|

市場調查報告書

商品編碼

1913305

萘市場機會、成長要素、產業趨勢分析及2026年至2035年預測Naphthalene Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035 |

||||||

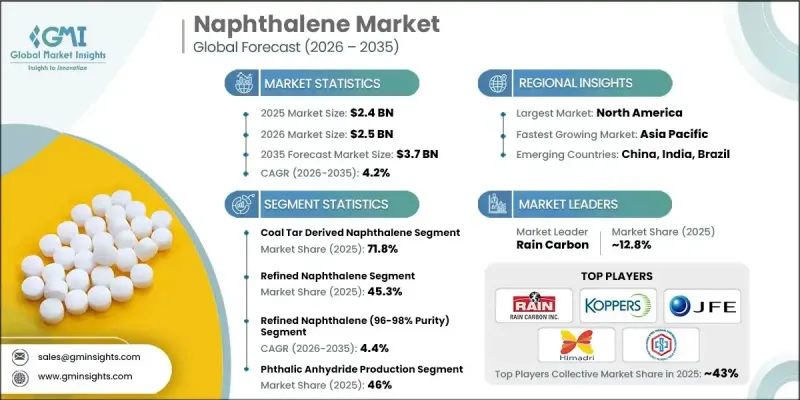

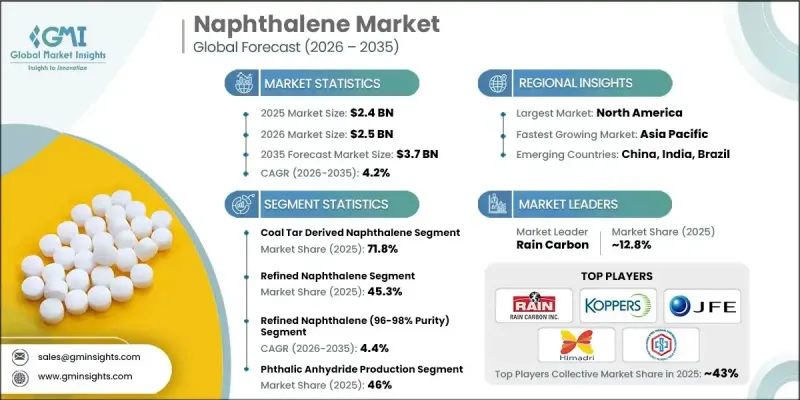

全球萘市場預計到 2025 年將達到 24 億美元,到 2035 年將達到 37 億美元,年複合成長率為 4.2%。

萘(化學式:CH)是一種多環芳烴,主要透過煤焦油加工和石油煉製生產。其商業供應形式多樣,包括精製萘、烷基萘和固體萘,純度從90-95%的麤品到99%以上的純度不等。萘廣泛用作化工生產鏈的核心原料、建築組合藥物以及成熟的工業應用。鄰鄰苯二甲酐需求的成長、建築化學品應用的擴展以及特種化學品應用的發展,共同推動了全球市場的擴張。生產商致力於清潔生產流程、精密精煉系統和差異化產品等級,以滿足不斷變化的客戶需求。加工效率和穩定性的提高,支撐了多個終端使用者產業和地區穩定的需求。不斷成長的需求、技術的進步和多樣化的應用,將繼續支撐萘市場的長期發展。

| 市場覆蓋範圍 | |

|---|---|

| 開始年份 | 2025 |

| 預測年份 | 2026-2035 |

| 起始值 | 24億美元 |

| 預測金額 | 37億美元 |

| 複合年成長率 | 4.2% |

精煉和品位控制技術的進步正在重塑高純度萘的生產方式。如今,無論是煤焦油原料或石油衍生原料,都能獲得純度超過99%的高純度萘,滿足高性能應用的需求。這得歸功於更嚴格的結晶控制和批次間一致性的提升。這些進步旨在滿足高價值化學合成和中間體生產所需的嚴格品質標準。先進的蒸餾技術、改良的結晶製程和基於氫化的製程在降低雜質含量的同時,提高了功能可靠性,使製造商能夠提供性能更可預測、更容易被工業界接受的萘產品。

2025年,煤焦油衍生萘市佔率佔比高達71.8%,預計2026年至2035年將以4%的複合年成長率持續成長。其市場主導地位主要歸功於與鋼鐵和焦化製程相銜接的成熟生產系統、良好的經濟效益以及穩定的產品品質。這項原料來源受益於全球廣泛的煤焦油基礎設施,該基礎設施支持大規模生產,同時保持了成本效益和供應穩定性。在主要消費地區擁有穩固的地位,並長期融入產業價值鏈,這些因素不斷鞏固了其在全球萘市場的主導地位。

2025年,精製萘市佔率佔比達45.3%,預計到2035年將以3.6%的複合年成長率成長。由於其純度穩定、操作性能優異,精製萘仍是大宗化學品加工的首選原料。其在綜合性化工生產設施中的廣泛應用,有助於高效的下游加工和可靠的運作性能。其完善的生產網路和顯著的經濟優勢,使其在全球化學品生產領域中持續佔據主導地位。

預計到2025年,美國萘市場規模將達到9.299億美元,反映了強勁的區域需求,而工業和建築相關行業的穩定消費則支撐了這一需求。成熟的生產設施、完善的加工基礎設施以及持續的終端用戶需求,共同支撐了國內市場的穩定性。持續投資於提高加工效率和供應鏈可靠性,將繼續為北美地區的需求成長奠定基礎。

目錄

第1章調查方法和範圍

第2章執行摘要

第3章業界考察

- 生態系分析

- 供應商情況

- 利潤率

- 每個階段的附加價值

- 影響價值鏈的因素

- 中斷

- 產業影響因素

- 促進要素

- 產業潛在風險與挑戰

- 市場機遇

- 成長潛力分析

- 監管環境

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特五力分析

- PESTEL 分析

- 科技與創新趨勢

- 當前技術趨勢

- 新興技術

- 價格趨勢

- 按地區

- 按產品等級

- 未來市場趨勢

- 專利狀態

- 貿易統計(HS編碼)(註:僅提供主要國家的貿易統計)

- 主要進口國

- 主要出口國

- 永續性和環境方面

- 永續努力

- 減少廢棄物策略

- 生產中的能源效率

- 環保舉措

- 考慮到碳足跡

第4章 競爭情勢

- 介紹

- 公司市佔率分析

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 按地區

- 企業矩陣分析

- 主要市場公司的競爭分析

- 競爭定位矩陣

- 重大進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章 按類型分類的市場估算與預測,2022-2035年

- 精製萘

- 烷基萘

- 萘固體

- 其他

6. 2022-2035年按來源分類的市場估計與預測

- 萘來自煤焦油

- 石油衍生的萘

- 回收和再生材料

第7章 依產品等級分類的市場估算與預測,2022-2035年

- 粗萘(純度90-95%)

- 精製萘(純度96-98%)

- 純萘(純度99%以上)

- 特殊等級和客製化產品

第8章 按應用領域分類的市場估算與預測,2022-2035年

- 鄰苯二甲酐的生產

- 表面活性劑和分散劑

- 減水劑(建築化學品)

- 染料和顏料(化學中間體)

- 傳統用途(驅蟲劑、鞣革劑)

- 新興及其他應用

第9章 2022-2035年各地區市場估算與預測

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 其他歐洲地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 亞太其他地區

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 其他拉丁美洲地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

- 其他中東和非洲地區

第10章:公司簡介

- Atom Scientific

- CDH Fine Chemical

- China Steel Chemical

- Deza

- Dong-Suh Chemical Ind. Co., Ltd.

- ExxonMobil Chemical

- Himadri Specialty Chemical Ltd.

- JFE Chemical Corporation

- King Industries

- Koppers

- PCC Group

- Rain Carbon

- Tulstar Products

The Global Naphthalene Market was valued at USD 2.4 billion in 2025 and is estimated to grow at a CAGR of 4.2% to reach USD 3.7 billion by 2035.

Naphthalene, chemically identified as C10H8, is a polycyclic aromatic hydrocarbon produced mainly through coal tar processing and petroleum refining. The material is supplied in multiple commercial forms such as refined naphthalene, alkyl naphthalene, and solid variants, with purity levels spanning from crude grades of 90-95% to high-purity grades exceeding 99%. It is widely used as a core feedstock in chemical manufacturing chains, construction-related formulations, and established industrial applications. Rising demand for phthalic anhydride, increasing use of construction chemicals, and the development of specialty chemical applications are collectively shaping market expansion worldwide. Producers are focusing on cleaner production routes, precision purification systems, and differentiated product grades to meet evolving customer specifications. Improvements in processing efficiency and consistency are supporting stable demand across multiple end-use industries and regions. This combination of demand growth, technology advancement, and diversified applications continues to support long-term development of the naphthalene market.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $2.4 billion |

| Forecast Value | $3.7 billion |

| CAGR | 4.2% |

Technological progress in purification and grade control is reshaping naphthalene manufacturing by enabling purity levels above 99% for high-performance uses, tighter crystallization management, and improved batch consistency from both coal tar and petroleum-based sources. These advancements are designed to meet strict quality benchmarks required for high-value chemical synthesis and intermediate production. Enhanced distillation, crystallization refinement, and hydrogenation-based processes are lowering impurity content while improving functional reliability, allowing manufacturers to deliver naphthalene products with more predictable performance and broader industrial acceptance.

The coal tar-based naphthalene segment held 71.8% share in 2025 and is forecast to grow at a CAGR of 4% from 2026 to 2035. Its dominance is attributed to mature production systems aligned with steel and coke processing operations, favorable yield economics, and stable output quality. This source benefits from extensive global coal tar infrastructure that supports large-scale production while maintaining cost efficiency and dependable supply. Its strong foothold across major consuming regions, combined with long-standing integration into industrial value chains, continues to reinforce its leadership in the global naphthalene landscape.

The refined naphthalene segment accounted for 45.3% share in 2025 and is anticipated to register a CAGR of 3.6% through 2035. This form remains the preferred choice for large-volume chemical processing due to its consistent purity and favorable handling characteristics. Its widespread use within integrated chemical manufacturing facilities supports efficient downstream processing and reliable operational performance. Established production networks and proven economic advantages contribute to its continued dominance across global chemical production hubs.

US Naphthalene Market generated USD 929.9 million in 2025, reflecting strong regional demand driven by steady consumption across industrial and construction-related sectors. The presence of established production facilities, integrated processing infrastructure, and sustained end-use requirements supports market stability within the country. Ongoing investment in processing efficiency and supply chain reliability continues to underpin demand growth across North America.

Key companies active in the Naphthalene Market include Rain Carbon, Himadri Specialty Chemical Ltd., ExxonMobil Chemical, Koppers, PCC Group, China Steel Chemical, JFE Chemical Corporation, and Dong-Suh Chemical Ind. Co., Ltd., Deza, King Industries, Atom Scientific, CDH Fine Chemical, and Tulstar Products. Companies operating in the Naphthalene Market are strengthening their market position through capacity optimization, investment in advanced purification technologies, and expansion of high-purity product portfolios. Many players are focusing on operational integration with upstream raw material sources to improve cost control and supply security. Strategic partnerships and long-term supply agreements are being used to stabilize demand and enhance regional presence. Firms are also prioritizing process efficiency, emission reduction, and sustainable production practices to align with evolving regulatory expectations.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Source

- 2.2.2 Form

- 2.2.3 Product Grade

- 2.2.4 Application

- 2.2.5 Regional

- 2.3 TAM Analysis, 2025-2035

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Technology and innovation landscape

- 3.7.1 Current technological trends

- 3.7.2 Emerging technologies

- 3.8 Price trends

- 3.8.1 By region

- 3.8.2 By product grade

- 3.9 Future market trends

- 3.10 Patent landscape

- 3.11 Trade statistics (HS code) ( Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Form, 2022-2035 (USD Million) (Kilo Tons)

- 5.1 Key trends

- 5.2 Refined naphthalene

- 5.3 Alkyl naphthalene

- 5.4 Naphthalene solid

- 5.5 Other

Chapter 6 Market Estimates and Forecast, By Source, 2022-2035 (USD Million) (Kilo Tons)

- 6.1 Key trends

- 6.2 Coal tar derived naphthalene

- 6.3 Petroleum derived naphthalene

- 6.4 Recycled and secondary sources

Chapter 7 Market Estimates and Forecast, By Product Grade, 2022-2035 (USD Million) (Kilo Tons)

- 7.1 Key trends

- 7.2 Crude naphthalene (90-95% purity)

- 7.3 Refined naphthalene (96-98% purity)

- 7.4 Pure naphthalene (99%+ purity)

- 7.5 Specialty grades and custom products

Chapter 8 Market Estimates and Forecast, By Application, 2022-2035 (USD Million) (Kilo Tons)

- 8.1 Key trends

- 8.2 Phthalic anhydride production

- 8.3 Surfactants & dispersants

- 8.4 Water reducing agents (construction chemicals)

- 8.5 Dyes & pigments (chemical intermediates)

- 8.6 Traditional applications (mothballs, tanning agents)

- 8.7 Emerging and other applications

Chapter 9 Market Estimates and Forecast, By Region, 2022-2035 (USD Million) (Kilo Tons)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Spain

- 9.3.5 Italy

- 9.3.6 Rest of Europe

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.4.6 Rest of Asia Pacific

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.5.4 Rest of Latin America

- 9.6 Middle East and Africa

- 9.6.1 Saudi Arabia

- 9.6.2 South Africa

- 9.6.3 UAE

- 9.6.4 Rest of Middle East and Africa

Chapter 10 Company Profiles

- 10.1 Atom Scientific

- 10.2 CDH Fine Chemical

- 10.3 China Steel Chemical

- 10.4 Deza

- 10.5 Dong-Suh Chemical Ind. Co., Ltd.

- 10.6 ExxonMobil Chemical

- 10.7 Himadri Specialty Chemical Ltd.

- 10.8 JFE Chemical Corporation

- 10.9 King Industries

- 10.10 Koppers

- 10.11 PCC Group

- 10.12 Rain Carbon

- 10.13 Tulstar Products