|

市場調查報告書

商品編碼

1773422

醫療科技塑膠注塑機市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Plastic Injection Molding Machine for MedTech Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

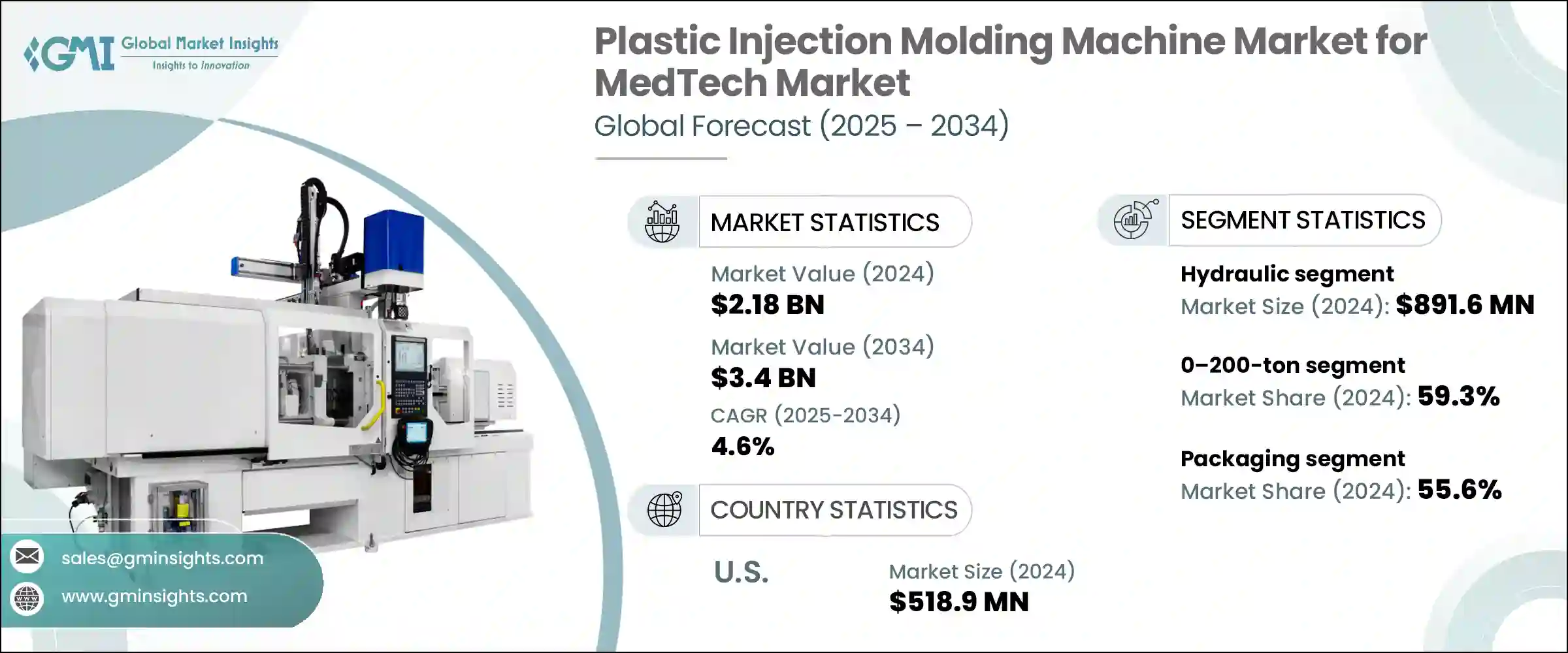

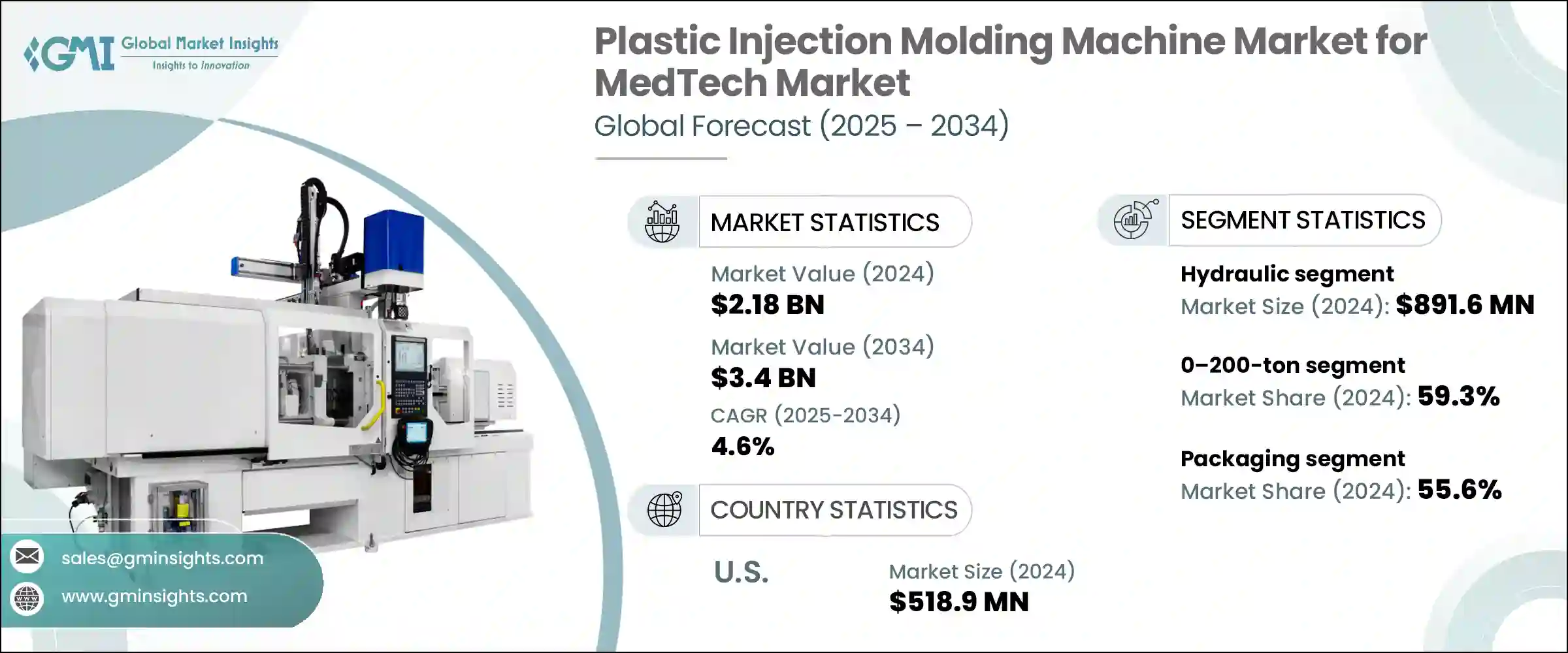

2024 年全球醫療技術市場塑膠注塑機的價值為 21.8 億美元,預計到 2034 年將以 4.6% 的複合年成長率成長至 34 億美元。人口老化和美國和歐洲慢性病激增推動了這一需求,導致對高品質、可靠醫療設備的需求增加。這些設備通常需要專為長期照護和慢性病管理設計的複雜包裝組件。新興市場醫療保健產業的擴張為美國和歐洲的機器製造商帶來了誘人的成長前景,無論是透過出口還是透過為滿足這些地區需求的國內醫療技術原始設備製造商提供服務。此外,亞太、拉丁美洲、東歐和中東部分地區等地區不斷成長的醫療保健支出,也提高了對經濟高效且精確的醫療設備生產的需求。

製造業在岸化趨勢和合約製造網路的快速擴張正在積極重塑全球醫療科技生產格局,為塑膠射出成型機供應商創造新的發展動力。隨著製造商尋求減少對海外供應鏈的依賴,並降低地緣政治和物流風險,許多製造商正在將生產遷移到更靠近北美和歐洲等關鍵市場的地方。這種轉變推動了對高度自動化、高精度注塑機的需求,這些注塑機支援精益生產模式並符合無塵室標準。此外,合約製造合作夥伴正在擴大生產規模,以處理醫療科技原始設備製造商 (OEM) 的多樣化產品組合,這推動了對能夠高效、大批量生產複雜部件的多功能注塑機的需求。這些不斷發展的動態正在為專注於醫療級應用的機器製造商開闢長期成長途徑。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 21.8億美元 |

| 預測值 | 34億美元 |

| 複合年成長率 | 4.6% |

2024年,液壓領域產值達到8.916億美元,預計2034年將以3.9%的複合年成長率成長。儘管液壓系統能耗高,但其高注射壓力、卓越的鎖模力和耐用性使其非常適合複雜生物醫學零件的大量生產。它們在高溫下成型高黏度材料時表現出色,使其成為關鍵醫療零件生產的可靠選擇。

2024年,0-200噸鎖模力的射出成型機佔據了59.3%的市場佔有率,預計到2034年將以5.1%的複合年成長率成長。這些緊湊型系統能夠在潔淨室內精確成型小型一次性零件,例如手術和牙科器械。其節能、更短的成型週期以及大批量生產精密零件的能力使其成為醫療科技領域不可或缺的一部分。

美國醫療科技市場塑膠射出成型機在2024年創下了5.189億美元的產值,預計到2034年將以3.1%的複合年成長率成長。由於液壓注塑機成本效益高,且能夠生產大量、複雜的零件,尤其是在合約製造領域,因此國內市場對液壓注塑機的偏好強烈。電動注塑機也因其快速循環、低噪音和低維護成本的特點,在中小企業和研究實驗室中越來越受到青睞。美國醫療科技公司越來越重視能源效率、清潔操作和精度,從而推動液壓和電動平台之間的市場平衡。

全球醫療科技市場塑膠射出成型機的領導製造商包括美聯(Million)、JSW、住友德馬格(Sumitomo Demag)、日精塑膠工業株式會社(Nissei Plastic Industrial Co., Ltd.)、泰瑞機械(Tederic Machinery)、威猛巴頓菲爾(Wittmann Bats, Ltd.)、泰瑞機械(Tederic Machinery)、威猛巴頓菲爾(Wittmann Battenfeld)、阿博克龍Milacron)、博樂機械(Bohle Machinery)、內格里博西(Negri Bossi)、震雄集團(Chen Hsong Holdings Limited)、恩格爾(Engel)、巴頓菲爾(Battenfeld)和赫斯基注塑系統(Husky Injection Molding Systems)。在這個專業設備市場中營運的公司正在採取策略性措施來鞏固其競爭地位。他們專注於開發專為醫療級零件設計的精密工程機器,同時投資研發以提高能源效率和循環速度。

與醫療科技原始設備製造商 (OEM) 的合作有助於驗證機器在高要求應用中的效能,而全球服務網路則可確保快速的支援和維護。此外,製造商正在客製化產品以符合區域潔淨室標準和監管需求,並透過預測性維護和遠端監控等智慧製造功能增強數位化能力。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商概況

- 利潤率

- 每個階段的增值

- 影響價值鏈的因素

- 中斷

- 產業衝擊力

- 成長動力

- 醫療器材需求不斷成長

- 醫療保健領域的技術進步

- 人口老化與慢性疾病

- 轉向微創手術

- 產業陷阱與挑戰

- 初期投資成本高

- 監理合規挑戰

- 機會

- 成長動力

- 成長潛力分析

- 未來市場趨勢

- 技術和創新格局

- 當前的技術趨勢

- 新興技術

- 價格趨勢

- 按地區

- 按機器類型

- 監理框架

- 標準和認證

- 環境法規

- 進出口法規

- 貿易統計(HS編碼847710)

- 主要進口國

- 主要出口國

- 波特五力分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估計與預測:按機器類型,2021 - 2034 年

- 主要趨勢

- 油壓機

- 電動機

- 油電混合機器

- 微型機器

第6章:市場估計與預測:依技術分類,2021 - 2034 年

- 主要趨勢

- 熱流道系統與冷流道系統

- 多腔和系列模具設計

- 疊模技術

- 伺服驅動模具系統

- 高精度模具技術

第7章:市場預估與預測:依鎖模力,2021 - 2034

- 主要趨勢

- 0-200噸力

- 201-500噸力

- 500噸以上力

第8章:市場估計與預測:按應用,2021 - 2034 年

- 主要趨勢

- 包裝

- 無菌包裝組件

- 瓶蓋和封口

- 保護性包裝

- 其他

- 診斷

- 外科

- 其他

第9章:市場估計與預測:依最終用途,2021 - 2034 年

- 主要趨勢

- B2B醫療科技公司

- 大的

- 中小企業

- 藥品和組合產品製造商

- 合約製造組織(CMO)

- 研發機構

- 醫學研究機構

- 醫療孵化器與創新中心

第10章:市場估計與預測:按地區,2021 - 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳洲

- 拉丁美洲

- 巴西

- 墨西哥

- MEA

- 沙烏地阿拉伯

- 阿拉伯聯合大公國

- 南非

第 11 章:公司簡介

- Arburg

- Billion

- BOLE Machinery

- Chen Hsong Holdings Limited

- Engel

- Ferromatik Milacron

- Husky Injection Molding Systems

- JSW

- KraussMaffei

- Negri Bossi

- Nissei Plastic Industrial Co., Ltd.

- Netstal

- Sumitomo Demag

- Tederic Machinery

- Wittmann Battenfeld

The Global Plastic Injection Molding Machine for MedTech Market was valued at USD 2.18 billion in 2024 and is estimated to grow at a CAGR of 4.6% to reach USD 3.4 billion by 2034. Demand is being driven by aging demographics and a surge in chronic diseases across the U.S. and Europe, resulting in increased requirements for high-quality, reliable medical devices. These devices often require intricate packaging components designed for long-term care and chronic disease management. Expansion in emerging market healthcare sectors presents compelling growth prospects for U.S. and European machine manufacturers, both through exports and through servicing domestic MedTech OEMs catering to these geographies. Additionally, rising healthcare expenditures in regions like Asia-Pacific, Latin America, Eastern Europe, and parts of the Middle East are elevating demand for cost-effective yet precise medical device production.

A broader trend toward onshoring and the rapid expansion of contract manufacturing networks is actively reshaping the global MedTech production landscape, creating new momentum for plastic injection molding machine suppliers. As manufacturers seek to reduce reliance on overseas supply chains and mitigate geopolitical and logistical risks, many are relocating production closer to key markets such as North America and Europe. This shift is fueling demand for highly automated, precision-focused molding machines that support lean manufacturing models and cleanroom compliance. Additionally, contract manufacturing partners are scaling up facilities to handle diverse product portfolios for MedTech OEMs, driving the need for versatile molding platforms capable of producing intricate components efficiently and at high volumes. These evolving dynamics are opening long-term growth avenues for machine makers specializing in medical-grade applications.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $2.18 Billion |

| Forecast Value | $3.4 Billion |

| CAGR | 4.6% |

The hydraulic segment generated USD 891.6 million in 2024 and is projected to grow at a CAGR of 3.9% through 2034. Though energy-intensive, their high injection pressures, exceptional clamping force, and durability suit large-batch production of complex biomedical components. Their consistent performance in molding high-viscosity materials under high temperatures makes them a dependable choice for critical medical parts production.

Machines with 0-200-ton clamping force segment held a 59.3% share in 2024 and are forecast to grow at a CAGR of 5.1% through 2034. These compact systems enable precise molding of small, disposable components-such as surgical and dental devices-within cleanroom settings. Their energy efficiency, shorter cycle times, and ability to produce high volumes of precision parts make them indispensable for the MedTech sector.

U.S. Plastic Injection Molding Machine for MedTech Market generated USD 518.9 million in 2024 and is expected to grow at a 3.1% CAGR through 2034. Domestic preference for hydraulic machines is strong due to their cost-effectiveness and capability for large-shot, complex part production, especially in contract manufacturing. Electric machines are also gaining traction in SMEs and research labs for their fast cycles, low noise, and minimal upkeep. U.S. MedTech firms increasingly value energy efficiency, clean operation, and precision, driving a balanced market between hydraulic and electric platforms.

Leading manufacturers in the Global Plastic Injection Molding Machine for MedTech Market include Million, JSW, Sumitomo Demag, Nissei Plastic Industrial Co., Ltd., Tederic Machinery, Wittmann Battenfeld, Arburg, Netstal, Ferromatik Milacron, Bohle Machinery, Negri Bossi, Chen Hsong Holdings Limited, Engel, Battenfeld, and Husky Injection Molding Systems. Companies operating in this specialized equipment market are employing strategic initiatives to reinforce their competitive positions. They focus on developing precision-engineered machines designed for medical-grade components while investing in R&D to improve energy efficiency and cycle speed.

Collaborations with MedTech OEMs help validate machine performance for demanding applications, while global service networks ensure rapid support and maintenance. Furthermore, manufacturers are customizing products to match regional cleanroom standards and regulatory needs and are enhancing digital capabilities through smart manufacturing features like predictive maintenance and remote monitoring.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Machine type

- 2.2.3 Technology

- 2.2.4 Clamping Force

- 2.2.5 Application

- 2.2.6 End Use

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier Landscape

- 3.1.2 Profit Margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rising demand for medical devices

- 3.2.1.2 Technological advancements in healthcare

- 3.2.1.3 Aging population and chronic diseases

- 3.2.1.4 Shift towards minimally invasive procedures

- 3.2.2 Industry pitfalls & challenges

- 3.2.2.1 High initial investment costs

- 3.2.2.2 Regulatory compliance challenges

- 3.2.3 opportunities

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and Innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By machine type

- 3.7 Regulatory framework

- 3.7.1 Standards and certifications

- 3.7.2 Environmental regulations

- 3.7.3 Import export regulations

- 3.8 Trade statistics (HS code 847710)

- 3.8.1 Major importing countries

- 3.8.2 Major exporting countries

- 3.9 Porter's five forces analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East and Africa

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates & Forecast, By Machine Type, 2021 - 2034, (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 Hydraulic machines

- 5.3 Electric machines

- 5.4 Hybrid machines

- 5.5 Micro machines

Chapter 6 Market Estimates & Forecast, By Technology, 2021 - 2034, (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Hot runner systems and cold runner systems

- 6.3 Multi-cavity and family mold designs

- 6.4 Stack mold technology

- 6.5 Servo-actuated mold systems

- 6.6 High-precision mold technologies

Chapter 7 Market Estimates & Forecast, By Clamping Force, 2021 - 2034, (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 0-200 ton force

- 7.3 201-500 ton force

- 7.4 Above 500 ton force

Chapter 8 Market Estimates & Forecast, By Application, 2021 - 2034, (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 Packaging

- 8.2.1 Sterile packaging components

- 8.2.2 Caps and closures

- 8.2.3 Protective packaging

- 8.2.4 Others

- 8.3 Diagnostic

- 8.4 Surgical

- 8.5 Others

Chapter 9 Market Estimates & Forecast, By End Use, 2021 - 2034, (USD Million) (Thousand Units)

- 9.1 Key trends

- 9.2 B2B MedTech Companies

- 9.2.1 Large

- 9.2.2 SME

- 9.3 Pharmaceutical and Combination Product Manufacturers

- 9.4 Contract Manufacturing Organizations (CMOs)

- 9.5 Research and Development Organizations

- 9.5.1 Medical Research Institutions

- 9.5.2 Medical Incubators and Innovation Centers

Chapter 10 Market Estimates & Forecast, By Region, 2021 - 2034, (USD Million) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.6 MEA

- 10.6.1 Saudi Arabia

- 10.6.2 UAE

- 10.6.3 South Africa

Chapter 11 Company Profiles

- 11.1 Arburg

- 11.2 Billion

- 11.3 BOLE Machinery

- 11.4 Chen Hsong Holdings Limited

- 11.5 Engel

- 11.6 Ferromatik Milacron

- 11.7 Husky Injection Molding Systems

- 11.8 JSW

- 11.9 KraussMaffei

- 11.10 Negri Bossi

- 11.11 Nissei Plastic Industrial Co., Ltd.

- 11.12 Netstal

- 11.13 Sumitomo Demag

- 11.14 Tederic Machinery

- 11.15 Wittmann Battenfeld