|

市場調查報告書

商品編碼

1892785

金屬粉末積層製造市場機會、成長促進因素、產業趨勢分析及預測(2026-2035年)Additive Manufacturing With Metal Powders Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035 |

||||||

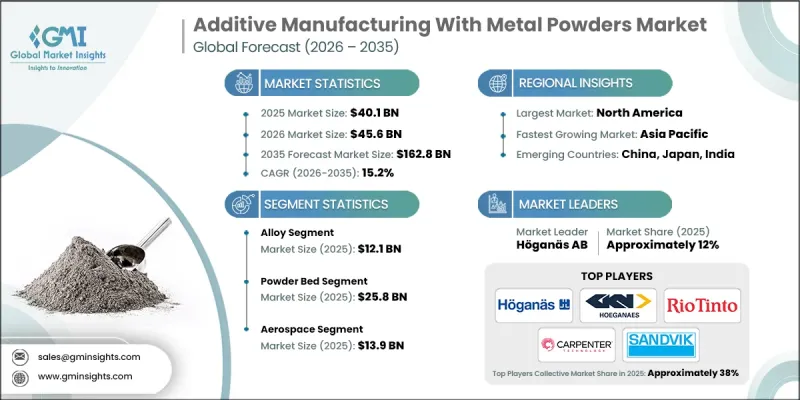

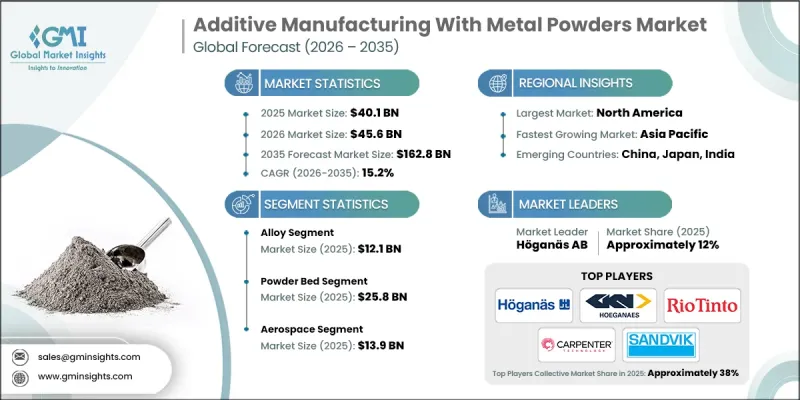

2025 年全球金屬粉末積層製造市場價值為 401 億美元,預計到 2035 年將以 15.2% 的複合年成長率成長至 1,628 億美元。

隨著各行業對輕量化、高強度零件的需求日益成長,以提升性能和燃油效率,金屬積層製造市場正在迅速擴張。航太、汽車和國防領域正轉向金屬積層製造,以實現複雜幾何形狀和輕量化,同時又不影響耐用性。包括雷射系統、電子束方法和多雷射裝置在內的3D列印技術的進步,正在加快建造速度並提高精度。粉末床熔融製程的廣泛應用提高了製程可靠性,縮短了生產週期,並改善了表面光潔度,從而推動了金屬積層製造解決方案的商業化。此外,醫療和牙科領域也透過採用金屬積層製造技術來生產客製化植入物、假體和手術器械,推動了市場成長,並帶來了對患者特定和高精度應用的大量需求。

| 市場範圍 | |

|---|---|

| 起始年份 | 2025 |

| 預測年份 | 2026-2035 |

| 起始值 | 401億美元 |

| 預測值 | 1628億美元 |

| 複合年成長率 | 15.2% |

2025年合金市場規模達121億美元,預計2035年將以15.5%的複合年成長率成長。包括不銹鋼在內的合金因其耐腐蝕性、機械強度和適用於複雜幾何形狀等優點而被廣泛應用。它們在航太、汽車、醫療和工業設備等領域的廣泛採用,正在創造永續的需求。其他類型的鋼材為結構件和模具應用提供了經濟高效的解決方案,使製造商能夠有效地擴大原型製作和功能性生產的規模。

2025年,航太領域市場規模達139億美元,佔全球市場佔有率的34.7%,預計2026年至2035年間將以14.9%的複合年成長率成長。航太、汽車和醫療產業正在推動對高性能、輕量化和高精度零件的需求。航太公司需要先進的結構件和引擎零件,而汽車製造商則利用金屬積層製造技術進行模具製造、原型製作以及小批量高性能零件的生產。隨著客製化植入物和手術器械的普及,醫療應用正在迅速擴展。這些產業的融合正在強化高精度金屬積層製造的發展趨勢。

預計2025年,北美金屬粉末積層製造市場規模將達138億美元。金屬粉末積層製造技術在航太、國防和醫療等領域的應用日益廣泛,尤其適用於製造輕量化、高精度零件。先進的數位化製造技術、完善的基礎設施以及持續的研發投入為該技術的商業化提供了有力支撐。金屬粉末積層製造在原型製作、模具製造和特殊零件製造領域的應用日益廣泛,加上混合和自動化製程的進步,正在推動區域市場的擴張。

目錄

第1章:方法論

第2章:執行概要

第3章:行業洞察

- 產業生態系分析

- 供應商格局

- 利潤率

- 每個階段的價值增加

- 影響價值鏈的因素

- 中斷

- 產業影響因素

- 成長促進因素

- 產業陷阱與挑戰

- 市場機遇

- 成長潛力分析

- 監管環境

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特的分析

- PESTEL 分析

- 價格趨勢

- 按地區

- 依產品

- 未來市場趨勢

- 技術與創新格局

- 當前技術趨勢

- 新興技術

- 專利格局

- 貿易統計(註:僅提供重點國家的貿易統計)

- 主要進口國

- 主要出口國

- 永續性和環境方面

- 永續實踐

- 減少廢棄物策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考量

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- MEA

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 合作夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估算與預測:依材料分類,2022-2035年

- 合金

- 鈦

- Ti6Al4V

- Ti6Al4V(ELI)

- 其他

- 鈷

- 鈷鉻

- CoCrWC

- 鈷鉻鉬

- 銅

- C18150

- CuCr1Zr

- CuNi2SiCr

- 鎳

- Inconel 625

- Inconel 718

- 哈氏合金X

- 鋁

- ALSi12

- ALSi7Mg

- ALSi10Mg

- AL6061

- 其他

- 鈦

- 不銹鋼

- 奧氏體鋼

- 馬氏體鋼

- 雙相鋼

- 鐵素體鋼

- 其他鋼鐵

- 高速鋼

- 工具鋼

- 低合金鋼

- 貴金屬

- 鉑

- 其他貴金屬

- 鎢

- 其他材料

- 碳化矽

- 氧化鋁粉末

- 鋯

- 二氧化鋯

- 鉬

- 鎂

- 氮化鋁

- 碳化鎢

第6章:市場估算與預測:依製造技術分類,2022-2035年

- 粉末床

- 直接金屬雷射燒結(DMLS)

- 選擇性雷射熔化(SLM)

- 電子束熔化(EBM)

- 吹粉

- 直接金屬沉積(DMD)

- 雷射工程淨成形(LENS)

- 其他

第7章:市場估計與預測:依應用領域分類,2022-2035年

- 航太

- 汽車

- 醫療的

- 石油和天然氣

- 能源

- 核

- 再生能源

- 其他

第8章:市場估算與預測:依地區分類,2022-2035年

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 歐洲其他地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 亞太其他地區

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

- 中東和非洲其他地區

第9章:公司簡介

- Hoganas AB

- GKN Powder Metallurgy (Hoeganaes)

- Rio Tinto

- Carpenter Technology Corporation

- Sandvik Additive Manufacturing

- LPW Technology

- AP&C (Advanced Powders & Coatings)

- Arcam AB

- EOS GmbH

- Bright Laser Technologies

- Huake 3D

- ReaLizer

The Global Additive Manufacturing With Metal Powders Market was valued at USD 40.1 billion in 2025 and is estimated to grow at a CAGR of 15.2% to reach USD 162.8 billion by 2035.

The market is expanding rapidly as industries increasingly demand lightweight, high-strength components to enhance performance and fuel efficiency. Aerospace, automotive, and defense sectors are transitioning to metal additive manufacturing to achieve complex geometries and weight reduction without compromising durability. Advances in 3D printing technologies, including laser systems, electron-beam methods, and multi-laser setups, are accelerating build speed and improving precision. Wider adoption of powder-bed fusion processes has enhanced process reliability, shortened production cycles, and improved surface finishes, driving the commercialization of metal AM solutions. Additionally, the medical and dental sectors are fueling growth by adopting metal additive manufacturing for customized implants, prosthetics, and surgical instruments, creating a surge in demand for patient-specific and high-precision applications.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $40.1 Billion |

| Forecast Value | $162.8 Billion |

| CAGR | 15.2% |

The alloy segment generated USD 12.1 billion in 2025 and is expected to grow at a CAGR of 15.5% through 2035. Alloys, including stainless steel, are widely used due to their corrosion resistance, mechanical strength, and suitability for complex geometries. Their broad adoption across aerospace, automotive, medical, and industrial equipment sectors is creating sustainable demand. Other types of steel provide cost-effective solutions for structural and tooling applications, allowing manufacturers to scale both prototyping and functional production efficiently.

The aerospace segment accounted for USD 13.9 billion in 2025, holding a 34.7% share, and is anticipated to grow at a CAGR of 14.9% during 2026-2035. Aerospace, automotive, and medical industries are driving demand for high-performance, lightweight, and precision components. Aerospace companies require advanced structural and engine parts, while automotive manufacturers use metal AM for tooling, prototyping, and limited-volume high-performance components. Medical applications are expanding rapidly as patient-specific implants and surgical tools gain traction. The convergence of these industries is reinforcing the trend toward high-precision metal additive manufacturing.

North America Additive Manufacturing With Metal Powders Market held USD 13.8 billion in 2025. Adoption of metal AM is rising across aerospace, defense, and medical sectors for lightweight, precise parts. Advanced digital manufacturing, well-established infrastructure, and ongoing R&D investments support commercialization. Growing use in prototyping, tooling, and specialty parts, along with hybrid and automated processes, is driving regional market expansion.

Key players in the Global Additive Manufacturing With Metal Powders Market include Hoganas AB, GKN Powder Metallurgy (Hoeganaes), Rio Tinto, Carpenter Technology Corporation, Sandvik Additive Manufacturing, and others. Companies in the Global Additive Manufacturing With Metal Powders Market are leveraging multiple strategies to strengthen their market presence. They are investing heavily in research and development to enhance printing speed, accuracy, and material compatibility. Strategic collaborations, joint ventures, and acquisitions are expanding product portfolios and geographic reach. Companies are introducing new alloy compositions and customizing solutions for aerospace, automotive, and medical applications. Adoption of digital and hybrid manufacturing systems, alongside automated post-processing and quality control solutions, helps streamline production and reduce costs. Additionally, firms are emphasizing customer training, technical support, and service networks to improve adoption rates, establish long-term partnerships, and maintain competitive advantage in a rapidly evolving industry.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Material

- 2.2.3 Manufacturing Technique

- 2.2.4 Application

- 2.3 TAM Analysis, 2026-2035

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By product

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and Environmental Aspects

- 3.12.1 Sustainable Practices

- 3.12.2 Waste Reduction Strategies

- 3.12.3 Energy Efficiency in Production

- 3.12.4 Eco-friendly Initiatives

- 3.13 Carbon Footprint Considerations

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Material, 2022- 2035 (USD Billion, Kilo Tons)

- 5.1 Key trends

- 5.2 Alloy

- 5.2.1 Titanium

- 5.2.1.1 Ti6Al4V

- 5.2.1.2 Ti6Al4V (ELI)

- 5.2.1.3 Others

- 5.2.2 Cobalt

- 5.2.2.1 CoCr

- 5.2.2.2 CoCrWC

- 5.2.2.3 CoCrMo

- 5.2.3 Copper

- 5.2.3.1 C18150

- 5.2.3.2 CuCr1Zr

- 5.2.3.3 CuNi2SiCr

- 5.2.4 Nickel

- 5.2.4.1 Inconel 625

- 5.2.4.2 Inconel 718

- 5.2.4.3 Hastelloy X

- 5.2.5 Aluminium

- 5.2.5.1 ALSi12

- 5.2.5.2 ALSi7Mg

- 5.2.5.3 ALSi10Mg

- 5.2.5.4 AL6061

- 5.2.5.5 Others

- 5.2.1 Titanium

- 5.3 Stainless Steel

- 5.3.1 Austenitic Steel

- 5.3.2 Martensitic Steel

- 5.3.3 Duplex steel

- 5.3.4 Ferritic Steel

- 5.4 Other Steel

- 5.4.1 High Speed Steel

- 5.4.2 Tool Steel

- 5.4.3 Low Alloy Steel

- 5.5 Precious Metal

- 5.5.1 Platinum

- 5.5.2 Other precious metal

- 5.6 Tungsten

- 5.7 Other materials

- 5.7.1 Silicon carbide

- 5.7.2 Aluminium oxide powder

- 5.7.3 Zirconium

- 5.7.4 Zirconium dioxide

- 5.7.5 Molybdenum

- 5.7.6 Magnesium

- 5.7.7 Aluminium nitride

- 5.7.8 Tungsten carbide

Chapter 6 Market Estimates and Forecast, By Manufacturing Technique, 2022 - 2035 (USD Billion, Kilo Tons)

- 6.1 Key trends

- 6.2 Powder Bed

- 6.2.1 Direct Metal Laser Sintering (DMLS)

- 6.2.2 Selective Laser Melting (SLM)

- 6.2.3 Electron Beam Melting (EBM)

- 6.3 Blown powder

- 6.3.1 Direct Metal Deposition (DMD)

- 6.3.2 Laser Engineering Net Shapes (LENS)

- 6.4 Others

Chapter 7 Market Estimates and Forecast, By Application, 2022 - 2035 (USD Billion, Kilo Tons)

- 7.1 Key trends

- 7.2 Aerospace

- 7.3 Automotive

- 7.4 Medical

- 7.5 Oil & Gas

- 7.6 Energy

- 7.6.1 Nuclear

- 7.6.2 Renewable

- 7.7 Other

Chapter 8 Market Estimates and Forecast, By Region, 2022 - 2035 (USD Billion, Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Italy

- 8.3.5 Spain

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East & Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East & Africa

Chapter 9 Company Profiles

- 9.1 Hoganas AB

- 9.2 GKN Powder Metallurgy (Hoeganaes)

- 9.3 Rio Tinto

- 9.4 Carpenter Technology Corporation

- 9.5 Sandvik Additive Manufacturing

- 9.6 LPW Technology

- 9.7 AP&C (Advanced Powders & Coatings)

- 9.8 Arcam AB

- 9.9 EOS GmbH

- 9.10 Bright Laser Technologies

- 9.11 Huake 3D

- 9.12 ReaLizer