|

市場調查報告書

商品編碼

1858858

印刷電子導電油墨市場機會、成長促進因素、產業趨勢分析及預測(2025-2034年)Conductive Inks for Printed Electronics Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

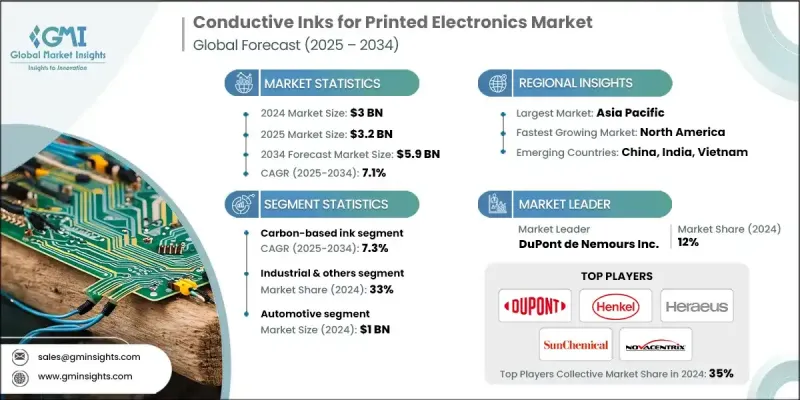

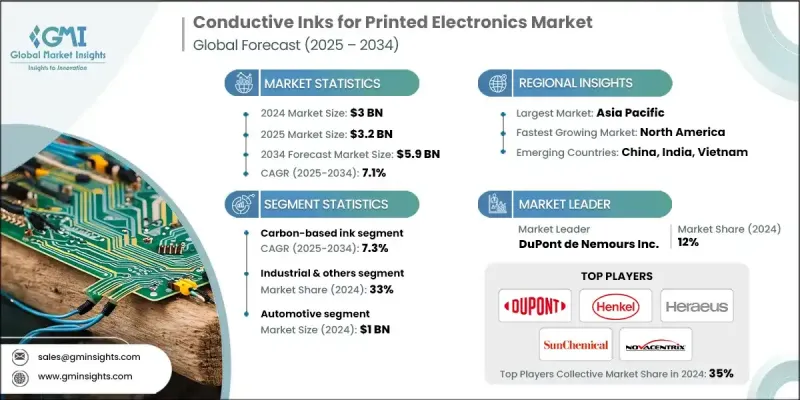

2024 年全球印刷電子導電油墨市場價值為 30 億美元,預計到 2034 年將以 7.1% 的複合年成長率成長至 59 億美元。

這一成長歸功於市場對軟性穿戴電子產品日益成長的需求,這類產品在各行各業都越來越受歡迎。同時,產品設計也越來越注重小型化和永續性。因此,製造商和消費者都在轉向環保、低VOC(揮發性有機化合物)的導電油墨,這類油墨具有廣泛的基材相容性,例如紙張、聚合物和紡織品。為了滿足這些需求,新的生產方法應運而生,並利用添加劑來最大限度地減少浪費,同時有效地擴大生產規模。一些公司推出了採用銀奈米顆粒、銅片、石墨烯和碳奈米管等材料的先進配方,旨在滿足RFID標籤、印刷感測器、軟性電路和太陽能電池等高性能應用的需求。此外,由於光子燒結油墨和紫外光固化油墨適用於低溫加工(這對敏感材料至關重要),因此對這類油墨的需求也不斷成長。導電油墨也被用於各種新興應用,包括印刷加熱器、物聯網設備和用於醫療保健的一次性生物感測器,所有這些都促進了市場的擴張。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 30億美元 |

| 預測值 | 59億美元 |

| 複合年成長率 | 7.1% |

2024年,銀漿市佔率達80%。這主要歸功於其優異的導電性,使其成為高性能應用的理想選擇。銀漿的導電率通常接近金屬銀的80%,因此非常適合光伏金屬化、RFID天線生產和精密電路印刷等領域。

2024年,工業應用領域佔了33%的市場。這一成長主要得益於太陽能技術的進步,尤其是在薄膜太陽能電池領域,導電油墨對於光伏電池的金屬化至關重要。這些油墨用於印刷正面柵格線、背面觸點和互連系統,而這些對於太陽能組件的效率和可擴展性至關重要。

2024年,北美印刷電子導電油墨市佔率達30.2%。該地區的成長主要得益於技術進步,包括先進5G系統的部署以及汽車電氣化和航太應用領域的快速發展。北美對優質油墨配方的需求不斷成長,因為這些油墨具有卓越的性能。此外,政府為促進再生能源和電動車基礎設施建設的措施也正在重塑市場競爭格局,為導電油墨供應商創造了有利的市場環境。

印刷電子導電油墨市場的主要參與者包括漢高股份公司 (Henkel AG & Co. KGaA)、杜邦電子與工業公司 (DuPont Electronics & Industrial)、SPGPrints BV、NovaCentrix、賀利氏控股有限公司 (Heraeus Holding GmbH)、Advanced Nano Products. Nano Inc.、Electroninks Incorporated、愛克發-吉華集團 (Agfa-Gevaert Group) 等。為了鞏固市場地位,印刷電子導電油墨市場的企業正致力於開發環保高性能產品。許多公司加大研發投入,開發創新油墨配方,以滿足包括再生能源和穿戴式技術在內的特定應用需求。策略合作也十分普遍,有助於企業開拓新市場並擴展產品組合。為了滿足日益成長的永續發展需求,一些公司正在推出低揮發性有機化合物 (VOC) 和可回收油墨系統。

目錄

第1章:方法論與範圍

第2章:執行概要

第3章:行業洞察

- 產業生態系分析

- 供應商格局

- 利潤率

- 每個階段的價值增加

- 影響價值鏈的因素

- 中斷

- 產業影響因素

- 成長促進因素

- 5G和毫米波技術普及加速

- 軟性電子產品和穿戴式裝置的普及

- 汽車電氣化和智慧車輛整合

- 產業陷阱與挑戰

- 白銀價格波動與原物料成本壓力

- 導電性和耐久性的技術限制

- 市場機遇

- 銅墨開發及成本降低潛力

- 永續和可回收材料創新

- 成長促進因素

- 成長潛力分析

- 監管環境

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特的分析

- PESTEL 分析

- 價格趨勢

- 按地區

- 透過技術

- 未來市場趨勢

- 技術與創新格局

- 當前技術趨勢

- 新興技術

- 專利格局

- 貿易統計(HS編碼)(註:僅提供重點國家的貿易統計資料)

- 主要進口國

- 主要出口國

- 永續性和環境方面

- 永續實踐

- 減少廢棄物策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考量

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- MEA

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 合作夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估計與預測:依技術分類,2021-2034年

- 主要趨勢

- 銀基油墨

- 碳基油墨

- 銅墨

- 特種油墨

第6章:市場估算與預測:依應用領域分類,2021-2034年

- 主要趨勢

- 工業及其他

- 軟性電子

- 衛生保健

- 汽車

- 光電發電

- 物聯網與連接

第7章:市場估算與預測:依最終用途分類,2021-2034年

- 主要趨勢

- 汽車

- 醫療保健及醫療器材

- 電信

- 包裝產業

第8章:市場估算與預測:依地區分類,2021-2034年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 歐洲其他地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 亞太其他地區

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

- 中東和非洲其他地區

第9章:公司簡介

- DuPont Electronics & Industrial

- Henkel AG & Co. KGaA

- Heraeus Holding GmbH

- Sun Chemical Corporation

- NovaCentrix

- Agfa-Gevaert Group

- Voltera Inc.

- XTPL SA

- Advanced Nano Products (ANP)

- Copprint Technologies

- Electroninks Incorporated

- SPGPrints BV

- C3 Nano Inc.

The Global Conductive Inks for Printed Electronics Market was valued at USD 3 billion in 2024 and is estimated to grow at a CAGR of 7.1% to reach USD 5.9 billion by 2034.

The growth is attributed to the increasing demand for flexible and wearable electronics, which are becoming increasingly popular across various industries. At the same time, there is a growing focus on miniaturization and sustainability in product design. As a result, both manufacturers and consumers are turning toward eco-friendly, low-VOC conductive inks that offer broad substrate compatibility, such as with paper, polymers, and textiles. To align with these needs, new production methods have emerged, utilizing additives to minimize waste while scaling up production efficiently. Companies have introduced advanced formulations with materials like silver nanoparticles, copper flakes, graphene, and carbon nanotubes, targeting high-performance applications such as RFID tags, printed sensors, flexible circuits, and solar cells. Additionally, the demand for photonic sintering and UV-curable inks is rising due to their suitability for low-temperature processing, which is crucial for sensitive materials. Conductive inks are also used in various emerging applications, including printed heaters, IoT devices, and disposable biosensors for healthcare, all contributing to the market's expansion.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $3 Billion |

| Forecast Value | $5.9 Billion |

| CAGR | 7.1% |

In 2024, the silver ink segment held an 80% share. This is due to its excellent electrical conductivity, which makes it ideal for high-performance applications. Silver inks typically achieve conductivities close to 80% of that of metallic silver, making them highly suitable for uses like photovoltaic metallization, RFID antenna production, and precision circuit printing.

The industrial applications segment held a 33% share in 2024. This growth is driven by advancements in solar energy, particularly in thin-film solar cells, where conductive inks are crucial for metallizing photovoltaic cells. These inks are used to print the front-side grid lines, back-side contacts, and interconnection systems, which are critical for the efficiency and scalability of solar modules.

North America Conductive Inks for Printed Electronics Market held a 30.2% share in 2024. The region's growth is largely driven by technological advancements, including the deployment of advanced 5G systems and the push toward automotive electrification and aerospace applications. North America's demand for premium ink formulations is rising, as these inks are needed for their superior performance characteristics. Additionally, the competitive environment is being shaped by government initiatives aimed at promoting renewable energy and the infrastructure of electric vehicles, creating a favorable market for conductive ink suppliers.

Leading players in the Conductive Inks for Printed Electronics Market include Henkel AG & Co. KGaA, DuPont Electronics & Industrial, SPGPrints B.V., NovaCentrix, Heraeus Holding GmbH, Advanced Nano Products (ANP), Voltera Inc., Sun Chemical Corporation, XTPL S.A., Copprint Technologies, C3 Nano Inc., Electroninks Incorporated, Agfa-Gevaert Group, and others. To bolster their presence, companies in the conductive inks for printed electronics market are focusing on developing eco-friendly and high-performance products. Many companies are investing in R&D to create innovative ink formulations that cater to specific applications, including renewable energy and wearable technology. Strategic partnerships and collaborations are also common, helping businesses access new markets and expand their product portfolios. To meet growing sustainability demands, some companies are introducing low-VOC and recyclable ink systems.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Technology

- 2.2.3 Application

- 2.2.4 End use

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 5G & mmWave technology adoption acceleration

- 3.2.1.2 Flexible electronics & wearable device proliferation

- 3.2.1.3 Automotive electrification & smart vehicle integration

- 3.2.2 Industry pitfalls and challenges

- 3.2.2.1 Silver price volatility & raw material cost pressures

- 3.2.2.2 Technical limitations in conductivity & durability

- 3.2.3 Market opportunities

- 3.2.3.1 Copper ink development & cost reduction potential

- 3.2.3.2 Sustainable & recycled material innovation

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By technology

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code) (Note: the trade statistics will be provided for key countries only

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Technology, 2021-2034 (USD Million & Tons)

- 5.1 Key trends

- 5.2 Silver-based inks

- 5.3 Carbon-based inks

- 5.4 Copper inks

- 5.5 Specialty inks

Chapter 6 Market Estimates and Forecast, By Application, 2021-2034 (USD Million & Tons)

- 6.1 Key trends

- 6.2 Industrial & others

- 6.3 Flexible electronics

- 6.4 Healthcare

- 6.5 Automotive

- 6.6 Photovoltaics

- 6.7 IoT & connectivity

Chapter 7 Market Estimates and Forecast, By End Use, 2021-2034 (USD Million & Tons)

- 7.1 Key trends

- 7.2 Automotive

- 7.3 Healthcare & medical device

- 7.4 Telecommunications

- 7.5 Packaging industry

Chapter 8 Market Estimates and Forecast, By Region, 2021-2034 (USD Million & Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 DuPont Electronics & Industrial

- 9.2 Henkel AG & Co. KGaA

- 9.3 Heraeus Holding GmbH

- 9.4 Sun Chemical Corporation

- 9.5 NovaCentrix

- 9.6 Agfa-Gevaert Group

- 9.7 Voltera Inc.

- 9.8 XTPL S.A.

- 9.9 Advanced Nano Products (ANP)

- 9.10 Copprint Technologies

- 9.11 Electroninks Incorporated

- 9.12 SPGPrints B.V.

- 9.13 C3 Nano Inc.