|

市場調查報告書

商品編碼

1892764

模切機市場機會、成長促進因素、產業趨勢分析及預測(2026-2035年)Die-Cutting Machine Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035 |

||||||

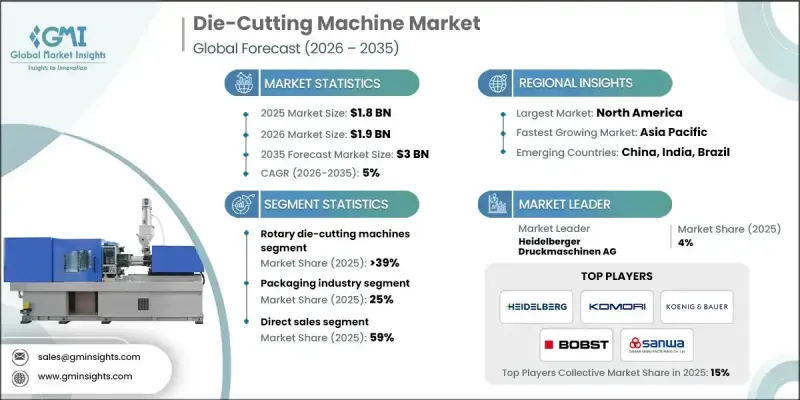

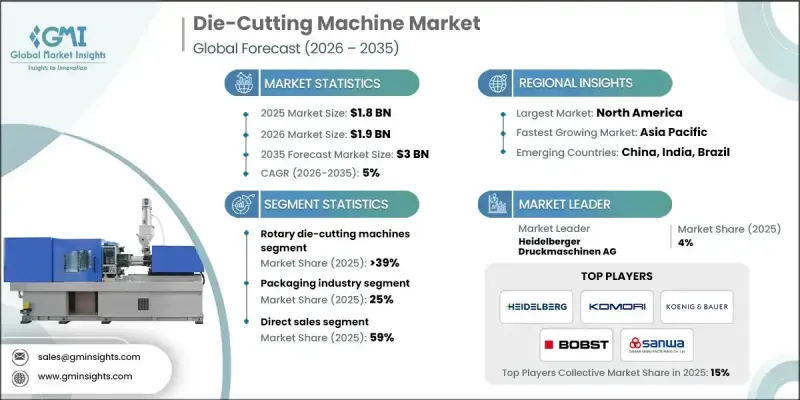

2025 年全球模切機市場價值為 18 億美元,預計到 2035 年將以 5% 的複合年成長率成長至 30 億美元。

隨著模切機從傳統機械工具向支援現代製造的先進智慧系統轉型,市場也在不斷發展。自動化是推動這一成長的主要動力,使製造商能夠實現更高的精度、更快的生產速度並減少對勞動力的依賴。電子商務的興起進一步加速了模切技術的應用,因為企業需要高效的方式來生產高品質、防護性強且外觀精美的包裝。永續性也影響市場,製造商在設計機器時力求符合全球環境標準,同時提高能源效率並減少浪費。物聯網和數位控制的整合正在幫助企業最佳化生產、最大限度地減少錯誤並提高整體營運效率,使模切機成為現代工業工作流程中不可或缺的工具。

| 市場範圍 | |

|---|---|

| 起始年份 | 2025 |

| 預測年份 | 2026-2035 |

| 起始值 | 18億美元 |

| 預測值 | 30億美元 |

| 複合年成長率 | 5% |

2024年,旋轉模切機市佔率達39%。其受歡迎的原因在於能夠高速連續切割材料,這對於包裝和標籤等大規模生產行業至關重要。與平板模切機不同,旋轉模切機在材料運動過程中進行加工,提高了大規模生產的效率和產量。

到2025年,包裝產業將佔全球市場佔有率的25%,創造5億美元的收入。該行業對紙盒、紙箱、標籤和軟包裝的精準切割需求,推動了對先進模切機的需求。電子商務和消費品產業的持續成長,也促使企業尋求創新的包裝解決方案,以提升產品吸引力並促進銷售。

2024年美國模切機市場規模達3.6億美元,預計2035年將以5%的複合年成長率成長。包裝、印刷和汽車行業的強勁需求,以及電子商務和消費品行業的快速成長,正在推動對自動化和高速機械的投資。美國製造商正擴大採用數位控制和物聯網系統,以提高生產效率、減少浪費並保持競爭力。

目錄

第1章:方法論與範圍

第2章:執行概要

第3章:行業洞察

- 產業生態系分析

- 供應商格局

- 利潤率

- 每個階段的價值增加

- 影響價值鏈的因素

- 產業影響因素

- 成長促進因素

- 包裝和印刷精度的需求日益成長

- 自動化和技術進步

- 電子商務和客製化趨勢的擴展

- 產業陷阱與挑戰

- 較高的初始投資和維護成本

- 技能差距與營運複雜性

- 機會

- 採用數位模切技術進行小批量生產

- 永續性和環保材料

- 成長促進因素

- 成長潛力分析

- 未來市場趨勢

- 技術與創新格局

- 當前技術趨勢

- 新興技術

- 價格趨勢

- 按地區

- 按機器類型

- 監管環境

- 標準和合規要求

- 區域監理框架

- 認證標準

- 波特的分析

- PESTEL 分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 合作夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估算與預測:依機器類型分類,2022-2035年

- 旋轉模切機

- 平板模切機

- 數位模切機

- 雷射標籤模切機

第6章:市場估算與預測:依營運模式分類,2022-2035年

- 半自動

- 自動的

第7章:市場估算與預測:依應用領域分類,2022-2035年

- 盒子

- 紙箱

- 標籤和貼紙

- 裝飾品

- 橡膠墊圈

- 其他(傳單等)

第8章:市場估算與預測:依最終用途產業分類,2022-2035年

- 包裝產業

- 汽車產業

- 製藥

- 紡織品

- 印刷和出版

- 其他(電子產品等)

第9章:市場估算與預測:依配銷通路分類,2022-2035年

- 直銷

- 間接銷售

第10章:市場估計與預測:依地區分類,2022-2035年

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 亞太地區

- 中國

- 日本

- 印度

- 澳洲

- 韓國

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中東和非洲

- 南非

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

第11章:公司簡介

- Heidelberger Druckmaschinen AG

- Komori Corporation

- Duplo International

- Yawa Printing Machinery Co., Ltd.

- Masterwork Machinery Co., Ltd.

- Hunkeler AG

- BOBST

- SANWA Co., Ltd.

- ASAHI MACHINERY Limited

- Delta ModTech

- Winkler+Dunnebier GmbH

- Sysco Machinery Co., Ltd.

- Berhalter AG

- DIMO TECH

- Koenig & Bauer AG

The Global Die-Cutting Machine Market was valued at USD 1.8 billion in 2025 and is estimated to grow at a CAGR of 5% to reach USD 3 billion by 2035.

The market is evolving as die-cutting machines transition from traditional mechanical tools to advanced, intelligent systems that support modern manufacturing. Automation is driving this growth, enabling manufacturers to achieve higher precision, faster production speeds, and reduced dependence on labor. The rise of e-commerce has further accelerated the adoption of die-cutting technologies, as businesses need efficient ways to produce high-quality, protective, and visually appealing packaging. Sustainability is also influencing the market, with manufacturers designing machines to meet global environmental standards while improving energy efficiency and reducing waste. The integration of IoT and digital controls is helping companies optimize production, minimize errors, and increase overall operational efficiency, positioning die-cutting machines as essential tools in contemporary industrial workflows.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $1.8 Billion |

| Forecast Value | $3 Billion |

| CAGR | 5% |

The rotary die-cutting machines segment held a 39% share in 2024. Their popularity stems from their ability to cut materials continuously at high speeds, a critical requirement in mass production industries such as packaging and labeling. Unlike flatbed cutters, rotary machines process materials in motion, improving efficiency and throughput for large-scale operations.

The packaging industry accounted for a 25% share in 2025, generating USD 500 million. The sector's reliance on precise cutting for boxes, cartons, labels, and flexible packaging drives the demand for advanced die-cutting machines. Growth in e-commerce and consumer goods continues to push companies toward innovative packaging solutions that enhance product appeal and boost sales.

U.S. Die-Cutting Machine Market generated USD 360 million in 2024 and is projected to grow at a CAGR of 5% through 2035. Strong demand from the packaging, printing, and automotive industries, coupled with rapid growth in e-commerce and consumer products, is driving investments in automated and high-speed machinery. U.S. manufacturers are increasingly adopting digital controls and IoT-enabled systems to enhance productivity, reduce waste, and stay competitive.

Key players in the Global Die-Cutting Machine Market include Komori Corporation, Hunkeler AG, Delta ModTech, Winkler+Dunnebier GmbH, Yawa Printing Machinery Co., Ltd., BOBST, Berhalter AG, Heidelberger Druckmaschinen AG, SANWA Co., Ltd., ASAHI MACHINERY Limited, DIMO TECH, Masterwork Machinery Co., Ltd., Duplo International, Sysco Machinery Co., Ltd., and Koenig & Bauer AG. Companies in the Die-Cutting Machine Market are leveraging several strategies to strengthen their market position and expand their footprint. They are heavily investing in research and development to deliver innovative, high-speed, and automated solutions tailored to evolving packaging needs. Strategic collaborations with industrial integrators and OEMs improve distribution channels and customer reach. Market players are also focusing on geographic expansion to tap into emerging markets while enhancing service networks and technical support. Adoption of smart technologies, including IoT and digital monitoring, helps manufacturers optimize machine performance, minimize downtime, and offer value-added solutions.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Machine type

- 2.2.3 Mode of operation

- 2.2.4 Application

- 2.2.5 End use industry

- 2.2.6 Distribution channel

- 2.3 CXO perspectives: strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Growing demand for precision in packaging and printing

- 3.2.1.2 Automation and technological advancements

- 3.2.1.3 Expansion of e-commerce and customization trends

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment and maintenance costs

- 3.2.2.2 Skill gap and operational complexity

- 3.2.3 Opportunities

- 3.2.3.1 Adoption of digital die cutting for short runs

- 3.2.3.2 Sustainability and eco-friendly materials

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By machine type

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Machine Type, 2022 - 2035 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Rotary die-cutting machines

- 5.3 Flatbed die-cutting machines

- 5.4 Digital die-cutting machines

- 5.5 Laser label die-cutting machine

Chapter 6 Market Estimates and Forecast, By Mode of Operation, 2022 - 2035 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Semi-automatic

- 6.3 Automatic

Chapter 7 Market Estimates and Forecast, By Application, 2022 - 2035 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Boxes

- 7.3 Cartons

- 7.4 Labels and stickers

- 7.5 Decorative items

- 7.6 Rubber gaskets

- 7.7 Others (flyers, etc.)

Chapter 8 Market Estimates and Forecast, By End Use Industry, 2022 - 2035 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Packaging industry

- 8.3 Automotive industry

- 8.4 Pharmaceuticals

- 8.5 Textile

- 8.6 Printing and publishing

- 8.7 Others (electronics, etc.)

Chapter 9 Market Estimates and Forecast, By Distribution Channel, 2022 - 2035 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 Direct sales

- 9.3 Indirect sales

Chapter 10 Market Estimates and Forecast, By Region, 2022 - 2035 (USD Billion) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 Japan

- 10.4.3 India

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 Middle East and Africa

- 10.6.1 South Africa

- 10.6.2 Saudi Arabia

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 Heidelberger Druckmaschinen AG

- 11.2 Komori Corporation

- 11.3 Duplo International

- 11.4 Yawa Printing Machinery Co., Ltd.

- 11.5 Masterwork Machinery Co., Ltd.

- 11.6 Hunkeler AG

- 11.7 BOBST

- 11.8 SANWA Co., Ltd.

- 11.9 ASAHI MACHINERY Limited

- 11.10 Delta ModTech

- 11.11 Winkler+Dunnebier GmbH

- 11.12 Sysco Machinery Co., Ltd.

- 11.13 Berhalter AG

- 11.14 DIMO TECH

- 11.15 Koenig & Bauer AG