|

市場調查報告書

商品編碼

1755254

化學錨栓市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Chemical Anchors Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

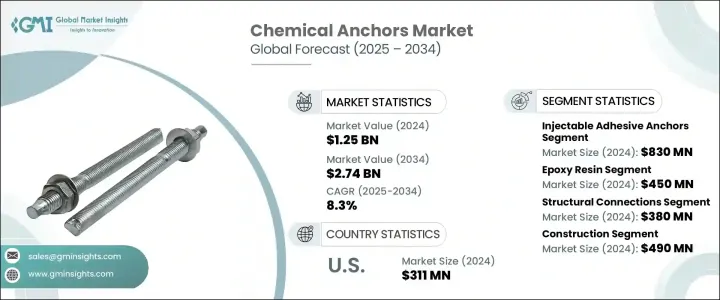

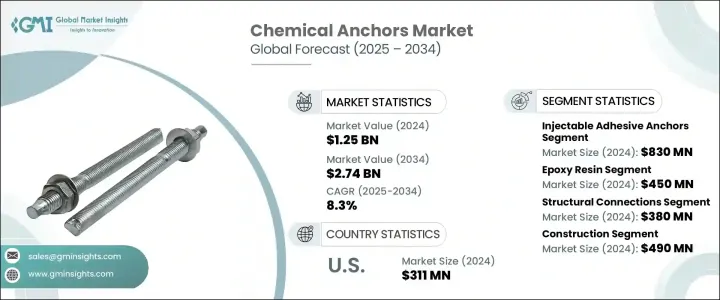

2024年,全球化學錨栓市場規模達12.5億美元,預計到2034年將以8.3%的複合年成長率成長,達到27.4億美元。這一成長主要源於全球建築活動量的不斷成長。隨著城市人口的擴張和城市的快速發展,對先進建築技術和現代化基礎設施的需求持續成長。因此,化學錨栓正成為各種複雜程度和規模的建築物中各種結構構件固定的必備組件。這些錨固解決方案在結構應用中提供強大且持久的黏結,並在住宅、商業和工業領域日益受到青睞。

隨著都市化進程的加快,對能夠在嚴苛環境下兼顧效能和安全性的錨固系統的需求日益成長。隨著建築結構日益複雜,以及對永續性的日益重視,工程師和承包商開始使用化學錨栓進行可靠的固定。它們能夠有效地為混凝土和鋼筋提供高強度的黏合力,因此在全球基礎設施開發和改造專案中正日益被採用。化學錨栓能夠承受動態和靜態負荷,因此尤其適合現代建築施工要求。目前,各公司正專注於生產符合嚴格安全標準的高效能錨定解決方案,以推動其在各種應用中的廣泛應用。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 12.5億美元 |

| 預測值 | 27.4億美元 |

| 複合年成長率 | 8.3% |

就產品類型而言,市場細分為注射式黏合劑錨固劑、膠囊黏合劑錨固劑和化學錨固固定件。注射式黏合劑錨固劑細分市場在2024年以8.3億美元的估值引領市場,預計到2034年將以8.9%的複合年成長率成長。其主導地位歸功於其易用性、在多種建築應用中的多功能性以及在嚴苛工況下的卓越性能。這些錨固劑因其能夠提供牢固、一致的黏合力而備受青睞,即使在需要精確承重性能和快速安裝時間的區域也是如此。樹脂配方技術的進步也促進了其日益普及,因為它可以實現更快的固化速度和更高的可靠性。

根據樹脂類型,市場分為乙烯基酯樹脂、環氧丙烯酸酯、環氧樹脂、聚酯樹脂和混合系統。環氧樹脂細分市場在2024年的估值為4.5億美元,預計在預測期內將以9%的複合年成長率擴張。環氧基化學錨栓因其高機械強度、優異的耐化學性以及在高負荷環境下的可靠黏合性,在重型建築環境中廣受青睞。這些樹脂還具有快速固化能力,在極端環境條件下表現良好,使其成為結構完整性至關重要的專案的首選。

按應用分析,市場涵蓋結構連接、鋼筋連接、重型設備安裝、外牆安裝、扶手和安全護欄、抗震加固等。結構連結細分市場在2024年的價值達到3.8億美元,預計2025年至2034年的複合年成長率為8.8%。該細分市場佔據重要佔有率,因為它在確保各種建築形式的穩定性和安全性方面發揮著至關重要的作用。隨著高層建築和現代基礎設施系統的發展,對結構接頭強力錨定解決方案的需求正在穩步成長。在這些應用中使用化學錨栓可以實現安全的負載傳遞,並將對周圍材料的干擾降至最低。

建築業在2024年成為最大的終端用途產業,價值4.9億美元,預計複合年成長率為7.8%,市佔率將達到39.5%。快速的城市發展趨勢、商業房地產的擴張以及對安全和永續建築實踐的日益重視,都促進了該行業的突出地位。建築商和開發商越來越依賴化學錨栓,因為它們具有適應性強、強度高且符合現代建築要求的特性。隨著設計複雜性和結構高度的不斷提高,對可靠錨定解決方案的需求將持續高漲。

從區域表現來看,美國化學錨栓市場在2024年的估值為3.11億美元,預計2034年將以8%的複合年成長率成長。基礎設施升級的增加,加上抗震加強標準的日益普及,正在推動需求成長。此外,建築法規的更新以及住宅和商業裝修投資的增加也推動了市場成長。頂級製造商的技術改進和創新也擴大了化學錨栓的應用範圍,為市場滲透提供了新的機會。

行業領導者透過持續創新、品牌建立和廣泛的國際分銷管道保持競爭優勢。這些公司專注於生產先進的配方,提供卓越的承載能力、更快的固化時間以及在不同環境條件下的可靠性能。主要製造商注重永續性和符合全球安全標準,並根據不斷變化的監管要求調整其產品線。此外,透過合作、合併和策略性收購進行擴張,使他們能夠增強在新興市場和成熟市場的影響力。專業的技術支援、先進的培訓項目以及針對不同建築需求的整合解決方案也塑造著該行業的發展。

目錄

第1章:方法論

- 市場範圍和定義

- 研究設計

- 研究方法

- 資料收集方法

- 資料探勘來源

- 全球的

- 地區/國家

- 基礎估算與計算

- 基準年計算

- 市場評估的主要趨勢

- 初步研究和驗證

- 主要來源

- 預測模型

- 研究假設和局限性

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商格局

- 利潤率

- 每個階段的增值

- 影響價值鏈的因素

- 中斷

- 產業衝擊力

- 成長動力

- 產業陷阱與挑戰

- 市場機會

- 成長潛力分析

- 監管格局

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- 中東和非洲

- 波特的分析

- PESTEL分析

- 價格趨勢

- 按地區

- 按產品

- 未來市場趨勢

- 技術和創新格局

- 當前的技術趨勢

- 新興技術

- 專利格局

- 貿易統計(HS編碼)

(註:僅提供重點國家的貿易統計)

- 主要進口國

- 主要出口國

- 永續性和環境方面

- 永續實踐

- 減少廢棄物的策略

- 生產中的能源效率

- 環保舉措

- 碳足跡考量

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 按地區

- 北美洲

- 歐洲

- 亞太地區

- 拉丁美洲

- MEA

- 按地區

- 公司矩陣分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 關鍵進展

- 併購

- 夥伴關係與合作

- 新產品發布

- 擴張計劃

第5章:市場估計與預測:依產品類型,2021 - 2034 年

- 主要趨勢

- 注射式黏合劑錨

- 膠囊黏合劑錨

- 化學錨栓固定件

第6章:市場估計與預測:按樹脂類型,2021 - 2034

- 主要趨勢

- 環氧樹脂

- 環氧丙烯酸酯

- 聚酯樹脂

- 乙烯基酯樹脂

- 混合系統

第7章:市場估計與預測:按應用,2021 - 2034 年

- 主要趨勢

- 結構連接

- 鋼筋連接

- 重型設備安裝

- 外牆安裝

- 扶手和安全護欄

- 抗震加固

- 其他

第8章:市場估計與預測:按最終用途產業,2021 - 2034 年

- 主要趨勢

- 建造

- 住宅

- 商業的

- 工業的

- 基礎設施

- 公路和橋樑

- 水壩和隧道

- 鐵路

- 其他

- 製造業

- 海洋和近海

- 石油和天然氣

- 礦業

- 其他

第9章:市場估計與預測:按地區,2021 - 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 義大利

- 西班牙

- 歐洲其他地區

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 亞太其他地區

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 拉丁美洲其他地區

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

- 中東和非洲其他地區

第10章:公司簡介

- Hilti Corporation

- Sika AG

- Simpson Strong-Tie Company, Inc.

- Illinois Tool Works Inc. (ITW)

- BASF SE

- 3M Company

- Henkel AG & Co. KGaA

- Fischer Group

- Powers Fasteners (Stanley Black & Decker)

- MKT Fastening LLC

- DEWALT (Stanley Black & Decker)

- Mapei SpA

- Rawlplug

- EJOT Holding GmbH & Co. KG

- CELO Fixings

- Chemfix Products Ltd

- FIXDEX Fastening Technology

- Evonik Industries AG

- Good Use Hardware Co., Ltd.

- Ripple Construction Products Pvt Ltd.

The Global Chemical Anchors Market was valued at USD 1.25 billion in 2024 and is estimated to grow at a CAGR of 8.3% to reach USD 2.74 billion by 2034. This growth is largely driven by the increasing volume of construction activity worldwide. As urban populations expand and cities develop rapidly, the demand for advanced construction techniques and modern infrastructure continues to rise. In response, chemical anchors are becoming essential components for securing various structural elements in buildings of varying complexity and size. These anchoring solutions provide strong, long-lasting bonds in structural applications and are gaining traction across residential, commercial, and industrial sectors.

As urbanization intensifies, there is a growing need for anchoring systems that ensure both performance and safety in demanding environments. With more complex structures being built and an increased focus on sustainability, engineers and contractors are turning to chemical anchors for reliable fastening. They are particularly effective in delivering high-strength adhesion to concrete and reinforcement bars, which is why they are being increasingly adopted in infrastructure development and renovation projects globally. Their ability to handle dynamic and static loads makes them especially suitable for modern-day construction requirements. Companies are now concentrating on manufacturing high-performance anchoring solutions that meet stringent safety standards, driving adoption across diverse applications.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.25 billion |

| Forecast Value | $2.74 billion |

| CAGR | 8.3% |

In terms of product types, the market is segmented into injectable adhesive anchors, capsule adhesive anchors, and chemical anchor fixings. The injectable adhesive anchors segment led the market in 2024 with a valuation of USD 830 million and is expected to grow at a CAGR of 8.9% through 2034. Its dominance is attributed to its ease of use, versatility across multiple construction applications, and superior performance in demanding scenarios. These anchors are favored for their ability to provide strong, consistent bonding, even in areas that require precise load-bearing performance and fast installation times. Technological advancements in resin formulations have also contributed to their rising popularity by enabling faster curing and improved reliability.

Based on resin types, the market is categorized into vinyl ester resin, epoxy acrylate, epoxy resin, polyester resin, and hybrid systems. The epoxy resin segment was valued at USD 450 million in 2024 and is anticipated to expand at a CAGR of 9% during the forecast period. Epoxy-based chemical anchors are widely preferred in heavy construction environments due to their high mechanical strength, excellent resistance to chemicals, and dependable bonding in high-load settings. These resins also offer rapid curing capabilities and perform well under extreme environmental conditions, making them the go-to option in projects where structural integrity is critical.

When analyzed by application, the market includes structural connections, rebar connections, heavy equipment mounting, facade installations, handrails and safety barriers, seismic retrofitting, and others. The structural connections segment recorded a value of USD 380 million in 2024 and is projected to grow at a CAGR of 8.8% from 2025 to 2034. This segment holds a significant share as it fulfills a crucial role in ensuring stability and safety across a broad range of construction formats. With the evolution of high-rise buildings and modern infrastructure systems, the demand for strong anchoring solutions in structural joints is growing steadily. The use of chemical anchors in these applications allows for secure load transfer and minimal disruption to surrounding materials.

The construction segment emerged as the largest end-use industry in 2024, valued at USD 490 million, and is forecasted to grow at a CAGR of 7.8%, capturing a market share of 39.5%. The growing trend of rapid urban development, expansion in commercial real estate, and increased focus on safe and sustainable construction practices have all contributed to the segment's prominence. Builders and developers increasingly rely on chemical anchors for their adaptability, strength, and compatibility with modern construction requirements. As design complexity and structural heights continue to rise, the need for reliable anchoring solutions will remain high.

In terms of regional performance, the United States chemical anchors market was valued at USD 311 million in 2024 and is anticipated to grow at a CAGR of 8% through 2034. The rise in infrastructure upgrades, coupled with the increasing adoption of seismic retrofitting standards, is fueling demand. Additionally, market growth is supported by updates in construction regulations and rising investments in residential and commercial renovations. Technological enhancements and innovations from top manufacturers are also expanding the application scope of chemical anchors, offering new opportunities for market penetration.

Leading industry players maintain a competitive edge through continuous innovation, brand development, and broad international distribution channels. These companies focus on producing advanced formulations that offer superior load-bearing capabilities, faster curing times, and reliable performance under varying environmental conditions. With an emphasis on sustainability and compliance with global safety standards, major manufacturers are aligning their product lines with evolving regulatory requirements. Moreover, expansion efforts through partnerships, mergers, and strategic acquisitions are enabling them to strengthen their presence across emerging and mature markets. The industry is also shaped by specialized technical support, advanced training programs, and integrated solutions tailored to diverse construction needs.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product type

- 2.2.3 Resin type

- 2.2.4 Application

- 2.2.5 End use industry

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.6.1 Technology and Innovation landscape

- 3.6.2 Current technological trends

- 3.6.3 Emerging technologies

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By product

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent landscape

- 3.11 Trade statistics (HS code)

( Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly Initiatives

- 3.13 Carbon footprint considerations

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates & Forecast, By Product Type, 2021 - 2034 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Injectable adhesive anchors

- 5.3 Capsule adhesive anchors

- 5.4 Chemical anchor fixings

Chapter 6 Market Estimates & Forecast, By Resin Type, 2021 - 2034 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Epoxy resin

- 6.3 Epoxy acrylate

- 6.4 Polyester resin

- 6.5 Vinyl ester resin

- 6.6 Hybrid systems

Chapter 7 Market Estimates & Forecast, By Application, 2021 - 2034 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Structural connections

- 7.3 Rebar connections

- 7.4 Heavy equipment mounting

- 7.5 Facade installations

- 7.6 Handrails and safety barriers

- 7.7 Seismic retrofitting

- 7.8 Others

Chapter 8 Market Estimates & Forecast, By End Use Industry, 2021 - 2034 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 Construction

- 8.2.1 Residential

- 8.2.2 Commercial

- 8.2.3 Industrial

- 8.3 Infrastructure

- 8.3.1 Highways and bridges

- 8.3.2 Dams and tunnels

- 8.3.3 Railways

- 8.3.4 Others

- 8.4 Manufacturing

- 8.5 Marine and offshore

- 8.6 Oil & gas

- 8.7 Mining

- 8.8 Others

Chapter 9 Market Estimates & Forecast, By Region, 2021 - 2034 (USD Billion) (Kilo Tons)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 Germany

- 9.3.2 UK

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Rest of Europe

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 Australia

- 9.4.5 South Korea

- 9.4.6 Rest of Asia Pacific

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.5.4 Rest of Latin America

- 9.6 Middle East & Africa

- 9.6.1 Saudi Arabia

- 9.6.2 South Africa

- 9.6.3 UAE

- 9.6.4 Rest of Middle East & Africa

Chapter 10 Company Profiles

- 10.1 Hilti Corporation

- 10.2 Sika AG

- 10.3 Simpson Strong-Tie Company, Inc.

- 10.4 Illinois Tool Works Inc. (ITW)

- 10.5 BASF SE

- 10.6 3M Company

- 10.7 Henkel AG & Co. KGaA

- 10.8 Fischer Group

- 10.9 Powers Fasteners (Stanley Black & Decker)

- 10.10 MKT Fastening LLC

- 10.11 DEWALT (Stanley Black & Decker)

- 10.12 Mapei S.p.A.

- 10.13 Rawlplug

- 10.14 EJOT Holding GmbH & Co. KG

- 10.15 CELO Fixings

- 10.16 Chemfix Products Ltd

- 10.17 FIXDEX Fastening Technology

- 10.18 Evonik Industries AG

- 10.19 Good Use Hardware Co., Ltd.

- 10.20 Ripple Construction Products Pvt Ltd.