|

市場調查報告書

商品編碼

1913461

矽烷市場機會、成長要素、產業趨勢分析及2026年至2035年預測Silanes Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035 |

||||||

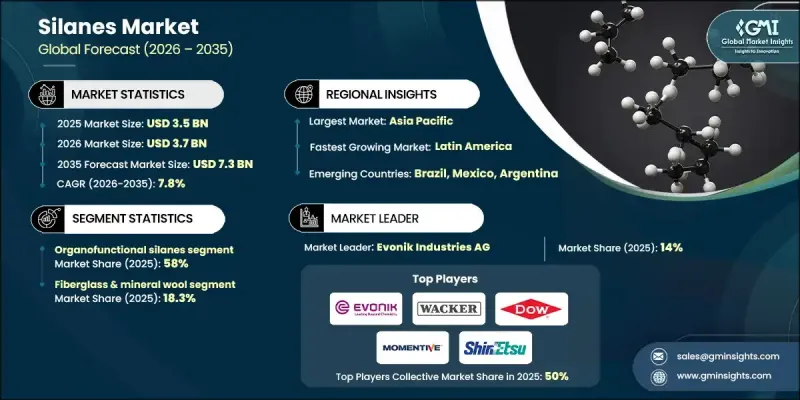

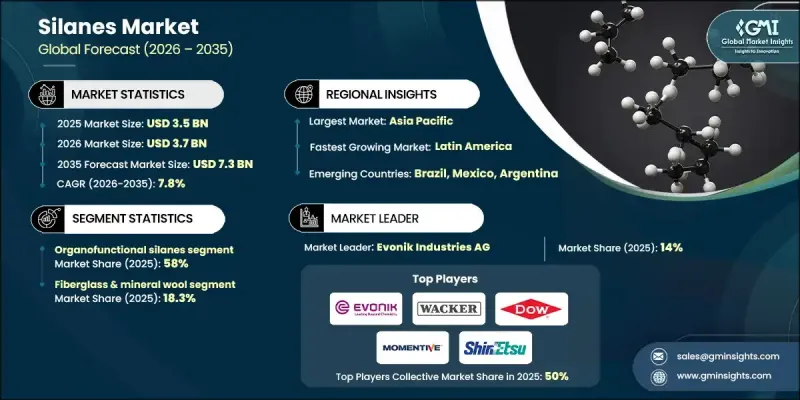

全球矽烷市場預計到 2025 年價值 35 億美元,到 2035 年達到 73 億美元,年複合成長率為 7.8%。

隨著建築、汽車和電子製造業活動的復甦,市場表現日益改善,推動了多個產業鏈對矽烷改質材料的需求成長。基礎設施投資和工業生產的增加,推動了矽烷增強密封劑、塗料和增強複合材料在結構、運輸和電氣設備應用領域的廣泛應用。減少排放的監管壓力促使製造商開發低排放、低溶劑和無金屬配方,加速了矽烷化學領域的創新。有機官能矽烷作為表面改質劑、黏合促進劑和尖端材料前驅物的應用日益廣泛,進一步促進了市場成長。高性能電子元件和先進封裝技術的產量增加也推動了市場需求,這些技術需要與精密製造環境相容的高純度矽烷。同時,交通運輸、可再生能源和工業複合材料領域的應用持續推動穩定的消費,因為製造商優先考慮材料的耐久性、黏合效率和長期性能。

| 市場覆蓋範圍 | |

|---|---|

| 開始年份 | 2025 |

| 預測年份 | 2026-2035 |

| 起始值 | 35億美元 |

| 預測金額 | 73億美元 |

| 複合年成長率 | 7.8% |

預計到 2025 年,有機官能矽烷市佔率將達到 58%,到 2035 年將以 8% 的複合年成長率成長。雖然其他類型的矽烷繼續作為矽基化學的重要中間體,但有機官能矽烷因其在塗料、電子產品和特種材料體系中的多功能性而越來越受到青睞。

2025年,玻璃纖維和礦物棉市場佔有率為18.3%,預計到2035年將以6.1%的複合年成長率成長。矽烷在提高隔熱材料、塗料和複合材料應用中的黏合強度、防潮性和機械穩定性方面發揮著至關重要的作用。

預計到 2025 年,美國矽烷市場規模將達到 6.092 億美元,主要得益於建築材料、電子製造和複合材料應用領域的強勁需求,以及基礎設施現代化和對高性能材料的持續投資。

目錄

第1章調查方法和範圍

第2章執行摘要

第3章業界考察

- 生態系分析

- 供應商情況

- 利潤率

- 每個階段的附加價值

- 影響價值鏈的因素

- 中斷

- 產業影響因素

- 促進要素

- 擴大電子設備、半導體和顯示器的生產

- 建築和基礎設施塗料市場的成長

- 增強塑膠和複合材料的使用日益增多

- 產業潛在風險與挑戰

- 某些矽烷化合物引發的環境與健康問題

- 對上游工程氯矽烷和矽供應的依賴

- 市場機遇

- 可再生能源、電纜和電網現代化

- 採用輕量化汽車和電動汽車零件

- 促進要素

- 成長潛力分析

- 監管環境

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特五力分析

- PESTEL 分析

- 價格趨勢

- 按地區

- 按類型

- 未來市場趨勢

- 科技與創新趨勢

- 當前技術趨勢

- 新興技術

- 專利狀態

- 貿易統計(HS編碼)

(註:貿易統計數據僅涵蓋主要國家。)

- 主要進口國

- 主要出口國

- 永續性和環境方面

- 永續努力

- 減少廢棄物策略

- 生產中的能源效率

- 環保舉措

- 考慮到碳足跡

第4章 競爭情勢

- 介紹

- 公司市佔率分析

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 按地區

- 企業矩陣分析

- 主要市場公司的競爭分析

- 競爭定位矩陣

- 重大進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 業務拓展計劃

第5章 按類型分類的市場估算與預測,2022-2035年

- 鹵代矽烷/氫化物官能化矽烷

- 氯矽烷

- 烷基矽烷

- 氫矽烷

- 有機官能矽烷

- 氨基矽烷

- 環氧矽烷

- 乙烯基矽烷

- 甲基丙烯醯氧基矽烷

- 硫矽烷

- 其他

第6章 按應用領域分類的市場估算與預測,2022-2035年

- 玻璃纖維和礦物棉

- 油漆和塗料

- 聚烯化合物

- 黏合劑和密封劑

- 溶膠-凝膠法

- 填料和顏料

- 澆鑄和澆鑄樹脂

- 矽酮

第7章 2022-2035年各地區市場估算與預測

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 亞太其他地區

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 其他拉丁美洲地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

- 其他中東和非洲地區

第8章 公司簡介

- Evonik Industries AG

- Wacker Chemie AG

- Momentive Performance Materials Inc.

- Dow Inc.

- Shin-Etsu Chemical Co., Ltd.

- Elkem ASA(Elkem Silicones)

- PCC SE

- Gelest, Inc.

- Nitrochemie AG

- Jiangxi Chenguang New Materials Co., Ltd.

- Nanjing Shuguang Chemical Group Co., Ltd.

- China National Bluestar(Group)Co., Ltd.

- Siltech Corporation

The Global Silanes Market was valued at USD 3.5 billion in 2025 and is estimated to grow at a CAGR of 7.8% to reach USD 7.3 billion by 2035.

Market performance is improving alongside the recovery of construction, automotive, and electronics manufacturing activities, which has strengthened demand for silane-modified materials across multiple industrial value chains. Rising investments in infrastructure and industrial output have increased the use of silane-enhanced sealants, coatings, and reinforced composites in structural, transportation, and electrical applications. Regulatory pressure to reduce emissions has encouraged manufacturers to develop low-emission, solvent-reduced, and metal-free formulations, accelerating innovation in silane chemistry. Growing adoption of organofunctional silanes as surface modifiers, adhesion promoters, and advanced material precursors is further supporting market expansion. Demand is also being reinforced by increased production of high-performance electronic components and advanced packaging technologies, which require high-purity silanes compatible with precision manufacturing environments. In parallel, applications in transportation, renewable energy, and industrial composites continue to drive consistent consumption as manufacturers prioritize durability, bonding efficiency, and long-term material performance.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $3.5 Billion |

| Forecast Value | $7.3 Billion |

| CAGR | 7.8% |

The organofunctional silanes segment accounted for 58% share in 2025 and is expected to grow at a CAGR of 8% through 2035. While other silane types continue to serve as essential intermediates in silicon-based chemistry, organofunctional grades are increasingly favored for their versatility across coatings, electronics, and specialty material systems.

The fiberglass and mineral wool segment held 18.3% share in 2025 and is forecast to expand at a CAGR of 6.1% by 2035. Silanes play a critical role in enhancing bonding strength, moisture resistance, and mechanical stability across insulation, coating, and composite applications.

U.S. Silanes Market reached USD 609.2 million in 2025, supported by strong demand from construction materials, electronics manufacturing, and composite applications, alongside continued investment in infrastructure modernization and high-performance materials.

Key companies operating in the Global Silanes Market include Dow Inc., Wacker Chemie AG, Shin-Etsu Chemical Co., Ltd., Evonik Industries AG, Elkem ASA, Momentive Performance Materials Inc., Gelest, Inc., Siltech Corporation, PCC SE, Nitrochemie AG, China National Bluestar (Group) Co., Ltd., Jiangxi Chenguang New Materials Co., Ltd., and Nanjing Shuguang Chemical Group Co., Ltd. Companies in the Silanes Market are strengthening their market position by investing in product innovation focused on low-emission and high-purity formulations. Strategic capacity expansions and process optimization are being used to ensure supply stability and cost efficiency. Many players are aligning their portfolios with regulatory requirements by developing environmentally compliant solutions. Collaboration with downstream manufacturers is helping accelerate application-specific customization and long-term supply agreements.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Type

- 2.2.3 Application

- 2.3 TAM Analysis, 2026-2035

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Expanding electronics, semiconductors and displays production

- 3.2.1.2 Growth of construction and infrastructure coatings

- 3.2.1.3 Rising use of reinforced plastics and composites

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 Environmental and health concerns around some silanes

- 3.2.2.2 Dependence on upstream chlorosilane, silicon supply

- 3.2.3 Market opportunities

- 3.2.3.1 Renewable energy, cable and grid modernization

- 3.2.3.2 Lightweight automotive and EV component adoption

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By type

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code)

( Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Type, 2022-2035 (USD Million) (Kilo Tons)

- 5.1 Key trends

- 5.2 Halosilanes / hydride functional silanes

- 5.2.1 Chlorosilanes

- 5.2.2 Alkylsilanes

- 5.2.3 Hydrosilanes

- 5.3 Organofunctional silanes

- 5.3.1 Amino silanes

- 5.3.2 Epoxy silanes

- 5.3.3 Vinyl silanes

- 5.3.4 Methacryloxy silanes

- 5.3.5 Sulfur silanes

- 5.3.6 Others

Chapter 6 Market Estimates and Forecast, By Application, 2022-2035 (USD Million) (Kilo Tons)

- 6.1 Key trends

- 6.2 Fiberglass & mineral wool

- 6.3 Paints & coatings

- 6.4 Polyolefin compounds

- 6.5 Adhesives & sealants

- 6.6 Sol-gel system

- 6.7 Fillers & pigments

- 6.8 Foundry & foundry resin

- 6.9 Silicones

Chapter 7 Market Estimates and Forecast, By Region, 2022-2035 (USD Million) (Kilo Tons)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.3 Europe

- 7.3.1 Germany

- 7.3.2 UK

- 7.3.3 France

- 7.3.4 Spain

- 7.3.5 Italy

- 7.3.6 Rest of Europe

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 India

- 7.4.3 Japan

- 7.4.4 Australia

- 7.4.5 South Korea

- 7.4.6 Rest of Asia Pacific

- 7.5 Latin America

- 7.5.1 Brazil

- 7.5.2 Mexico

- 7.5.3 Argentina

- 7.5.4 Rest of Latin America

- 7.6 Middle East and Africa

- 7.6.1 Saudi Arabia

- 7.6.2 South Africa

- 7.6.3 UAE

- 7.6.4 Rest of Middle East and Africa

Chapter 8 Company Profiles

- 8.1 Evonik Industries AG

- 8.2 Wacker Chemie AG

- 8.3 Momentive Performance Materials Inc.

- 8.4 Dow Inc.

- 8.5 Shin-Etsu Chemical Co., Ltd.

- 8.6 Elkem ASA (Elkem Silicones)

- 8.7 PCC SE

- 8.8 Gelest, Inc.

- 8.9 Nitrochemie AG

- 8.10 Jiangxi Chenguang New Materials Co., Ltd.

- 8.11 Nanjing Shuguang Chemical Group Co., Ltd.

- 8.12 China National Bluestar (Group) Co., Ltd.

- 8.13 Siltech Corporation