|

市場調查報告書

商品編碼

1822653

鑽石工具市場機會、成長動力、產業趨勢分析及2025-2034年預測Diamond Tools Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

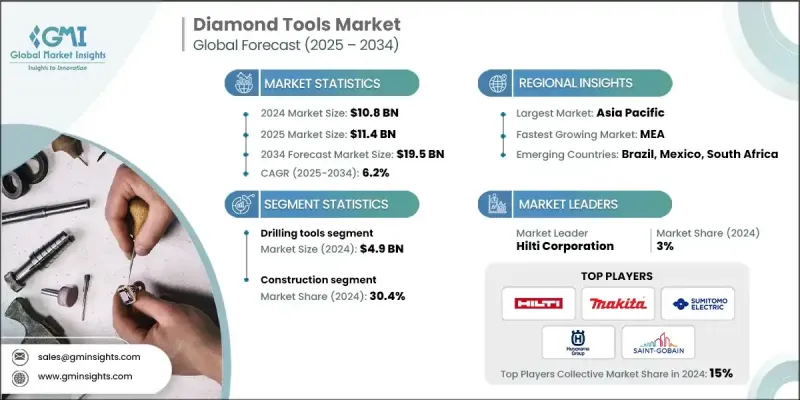

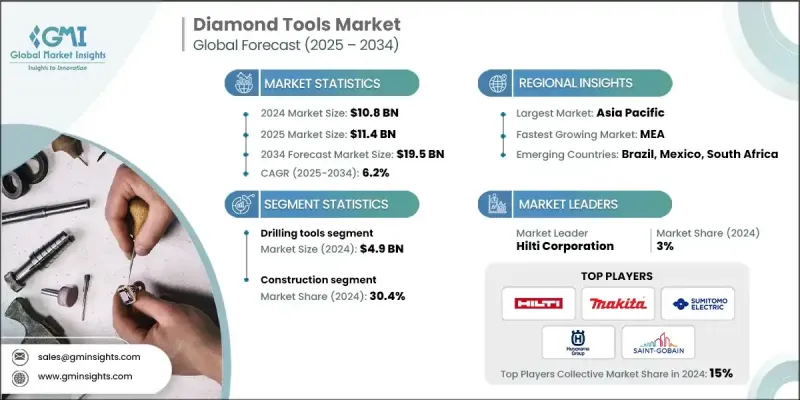

2024 年全球鑽石工具市場價值為 108 億美元,預計到 2034 年將以 6.2% 的複合年成長率成長至 195 億美元。

全球城鎮化的快速發展和基礎設施投資的不斷增加是推動鑽石工具市場需求的主要力量。隨著政府和私人開發商加大住宅區、商業建築、高速公路、橋樑和地鐵系統的建設力度,對耐用且精密的工具的需求也隨之激增。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 108億美元 |

| 預測值 | 195億美元 |

| 複合年成長率 | 6.2% |

鑽井工具獲得牽引力

鑽井工具領域在2024年佔據了相當大的佔有率,這得益於其在採礦、建築和石油探勘等高要求應用領域的廣泛應用。這些工具對於在混凝土、石材和鋼筋材料等堅硬表面進行鑽孔至關重要,而傳統工具則無法有效發揮作用。鑽石鑽頭精度高、停機時間短、使用壽命長,使其成為手動和自動化系統的首選。

建築業採用率不斷上升

受全球住宅、商業和基礎設施建設持續擴張的推動,建築業在2024年創造了可觀的收入。鑽石鋸片、岩芯鑽和砂輪等工具對於切割和塑造混凝土、瀝青和瓷磚等硬建築材料至關重要。隨著建築標準不斷發展,要求更快的周轉時間和更高的精度,承包商越來越依賴鑽石工具來以最少的浪費交付高品質的成果。

區域洞察

亞太地區將崛起成為推動力地區

2024年,亞太地區鑽石工具市場實現了顯著成長,這得益於蓬勃發展的建築業、工業化進程以及汽車和電子製造中心的崛起。中國、印度和韓國等國家正在經歷大規模的基礎設施投資和製造業規模擴張,這兩者都需要高性能的切割、研磨和鑽孔解決方案。該地區強大的原料供應鏈和相對較低的生產成本使本地製造商擁有競爭優勢。

鑽石工具市場的主要參與者有 OX Group International、住友電工株式會社、博世、MK Diamond Products、Core Plus Specialist、聖戈班、Metabo Power Tools、Asahi Diamond Industrial、Tyrolit、Hilti、Continental Diamond Tool Corporation、Husqvarna AB、Oregon Construction Business、Milti、Continental Diamond Tool Corporation、Husqvarna AB、Oregon Construction Business。

為了鞏固市場地位,鑽石工具市場中的企業正優先進行研發,以開發出具有更高耐用性、更快切割速度和更強耐熱性的產品。許多企業正在採用雷射焊接和精密黏合等先進製造技術,以提高產品性能和一致性。與建築公司和設備製造商建立策略合作夥伴關係也有助於品牌將其工具整合到更廣泛的系統中,從而提高各行業的使用率。此外,企業正在透過併購和分銷網路擴大其全球影響力,尤其是在新興市場,同時也投資數位平台,以改善客戶互動和售後支援。

目錄

第1章:方法論與範圍

第 2 章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商格局

- 利潤率

- 每個階段的增值

- 影響價值鏈的因素

- 產業衝擊力

- 成長動力

- 建築、石材加工、機械加工等各行業的需求不斷成長

- 精密加工需求不斷成長

- 電子和半導體產業擴張

- 產業陷阱與挑戰

- 初始成本高

- 替代材料的可用性

- 機會

- 採用自動化和智慧製造

- 再生能源領域的成長

- 成長動力

- 成長潛力分析

- 未來市場趨勢

- 技術和創新格局

- 當前的技術趨勢

- 新興技術

- 價格趨勢

- 按地區

- 按類型

- 監管格局

- 標準和合規性要求

- 區域監理框架

- 認證標準

- 貿易統計

- 主要進口國

- 主要出口國

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估計與預測:按類型,2021-2034

- 主要趨勢

- 磨料

- 鑽石砂輪

- 鑽石拋光墊

- 鑽石研磨膏

- 鑽石砂帶

- 切削刀具

- 鑽石塗層立銑刀

- 鑽石車刀

- 鑽石切削刀片

- PCD(聚晶鑽石)工具

- 鑽井工具

- 鑽石岩心鑽頭

- 鑽石麻花鑽

- 鑽石鑽頭旋轉鑽

- 電鍍鑽石鑽頭

- 鋸切工具

- 鑽石鋸片(圓形、排形、線狀)

- 鑽石線鋸

- 分段式鑽石鋸片

- 其他(連續邊緣鑽石鋸片等)

第6章:市場估計與預測:依製造方法,2021-2034 年

- 主要趨勢

- 金屬結合

- 樹脂黏合

- 電鍍

- 燒結

- 其他(釬焊等)

第7章:市場估計與預測:按應用 2021-2034

- 主要趨勢

- 石材加工

- 運輸

- 加工

- 地質探勘

- 建造

第 8 章:市場估計與預測:按配銷通路,2021-2034 年

- 主要趨勢

- 直銷

- 間接銷售

第9章:市場估計與預測:按地區,2021-2034

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 多邊環境協定

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

第10章:公司簡介

- Asahi Diamond Industrial

- Bosch

- Bosun

- Hilti

- Husqvarna AB

- Lackmond

- Makita

- Metabo Power Tools

- MK Diamond Products

- Nanjing Sanchao Advanced Materials

- Oregon Construction Business

- OX Group International

- Saint-Gobain

- Sumitomo Electric Industries, Ltd.

- Tyrolit

The Global Diamond Tools Market was valued at USD 10.8 billion in 2024 and is estimated to grow at a CAGR of 6.2% to reach USD 19.5 billion by 2034.

The rapid pace of urbanization and increasing investment in infrastructure worldwide are major forces driving demand in the diamond tools market. As governments and private developers ramp up construction of residential complexes, commercial buildings, highways, bridges, and metro systems, the need for durable and precise tools has surged.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $10.8 Billion |

| Forecast Value | $19.5 Billion |

| CAGR | 6.2% |

Drilling Tools to Gain Traction

The drilling tools segment held a significant share in 2024 owing to its widespread use in demanding applications such as mining, construction, and oil exploration. These tools are essential for boring into hard surfaces like concrete, stone, and reinforced materials where conventional tools fail to perform efficiently. Diamond drill bits offer high precision, reduced downtime, and extended operational life, making them a preferred choice in both manual and automated systems.

Rising Adoption in Construction

The construction segment generated notable revenues in 2024, driven by the ongoing expansion of residential, commercial, and infrastructure developments worldwide. Tools like diamond saw blades, core drills, and grinding wheels are critical for cutting and shaping hard construction materials such as concrete, asphalt, and tiles. As construction standards evolve to demand faster turnaround times and higher precision, contractors increasingly rely on diamond tools to deliver quality results with minimal waste.

Regional Insights

Asia Pacific to Emerge as a Propelling Region

Asia Pacific diamond tools market held a sizeable growth in 2024, supported by booming construction activity, industrialization, and the rise of automotive and electronics manufacturing hubs. Countries like China, India, and South Korea are witnessing massive infrastructure investments and manufacturing scale-ups, both of which require high-performance cutting, grinding, and drilling solutions. The region's strong raw material supply chain and relatively lower production costs give local manufacturers a competitive edge.

Major players in the diamond tools market are OX Group International, Sumitomo Electric Industries, Ltd., Bosch, MK Diamond Products, Core Plus Specialist, Saint-Gobain, Metabo Power Tools, Asahi Diamond Industrial, Tyrolit, Hilti, Continental Diamond Tool Corporation, Husqvarna AB, Oregon Construction Business, Makita, and Bosun.

To strengthen their market position, companies in the diamond tools market are prioritizing R&D to develop products with higher durability, faster cutting speeds, and enhanced heat resistance. Many firms are adopting advanced manufacturing techniques such as laser welding and precision bonding to improve product performance and consistency. Strategic partnerships with construction firms and equipment manufacturers are also helping brands integrate their tools into broader systems, increasing usage across industries. Additionally, companies are expanding their global footprint through mergers, acquisitions, and distribution networks, particularly in emerging markets, while also investing in digital platforms for better customer engagement and after-sales support.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Type

- 2.2.3 Manufacturing method

- 2.2.4 Application

- 2.2.5 Distribution channel

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Increasing demand from various industries such as construction, stone processing, and machining

- 3.2.1.2 Growing demand for precision machining

- 3.2.1.3 Electronics and semiconductor industry expansion

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial cost

- 3.2.2.2 Availability of alternative materials

- 3.2.3 Opportunities

- 3.2.3.1 Adoption of automation and smart manufacturing

- 3.2.3.2 Growth in renewable energy sector

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By type

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Trade statistics

- 3.8.1 Major importing countries

- 3.8.2 Major exporting countries

- 3.9 Porter's analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Type, 2021-2034 (USD Billion) (Thousand Units)

- 5.1 Key trends

- 5.2 Abrasive

- 5.2.1 Diamond grinding wheels

- 5.2.2 Diamond polishing pads

- 5.2.3 Diamond lapping compounds

- 5.2.4 Diamond abrasive belts

- 5.3 Cutting Tools

- 5.3.1 Diamond-coated end mills

- 5.3.2 Diamond turning tools

- 5.3.3 Diamond cutting inserts

- 5.3.4 PCD (Polycrystalline Diamond) tools

- 5.4 Drilling Tools

- 5.4.1 Diamond core drill bits

- 5.4.2 Diamond twist drills

- 5.4.3 Diamond-tipped rotary drills

- 5.4.4 Electroplated diamond drills

- 5.5 Sawing Tools

- 5.5.1 Diamond saw blades (circular, gang, wire)

- 5.5.2 Diamond wire saws

- 5.5.3 Segmented diamond blades

- 5.5.4 Others (Continuous rim diamond blades, etc.)

Chapter 6 Market Estimates and Forecast, By Manufacturing Method, 2021-2034 (USD Billion) (Thousand Units)

- 6.1 Key trends

- 6.2 Metal bonded

- 6.3 Resin bonded

- 6.4 Electroplated

- 6.5 Sintering

- 6.6 Others (brazing, etc.)

Chapter 7 Market Estimates and Forecast, By Application 2021-2034 (USD Billion) (Thousand Units)

- 7.1 Key trends

- 7.2 Stone processing

- 7.3 Transportation

- 7.4 Machining

- 7.5 Geological prospecting

- 7.6 Construction

Chapter 8 Market Estimates and Forecast, By Distribution Channel, 2021-2034 (USD Billion) (Thousand Units)

- 8.1 Key trends

- 8.2 Direct sales

- 8.3 Indirect sales

Chapter 9 Market Estimates and Forecast, By Region, 2021-2034 (USD Billion) (Thousand Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 Australia

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 MEA

- 9.6.1 Saudi Arabia

- 9.6.2 UAE

- 9.6.3 South Africa

Chapter 10 Company Profiles

- 10.1 Asahi Diamond Industrial

- 10.2 Bosch

- 10.3 Bosun

- 10.4 Hilti

- 10.5 Husqvarna AB

- 10.6 Lackmond

- 10.7 Makita

- 10.8 Metabo Power Tools

- 10.9 MK Diamond Products

- 10.10 Nanjing Sanchao Advanced Materials

- 10.11 Oregon Construction Business

- 10.12 OX Group International

- 10.13 Saint-Gobain

- 10.14 Sumitomo Electric Industries, Ltd.

- 10.15 Tyrolit