|

市場調查報告書

商品編碼

1892771

全氟聚醚市場機會、成長促進因素、產業趨勢分析及預測(2026-2035年)Perfluoropolyether Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035 |

||||||

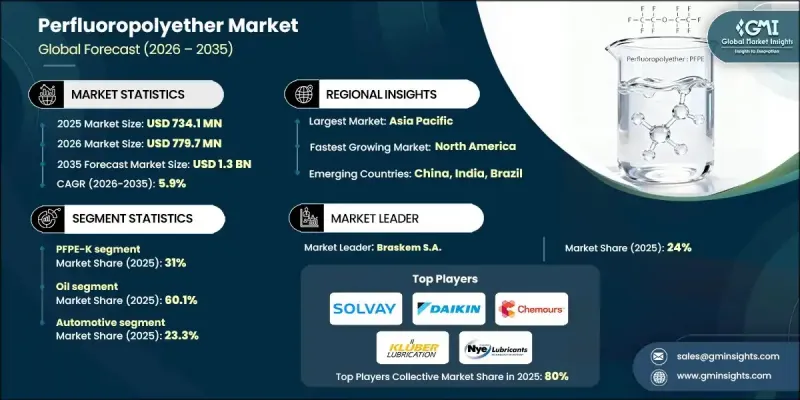

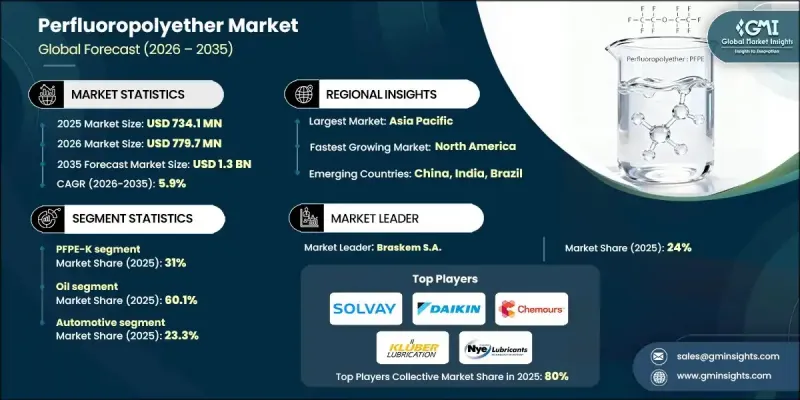

2025 年全球全氟聚醚市值為 7.341 億美元,預計到 2035 年將以 5.9% 的複合年成長率成長至 13 億美元。

全氟聚醚(PFPE)潤滑劑的獨特之處在於其能夠在極端條件下保持優異性能,包括高溫、腐蝕性化學品、真空環境和超潔淨的生產空間。這使得它們在航太、半導體製造、醫療器材和高科技電子等行業中至關重要,因為這些行業對可靠性、低揮發性和長使用壽命的要求極高。 2021年至2024年間,PFPE的需求與先進製造業的發展趨勢密切相關,尤其是在半導體、攜帶式電子產品和航太回收領域,這反映出這些產業對清潔、高性能潤滑劑的需求日益成長。自動化程度的提高、資料中心的擴張以及對半導體晶圓廠的投資進一步推動了PFPE在晶圓加工工具、真空幫浦和精密微機械裝置中的應用。此外,食品、醫療、製藥和發電行業日益嚴格的安全、環境和性能法規也支撐了對高純度PFPE配方的持續需求。

| 市場範圍 | |

|---|---|

| 起始年份 | 2025 |

| 預測年份 | 2026-2035 |

| 起始值 | 7.341億美元 |

| 預測值 | 13億美元 |

| 複合年成長率 | 5.9% |

2025年,PFPE-K市佔率達到31%,預計到2035年將以5.1%的複合年成長率成長。製造商正根據黏度、揮發性和熱穩定性對這些等級的產品進行客製化,以滿足半導體、航太、電動車和食品級應用領域的特定需求。許多客戶選擇從同一供應商購買兩種不同等級的PFPE產品,以簡化核准流程並減少認證延誤。

從產品形態來看,PFPE油品在2025年佔據了60.1%的市場佔有率,預計2026年至2035年將以5.8%的複合年成長率成長。企業正日益提供整合式油脂系統,旨在最佳化整個設備系統的耐溫性、承載能力和揮發性,而非僅提供單一的潤滑劑。這些解決方案廣泛應用於半導體機械、渦輪機、電動車傳動系統和無塵室作業等領域。

2025年北美全氟聚醚(PFPE)市場規模為2.06億美元,預計到2035年將達到3.676億美元,成為成長最快的區域市場。航太、半導體和先進汽車產業的需求成長,以及日益嚴格的可靠性標準和不斷成長的電動車產量,都推動了PFPE相對於傳統潤滑劑的日益普及。美國仍然是該地區PFPE的主要消費國,這得益於其集中的半導體製造廠、航太OEM廠商和先進醫療技術製造企業,從而支撐了對高純度、長壽命PFPE解決方案的強勁需求。

目錄

第1章:方法論與範圍

第2章:執行概要

第3章:行業洞察

- 產業生態系分析

- 供應商格局

- 利潤率

- 每個階段的價值增加

- 影響價值鏈的因素

- 中斷

- 產業影響因素

- 成長促進因素

- 在半導體和先進電子領域的應用日益廣泛

- 航太和高性能行動應用領域的恢復

- 更嚴格的安全、清潔和可靠性法規工程

- 產業陷阱與挑戰

- 高成本且複雜的氟化學品生產

- 對有限、專業化的全球供應商群體的依賴

- 市場機遇

- 電動車、電力電子和再生能源基礎設施的擴張

- 亞太地區先進製造業投資不斷成長

- 成長促進因素

- 成長潛力分析

- 監管環境

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特的分析

- PESTEL 分析

- 價格趨勢

- 按地區

- 依產品

- 未來市場趨勢

- 技術與創新格局

- 當前技術趨勢

- 新興技術

- 專利格局

- 貿易統計(HS編碼)(註:僅提供重點國家的貿易統計資料)

- 主要進口國

- 主要出口國

- 永續性和環境方面

- 永續實踐

- 減少廢棄物策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考量

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- MEA

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 合作夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估算與預測:依產品分類,2022-2035年

- PFPE-K

- PFPE-M

- PFPE-Z

- PFPE-Y

- PFPE-D

第6章:市場估算與預測:依類型分類,2022-2035年

- 油

- 潤滑脂

第7章:市場估算與預測:依最終用途分類,2022-2035年

- 汽車

- 引擎和動力總成部件

- 電動車傳動系統與電動機

- 軸承、密封件和接頭

- 煞車系統和執行器

- 內部機械裝置(開關、天窗、座椅滑軌)

- 航太

- 機身和控制系統

- 引擎和渦輪部件

- 起落架與作動系統

- 航空電子設備、連接器和感測器

- 太空船和衛星機制

- 電子

- 連接器和開關

- 微電子和半導體

- 硬碟驅動器和精密驅動器

- 冷卻和散熱系統

- 潔淨室和真空應用

- 金屬加工

- 熱軋和冷軋設備

- 熱處理爐

- 發電

- 燃氣渦輪機和蒸汽渦輪機

- 風力渦輪機齒輪箱和軸承

- 水力發電設備

- 核電廠輔助設備

- 紡織品

- 紡紗和撚線設備

- 織布機和針織機

- 染色和整理生產線

- 紙漿和造紙

- 烘乾機和日曆堆疊

- 壓機部件和輥筒

- 輸送機和搬運系統

- 其他

第8章:市場估算與預測:依地區分類,2022-2035年

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 歐洲其他地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 亞太其他地區

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

- 中東和非洲其他地區

第9章:公司簡介

- The Chemours Company

- Daikin Industries, Inc.

- Solvay

- M&I Materials Limited

- LUBRILOG SAS

- IKV Tribology

- Fluorotech USA

- Metalubgroup

- Setral Chemie GmbH

- Jet-Lube

- Kluber Lubrication

- Fomblin (Solvay brand)

- Nye Lubricants

- Dow (Specialty Fluids)

- Halocarbon Products Corporation

The Global Perfluoropolyether Market was valued at USD 734.1 million in 2025 and is estimated to grow at a CAGR of 5.9% to reach USD 1.3 billion by 2035.

PFPE lubricants are unique in their ability to perform under extreme conditions, including high temperatures, aggressive chemicals, vacuum environments, and ultra-clean manufacturing spaces. This makes them essential across industries such as aerospace, semiconductor fabrication, medical devices, and high-tech electronics, where reliability, low volatility, and long service life are critical. Between 2021 and 2024, PFPE demand closely aligns with advanced manufacturing trends, particularly in semiconductors, portable electronics, and aerospace recovery, reflecting the growing need for clean, high-performance lubricants in these sectors. Increasing automation, expansion of data centers, and investments in semiconductor fabs have further driven the adoption of PFPE in wafer processing tools, vacuum pumps, and precision micro-mechanisms. Additionally, stricter safety, environmental, and performance regulations in food, medical, pharmaceutical, and power-generation sectors are supporting sustained demand for high-purity PFPE formulations.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $734.1 Million |

| Forecast Value | $1.3 Billion |

| CAGR | 5.9% |

The PFPE-K segment held a 31% share in 2025 and is expected to grow at a CAGR of 5.1% through 2035. Manufacturers are customizing these grades based on viscosity, volatility, and thermal stability to meet the precise needs of semiconductors, aerospace, electric vehicles, and food-grade applications. Many clients opt to dual-source different PFPE grades from a single supplier to streamline approval processes and reduce qualification delays.

In terms of form, the PFPE oils segment held a 60.1% share in 2025 and is projected to grow at a CAGR of 5.8% from 2026 to 2035. Companies are increasingly offering integrated oil-grease systems designed to optimize temperature resistance, load-carrying capacity, and volatility across entire equipment systems, rather than providing standalone lubricants. These solutions are widely applied in semiconductor machinery, turbines, EV drivetrains, and cleanroom operations.

North America Perfluoropolyether Market accounted for USD 206 million in 2025 and is anticipated to reach USD 367.6 million by 2035, emerging as the fastest-growing regional market. Demand is driven by aerospace, semiconductor, and advanced automotive sectors, alongside stringent reliability standards and growing electric vehicle production, which increasingly favors PFPE over conventional lubricants. The U.S. remains the key PFPE consumer within the region due to its concentration of semiconductor fabs, aerospace OEMs, and advanced medical technology manufacturing, supporting robust demand for high-purity, long-life PFPE solutions.

Leading companies operating in the Global Perfluoropolyether Market include The Chemours Company, Daikin Industries, Inc., Solvay, M&I Materials Limited, LUBRILOG SAS, IKV Tribology, Fluorotech USA, Metalubgroup, Setral Chemie GmbH, Jet-Lube, Kluber Lubrication, Fomblin (Solvay brand), Nye Lubricants, Dow Specialty Fluids, and Halocarbon Products Corporation. Companies in the Global Perfluoropolyether Market are employing multiple strategies to strengthen their market presence and maintain a competitive edge. They are investing in R&D to develop customized PFPE grades that meet specific industrial requirements for viscosity, thermal stability, and low volatility. Strategic partnerships with semiconductor, aerospace, and medical equipment manufacturers help secure long-term supply agreements. Firms are expanding production facilities in high-demand regions to reduce lead times and improve supply chain efficiency.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product

- 2.2.3 Type

- 2.2.4 End Use

- 2.3 TAM Analysis, 2026-2035

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Growing use in semiconductor and advanced electronics

- 3.2.1.2 Recovery in aerospace and high-performance mobility applications

- 3.2.1.3 Stricter safety, cleanliness and reliability regulations engineering

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 High cost and complex fluorochemical production

- 3.2.2.2 Dependence on limited, specialized global supplier base

- 3.2.3 Market opportunities

- 3.2.3.1 Expansion of EV, power electronics and renewables infrastructure

- 3.2.3.2 Rising advanced manufacturing investments in Asia Pacific n

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By Product

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code) ( Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Product, 2022-2035 (USD Million) (Kilo Tons)

- 5.1 Key trends

- 5.2 PFPE-K

- 5.3 PFPE-M

- 5.4 PFPE-Z

- 5.5 PFPE-Y

- 5.6 PFPE-D

Chapter 6 Market Estimates and Forecast, By Type, 2022-2035 (USD Million) (Kilo Tons)

- 6.1 Key trends

- 6.2 Oil

- 6.3 Grease

Chapter 7 Market Estimates and Forecast, By End Use, 2022-2035 (USD Million) (Kilo Tons)

- 7.1 Key trends

- 7.2 Automotive

- 7.2.1 Engine and powertrain components

- 7.2.2 Electric vehicle drivetrains and e-motors

- 7.2.3 Bearings, seals, and joints

- 7.2.4 Brake systems and actuators

- 7.2.5 Interior mechanisms (switches, sunroof, seat tracks)

- 7.3 Aerospace

- 7.3.1 Airframe and control systems

- 7.3.2 Engine and turbine components

- 7.3.3 Landing gear and actuation systems

- 7.3.4 Avionics, connectors, and sensors

- 7.3.5 Spacecraft and satellite mechanisms

- 7.4 Electronics

- 7.4.1 Connectors and switches

- 7.4.2 Microelectronics and semiconductors

- 7.4.3 Hard disk drives and precision drives

- 7.4.4 Cooling and heat dissipation systems

- 7.4.5 Cleanroom and vacuum applications

- 7.5 Metal Processing

- 7.5.1 Hot and cold rolling equipment

- 7.5.2 Heat treatment furnaces

- 7.6 Power Generation

- 7.6.1 Gas and steam turbines

- 7.6.2 Wind turbine gearboxes and bearings

- 7.6.3 Hydropower equipment

- 7.6.4 Nuclear plant auxiliary equipment

- 7.7 Textile

- 7.7.1 Spinning and twisting equipment

- 7.7.2 Weaving and knitting machines

- 7.7.3 Dyeing and finishing lines

- 7.8 Pulp and Paper

- 7.8.1 Dryers and calendar stacks

- 7.8.2 Press sections and rollers

- 7.8.3 Conveyors and handling systems

- 7.9 Others

Chapter 8 Market Estimates and Forecast, By Region, 2022-2035 (USD Million) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 The Chemours Company

- 9.2 Daikin Industries, Inc.

- 9.3 Solvay

- 9.4 M&I Materials Limited

- 9.5 LUBRILOG SAS

- 9.6 IKV Tribology

- 9.7 Fluorotech USA

- 9.8 Metalubgroup

- 9.9 Setral Chemie GmbH

- 9.10 Jet-Lube

- 9.11 Kluber Lubrication

- 9.12 Fomblin (Solvay brand)

- 9.13 Nye Lubricants

- 9.14 Dow (Specialty Fluids)

- 9.15 Halocarbon Products Corporation