|

市場調查報告書

商品編碼

1750328

吹塑拉伸包裝膜市場機會、成長動力、產業趨勢分析及2025-2034年預測Blown Stretch Packaging Films Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

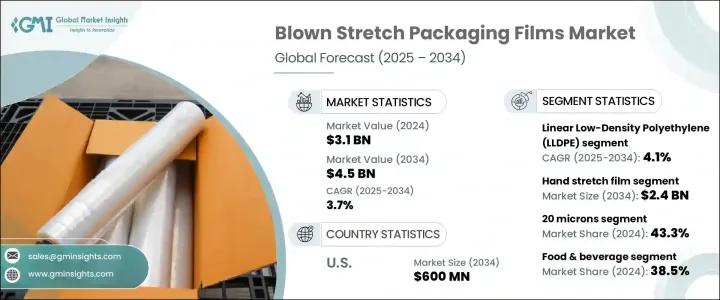

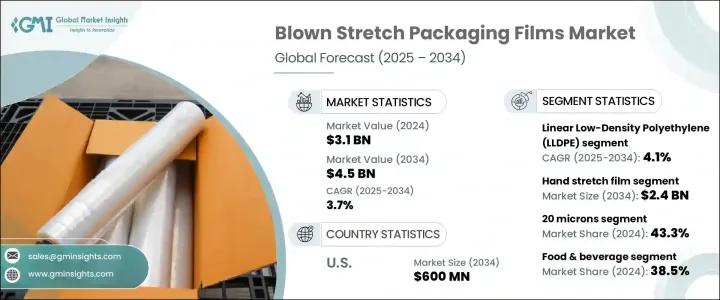

2024年,全球吹塑拉伸包裝膜市場規模達31億美元,預計到2034年將以3.7%的複合年成長率成長,達到45億美元。這一成長主要源於各種包裝應用領域日益成長的需求,其中食品和飲料行業的需求尤為突出。隨著對耐用、柔韌、輕質包裝材料的需求不斷成長,吹塑拉伸膜的需求顯著成長。這些薄膜具有卓越的承載穩定性、產品保護性和成本效益,使其成為注重包裝完整性和效率的行業中不可或缺的利器。多年來,經濟和政治因素也在塑造市場格局方面發揮了作用。貿易限制和關稅變化給供應鏈帶來了壓力,尤其是在投入成本上升的情況下。為此,製造商正在採用針對特定區域的生產策略,以降低地緣政治風險並確保業務連續性。這種轉變有助於企業透過建立能夠快速適應市場動態的在地化生態系統來降低營運成本、保障供應鏈安全並保護利潤率。

材料類型在市場發展中起著至關重要的作用。線性低密度聚乙烯 (LLDPE) 憑藉其卓越的機械性能(例如更高的拉伸強度、柔韌性和抗穿刺性)佔據了相當大的市場佔有率。這些特性使 LLDPE 成為拉伸膜製造的首選,尤其是在需要更薄的薄膜以減少材料用量且不影響耐用性的情況下。預計到 2034 年,LLDPE 市場的複合年成長率將達到 4.1%,反映出物流和消費品等行業對高性能、具成本效益包裝解決方案的偏好日益成長。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 31億美元 |

| 預測值 | 45億美元 |

| 複合年成長率 | 3.7% |

就產品類型而言,市場包括手動拉伸膜、機用拉伸膜和特殊拉伸膜。其中,手動拉伸膜因其成本效益和多功能性而日益受到青睞。預計到2034年,手動拉伸膜市場規模將達到24億美元,這得益於依賴人工包裝的中小企業和倉儲業務的使用量不斷成長。這些薄膜為小批量包裝需求提供了實用的解決方案,尤其是在自動化基礎設施匱乏的市場。

厚度是影響需求的另一個關鍵參數。 2024年,厚度不超過20微米的薄膜佔了43.3%的市佔率。隨著越來越多的行業轉向使用更薄的薄膜來包裝更輕的貨物,這個細分市場正在不斷擴大。對較低厚度的偏好有助於減少包裝浪費、降低運輸成本並支持永續發展,而這些在現代供應鏈中日益重要。

終端用途產業細分顯示,食品和飲料產業佔據主導地位,2024 年該產業的市佔率為 38.5%。吹塑拉伸膜在該行業中發揮著至關重要的作用,它能夠防止產品受潮和物理損壞,延長保存期限。吹塑拉伸膜在儲存和運輸過程中能夠提供安全衛生的包裝,非常適合易腐爛商品。隨著消費者對安全便捷包裝的需求日益成長,吹塑拉伸膜在該行業的應用也持續成長。

分銷管道也塑造市場動態,其中直銷佔據主導地位,到2024年將佔總市場佔有率的52%。直銷使製造商能夠根據客戶的特定需求(例如薄膜厚度、抗張強度或視覺屬性)提供客製化包裝解決方案。這種方式可以加強客戶關係,實現無縫溝通,從而確保提供更優質的服務和產品支援。

就區域而言,美國預計將迎來強勁成長,預計到2034年其市場規模將達到6億美元。高性能食品包裝材料的需求正在不斷成長,這尤其得益於電子商務的蓬勃發展以及消費者對安全高效產品配送的期望值不斷提升。因此,市場正在不斷湧現包裝解決方案的創新,以確保產品完整性並滿足日益成長的物流需求。

吹塑拉伸包裝膜市場的競爭仍然激烈,領導企業在品質、創新和永續性方面展開競爭。各公司正大力投資開發可生物分解和多層薄膜技術,以滿足環保標準和消費者偏好。此外,各公司正專注於策略性併購和區域擴張,以增強市場影響力並提昇技術能力。此外,人們對智慧包裝解決方案(包括RFID整合和溫度監控)的興趣也日益濃厚,旨在提高供應鏈效率並確保安全。針對製藥、物流和消費品等目標產業的客製化服務,正日益成為這個不斷發展的市場中差異化競爭的重要因素。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 川普政府關稅分析

- 對貿易的影響

- 貿易量中斷

- 報復措施

- 對產業的影響

- 供給側影響(原料)

- 主要材料價格波動

- 供應鏈重組

- 生產成本影響

- 需求面影響(售價)

- 價格傳導至終端市場

- 市佔率動態

- 消費者反應模式

- 供給側影響(原料)

- 受影響的主要公司

- 策略產業反應

- 供應鏈重組

- 定價和產品策略

- 政策參與

- 展望與未來考慮

- 對貿易的影響

- 產業衝擊力

- 生長

- 寒冷地區空中交通量不斷成長

- 嚴格的航空安全法規

- 除冰技術的進步

- 擴建機場基礎設施

- 氣候變遷與嚴冬

- 產業陷阱與挑戰

- 營運和維護成本高

- 環境和監管問題

- 生長

- 成長潛力分析

- 監管格局

- 技術格局

- 未來市場趨勢

- 差距分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 主要市場參與者的競爭分析

- 競爭定位矩陣

- 策略儀表板

第5章:市場估計與預測:依產品類型,2021 年至 2034 年

- 主要趨勢

- 手用拉伸膜

- 機用拉伸膜

- 特種拉伸膜

第6章:市場估計與預測:依材料類型,2021 年至 2034 年

- 主要趨勢

- 線性低密度聚乙烯(LLDPE)

- 低密度聚乙烯(LDPE)

- 高密度聚乙烯(HDPE)

- 聚丙烯(PP)

- 其他

第7章:市場估計與預測:依厚度,2021-2034

- 主要趨勢

- 高達 20 微米

- 21–40微米

- 40微米以上

第8章:市場估計與預測:按最終用途產業,2021 年至 2034 年

- 主要趨勢

- 食品和飲料

- 工業包裝

- 消費品

- 製藥

- 其他

第9章:市場估計與預測:按配銷通路,2021 年至 2034 年

- 主要趨勢

- 直銷

- 分銷商/批發商

- 線上通路

第10章:市場估計與預測:按地區,2021 年至 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 荷蘭

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

第 11 章:公司簡介

- Berry Global Inc.

- AEP Industries Inc.

- Amcor Plc

- Coveris Holdings SA

- DUO PLAST AG

- Eurofilms Extrusion Ltd

- FlexSol Packaging Corp.

- Integrated Packaging Group Pty Ltd

- Intertape Polymer Group Inc.

- Manuli Stretch SpA

- Megaplast India Pvt. Ltd.

- Mondi Group

- Paragon Films Inc.

- Polifilm GmbH

- RKW Group

- Sealed Air Corporation

- Sigma Plastics Group

- Trioplast Industrier AB

The Global Blown Stretch Packaging Films Market was valued at USD 3.1 billion in 2024 and is estimated to grow at a CAGR of 3.7% to reach USD 4.5 billion by 2034. This growth is primarily driven by increasing demand across various packaging applications, with the food and beverage sector at the forefront. As the need for durable, flexible, and lightweight packaging materials rises, blown stretch films have gained significant traction. These films offer superior load stability, product protection, and cost-effectiveness, making them essential in industries where packaging integrity and efficiency are vital. Over the years, economic and political factors have also played a role in shaping the market landscape. Trade restrictions and tariff changes have pressured the supply chain, particularly due to rising input costs. In response, manufacturers are adopting region-specific production strategies to reduce geopolitical risks and ensure business continuity. This shift helps companies lower operational costs, secure supply chains, and protect their profit margins by building localized ecosystems that can quickly adapt to market dynamics.

Material type plays a vital role in the market's evolution. Linear Low-Density Polyethylene (LLDPE) holds a significant portion of the market due to its outstanding mechanical properties, such as higher tensile strength, flexibility, and puncture resistance. These features make LLDPE a preferred choice for stretch film manufacturing, especially when thinner films are required to reduce material usage without compromising durability. The LLDPE segment is forecast to grow at a CAGR of 4.1% by 2034, reflecting the rising preference for high-performance and cost-efficient packaging solutions in sectors like logistics and consumer goods.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $3.1 Billion |

| Forecast Value | $4.5 Billion |

| CAGR | 3.7% |

In terms of product types, the market includes hand stretch films, machine stretch films, and specialty variants. Among these, hand stretch films are gaining traction due to their cost-effectiveness and versatility. The hand stretch film segment is projected to reach USD 2.4 billion by 2034, fueled by increasing usage among small to medium businesses and warehousing operations that rely on manual wrapping. These films provide a practical solution for low-volume packaging needs, especially in markets with minimal automation infrastructure.

Thickness is another key parameter influencing demand. Films with up to 20 microns in thickness accounted for a market share of 43.3% in 2024. This segment is expanding as more industries turn to thinner films to wrap lighter goods. The preference for lower thickness helps reduce packaging waste, cut transportation costs, and support sustainability efforts, which are increasingly important in modern supply chains.

The end-use industry segmentation shows a dominant presence in the food and beverage sector, which held a 38.5% market share in 2024. Blown stretch films serve a crucial role in this industry by offering protection against moisture and physical damage, extending product shelf life. Their ability to support secure and hygienic packaging during storage and transit makes them highly suitable for perishable goods. As consumers increasingly demand safe and convenient packaging, the adoption of blown stretch films continues to rise in this sector.

Distribution channels also shape the market dynamics, with direct sales leading the way by accounting for 52% of the total share in 2024. Direct sales allow manufacturers to provide customized packaging solutions tailored to specific customer requirements such as film thickness, tensile strength, or visual attributes. This approach strengthens client relationships and enables seamless communication, ensuring better service and product support.

In the regional landscape, the United States is expected to witness strong growth, with its market projected to hit USD 600 million by 2034. The demand for high-performance food packaging materials is rising, particularly due to expanding e-commerce and increased consumer expectations for safe and efficient product delivery. As a result, the market is seeing increased innovation in packaging solutions to ensure product integrity and support growing logistical needs.

The competitive environment in the blown stretch packaging films market remains intense, with leading players competing on quality, innovation, and sustainability. Companies are heavily investing in developing biodegradable and multi-layer film technologies to meet environmental standards and consumer preferences. In addition, firms are focusing on strategic mergers, acquisitions, and regional expansions to strengthen their market presence and improve technological capabilities. There is also growing interest in smart packaging solutions, including RFID integration and temperature monitoring, to enhance supply chain efficiency and ensure safety. Customization for targeted industries like pharmaceuticals, logistics, and consumer goods is becoming increasingly important as a differentiating factor in this evolving market.

Table of Contents

Chapter 1 Methodology and Scope

- 1.1 Market scope and definitions

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Base estimates and calculations

- 1.3.1 Base year calculation

- 1.3.2 Key trends for market estimation

- 1.4 Forecast model

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.5.2 Data mining sources

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Trump administration tariffs analysis

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1.1 Supply chain reconfiguration

- 3.2.4.1.2 Pricing and product strategies

- 3.2.4.1.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Industry impact forces

- 3.3.1 Growth

- 3.3.1.1.1 Growing air traffic in cold regions

- 3.3.1.1.2 Stringent aviation safety regulations

- 3.3.1.1.3 Advancements in de-icing technologies

- 3.3.1.1.4 Expansion of airport infrastructure

- 3.3.1.1.5 Climate variability and severe winters

- 3.3.2 Industry pitfalls and challenges

- 3.3.2.1 High operational and maintenance costs

- 3.3.2.2 Environmental and regulatory concerns

- 3.3.1 Growth

- 3.4 Growth potential analysis

- 3.5 Regulatory landscape

- 3.6 Technology landscape

- 3.7 Future market trends

- 3.8 Gap analysis

- 3.9 Porter's analysis

- 3.10 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategy dashboard

Chapter 5 Market Estimates and Forecast, By Product Type, 2021 – 2034 (USD Billion & kilo tons)

- 5.1 Key trends

- 5.2 Hand stretch film

- 5.3 Machine stretch film

- 5.4 Specialty stretch film

Chapter 6 Market Estimates and Forecast, By Material Type, 2021 – 2034 (USD Billion & kilo tons)

- 6.1 Key trends

- 6.2 Linear low-density polyethylene (LLDPE)

- 6.3 Low-density polyethylene (LDPE)

- 6.4 High-density polyethylene (HDPE)

- 6.5 Polypropylene (PP)

- 6.6 Others

Chapter 7 Market Estimates & Forecast, By Thickness, 2021-2034 (USD Billion & kilo tons)

- 7.1 Key trends

- 7.2 Up to 20 microns

- 7.3 21–40 microns

- 7.4 Above 40 microns

Chapter 8 Market Estimates and Forecast, By End Use Industry, 2021 – 2034 (USD Billion & kilo tons)

- 8.1 Key trends

- 8.2 Food & beverage

- 8.3 Industrial packaging

- 8.4 Consumer goods

- 8.5 Pharmaceuticals

- 8.6 Others

Chapter 9 Market Estimates and Forecast, By Distribution Channel, 2021 – 2034 (USD Billion & kilo tons)

- 9.1 Key trends

- 9.2 Direct sales

- 9.3 Distributors/wholesalers

- 9.4 Online channels

Chapter 10 Market Estimates and Forecast, By Region, 2021 – 2034 (USD Billion & kilo tons)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Spain

- 10.3.5 Italy

- 10.3.6 Netherlands

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 Australia

- 10.4.5 South Korea

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 Middle East and Africa

- 10.6.1 Saudi Arabia

- 10.6.2 South Africa

- 10.6.3 UAE

Chapter 11 Company Profiles

- 11.1 Berry Global Inc.

- 11.2 AEP Industries Inc.

- 11.3 Amcor Plc

- 11.4 Coveris Holdings S.A.

- 11.5 DUO PLAST AG

- 11.6 Eurofilms Extrusion Ltd

- 11.7 FlexSol Packaging Corp.

- 11.8 Integrated Packaging Group Pty Ltd

- 11.9 Intertape Polymer Group Inc.

- 11.10 Manuli Stretch S.p.A.

- 11.11 Megaplast India Pvt. Ltd.

- 11.12 Mondi Group

- 11.13 Paragon Films Inc.

- 11.14 Polifilm GmbH

- 11.15 RKW Group

- 11.16 Sealed Air Corporation

- 11.17 Sigma Plastics Group

- 11.18 Trioplast Industrier AB