- TABLE 192 CABOT CORPORATION: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 193 CABOT CORPORATION: EXPANSIONS

- TABLE 194 DYSTAR SINGAPORE PTE LTD: COMPANY OVERVIEW

- TABLE 195 DYSTAR SINGAPORE PTE LTD: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 196 LANXESS: COMPANY OVERVIEW

- TABLE 197 LANXESS: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 198 LANXESS: DEALS

- TABLE 199 PENN COLOR INC.: COMPANY OVERVIEW

- TABLE 200 PENN COLOR INC.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 201 PENN COLOR INC.: PRODUCT LAUNCHES

- TABLE 202 PENN COLOR INC.: DEALS

- TABLE 203 PENN COLOR INC.: EXPANSIONS

- TABLE 204 PIDILITE PIGMENT: COMPANY OVERVIEW

- TABLE 205 PIDILITE PIGMENT: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 206 ARALON COLOR GMBH: COMPANY OVERVIEW

- TABLE 207 ARALON COLOR GMBH: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 208 AUM FARBENCHEM: COMPANY OVERVIEW

- TABLE 209 ACHITEX MINERVA S.P.A: COMPANY OVERVIEW

- TABLE 210 CHROMATECH INCORPORATED: COMPANY OVERVIEW

- TABLE 211 DCL CORPORATION: COMPANY OVERVIEW

- TABLE 212 DECORATIVE COLOR & CHEMICAL, INC.: COMPANY OVERVIEW

- TABLE 213 DCC GROUP COMPANY LIMITED: COMPANY OVERVIEW

- TABLE 214 KEMITEKS: COMPANY OVERVIEW

- TABLE 215 MANALI PIGMENTS PVT. LTD.: COMPANY OVERVIEW

- TABLE 216 MIKUNI-COLOR LTD.: COMPANY OVERVIEW

- TABLE 217 RPM INTERNATIONAL INC.: COMPANY OVERVIEW

- TABLE 218 SYNTHESIA, A.S.: COMPANY OVERVIEW

- TABLE 219 TIARCO CHEMICAL: COMPANY OVERVIEW

- TABLE 220 TENNANTS TEXTILE COLOURS LTD.: COMPANY OVERVIEW

- TABLE 221 VIPUL ORGANICS LTD.: COMPANY OVERVIEW

- TABLE 222 QUAKER COLOR: COMPANY OVERVIEW

List of Figures

- FIGURE 1 PIGMENT DISPERSIONS MARKET SEGMENTATION & REGIONAL SCOPE

- FIGURE 2 PIGMENT DISPERSIONS MARKET: RESEARCH DESIGN

- FIGURE 3 PIGMENT DISPERSIONS MARKET: BOTTOM-UP APPROACH

- FIGURE 4 PIGMENT DISPERSIONS MARKET: TOP-DOWN APPROACH

- FIGURE 5 PIGMENT DISPERSIONS MARKET: DATA TRIANGULATION

- FIGURE 6 WATER-BASED DISPERSIONS TO DOMINATE PIGMENT DISPERSIONS MARKET IN 2025

- FIGURE 7 DECORATIVE PAINTS & COATINGS TO DOMINATE PIGMENT DISPERSIONS MARKET IN 2025

- FIGURE 8 PACKAGING TO BE FASTEST-GROWING END-USE INDUSTRY OF PIGMENT DISPERSIONS DURING FORECAST PERIOD

- FIGURE 9 ASIA PACIFIC TO BE FASTEST-GROWING PIGMENT DISPERSIONS MARKET

- FIGURE 10 GROWING BUILDING & CONSTRUCTION AND AUTOMOTIVE INDUSTRIES TO DRIVE PIGMENT DISPERSIONS MARKET

- FIGURE 11 WATER-BASED TO BE LARGER AND FASTER-GROWING DISPERSION TYPE DURING FORECAST PERIOD

- FIGURE 12 DECORATIVE PAINTS & COATINGS TO BE LARGEST AND FASTEST-GROWING DISPERSION TYPE DURING FORECAST PERIOD

- FIGURE 13 BUILDING & CONSTRUCTION TO BE LARGEST END-USE INDUSTRY DURING FORECAST PERIOD

- FIGURE 14 BUILDING & CONSTRUCTION INDUSTRY ACCOUNTED FOR LARGEST MARKET SHARE IN 2024

- FIGURE 15 INDIA TO REGISTER HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 16 PIGMENT DISPERSIONS MARKET: DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES

- FIGURE 17 PIGMENT DISPERSIONS MARKET: PORTER'S FIVE FORCES ANALYSIS

- FIGURE 18 VALUE CHAIN ANALYSIS

- FIGURE 19 AVERAGE SELLING PRICE TREND, BY REGION, 2022-2030 (USD/KG)

- FIGURE 20 IMPORT DATA FOR HS CODE 321290-COMPLIANT PRODUCTS, BY KEY COUNTRY, 2020-2024 (USD THOUSAND)

- FIGURE 21 EXPORT DATA FOR HS CODE 321290-COMPLIANT PRODUCTS, BY KEY COUNTRY, 2020-2024 (USD THOUSAND)

- FIGURE 22 PIGMENT DISPERSIONS MARKET: ECOSYSTEM

- FIGURE 23 TRENDS /DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 24 WATER-BASED DISPERSIONS SEGMENT TO DOMINATE PIGMENT DISPERSIONS MARKET DURING FORECAST PERIOD

- FIGURE 25 DECORATIVE PAINTS & COATINGS SEGMENT TO DOMINATE PIGMENT DISPERSIONS MARKET DURING FORECAST PERIOD

- FIGURE 26 BUILDING & CONSTRUCTION SEGMENT TO DOMINATE PIGMENT DISPERSIONS MARKET DURING FORECAST PERIOD

- FIGURE 27 PIGMENT DISPERSIONS MARKET IN INDIA TO REGISTER HIGHEST CAGR

- FIGURE 28 ASIA PACIFIC: PIGMENT DISPERSIONS MARKET SNAPSHOT

- FIGURE 29 EUROPE: PIGMENT DISPERSIONS MARKET SNAPSHOT

- FIGURE 30 OVERVIEW OF STRATEGIES ADOPTED BY KEY MARKET PLAYERS, JANUARY 2020-JUNE 2025

- FIGURE 31 PIGMENT DISPERSIONS MARKET: REVENUE ANALYSIS OF KEY PLAYERS, 2022-2024

- FIGURE 32 PIGMENT DISPERSIONS MARKET SHARE ANALYSIS, 2024

- FIGURE 33 PIGMENT DISPERSIONS MARKET: COMPANY EVALUATION MATRIX (KEY PLAYERS), 2024

- FIGURE 34 PRODUCT PORTFOLIO ANALYSIS OF KEY PLAYERS IN PIGMENT DISPERSIONS MARKET

- FIGURE 35 BUSINESS STRATEGY EXCELLENCE OF KEY PLAYERS IN PIGMENT DISPERSIONS MARKET

- FIGURE 36 PIGMENT DISPERSIONS MARKET: COMPANY EVALUATION MATRIX (STARTUPS/SMES), 2024

- FIGURE 37 PRODUCT PORTFOLIO ANALYSIS OF STARTUPS/SMES IN PIGMENT DISPERSIONS MARKET

- FIGURE 38 BUSINESS STRATEGY EXCELLENCE OF STARTUPS/SMES IN PIGMENT DISPERSIONS MARKET

- FIGURE 39 BASF SE: COMPANY SNAPSHOT

- FIGURE 40 DIC CORPORATION: COMPANY SNAPSHOT

- FIGURE 41 SUDARSHAN CHEMICAL INDUSTRIES LIMITED: COMPANY SNAPSHOT

- FIGURE 42 CABOT CORPORATION: COMPANY SNAPSHOT

- FIGURE 43 LANXESS: COMPANY SNAPSHOT

- FIGURE 44 PIDILITE PIGMENT: COMPANY SNAPSHOT