|

市場調查報告書

商品編碼

1740958

汽車門檻市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Automotive Door Sills Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

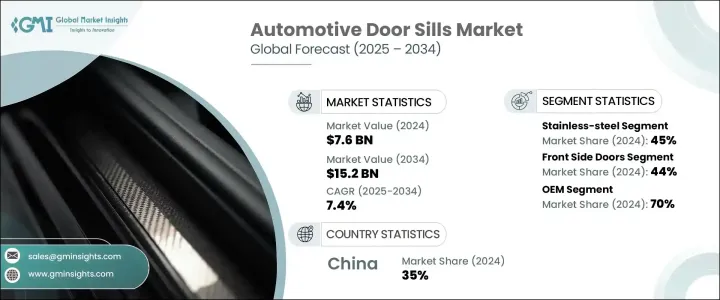

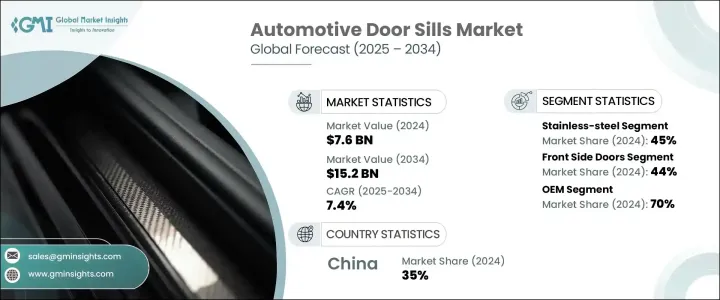

2024年,全球汽車門檻板市場規模達76億美元,預計到2034年將以7.4%的複合年成長率成長,達到152億美元。推動這一成長的關鍵因素是人們對車輛進入系統的高度關注以及全球汽車產量的持續成長。隨著汽車技術日趨智慧化,外觀設計也愈發精緻,門檻板不再被視為簡單的保護性飾條,而是兼具設計感和功能性的多功能部件。汽車製造商正在整合照明系統、接近偵測和高強度材料等先進功能,以提升使用者體驗、耐用性和視覺吸引力。輕量化設計在電動和混合動力汽車中尤其重要,這推動了對既能提供強度又不增加額外重量的材料的需求。碳纖維、鋁和抗衝擊聚合物在打造兼具性能和造型標準的現代門檻板方面正變得至關重要。這些材料能夠實現複雜的設計、提升結構性能並增強對環境條件的耐受性,所有這些都有助於實現更廣泛的節能和長期使用目標。

汽車門檻也正在透過基於感測器的創新進行變革,這些創新將互動元素融入其中。製造商正在探索能夠響應人體接近、與環境照明協調,甚至支援觸控或手勢控制的智慧門檻。這些功能將門檻定位為現代汽車智慧架構的一部分,並與汽車更廣泛的資訊娛樂和門禁系統無縫整合。隨著科技與汽車內裝的不斷融合,這些增強型門檻對於提供高品質、個人化的駕駛體驗至關重要。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 76億美元 |

| 預測值 | 152億美元 |

| 複合年成長率 | 7.4% |

2024年,不銹鋼佔據了最大的市場佔有率,約佔45%,預計到2034年,其複合年成長率將超過7%。這種優勢得益於不銹鋼無與倫比的耐用性、成本效益和抗衝擊性。它能夠承受頻繁進出,尤其是在SUV和車隊車輛等高流量車輛中。其耐腐蝕性還能確保即使在惡劣的天氣或路況下,不銹鋼也能保持外觀和結構完好。對於電動和混合動力車型,不鏽鋼可提供支撐車身完整性所需的結構強度,同時還能容納發光標誌、動態照明或智慧門禁模組等現代化功能。

從應用角度來看,前側門領域在2024年以44%的市佔率領先市場,預計在2025年至2034年期間的複合年成長率將超過7%。前側門與駕駛和乘客的互動最為頻繁,因此成為防護和裝飾升級的主要重點。汽車製造商利用這一區域引入品牌元素和以用戶為中心的功能,因為它是進入車輛時主要的視覺和觸覺接觸點。發光側門和帶有標識的裝飾條經常被整合在這裡,以留下持久的第一印象,並強調車輛的整體設計品質。

按車型分類,由於轎車、掀背車和小型SUV的全球產量較高,乘用車市場繼續佔據主導地位。由於消費者更注重外觀和功能性的內裝升級,製造商正在為這些車輛配備不銹鋼和照明的門檻板,將安全性與奢華感融為一體。隨著電動車和自動駕駛汽車的普及,門檻板部件也在不斷發展,以相容於整合式電子系統,這進一步凸顯了它們的重要性,而不僅僅是起到美觀的作用。

在亞太地區,中國在2024年成為主導市場,創造了約7億美元的市場規模,佔據該地區約35%的佔有率。中國作為全球最大汽車生產國的地位以及國內對電動車日益成長的需求,為其佔據領先地位做出了重要貢獻。中國強大的製造業生態系統使其能夠高效生產和出口先進的門檻系統。

汽車產業趨勢正在塑造市場,例如以用戶為中心的人體工學、高性能材料和環境整合。為了應對機械應力、天氣暴露和電子元件穩定性等挑戰,製造商如今採用具有高抗衝擊性的熱塑性塑膠、抗紫外線塗層和防水LED系統。這些升級增強了門檻在極端氣候和持續使用條件下的耐用性,尤其是在高階汽車領域。

先進的製造技術正在提高組裝精度,尤其適用於整合照明燈和感測器的車型。快速組裝黏合劑和卡扣系統的使用可最大限度地減少振動損傷,並確保安裝更清潔。同時,EMI屏蔽線路和最佳化的線纜佈線有助於避免照明門檻板中的訊號干擾。基於人工智慧和3D視覺化技術的智慧設計平台如今能夠快速實現門檻板模組的原型設計和客製化。這些工具能夠精確地匹配品牌目標、使用者介面預期和車輛美觀度,使門檻板成為下一代汽車座艙的關鍵互動點。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 供應商格局

- 製造商

- 原物料供應商

- 汽車OEM

- 配銷通路

- 最終用途

- 川普政府關稅的影響

- 貿易影響

- 貿易量中斷

- 報復措施

- 對產業的影響

- 供給側影響(原料)

- 主要材料價格波動

- 供應鏈重組

- 生產成本影響

- 需求面影響(客戶成本)

- 價格傳導至終端市場

- 市佔率動態

- 消費者反應模式

- 供給側影響(原料)

- 受影響的主要公司

- 策略產業反應

- 供應鏈重組

- 定價和產品策略

- 政策參與

- 展望與未來考慮

- 貿易影響

- 利潤率分析

- 技術與創新格局

- 專利分析

- 重要新聞和舉措

- 監管格局

- 價格趨勢分析

- 產品

- 地區

- 成本細分分析

- 對部隊的影響

- 成長動力

- 車輛客製化需求不斷成長

- 室內防護意識不斷增強

- 電動車和豪華汽車銷售成長

- 全球汽車產量增加

- 產業陷阱與挑戰

- 先進設計的製造成本高

- 惡劣環境下的耐久性問題

- 成長動力

- 成長潛力分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 競爭定位矩陣

- 戰略展望矩陣

第5章:市場估計與預測:依資料,2021 - 2034 年

- 主要趨勢

- 不銹鋼

- 鋁

- 橡皮

- 塑膠

- 碳纖維

第6章:市場估計與預測:按應用,2021 - 2034 年

- 主要趨勢

- 前側門

- 後側門

- 尾門

第7章:市場估計與預測:依車型,2021 - 2034 年

- 主要趨勢

- 搭乘用車

- 商用車

- 輕型商用車

- 中型商用車

- 重型商用車

第8章:市場估計與預測:依銷售管道,2021 - 2034 年

- 主要趨勢

- OEM

- 售後市場

第9章:市場估計與預測:按地區,2021 - 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 義大利

- 西班牙

- 俄羅斯

- 北歐人

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳新銀行

- 東南亞

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- MEA

- 阿拉伯聯合大公國

- 沙烏地阿拉伯

- 南非

第10章:公司簡介

- AC Schnitzer

- BMW

- Bosch

- Galio

- Gestamp

- Gronbach

- Hangzhou Green Offroad Auto Parts

- Honda Access

- Innotec

- Key Safety Systems (KSS)

- Mahle

- Mopar (FCA)

- Normic Industries

- Prius Auto Industries

- Rugged Ridge

- Shenzhen ATR Industry

- Shenzhen Yanming Plate Process

- SKS Kontakttechnik

- STEProtect (Sliplo)

- Zealio Electronics

The Global Automotive Door Sills Market was valued at USD 7.6 billion in 2024 and is estimated to grow at a CAGR of 7.4% to reach USD 15.2 billion by 2034. A key factor fueling this expansion is the heightened focus on vehicle entry systems and the consistent rise in global automobile production. As vehicles evolve with smarter technologies and more refined aesthetics, door sills are no longer viewed as simple protective trims but as multifunctional components that enhance both design and functionality. Automakers are integrating advanced features like lighting systems, proximity detection, and high-strength materials to improve user experience, durability, and visual appeal. Lightweight designs are especially important in electric and hybrid vehicles, driving the demand for materials that provide strength without adding extra weight. Carbon fiber, aluminum, and impact-resistant polymers are becoming essential in creating modern sills that meet both performance and styling standards. These materials allow for intricate designs, improved structural performance, and better resistance to environmental conditions, all of which support the broader goals of energy efficiency and long-term use.

Automotive door sills are also being transformed through sensor-based innovations that bring interactive elements into the mix. Manufacturers are exploring smart sills that can respond to human proximity, coordinate with ambient lighting, and even enable touch or gesture controls. These features position the door sill as part of the intelligent architecture of modern vehicles, seamlessly integrating with the car's broader infotainment and entry systems. As technology continues to merge with automotive interiors, these enhanced sills are becoming crucial for delivering a high-quality, customized driving experience.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $7.6 billion |

| Forecast Value | $15.2 Billion |

| CAGR | 7.4% |

In 2024, stainless steel held the largest share of the market, accounting for approximately 45%, and is projected to grow at a CAGR exceeding 7% through 2034. This dominance is due to stainless steel's unmatched durability, cost-effectiveness, and impact resistance. It holds up well under repeated entry and exit, especially in high-traffic vehicles like SUVs and fleet cars. Its corrosion resistance also ensures that it remains visually and structurally intact even under harsh weather or road conditions. For electric and hybrid models, stainless steel offers the structural strength needed to support vehicle body integrity while accommodating modern features like illuminated logos, dynamic lighting, or smart access modules.

From an application perspective, the front side doors segment led the market with a 44% share in 2024 and is expected to expand at a CAGR of over 7% between 2025 and 2034. Front door sills see the highest interaction from both drivers and passengers, making them the primary focus for protective and decorative upgrades. Auto manufacturers leverage this section to introduce branding elements and user-centric features, as it forms a major visual and tactile contact point when entering the vehicle. Illuminated sills and logo-enhanced trims are frequently integrated here to leave a lasting first impression and emphasize the vehicle's overall design quality.

When classified by vehicle type, the passenger cars segment continues to dominate due to the high global production volumes of sedans, hatchbacks, and compact SUVs. As buyers lean toward visually appealing and functional interior upgrades, manufacturers are equipping these vehicles with stainless steel and lighted sill plates that combine protection with a touch of luxury. With the increasing shift toward electric and autonomous models, door sill components are also evolving to be compatible with integrated electronic systems, reinforcing their importance beyond just cosmetic roles.

In the Asia-Pacific region, China emerged as the dominant market player in 2024, generating approximately USD 700 million and holding around 35% of the regional share. Its position as the world's largest vehicle producer and growing domestic appetite for electric vehicles contribute significantly to this leadership. The country's robust manufacturing ecosystem enables efficient production and export of advanced door sill systems.

The market is being shaped by automotive industry trends such as user-focused ergonomics, high-performance materials, and ambient integration. To address challenges like mechanical stress, weather exposure, and electronic component stability, manufacturers now employ thermoplastics with high impact resistance, UV-stable finishes, and waterproof LED systems. These upgrades enhance the sills' durability in extreme climates and under constant use, especially in premium vehicle segments.

Advanced manufacturing techniques are improving fitment accuracy, particularly for models featuring integrated lights and sensors. The use of quick-assembly adhesives and clip-lock systems minimizes vibration damage and ensures cleaner installations. Meanwhile, EMI-shielded wiring and optimized cable routing helps avoid signal interference in illuminated sills. Intelligent design platforms powered by AI and 3D visualization are now enabling rapid prototyping and customization of sill modules. These tools allow for precise alignment with branding goals, user interface expectations, and vehicle aesthetics, making door sills a key point of interaction in next-generation vehicle cabins.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates and calculations

- 1.2.1 Base year calculation

- 1.2.2 Key trends for market estimates

- 1.3 Forecast model

- 1.4 Primary research & validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Supplier landscape

- 3.2.1 Manufacturers

- 3.2.2 Raw material suppliers

- 3.2.3 Automotive OEM

- 3.2.4 Distribution channel

- 3.2.5 End use

- 3.3 Impact of Trump administration tariffs

- 3.3.1 Trade impact

- 3.3.1.1 Trade volume disruptions

- 3.3.1.2 Retaliatory measures

- 3.3.2 Impact on industry

- 3.3.2.1 Supply-side impact (raw materials)

- 3.3.2.1.1 Price volatility in key materials

- 3.3.2.1.2 Supply chain restructuring

- 3.3.2.1.3 Production cost implications

- 3.3.2.2 Demand-side impact (Cost to customers)

- 3.3.2.2.1 Price transmission to end markets

- 3.3.2.2.2 Market share dynamics

- 3.3.2.2.3 Consumer response patterns

- 3.3.2.1 Supply-side impact (raw materials)

- 3.3.3 Key companies impacted

- 3.3.4 Strategic industry responses

- 3.3.4.1 Supply chain reconfiguration

- 3.3.4.2 Pricing and product strategies

- 3.3.4.3 Policy engagement

- 3.3.5 Outlook & future considerations

- 3.3.1 Trade impact

- 3.4 Profit margin analysis

- 3.5 Technology & innovation landscape

- 3.6 Patent analysis

- 3.7 Key news & initiatives

- 3.8 Regulatory landscape

- 3.9 Pricing trend analysis

- 3.9.1 Product

- 3.9.2 Region

- 3.10 Cost breakdown analysis

- 3.11 Impact on forces

- 3.11.1 Growth drivers

- 3.11.1.1 Rising demand for vehicle customization

- 3.11.1.2 Growing awareness of interior protection

- 3.11.1.3 Growth in electric and luxury vehicle sales

- 3.11.1.4 Increasing automotive production globally

- 3.11.2 Industry pitfalls & challenges

- 3.11.2.1 High manufacturing costs of advanced designs

- 3.11.2.2 Durability concerns in harsh environments

- 3.11.1 Growth drivers

- 3.12 Growth potential analysis

- 3.13 Porter's analysis

- 3.14 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Material, 2021 - 2034 ($Mn, Units)

- 5.1 Key trends

- 5.2 Stainless steel

- 5.3 Aluminum

- 5.4 Rubber

- 5.5 Plastic

- 5.6 Carbon fiber

Chapter 6 Market Estimates & Forecast, By Application, 2021 - 2034 ($Mn, Units)

- 6.1 Key trends

- 6.2 Front side doors

- 6.3 Back side door

- 6.4 Tailgate

Chapter 7 Market Estimates & Forecast, By Vehicle, 2021 - 2034 ($Mn, Units)

- 7.1 Key trends

- 7.2 Passenger cars

- 7.3 Commercial vehicles

- 7.3.1 Light commercial vehicles

- 7.3.2 Medium commercial vehicles

- 7.3.3 Heavy commercial vehicles

Chapter 8 Market Estimates & Forecast, By Sales Channel, 2021 - 2034 ($Mn, Units)

- 8.1 Key trends

- 8.2 OEM

- 8.3 Aftermarket

Chapter 9 Market Estimates & Forecast, By Region, 2021 - 2034 ($Mn, Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 Germany

- 9.3.3 France

- 9.3.4 Italy

- 9.3.5 Spain

- 9.3.6 Russia

- 9.3.7 Nordics

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 ANZ

- 9.4.6 Southeast Asia

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 MEA

- 9.6.1 UAE

- 9.6.2 Saudi Arabia

- 9.6.3 South Africa

Chapter 10 Company Profiles

- 10.1 AC Schnitzer

- 10.2 BMW

- 10.3 Bosch

- 10.4 Galio

- 10.5 Gestamp

- 10.6 Gronbach

- 10.7 Hangzhou Green Offroad Auto Parts

- 10.8 Honda Access

- 10.9 Innotec

- 10.10 Key Safety Systems (KSS)

- 10.11 Mahle

- 10.12 Mopar (FCA)

- 10.13 Normic Industries

- 10.14 Prius Auto Industries

- 10.15 Rugged Ridge

- 10.16 Shenzhen ATR Industry

- 10.17 Shenzhen Yanming Plate Process

- 10.18 SKS Kontakttechnik

- 10.19 STEProtect (Sliplo)

- 10.20 Zealio Electronics