|

市場調查報告書

商品編碼

1773477

噴射混凝土噴塗機市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Shotcrete Spray Machines Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

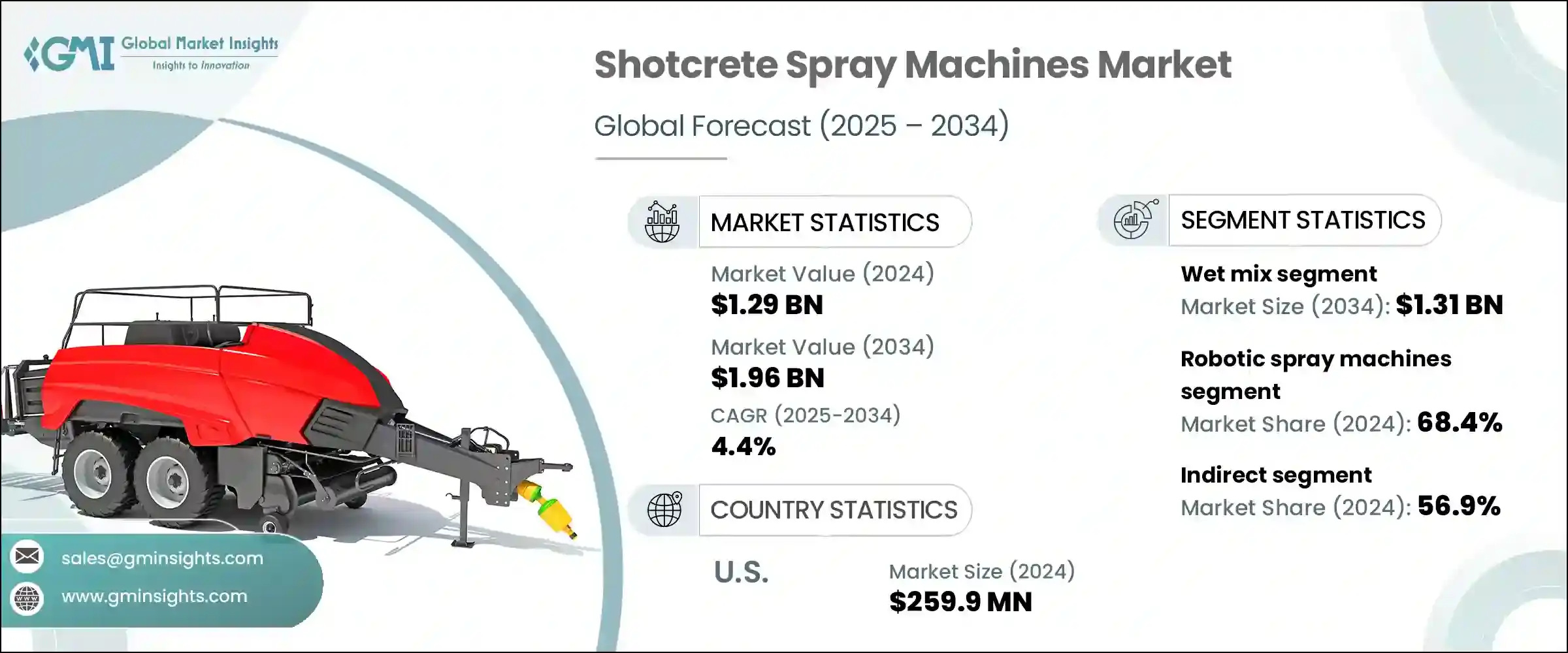

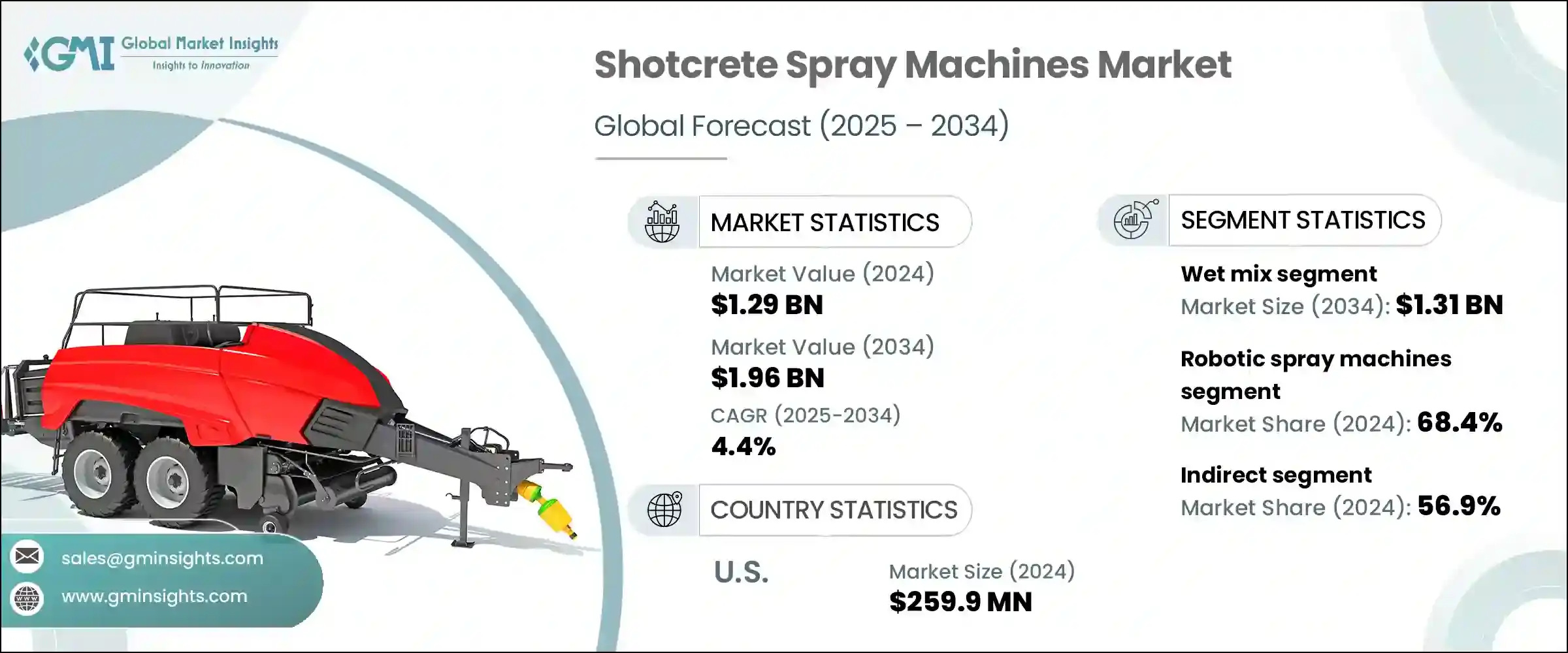

2024年,全球噴射混凝土噴塗機市場規模達12.9億美元,預計2034年將以4.4%的複合年成長率成長,達到19.6億美元。這一成長主要得益於城市發展的加速和基礎設施投資的強勁成長。聯合國預測,到2050年,全球近三分之二的人口將居住在城市地區,各國政府和建築商正致力於高效、節省空間的施工方法。噴射混凝土噴塗機在滿足這些需求方面發揮著至關重要的作用,尤其是在隧道襯砌和地下加固應用中。

亞洲和歐洲各國正大力投資興建交通隧道、地下管線和基礎設施走廊。因此,市場需求正迅速轉向機器人噴射混凝土機,這類設備能夠快速噴塗、提供卓越的表面附著力,並可進入狹窄區域。這些自動化解決方案可提供一致的噴塗精度,同時最大限度地減少人工需求並提高安全標準。北美和歐洲等地區的勞動力短缺和安全法規日益嚴格,進一步推動了機器人系統的普及。自動化和遠端控制噴射混凝土設備的興起,正在透過提高速度、精度和整體施工效率來改變施工現場的運作方式。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 12.9億美元 |

| 預測值 | 19.6億美元 |

| 複合年成長率 | 4.4% |

濕拌混凝土製程領域在2024年創造了8.463億美元的產值,預計到2034年將達到13.1億美元。濕噴混凝土因其均勻的稠度和較高的抗壓強度(通常在4,000至7,000 psi之間)已迅速成為大型專案的首選施工方法。由於所有材料在噴塗前均已預先混合,此工藝可確保施工平穩均勻,並將材料損失降至最低。回彈率遠低於10%,從而實現更清潔的施工現場、更高品質的產出並減少浪費,最終有助於節省專案成本並提升環境安全。

機器人噴塗機市場在2024年佔據了68.4%的市場佔有率,預計2025年至2034年的複合年成長率將達到4.7%。這些先進的系統透過提供高度均勻的噴塗層並減少操作員暴露在危險的頂部區域,正在為該行業樹立新的標竿。許多系統的定位精度在±5毫米以內,確保一致的品質。機器人噴塗機每小時的噴塗量高達20立方公尺,可將工程工期縮短近四分之一,同時降低人力成本。 Normet和Aliva等供應商正在整合智慧功能,實現噴嘴自動移動並提供即時資料回饋,以最佳化效能和表面光潔度。

2024年,美國噴射混凝土噴塗機市場規模達2.599億美元,預計到2034年將以4.4%的複合年成長率成長。基礎設施老化以及對維修和修復的重視,持續推動交通運輸和公共工程領域的需求。同時,住宅和商業開發的穩定發展也推動了對高效噴塗系統的額外需求。由於對生產力和工作場所安全的日益重視,市場對大型建築專案中的機器人濕拌設備表現出明顯的偏好。在北美,由於對地下城市開發和資源開採計畫的投資不斷增加,加拿大也正獲得發展。

影響噴射混凝土噴塗機產業的知名公司包括 YG Machinery、Normet、Filamos、Sika、Reed、JUHE Group、Putzmeister、Gunite Supply & Equipment、CIFA、Epiroc Deutschland、Tunelmak、Gengli、Leadcrete、Blastcrete 和 MacLean。噴射混凝土噴塗機市場的領先製造商正致力於透過自動化驅動模型來擴展其產品組合,以提高安全性和效率。與基礎設施承包商的策略合作使他們能夠提供滿足不斷發展的監管標準的特定應用解決方案。公司還在研發方面進行投資,以整合基於人工智慧的控制系統,提高噴塗精度,並減少對操作員的依賴。全球參與者正在透過經銷商合作夥伴關係和服務網路加強其在高成長地區的供應鏈,以確保更快的交付和售後支援。一些公司提供模組化設備設計和遠端診斷,以最佳化維護和使用壽命。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商概況

- 利潤率

- 每個階段的增值

- 影響價值鏈的因素

- 中斷

- 產業衝擊力

- 成長動力

- 產業陷阱與挑戰

- 機會

- 成長潛力分析

- 未來市場趨勢

- 技術和創新格局

- 當前的技術趨勢

- 新興技術

- 價格趨勢

- 按地區

- 依產品類型

- 監理框架

- 標準和認證

- 環境法規

- 進出口法規

- 貿易統計數據

- 主要進口國

- 主要出口國

- 波特五力分析

- PESTEL分析

- 消費者行為分析

- 購買模式

- 偏好分析

- 消費者行為的區域差異

- 電子商務對購買決策的影響

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估計與預測:依類型,2021-2034

- 主要趨勢

- 濕混料

- 乾混料

第6章:市場估計與預測:按機制,2021-2034 年

- 主要趨勢

- 手動噴霧機

- 機器人噴塗機

第7章:市場估計與預測:依移動性,2021-2034

- 主要趨勢

- 固定式

- 移動的

- 拖車式

- 卡車安裝

第 8 章:市場估計與預測:按應用,2021 年至 2034 年

- 主要趨勢

- 礦業

- 隧道

- 建築施工

- 擋水結構

- 修復工程

- 其他(邊坡穩定、軍事設施等)

第9章:市場估計與預測:依最終用途,2021-2034

- 主要趨勢

- 建築和採礦公司

- 政府機構

- 其他(租賃機構、承包商等)

第 10 章:市場估計與預測:按配銷通路,2021-2034 年

- 主要趨勢

- 直接的

- 間接

第 11 章:市場估計與預測:按地區,2021 年至 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 南非

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

第12章:公司簡介

- Blastcrete

- CIFA

- Epiroc Deutschland

- Filamos

- Gengli

- Gunite Supply & Equipment

- JUHE Group

- Leadcrete

- MacLean Engineering

- Normet

- Putzmeister

- Reed

- Sika

- Tunelmak

- YG Machinery

The Global Shotcrete Spray Machines Market was valued at USD 1.29 billion in 2024 and is estimated to grow at a CAGR of 4.4% to reach USD 1.96 billion by 2034. This growth is fueled by accelerating urban development and robust infrastructure investments. With the United Nations projecting that nearly two-thirds of the global population will live in urban settings by 2050, governments and builders are focusing on efficient, space-saving construction methods. Shotcrete spray machines have become critical in meeting these demands, especially in tunnel lining and underground stabilization applications.

Countries across Asia and Europe are significantly funding transit tunnels, underground utilities, and infrastructure corridors. As a result, demand is rapidly shifting toward robotic shotcrete sprayers that deliver fast application, superior surface adhesion, and access to confined zones. These automated solutions offer consistent spraying accuracy while minimizing manual labor requirements and improving safety standards. Labor shortages and stricter safety regulations in regions like North America and Europe are further driving the adoption of robotic systems. The rise of automated and remote-controlled shotcrete equipment is transforming worksite operations by boosting speed, precision, and overall job site efficiency.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.29 Billion |

| Forecast Value | $1.96 Billion |

| CAGR | 4.4% |

The wet-mix process segment generated USD 846.3 million in 2024 and is expected to reach USD 1.31 billion by 2034. Wet-mix shotcrete has rapidly become the preferred application method across large-scale projects due to its uniform consistency and enhanced compressive strength, which typically ranges between 4,000 to 7,000 psi. Since all materials are pre-mixed before spraying, this process ensures a smooth and even application with minimal material loss. Rebound rates stay well below 10%, resulting in cleaner job sites, better quality output, and reduced waste, which together contribute to project cost savings and safer environments.

The robotic spray machines segment held a 68.4% share in 2024 and is projected to grow at a CAGR of 4.7% from 2025 through 2034. These advanced systems are setting new benchmarks in the industry by delivering highly uniform layers and reducing operator exposure to hazardous overhead zones. Many systems offer positioning precision within +-5 mm, ensuring consistent quality. Capable of spraying up to 20 cubic meters per hour, robotic sprayers can shorten project timelines by nearly a quarter while lowering labor costs. Suppliers like Normet and Aliva are integrating smart features that automate nozzle movement and provide live data feedback to optimize performance and surface finish.

U.S. Shotcrete Spray Machines Market was valued at USD 259.9 million in 2024 and is forecast to grow at a CAGR of 4.4% through 2034. Aging infrastructure and a focus on repair and rehabilitation continue to drive demand across transportation and public works sectors. In parallel, steady activity in housing and commercial development has supported additional demand for efficient spraying systems. The market shows a clear preference for robotic wet-mix equipment in large-scale construction projects, underpinned by an increasing focus on productivity and workplace safety. Within North America, Canada is also gaining traction due to growing investments in underground urban development and resource mining projects.

Prominent companies shaping the Shotcrete Spray Machines Industry include YG Machinery, Normet, Filamos, Sika, Reed, JUHE Group, Putzmeister, Gunite Supply & Equipment, CIFA, Epiroc Deutschland, Tunelmak, Gengli, Leadcrete, Blastcrete, and MacLean Engineering. Leading manufacturers in the shotcrete spray machines market are focusing on expanding their product portfolios with automation-driven models that enhance safety and efficiency. Strategic collaborations with infrastructure contractors allow them to deliver application-specific solutions that meet evolving regulatory standards. Companies are also investing in R&D to integrate AI-based control systems, improve precision spraying, and reduce operator dependency. Global players are strengthening their supply chains in high-growth regions through distributor partnerships and service networks to ensure quicker delivery and post-sale support. Some firms are offering modular equipment designs and remote diagnostics to optimize maintenance and lifespan.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Type

- 2.2.3 Mechanism

- 2.2.4 Mobility

- 2.2.5 Application

- 2.2.6 End use

- 2.2.7 Distribution channel

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls & challenges

- 3.2.3 Opportunities

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and Innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By product type

- 3.7 Regulatory framework

- 3.7.1 Standards and certifications

- 3.7.2 Environmental regulations

- 3.7.3 Import export regulations

- 3.8 Trade statistics

- 3.8.1 Major importing countries

- 3.8.2 Major exporting countries

- 3.9 Porter's five forces analysis

- 3.10 PESTEL analysis

- 3.11 Consumer behavior analysis

- 3.11.1 Purchasing patterns

- 3.11.2 Preference analysis

- 3.11.3 Regional variations in consumer behavior

- 3.11.4 Impact of e-commerce on buying decisions

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Type, 2021-2034 (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 Wet mix

- 5.3 Dry mix

Chapter 6 Market Estimates & Forecast, By Mechanism, 2021-2034 (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Manual spray machines

- 6.3 Robotic spray machines

Chapter 7 Market Estimates & Forecast, By Mobility, 2021-2034 (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 Stationary

- 7.3 Mobile

- 7.3.1 Trailer mounted

- 7.3.2 Truck mounted

Chapter 8 Market Estimates & Forecast, By Application, 2021-2034 (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 Mining

- 8.3 Tunneling

- 8.4 Building construction

- 8.5 Water retaining structures

- 8.6 Repair works

- 8.7 Others (slope stabilization, military installation, etc.)

Chapter 9 Market Estimates & Forecast, By End Use, 2021-2034 (USD Million) (Thousand Units)

- 9.1 Key trends

- 9.2 Construction & mining companies

- 9.3 Government agencies

- 9.4 Others (rental agencies, contractors, etc.)

Chapter 10 Market Estimates & Forecast, By Distribution channel, 2021-2034 (USD Million) (Thousand Units)

- 10.1 Key trends

- 10.2 Direct

- 10.3 Indirect

Chapter 11 Market Estimates & Forecast, By Region, 2021-2034 (USD Million) (Thousand Units)

- 11.1 Key trends

- 11.2 North America

- 11.2.1 U.S.

- 11.2.2 Canada

- 11.3 Europe

- 11.3.1 UK

- 11.3.2 Germany

- 11.3.3 France

- 11.3.4 Italy

- 11.3.5 Spain

- 11.4 Asia Pacific

- 11.4.1 China

- 11.4.2 India

- 11.4.3 Japan

- 11.4.4 South Korea

- 11.4.5 Australia

- 11.5 Latin America

- 11.5.1 Brazil

- 11.5.2 Mexico

- 11.6 MEA

- 11.6.1 South Africa

- 11.6.2 UAE

- 11.6.3 Saudi Arabia

Chapter 12 Company Profiles

- 12.1 Blastcrete

- 12.2 CIFA

- 12.3 Epiroc Deutschland

- 12.4 Filamos

- 12.5 Gengli

- 12.6 Gunite Supply & Equipment

- 12.7 JUHE Group

- 12.8 Leadcrete

- 12.9 MacLean Engineering

- 12.10 Normet

- 12.11 Putzmeister

- 12.12 Reed

- 12.13 Sika

- 12.14 Tunelmak

- 12.15 YG Machinery