|

市場調查報告書

商品編碼

1773439

機器人碼垛機市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Robotic Palletizers Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

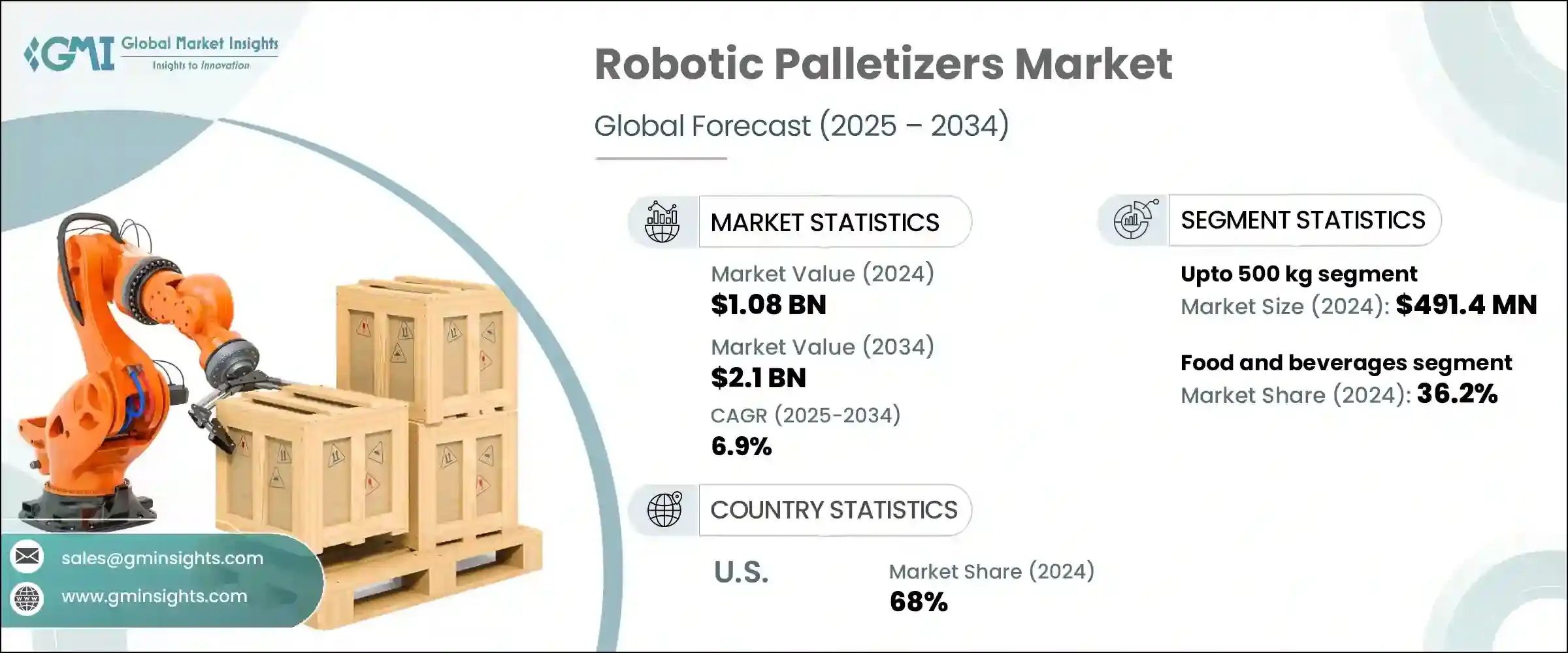

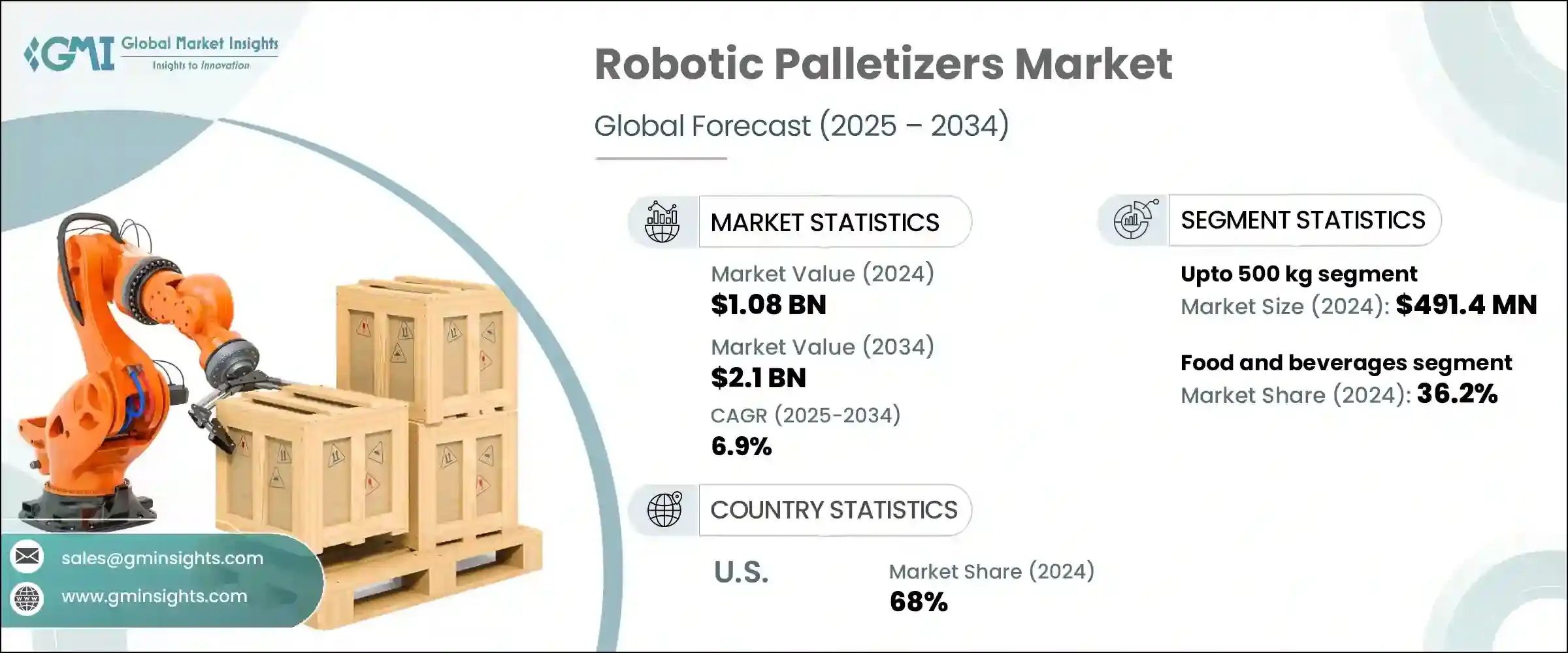

2024年,全球機器人碼垛機市場規模達10.8億美元,預計到2034年將以6.9%的複合年成長率成長,達到21億美元。各行各業對自動化的需求激增是推動該市場發展的主要因素。機器人碼高機旨在實現堆疊和拆垛任務的自動化,從而縮短生產週期、提高產量、減少佔地面積並提高成本效益。勞動力短缺加劇、薪資上漲以及對更安全、更有效率的物料搬運的需求是主要的成長動力。透過自動化將貨物堆放到托盤上的勞動密集型流程,這些機器人系統減少了對人工的依賴,減少了錯誤,並透過最大限度地降低事故風險來提高工作場所的安全性。

全球物流的複雜性和電子商務的擴張進一步推動了成長,這兩者都要求倉庫和配送中心能夠有效率地處理各種產品,以便快速處理訂單。先進機械手臂和協作機器人等創新技術使機器人碼垛機更加靈活,也更容易中小企業使用。儘管機器人碼垛機具有許多優勢,但由於前期成本高昂、與現有系統的整合複雜、持續的維護和編程費用以及對熟練人員的需求,市場仍面臨挑戰。儘管如此,持續的技術創新和經濟效益正在推動機器人碼垛機在自動化製造和供應鏈環境中的應用。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 10.8億美元 |

| 預測值 | 21億美元 |

| 複合年成長率 | 6.9% |

2024年,500公斤以下產品搬運領域創造了4.914億美元的市場規模。這類機器人專為輕型至中型包裝而設計,正經歷快速成長,尤其是在電子商務和消費品搬運自動化程度不斷提高的背景下。這些機器人碼垛機在製藥、食品飲料、消費品和其他製造業等行業備受青睞。它們能夠處理各種尺寸的紙箱、袋子和箱子,因此用途廣泛,在各種碼垛應用中需求旺盛。

2024年,食品和飲料行業佔據了最大的市場佔有率,佔36.2%。在這個效率、衛生和一致性至關重要的行業中,機器人碼垛機已成為不可或缺的一部分。大量生產和快速配送的需求,加上持續的勞動力短缺以及碼垛等重複性任務成本的上升,促使企業推行流程自動化。機器人系統不僅提高了營運效率,還減少了人與食品的接觸,最大限度地降低了污染風險。此外,專門研發的食品級機器人符合嚴格的衛生標準,進一步推動了該產業的應用。

2024年,美國機器人碼垛機市場佔68%的市場。推動這一成長的因素包括供應鏈日益複雜以及勞動力成本高昂,這使得機器人碼垛機成為維持營運連續性的一項切實可行的投資。美國也受益於製造技術的進步和工業4.0計劃,從而推動了對機器人碼垛解決方案的需求。作為機器人應用的領先國家之一,美國在多個製造環節的機器人密度不斷成長,增強了市場發展勢頭。

在全球機器人碼垛機行業競爭的領先公司包括 FANUC 公司、KUKA AG、ABB、霍尼韋爾國際公司、施耐德包裝設備公司、Bastian Solutions、Fuji Robotics、Okura LLC、Pasco Systems、Premier Tech、Robotiq、川崎重工業有限公司、KION Group AG、Sidel 和安川電機株式會川會。為加強市場地位,機器人碼垛機領域的公司專注於創新,開發能夠精確處理各種尺寸和重量產品的高度適應性機器人系統。他們投資研發,以提高自動化效率、易於整合和方便用戶使用的介面。與包裝和物流解決方案提供商的策略合作使他們能夠提供無縫融入現有供應鏈的端到端自動化解決方案。公司還透過在地化生產、增強客戶服務網路和量身定做的售後支援擴大全球影響力,確保穩固的客戶關係。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商格局

- 利潤率

- 每個階段的增值

- 影響價值鏈的因素

- 產業衝擊力

- 成長動力

- 自動化需求不斷成長

- 機器人技術與人工智慧的進步

- 電子商務和物流的成長

- 產業陷阱與挑戰

- 初期投資和安裝成本高

- 技術複雜性和對熟練勞動力的需求

- 機會

- 成長動力

- 成長潛力分析

- 未來市場趨勢

- 技術和創新格局

- 當前的技術趨勢

- 新興技術

- 價格趨勢

- 按地區

- 監管格局

- 標準和合規性要求

- 區域監理框架

- 認證標準

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估計與預測:按有效載荷容量,2021 - 2034 年

- 主要趨勢

- 最多 500 公斤

- 501-1000公斤

- 1000公斤以上

第6章:市場估計與預測:按最終用途產業,2021 - 2034 年

- 主要趨勢

- 食品和飲料

- 製藥

- 化妝品和個人護理

- 電子商務與物流

- 其他

第7章:市場估計與預測:按地區,2021 - 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 亞太地區

- 中國

- 日本

- 印度

- 澳洲

- 韓國

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中東和非洲

- 南非

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

第8章:公司簡介

- ABB

- Bastian Solutions

- FANUC Corporation

- Fuji Robotics

- Honeywell International Inc

- Kawasaki Heavy Industries Ltd

- KION Group AG

- KUKA AG

- Okura LLC

- Pasco Systems

- Premier Tech

- Robotiq

- Schneider Packaging Equipment Company

- Sidel

- Yaskawa Electric Corporation

The Global Robotic Palletizers Market was valued at USD 1.08 billion in 2024 and is estimated to grow at a CAGR of 6.9% to reach USD 2.1 billion by 2034. The surge in automation demand across various sectors is a major factor propelling this market. Robotic palletizers are engineered to automate palletizing and depalletizing tasks, enabling faster cycle times, increased throughput, compact footprints, and cost-efficiency. Rising labor shortages, escalating wages, and the drive for safer, more efficient material handling are primary growth drivers. By automating the labor-intensive process of stacking goods onto pallets, these robotic systems reduce the dependency on manual labor, limit errors, and enhance workplace safety by minimizing accident risks.

Growth is further supported by the complexity of global logistics and the expansion of e-commerce, both of which require highly efficient handling of diverse products in warehouses and distribution centers for rapid order processing. Innovations such as advanced robotic arms and the introduction of collaborative robots have made robotic palletizers more versatile and accessible to small and medium-sized businesses alike. Despite their advantages, the market faces challenges due to high upfront costs, integration complexities with existing systems, ongoing maintenance and programming expenses, and the need for skilled personnel. Nevertheless, ongoing technological innovations and economic benefits are driving the adoption of robotic palletizers within automated manufacturing and supply chain environments.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.08 billion |

| Forecast Value | $2.1 billion |

| CAGR | 6.9% |

The handling products up to 500 kg segment generated USD 491.4 million in 2024. Robots in this category are designed for light to medium-weight packages and are experiencing rapid growth, particularly due to increasing automation in e-commerce and consumer product handling. These robotic palletizers are favored across industries such as pharmaceuticals, food and beverages, consumer goods, and other manufacturing sectors. Their ability to manage varying box sizes, bags, and cases makes them versatile and highly demanded for diverse palletizing applications.

The food & beverages segment held the largest market share in 2024, accounting for 36.2%. Robotic palletizers have become indispensable in this industry where efficiency, hygiene, and consistency are critical. High-volume production and swift distribution demands, combined with persistent labor shortages and rising costs for repetitive tasks like palletizing, push companies to automate processes. Robotic systems not only improve operational efficiency but also reduce human contact with food products, minimizing contamination risks. Additionally, specialized food-grade robots are developed to comply with strict hygiene standards, further driving adoption in this sector.

United States Robotic Palletizers Market held a 68% share in 2024. Factors fueling this growth include increasing supply chain complexity and high labor costs, which make robotic palletizers a practical investment to maintain operational continuity. The U.S. also benefits from advancements in manufacturing technology and Industry 4.0 initiatives, boosting the demand for robotic palletizing solutions. As one of the leaders in robotics adoption, the country exhibits growing robot density across multiple manufacturing processes, enhancing market momentum.

Leading companies competing in the Global Robotic Palletizers Industry include FANUC Corporation, KUKA AG, ABB, Honeywell International Inc, Schneider Packaging Equipment Company, Bastian Solutions, Fuji Robotics, Okura LLC, Pasco Systems, Premier Tech, Robotiq, Kawasaki Heavy Industries Ltd, KION Group AG, Sidel, and Yaskawa Electric Corporation. To strengthen their market presence, companies in the robotic palletizers sector focus on innovation by developing highly adaptable robotic systems capable of handling a wide range of product sizes and weights with precision. They invest in research and development to improve automation efficiency, ease of integration, and user-friendly interfaces. Strategic collaborations with packaging and logistics solution providers allow them to deliver end-to-end automation solutions that fit seamlessly into existing supply chains. Firms also expand their global footprint through localized production, enhanced customer service networks, and tailored after-sales support, ensuring robust client relationships.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Payload Capacity

- 2.2.3 End Use Industry

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rising demand for automation

- 3.2.1.2 Advancements in robotic technology and AI

- 3.2.1.3 Growth of e-commerce and logistics

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment and installation costs

- 3.2.2.2 Technical complexity and need for skilled labor

- 3.2.3 Opportunities

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter's analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates and Forecast, By Payload Capacity, 2021 - 2034 (USD Billion) (Units)

- 5.1 Key trends

- 5.2 Upto 500 kg

- 5.3 501-1000 kg

- 5.4 Above 1000 kg

Chapter 6 Market Estimates and Forecast, By End Use Industry, 2021 - 2034 (USD Billion) (Units)

- 6.1 Key trends

- 6.2 Food and beverages

- 6.3 Pharmaceuticals

- 6.4 Cosmetics and personal care

- 6.5 E-commerce and logistics

- 6.6 Others

Chapter 7 Market Estimates and Forecast, By Region, 2021 - 2034 (USD Billion) (Units)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.3 Europe

- 7.3.1 Germany

- 7.3.2 UK

- 7.3.3 France

- 7.3.4 Spain

- 7.3.5 Italy

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 Japan

- 7.4.3 India

- 7.4.4 Australia

- 7.4.5 South Korea

- 7.5 Latin America

- 7.5.1 Brazil

- 7.5.2 Mexico

- 7.5.3 Argentina

- 7.6 Middle East and Africa

- 7.6.1 South Africa

- 7.6.2 Saudi Arabia

- 7.6.3 UAE

Chapter 8 Company Profiles

- 8.1 ABB

- 8.2 Bastian Solutions

- 8.3 FANUC Corporation

- 8.4 Fuji Robotics

- 8.5 Honeywell International Inc

- 8.6 Kawasaki Heavy Industries Ltd

- 8.7 KION Group AG

- 8.8 KUKA AG

- 8.9 Okura LLC

- 8.10 Pasco Systems

- 8.11 Premier Tech

- 8.12 Robotiq

- 8.13 Schneider Packaging Equipment Company

- 8.14 Sidel

- 8.15 Yaskawa Electric Corporation