|

市場調查報告書

商品編碼

1885783

機器人包裝系統市場機會、成長促進因素、產業趨勢分析及預測(2025-2034年)Robotic Packaging System Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

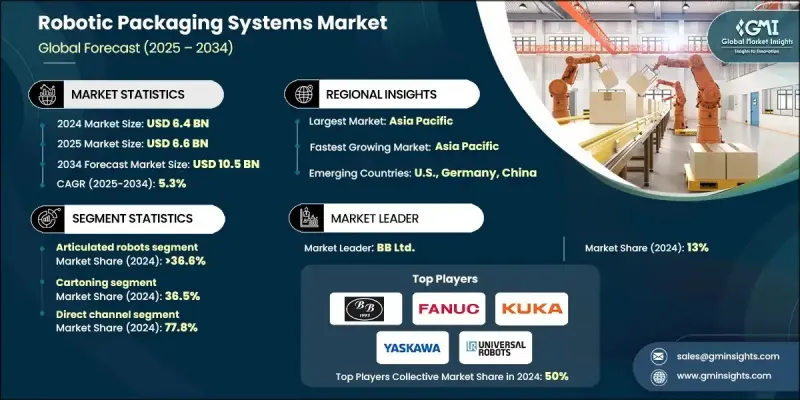

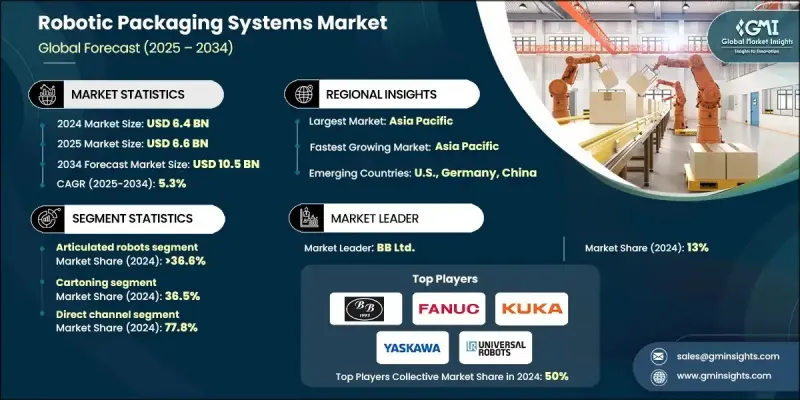

2024 年全球機器人包裝系統市場價值為 64 億美元,預計到 2034 年將以 5.3% 的複合年成長率成長至 105 億美元。

自動化技術的快速發展推動了包裝產業的成長。機器視覺、人工智慧、軟性抓取工具和協作機器人等技術的進步,使包裝作業更加快速、安全和精準。工業4.0功能的深度整合,使機器人能夠與互聯設備協同工作,從而實現生產線的預測性維護和即時最佳化。隨著製造商採用可靈活部署到不同工作流程並以最小停機時間重新編程的系統,協作機器人的應用日益普及。這些解決方案增強了人機交互,有助於提高生產效率、改善工作場所安全性並提升可靠性。現代機器人包裝平台融合了先進的視覺系統、機器學習驅動的最佳化、物聯網遠端監控和雲端分析,從而最大限度地延長正常運行時間和提高營運效率。這種技術融合支援持續的效能提升,並使製造商能夠根據即時生產資料即時調整包裝流程。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 64億美元 |

| 預測值 | 105億美元 |

| 複合年成長率 | 5.3% |

2024年,關節型機器人市佔率達到36.6%,預計2034年將以5.9%的複合年成長率成長。這類機器人擅長包裝環境,能勝任需要多軸運動和靈活操控的工作。其結構靈活性使其能夠在單一自動化系統中適應各種產品形狀和包裝形式,從而滿足不斷變化的生產需求。預計的成長凸顯了市場對能夠滿足不斷變化的自動化需求的高性能系統的日益成長的需求。

2024年,包裝材料市場規模預計將達21億美元。該市場涵蓋一系列包裝技術,旨在確保產品在整個運輸鏈中的安全。自動化包裝系統可實現薄膜均勻塗覆、提高貨物穩定性並減少材料用量,從而提高效率並最大限度地減少分銷過程中的產品損壞。

亞太地區機器人包裝系統市場預計在2024年達到28億美元。該地區的成長得益於強勁的製造業活動、政府對自動化日益成長的支持以及不斷上漲的勞動力成本,這些因素都促使機器人技術得到更廣泛的應用。消費品、汽車和電子產業的大批量生產環境對該地區的成長尤為重要。隨著各行業採用更先進的自動化系統來實現包裝作業的現代化,中國仍然是該地區需求的主要貢獻者。

全球機器人包裝系統市場的主要參與者包括ABB有限公司、Brenton Engineering、斗山機器人、發那科株式會社、克朗斯股份公司、庫卡股份公司、三菱電機、歐姆龍株式會社、施耐德電氣、Standard Bots、史陶比爾、Syntegon Technology、TechMan Robot、Universal Robots以及安川電機/Motoman。參與機器人包裝系統市場的企業採取多種策略措施來鞏固其市場地位。許多企業加強研發投入,以提高機器人的精度、速度和多功能性,同時整合先進的感測器和人工智慧驅動的分析技術。製造商正在擴展模組化和靈活的產品線,以實現輕鬆客製化和快速換型。與系統整合商和終端用戶行業的策略合作有助於拓寬應用範圍,並支援客製化的自動化解決方案。

目錄

第1章:方法論與範圍

第2章:執行概要

第3章:行業洞察

- 產業生態系分析

- 供應商格局

- 利潤率

- 每個階段的價值增加

- 影響價值鏈的因素

- 產業影響因素

- 成長促進因素

- 勞動成本上升和勞動短缺

- 對效率、品質、速度和可擴展性的需求

- 技術進步和自動化推動

- 產業陷阱與挑戰

- 初始投資和資本成本高

- 整合複雜性和遺留系統/員工技能差距

- 產品/包裝形式的多樣性及靈活性需求

- 機會

- 包裝機器人市場快速成長

- 在食品、飲料和消費品領域不斷擴大應用

- 對靈活、模組化和經濟高效的系統的需求不斷成長

- 成長促進因素

- 成長潛力分析

- 未來市場趨勢

- 技術與創新格局

- 當前技術趨勢

- 新興技術

- 價格趨勢

- 按地區

- 按機器人類型

- 監管環境

- 標準和合規要求

- 區域監理框架

- 波特的分析

- PESTEL 分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 合作夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估算與預測:依機器人類型分類,2021-2034年

- 主要趨勢

- 關節機器人(6軸)

- SCARA機器人

- Delta機器人

- 笛卡兒/龍門機器人

- 協作機器人(Cobots)

- 圓柱形機器人

- 移動機器人(AMR/AGV)

第6章:市場估價與預測:依包裝類型分類,2021-2034年

- 主要趨勢

- 裝盒

- 包裝

- 托盤堆疊

- 裝瓶

第7章:市場估計與預測:依應用領域分類,2021-2034年

- 主要趨勢

- 揀選和放置操作

- 托盤堆疊和卸垛

- 裝箱和托盤包裝

- 物料搬運

- 灌裝和分發

- 密封和封蓋

- 標籤和編碼

- 檢驗與品質管制

第8章:市場估算與預測:依最終用途產業分類,2021-2034年

- 主要趨勢

- 餐飲

- 醫藥與醫療保健

- 消費品和化妝品

- 汽車

- 電學

- 物流與電子商務

- 化工及工業

第9章:市場估算與預測:依配銷通路分類,2021-2034年

- 主要趨勢

- 直接的

- 間接

第10章:市場估計與預測:依地區分類,2021-2034年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- MEA

- 阿拉伯聯合大公國

- 南非

- 沙烏地阿拉伯

第11章:公司簡介

- ABB Ltd.

- Brenton Engineering

- Doosan Robotics

- FANUC Corporation

- Krones AG

- KUKA AG

- Mitsubishi Electric

- Omron Corporation

- Schneider Electric

- Standard Bots

- Staubli

- Syntegon Technology

- TechMan Robot

- Universal Robots

- Yaskawa Electric / Motoman

The Global Robotic Packaging Systems Market was valued at USD 6.4 billion in 2024 and is estimated to grow at a CAGR of 5.3% to reach USD 10.5 billion by 2034.

Growth is driven by rapid advancements in automation technologies, where machine vision, artificial intelligence, flexible gripping tools, and collaborative robotics are making packaging operations faster, safer, and more precise. Greater integration of Industry 4.0 capabilities allows robots to coordinate with connected devices, enabling predictive maintenance and real-time optimization across production lines. Collaborative robots continue to gain traction as manufacturers adopt flexible systems that can be redeployed across different workflows and reprogrammed with minimal downtime. These solutions enhance human-robot interaction and contribute to better throughput, improved workplace safety, and higher reliability. Modern robotic packaging platforms now combine advanced vision systems, machine-learning-powered optimization, IoT-enabled remote monitoring, and cloud-driven analytics to maximize uptime and operational efficiency. This technological convergence supports continuous performance improvements and allows manufacturers to adjust packaging processes instantly based on live production data.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $6.4 Billion |

| Forecast Value | $10.5 Billion |

| CAGR | 5.3% |

The articulated robotics segment held a 36.6% share in 2024 and is forecast to grow at a CAGR of 5.9% through 2034. These robots excel in packaging environments requiring multiple axes of motion and adaptable handling capabilities. Their structural flexibility enables them to accommodate varied product shapes and packaging formats within a single automated setup, making them suitable for operations that deal with shifting production requirements. Their projected growth underscores rising demand for highly capable systems that can meet evolving automation needs.

The wrapping segment generated USD 2.1 billion in 2024. This segment includes a range of wrapping technologies designed to ensure product protection throughout the transportation chain. Automated wrapping systems deliver consistent film application, improved load stabilization, and reduced material usage, which supports efficiency and minimizes product damage throughout distribution.

Asia Pacific Robotic Packaging Systems Market generated USD 2.8 billion in 2024. Expansion in this region is supported by strong manufacturing activity, increased government support for automation, and rising labor costs that encourage wider adoption of robotics. The region's growth is particularly influenced by high-volume production environments across consumer goods, automotive, and electronics sectors. China remains the leading contributor to regional demand as industries modernize their packaging operations with more advanced automation systems.

Key companies active in the Global Robotic Packaging Systems Market include ABB Ltd., Brenton Engineering, Doosan Robotics, FANUC Corporation, Krones AG, KUKA AG, Mitsubishi Electric, Omron Corporation, Schneider Electric, Standard Bots, Staubli, Syntegon Technology, TechMan Robot, Universal Robots, and Yaskawa Electric / Motoman. Companies participating in the Robotic Packaging Systems Market implement a variety of strategic measures to strengthen their market position. Many invest in R&D to enhance robotic precision, speed, and multi-functionality while integrating advanced sensors and AI-driven analytics. Manufacturers are expanding modular and flexible product lines that allow easy customization and faster changeovers. Strategic partnerships with system integrators and end-use industries help broaden application reach and support tailored automation solutions.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.3 Data collection methods

- 1.4 Data mining sources

- 1.4.1 Global

- 1.4.2 Regional/Country

- 1.5 Base estimates and calculations

- 1.5.1 Base year calculation

- 1.5.2 Key trends for market estimation

- 1.6 Primary research and validation

- 1.6.1 Primary sources

- 1.7 Forecast model

- 1.8 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Robot type

- 2.2.3 Packaging type

- 2.2.4 Application

- 2.2.5 End Use industry

- 2.2.6 Distribution channel

- 2.3 CXO perspectives: strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factors affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rising labor costs & labor shortage

- 3.2.1.2 Need for efficiency, quality, speed & scalability

- 3.2.1.3 Technological advancement & automation push

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment & capital cost

- 3.2.2.2 Integration complexity & legacy systems/workforce skill gap

- 3.2.2.3 Variability in product/pack formats & flexibility needs

- 3.2.3 Opportunities

- 3.2.3.1 Rapid market growth in packaging robotics

- 3.2.3.2 Expanding use in food, beverage, and consumer goods sectors

- 3.2.3.3 Rising demand for flexible, modular, and cost-efficient systems

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By Robot type

- 3.7 Regulatory landscape

- 3.7.1 standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Robot Type, 2021 - 2034 ($Bn, Thousand Units)

- 5.1 Key trends

- 5.2 Articulated robots (6-axis)

- 5.3 SCARA robots

- 5.4 Delta robots

- 5.5 Cartesian/gantry robots

- 5.6 Collaborative robots (Cobots)

- 5.7 Cylindrical robots

- 5.8 Mobile robots (AMRs/AGVs)

Chapter 6 Market Estimates & Forecast, By Packaging Type, 2021 - 2034 ($Bn, Thousand Units)

- 6.1 Key trends

- 6.2 Cartoning

- 6.3 Wrapping

- 6.4 Palletizing

- 6.5 Bottling

Chapter 7 Market Estimates & Forecast, By Application, 2021 - 2034 ($Bn, Thousand Units)

- 7.1 Key trends

- 7.2 Pick & place operations

- 7.3 Palletizing & depalletizing

- 7.4 Case packing & tray packing

- 7.5 Material handling

- 7.6 Filling & dispensing

- 7.7 Sealing & capping

- 7.8 Labeling & coding

- 7.9 Inspection & quality control

Chapter 8 Market Estimates & Forecast, By End Use Industry, 2021 - 2034 ($Bn, Thousand Units)

- 8.1 Key trends

- 8.2 Food & beverage

- 8.3 Pharmaceuticals & healthcare

- 8.4 Consumer goods & cosmetics

- 8.5 Automotive

- 8.6 Electronics & electrical

- 8.7 Logistics & e-commerce

- 8.8 Chemicals & Industrials

Chapter 9 Market Estimates & Forecast, By Distribution Channel, 2021 - 2034 ($Bn, Thousand Units)

- 9.1 Key trends

- 9.2 Direct

- 9.3 Indirect

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034 ($Bn, Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 UK

- 10.3.2 Germany

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.3.6 Russia

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 MEA

- 10.6.1 UAE

- 10.6.2 South Africa

- 10.6.3 Saudi Arabia

Chapter 11 Company Profiles

- 11.1 ABB Ltd.

- 11.2 Brenton Engineering

- 11.3 Doosan Robotics

- 11.4 FANUC Corporation

- 11.5 Krones AG

- 11.6 KUKA AG

- 11.7 Mitsubishi Electric

- 11.8 Omron Corporation

- 11.9 Schneider Electric

- 11.10 Standard Bots

- 11.11 Staubli

- 11.12 Syntegon Technology

- 11.13 TechMan Robot

- 11.14 Universal Robots

- 11.15 Yaskawa Electric / Motoman