|

市場調查報告書

商品編碼

1740842

特種炭黑市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Specialty Carbon Black Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

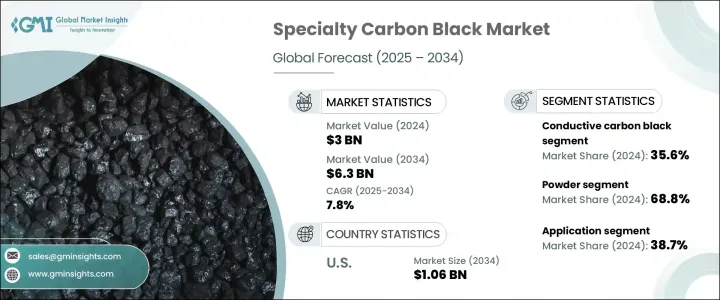

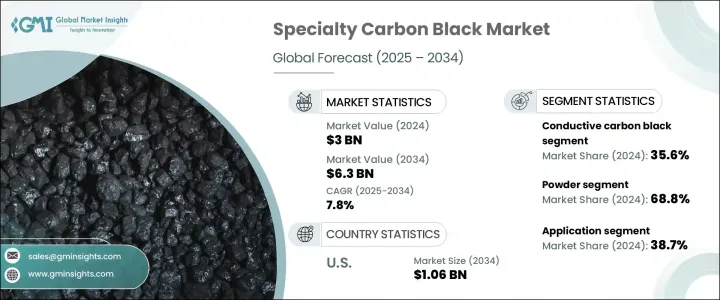

2024年,全球特種炭黑市場規模達30億美元,預計2034年將以7.8%的複合年成長率成長至63億美元。由於各行各業對高性能添加劑(例如導電性、抗紫外線和增強的機械耐久性)的需求不斷成長,特種炭黑市場正呈現穩定成長動能。主要成長動力之一是特種炭黑在先進電池技術中的應用日益廣泛,尤其是在儲能系統中,穩定的性能和穩定性至關重要。塑膠和聚合物產業也呈現類似的成長趨勢,這些產業正將特種炭黑應用於包裝材料和各種高性能塑膠零件中,以發揮其增強和導電性能。從汽車到農業,各行各業對永續高效材料解決方案的興趣日益濃厚,進一步推動了這項需求。農業薄膜和工業包裝袋對特種炭黑的應用,進一步增加了戶外應用的需求,因為這些應用對紫外線防護和物理彈性至關重要。市場參與者也認知到其在下一代材料持續開發中的潛力,這使得特種炭黑成為創新管道中的重要組成部分。

就形態而言,2024 年特種炭黑市場細分為粉末和顆粒,總市值達 30 億美元。粉末型特種炭黑佔據主導地位,佔總市佔率的 68.8%。此形態廣泛應用於導電材料、高效塗料和鋰離子電池組件的生產,這些產品中,細顆粒分散性和材料相容性對性能至關重要。塑膠產業也是粉末特種炭黑的主要消費領域,尤其是在需要外觀均勻性和結構完整性的精密應用中。儘管顆粒形態目前市場佔有率較小,但由於其無塵特性和更佳的加工性能,其市場吸引力逐漸增強,成為清潔高效工業環境的理想選擇。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 30億美元 |

| 預測值 | 63億美元 |

| 複合年成長率 | 7.8% |

市場也依等級分類,主要細分市場包括導電炭黑、纖維炭黑、食品級炭黑等。 2024年,導電炭黑成為領先細分市場,佔整體市場的35.6%。此等級的市場偏好主要源自於其在增強導電性、改善電荷保持率以及延長關鍵應用中組件使用壽命的有效性。在不斷發展的能源領域以及電子應用的先進材料開發中,導電炭黑持續受到歡迎。纖維炭黑在該細分市場細分中緊隨其後,在高耐久性材料生產中保持著重要的相關性。

按應用領域分類,橡膠產業在2024年佔據了最大的市場佔有率,佔全球需求的38.7%。這種主導地位源於其在輪胎和非輪胎橡膠製品中的廣泛應用,而這些產品對補強和耐環境性能至關重要。特種炭黑與橡膠化合物的結合可以延長產品的使用壽命、提高表面穩定性和保護功能,使其成為各種橡膠製品生產週期中的基礎材料。

從地理分佈來看,美國在全球特種炭黑市場中佔有顯著佔有率,2024年佔16.1%。這一佔有率相當於4.9億美元的市場價值,預計2034年將成長至約10.6億美元。美國市場的強勁表現與其先進的製造業生態系統、汽車和儲能產業的需求以及對永續材料創新的持續投資密切相關。政府支持的推廣生物基替代品的措施也促進了生物基替代品的採用和國內生產能力的穩定提升。

特種炭黑產業的競爭格局由多家全球企業塑造,這些企業積極透過策略聯盟、產品創新和區域擴張來擴大市場佔有率。各企業正致力於增強供應鏈、提高產品品質並實現永續發展目標,以在快速發展的市場格局中脫穎而出。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 影響價值鏈的因素

- 利潤率分析

- 中斷

- 未來展望

- 製造商

- 經銷商

- 川普政府關稅

- 對貿易的影響

- 貿易量中斷

- 報復措施

- 對產業的影響

- 供應方影響(原料)

- 主要材料價格波動

- 供應鏈重組

- 生產成本影響

- 需求面影響(售價)

- 價格傳導至終端市場

- 市佔率動態

- 消費者反應模式

- 供應方影響(原料)

- 受影響的主要公司

- 策略產業反應

- 供應鏈重組

- 定價和產品策略

- 政策參與

- 展望與未來考慮

- 對貿易的影響

- 貿易統計(HS編碼)

- 主要出口國

- 主要進口國

註:以上貿易統計僅針對重點國家。

- 利潤率分析

- 供應商格局

- 重要新聞和舉措

- 監管格局

- 衝擊力

- 成長動力

- 導電應用需求不斷成長

- 汽車產業不斷擴張,輕量化趨勢

- 塑膠和聚合物產業的成長

- 蓬勃發展的電動車(EV)和儲能市場

- 高性能塗料和油漆的應用日益增多

- 聚合物複合材料的進展

- 產業陷阱與挑戰

- 原料成本高且供應鏈波動

- 嚴格的碳排放環境法規

- 來自替代材料(石墨烯、二氧化矽和奈米管)的競爭

- 成長動力

- 成長潛力分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 競爭定位矩陣

- 戰略展望矩陣

第5章:市場估計與預測:依形式,2021 年至 2034 年

- 主要趨勢

- 粉末

- 顆粒

第6章:市場估計與預測:依等級,2021 年至 2034 年

- 主要趨勢

- 導電碳黑

- 纖維炭黑

- 食品級炭黑

- 其他

第7章:市場估計與預測:按應用,2021 年至 2034 年

- 主要趨勢

- 橡皮

- 塑膠

- 印刷油墨和碳粉

- 油漆和塗料

- 電池電極

- 其他

第8章:市場估計與預測:按地區,2021 年至 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 德國

- 英國

- 法國

- 西班牙

- 義大利

- 俄羅斯

- 亞太地區

- 中國

- 印度

- 日本

- 澳洲

- 韓國

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- 中東和非洲

- 沙烏地阿拉伯

- 南非

- 阿拉伯聯合大公國

第9章:公司簡介

- Asahi Carbon Co. Ltd.

- Atlas Organics Private Limited

- Birla Carbon

- Black Bear Carbon BV

- Cabot Corporation

- Continental Carbon Company

- Denka Company Limited

- Himadri Specialty Chemical Ltd

- Omsk Carbon Group

- Orion Engineered Carbons GmbH

- Phillips Carbon Black Limited

- Ralson

- Tokai Carbon Co., Ltd.

The Global Specialty Carbon Black Market was valued at USD 3 billion in 2024 and is estimated to grow at a CAGR of 7.8% to reach USD 6.3 billion by 2034. The market is witnessing steady momentum due to increasing utilization across several industries demanding high-performance additives with specific attributes like electrical conductivity, ultraviolet resistance, and enhanced mechanical durability. One of the primary growth drivers is the rising adoption of specialty carbon black in advanced battery technologies, particularly in energy storage systems where consistent performance and stability are critical. A parallel growth trend is observed in the plastics and polymer industries, which are incorporating specialty carbon black for its reinforcing and conductive properties in packaging materials and various high-performance plastic components. This demand is further supported by increased interest in sustainable and efficient material solutions across sectors ranging from automotive to agriculture. The use of specialty carbon black in agricultural films and industrial sacks adds another layer of demand in outdoor applications, where UV protection and physical resilience are essential. Market participants are also recognizing its potential in the ongoing development of next-generation materials, which positions specialty carbon black as a vital component in the innovation pipeline.

In terms of form, the specialty carbon black market in 2024 was segmented into powder and granules, with a combined market value of USD 3 billion. Powder-based specialty carbon black dominated the segment, accounting for 68.8% of the total share. This form is widely used in the production of conductive materials, high-efficiency coatings, and lithium-ion battery components, where fine particle dispersion and material compatibility are essential for performance. The plastics sector is also a key consumer of powder specialty carbon black, particularly in precision applications where visual uniformity and structural integrity are required. Although the granule form currently holds a smaller portion of the market, it is gradually gaining traction due to its dust-free properties and improved processing performance, making it a desirable option for clean and efficient industrial environments.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $3 Billion |

| Forecast Value | $6.3 Billion |

| CAGR | 7.8% |

The market is also categorized by grade, with the major segments including conductive carbon black, fiber carbon black, food-grade carbon black, and others. In 2024, conductive carbon black emerged as the leading segment, representing 35.6% of the overall market. The preference for this grade is largely driven by its effectiveness in enhancing electrical conductivity, improving charge retention, and extending the operational life of components in critical applications. It continues to gain popularity in the evolving energy sector and advanced material development for electronic applications. Fiber carbon black follows closely in the segment breakdown, maintaining strong relevance in high-durability material production.

By application, the rubber industry held the largest market share in 2024, accounting for 38.7% of the global demand. This dominance stems from its broad use in both tire and non-tire rubber products, where reinforcement and environmental resistance are essential. The integration of specialty carbon black in rubber compounds improves product lifespan, surface stability, and protective functionality, making it a cornerstone material in the production cycle of various rubber-based goods.

Geographically, the United States accounted for a significant share of the global specialty carbon black market, capturing 16.1% of the total market in 2024. This share translates to a market value of USD 490 million, with projections indicating growth to approximately USD 1.06 billion by 2034. The strong market performance in the U.S. is closely linked to its advanced manufacturing ecosystem, demand from the automotive and energy storage sectors, and ongoing investments in sustainable material innovations. Government-backed initiatives promoting bio-based alternatives are also contributing to a steady increase in adoption and domestic production capabilities.

The competitive structure of the specialty carbon black industry is shaped by the presence of several global players actively working to expand their market share through strategic alliances, product innovations, and regional expansions. Companies are focusing on enhancing their supply chains, improving product quality, and addressing sustainability goals to differentiate themselves in a rapidly evolving market landscape.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definition

- 1.2 Base estimates & calculations

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid sources

- 1.4.2.2 Public sources

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.5.2 Data mining sources

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021-2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Factor affecting the value chain

- 3.1.2 Profit margin analysis

- 3.1.3 Disruptions

- 3.1.4 Future outlook

- 3.1.5 Manufacturers

- 3.1.6 Distributors

- 3.2 Trump administration tariffs

- 3.2.1 Impact on trade

- 3.2.1.1 Trade volume disruptions

- 3.2.1.2 Retaliatory measures

- 3.2.2 Impact on the industry

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.2.1.1 Price volatility in key materials

- 3.2.2.1.2 Supply chain restructuring

- 3.2.2.1.3 Production cost implications

- 3.2.2.2 Demand-side impact (selling price)

- 3.2.2.2.1 Price transmission to end markets

- 3.2.2.2.2 Market share dynamics

- 3.2.2.2.3 Consumer response patterns

- 3.2.2.1 Supply-side impact (raw materials)

- 3.2.3 Key companies impacted

- 3.2.4 Strategic industry responses

- 3.2.4.1 Supply chain reconfiguration

- 3.2.4.2 Pricing and product strategies

- 3.2.4.3 Policy engagement

- 3.2.5 Outlook and future considerations

- 3.2.1 Impact on trade

- 3.3 Trade statistics (HS code)

- 3.3.1 Major exporting countries

- 3.3.2 Major importing countries

Note: the above trade statistics will be provided for key countries only.

- 3.4 Profit margin analysis

- 3.5 Supplier landscape

- 3.6 Key news & initiatives

- 3.7 Regulatory landscape

- 3.8 Impact forces

- 3.8.1 Growth drivers

- 3.8.1.1 Rising demand for conductive applications

- 3.8.1.2 Expanding automotive sector and lightweighting trend

- 3.8.1.3 Growth in plastics and polymers industry

- 3.8.1.4 Booming electric vehicle (EV) and energy storage market

- 3.8.1.5 Increasing use in high-performance coatings and paints

- 3.8.1.6 Advancements in polymer composite materials

- 3.8.2 Industry pitfalls & challenges

- 3.8.2.1 High raw material costs and supply chain volatility

- 3.8.2.2 Stringent environmental regulations on carbon emissions

- 3.8.2.3 Competition from alternative materials (graphene, silica, and nanotubes)

- 3.8.1 Growth drivers

- 3.9 Growth potential analysis

- 3.10 Porter's analysis

- 3.11 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates and Forecast, By Form, 2021 – 2034 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Powder

- 5.3 Granules

Chapter 6 Market Estimates and Forecast, By Grade, 2021 – 2034 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Conductive carbon black

- 6.3 Fiber carbon black

- 6.4 Food-grade carbon black

- 6.5 Others

Chapter 7 Market Estimates and Forecast, By Application, 2021 – 2034 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Rubber

- 7.3 Plastics

- 7.4 Printing inks & toners

- 7.5 Paints & coatings

- 7.6 Battery electrodes

- 7.7 Others

Chapter 8 Market Estimates and Forecast, By Region, 2021 – 2034 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Russia

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

Chapter 9 Company Profiles

- 9.1 Asahi Carbon Co. Ltd.

- 9.2 Atlas Organics Private Limited

- 9.3 Birla Carbon

- 9.4 Black Bear Carbon B.V.

- 9.5 Cabot Corporation

- 9.6 Continental Carbon Company

- 9.7 Denka Company Limited

- 9.8 Himadri Specialty Chemical Ltd

- 9.9 Omsk Carbon Group

- 9.10 Orion Engineered Carbons GmbH

- 9.11 Phillips Carbon Black Limited

- 9.12 Ralson

- 9.13 Tokai Carbon Co., Ltd.