|

市場調查報告書

商品編碼

1740818

轉向拉桿市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Steering Tie Rod Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

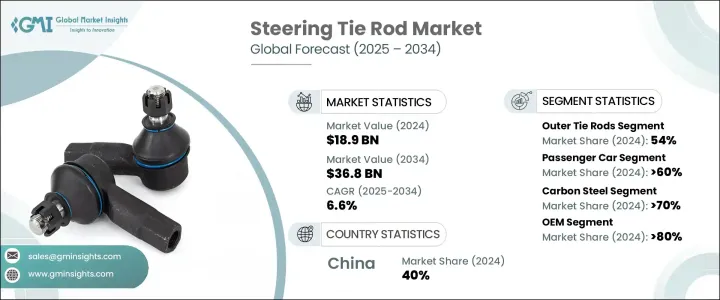

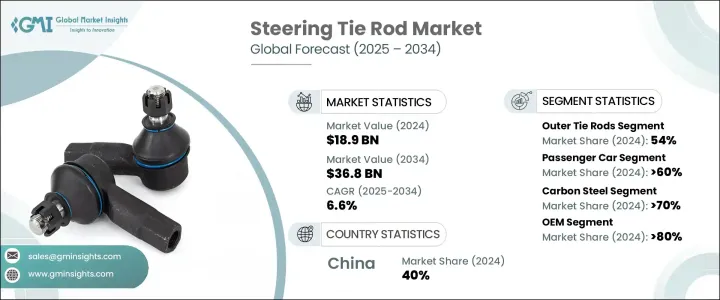

2024年,全球轉向拉桿市場規模達189億美元,預計到2034年將以6.6%的複合年成長率成長,達到368億美元。這一成長主要得益於汽車產業的快速擴張,尤其是在工業化和城市化快速發展的地區。隨著越來越多的人獲得更高的可支配收入以及基礎設施的改善,汽車需求大幅增加。汽車產量的激增自然轉化為對轉向拉桿等關鍵部件的需求成長,這些部件對於保持車輛的正常控制和確保道路安全至關重要。隨著人們對車輛性能和使用壽命的期望不斷提高,汽車製造商和消費者都要求轉向系統先進、耐用,能夠適應現代駕駛條件。

隨著汽車技術創新不斷重塑汽車產業,轉向系統也正在經歷顯著的變化。電動輔助轉向、線控轉向配置以及感測器整合等現代技術進步正日益普及。這些發展不僅提升了車輛性能,也使汽車更加省油、駕駛更安全。隨著汽車變得更加智慧化,對電子設備的依賴程度也越來越高,對轉向拉桿等精密工程零件的需求也愈發重要。這些部件現在必須滿足更高的精度和可靠性標準,以確保與先進的轉向系統實現最佳整合。自動化和電子駕駛輔助系統的轉變,也加劇了對能夠提供高精度、低機械複雜性和更高操控性的零件的需求。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 189億美元 |

| 預測值 | 368億美元 |

| 複合年成長率 | 6.6% |

就產品細分而言,市場分為內拉桿和外拉桿。外拉桿在2024年佔據主導地位,約佔市場佔有率的54%,預計在整個預測期內將以7.2%的複合年成長率成長。由於這些零件位於外部,因此更換頻率更高,更容易受到環境侵蝕和磨損的影響。由於經常受到道路碎屑、潮濕和惡劣環境的影響,會導致零件更快老化。如果不及時更換,磨損的外拉桿會導致轉向反應遲緩和輪胎磨損不均。這自然會增加汽車售後市場的需求,使外拉桿成為關鍵的收入驅動部分。

按車型細分市場,乘用車在2024年佔總銷量的60%以上,預計到2034年將繼續以約6%的複合年成長率成長。乘用車的使用壽命通常更長,並且隨著使用年限的增加而需要持續維護,因此對替換零件的需求持續成長。轉向拉桿對車輛安全操控至關重要,通常需要定期檢查和更換,尤其是在高里程或崎嶇路面駕駛的情況下。全球乘用車數量的成長確保了對OEM和售後市場轉向拉桿產品的持續需求,從而鞏固了該細分市場在整個市場的領先地位。

從材料角度來看,碳鋼在2024年成為製造轉向拉桿的首選材料,佔了超過70%的市場。碳鋼的受歡迎程度源於其高強度和高耐用性的結合,使其能夠長期承受持續的壓力和道路衝擊。與鋁或鈦等替代材料相比,碳鋼還具有成本優勢,使製造商能夠以具有競爭力的價格提供高性能零件。這種品質與成本效益的平衡使碳鋼成為原始設備製造商和售後市場供應商的實用選擇,尤其是在汽車零件這樣一個對價格敏感的市場。

從銷售管道來看,2024年,原始設備製造商(OEM)佔據了轉向拉桿市場80%以上的佔有率。 OEM的強勁表現可以歸因於車輛組裝過程中對原廠零件的需求。 OEM零件的設計旨在精確匹配新車的規格,並提供性能和相容性保證的保固。汽車製造商青睞這些零件,因為它們一致性高、品質保證,並且能夠支援車輛的原始工程設計。全球汽車產量的成長顯著推動了該領域的需求。

從地理分佈來看,中國在2024年佔據全球近40%的市場佔有率,創造了約164億美元的市場收入,佔據了市場主導地位。這一領先地位得益於中國強大的汽車產量和完善的汽車零件供應鏈。中國擁有強大的製造商和供應商基礎,這使得轉向拉桿的生產效率更高、分銷管道更廣。具競爭力的價格加上高品質的標準,使本土生產商能夠有效滿足國內外市場需求。

全球企業持續投資,拓展產品線,整合先進技術。他們透過建立策略夥伴關係和進行研發活動,提升產品性能和耐用性。這些公司積極擁抱線控轉向和電動轉向系統等創新技術,確保其產品滿足現代汽車市場不斷變化的需求。同時,區域製造商則專注於根據本地需求客製化產品,提供與特定車型和駕駛環境相契合的客製化解決方案。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 汽車原廠設備製造商

- 供應商

- 材料和鍛造公司

- 售後市場經銷商和零售商

- 最終用途

- 供應商格局

- 川普政府關稅的影響

- 對貿易的影響

- 貿易量中斷

- 報復措施

- 對產業的影響

- 主要材料價格波動

- 供應鏈重組

- 價格傳導至終端市場

- 策略產業反應

- 供應鏈重組

- 定價和產品策略

- 對貿易的影響

- 價格趨勢

- 地區

- 產品

- 成本細分分析

- 利潤率分析

- 技術與創新格局

- 重要新聞和舉措

- 監管格局

- 衝擊力

- 成長動力

- 全球汽車產量不斷成長

- 轉向系統的技術進步

- 強調車輛安全和法規合規性

- 電動車和自動駕駛汽車的成長

- 產業陷阱與挑戰

- 電動和自動駕駛汽車技術的顛覆

- 原物料價格波動與供應鏈中斷

- 成長動力

- 成長潛力分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 公司市佔率分析

- 競爭定位矩陣

- 戰略展望矩陣

第5章:市場估計與預測:按產品,2021-2034

- 主要趨勢

- 內拉桿

- 外拉桿

第6章:市場估計與預測:依車型,2021-2034

- 主要趨勢

- 搭乘用車

- 掀背車

- 轎車

- 越野車

- 商用車

- 輕型商用車(LCV)

- 中型商用車(MCV)

- 重型商用車(HCV)

第7章:市場估計與預測:依材料,2021-2034

- 主要趨勢

- 碳鋼

- 不銹鋼

第 8 章:市場估計與預測:按銷售管道,2021-2034 年,

- 主要趨勢

- OEM

- 售後市場

第9章:市場估計與預測:按地區,2021 - 2034 年

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 歐洲

- 英國

- 德國

- 法國

- 西班牙

- 義大利

- 俄羅斯

- 北歐人

- 亞太地區

- 中國

- 印度

- 日本

- 韓國

- 澳新銀行

- 東南亞

- 拉丁美洲

- 巴西

- 墨西哥

- 阿根廷

- MEA

- 阿拉伯聯合大公國

- 南非

- 沙烏地阿拉伯

第10章:公司簡介

- ACDelco

- APA Industries

- BorgWarner

- Bosch Group

- Crown Automotive Sales

- CTR

- Delphi Technologies

- Dorman Products

- First Line

- HL Mando

- Ingalls Engineering

- JTEKT

- Mando

- Moog

- Motorcraft

- Nexteer Automotive Group Limited

- NSK

- Sankei Industry

- Synergy Manufacturing

- ZF Friedrichshafen

The Global Steering Tie Rod Market was valued at USD 18.9 billion in 2024 and is estimated to grow at a CAGR of 6.6% to reach USD 36.8 billion by 2034. This growth is primarily fueled by the rapid expansion of the automotive industry, especially in regions undergoing fast-paced industrialization and urban development. As more people gain access to higher disposable incomes and infrastructure improves, the demand for vehicles rises significantly. The surge in vehicle production naturally translates into higher demand for crucial components like steering tie rods, which are essential for maintaining proper vehicle control and ensuring safety on the road. With growing expectations for vehicle performance and longevity, automakers and consumers alike are demanding advanced, durable steering systems that can withstand modern driving conditions.

The steering system is undergoing a notable transformation as innovations in vehicle technology continue to reshape the automotive sector. Modern advancements such as electric power steering, steer-by-wire configurations, and the incorporation of sensors are becoming more widespread. These developments are not just enhancing vehicle performance-they are also making cars more fuel-efficient and safer to drive. As vehicles become smarter and more reliant on electronics, the demand for precisely engineered parts like steering tie rods becomes even more important. These components must now meet higher standards of accuracy and reliability to ensure optimal integration with advanced steering systems. The shift toward automation and electronic driving assistance has intensified the need for parts that can deliver precision, minimal mechanical complexity, and improved handling.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $18.9 Billion |

| Forecast Value | $36.8 Billion |

| CAGR | 6.6% |

In terms of product segmentation, the market is divided into inner and outer tie rods. Outer tie rods held the dominant position in 2024, accounting for around 54% of the market, and are projected to grow at a CAGR of 7.2% throughout the forecast period. These components face more frequent replacements due to their external position, which makes them more vulnerable to environmental exposure and wear. Being constantly subjected to road debris, moisture, and harsh elements leads to quicker degradation. When not replaced in time, worn-out outer tie rods can contribute to poor steering response and uneven tire wear. This naturally increases demand within the automotive aftermarket, making outer tie rods a crucial revenue-driving segment.

When examining the market by vehicle type, passenger cars represented more than 60% of total sales in 2024 and are expected to continue expanding at a CAGR of approximately 6% through 2034. Passenger vehicles tend to remain in service longer and require ongoing maintenance as they age, leading to consistent demand for replacement parts. Steering tie rods, being critical to safe vehicle handling, often need periodic inspection and substitution, especially in high-mileage or rough-road driving scenarios. The growing number of passenger cars in operation globally ensures a sustained need for both OEM and aftermarket tie rod products, reinforcing this segment's leading position in the overall market.

Material-wise, carbon steel emerged as the preferred choice for manufacturing steering tie rods in 2024, accounting for over 70% of the market share. Its popularity stems from a combination of high strength and durability, allowing it to endure continuous stress and road shocks over time. Carbon steel also offers a cost advantage over alternative materials like aluminum or titanium, enabling manufacturers to deliver high-performance parts at competitive pricing. This balance of quality and cost-effectiveness makes carbon steel a practical option for both OEMs and aftermarket suppliers, especially in a price-sensitive market like automotive components.

From a sales channel perspective, OEMs captured more than 80% of the steering tie rod market in 2024. The strong presence of OEMs can be attributed to the need for original parts during vehicle assembly. OEM components are designed to match the exact specifications of new vehicles and come with warranties that assure performance and compatibility. Automakers prefer these components for their consistency, quality assurance, and the ability to support the vehicle's original engineering design. The growth in global vehicle production has significantly driven demand from this segment.

Geographically, China led the market in 2024 with nearly 40% of the global share, generating around USD 16.4 billion in revenue. This leadership is supported by the country's high volume of vehicle production and a well-established supply chain for automotive components. China benefits from a strong base of manufacturers and suppliers, enabling efficient production and widespread distribution of steering tie rods. Competitive pricing, combined with high-quality standards, has allowed local producers to meet both domestic and international demands effectively.

Global players continue to invest in expanding their product lines and integrating advanced technologies. Strategic partnerships and R&D initiatives are being used to enhance product performance and durability. These companies are embracing innovations like steer-by-wire and electric steering systems, ensuring their offerings align with the evolving demands of the modern automotive market. Meanwhile, regional manufacturers focus on tailoring their products to local requirements, offering customized solutions that resonate with specific vehicle types and driving environments.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.1.1 Research approach

- 1.1.2 Data collection methods

- 1.2 Base estimates and calculations

- 1.2.1 Base year calculation

- 1.2.2 Key trends for market estimates

- 1.3 Forecast model

- 1.4 Primary research & validation

- 1.4.1 Primary sources

- 1.4.2 Data mining sources

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Automotive OEMs

- 3.1.2 Suppliers

- 3.1.3 Material and forging companies

- 3.1.4 Aftermarket distributors and retailers

- 3.1.5 End use

- 3.2 Supplier landscape

- 3.3 Impact of trump administration tariffs

- 3.3.1 Impact on trade

- 3.3.1.1 Trade volume disruptions

- 3.3.1.2 Retaliatory measures

- 3.3.2 Impact on the industry

- 3.3.2.1 Price volatility in key materials

- 3.3.2.2 Supply chain restructuring

- 3.3.2.3 Price transmission to end markets

- 3.3.3 Strategic industry responses

- 3.3.3.1 Supply chain reconfiguration

- 3.3.3.2 Pricing and product strategies

- 3.3.1 Impact on trade

- 3.4 Price trend

- 3.4.1 Region

- 3.4.2 Product

- 3.5 Cost breakdown analysis

- 3.6 Profit margin analysis

- 3.7 Technology & innovation landscape

- 3.8 Key news & initiatives

- 3.9 Regulatory landscape

- 3.10 Impact forces

- 3.10.1 Growth drivers

- 3.10.1.1 Rising global automotive production

- 3.10.1.2 Technological advancements in steering systems

- 3.10.1.3 Emphasis on vehicle safety and regulatory compliance

- 3.10.1.4 Growth in electric and autonomous vehicles

- 3.10.2 Industry pitfalls & challenges

- 3.10.2.1 Disruption from electric and autonomous vehicle technologies

- 3.10.2.2 Fluctuating raw material prices and supply chain disruptions

- 3.10.1 Growth drivers

- 3.11 Growth potential analysis

- 3.12 Porter's analysis

- 3.13 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.3 Competitive positioning matrix

- 4.4 Strategic outlook matrix

Chapter 5 Market Estimates & Forecast, By Product, 2021-2034, ($Bn, Units)

- 5.1 Key trends

- 5.2 Inner tie rods

- 5.3 Outer tie rods

Chapter 6 Market Estimates & Forecast, By Vehicle, 2021-2034, ($Bn, Units)

- 6.1 Key trends

- 6.2 Passenger cars

- 6.2.1 Hatchback

- 6.2.2 Sedan

- 6.2.3 SUV

- 6.3 Commercial vehicles

- 6.3.1 Light commercial vehicle (LCV)

- 6.3.2 Medium commercial vehicle (MCV)

- 6.3.3 Heavy commercial vehicle (HCV)

Chapter 7 Market Estimates & Forecast, By Material, 2021-2034, ($Bn, Units)

- 7.1 Key trends

- 7.2 Carbon steel

- 7.3 Stainless steel

Chapter 8 Market Estimates & Forecast, By Sales Channel, 2021-2034, ($Bn, Units)

- 8.1 Key trends

- 8.2 OEM

- 8.3 Aftermarket

Chapter 9 Market Estimates & Forecast, By Region, 2021 - 2034 ($Bn, Units)

- 9.1 Key trends

- 9.2 North America

- 9.2.1 U.S.

- 9.2.2 Canada

- 9.3 Europe

- 9.3.1 UK

- 9.3.2 Germany

- 9.3.3 France

- 9.3.4 Spain

- 9.3.5 Italy

- 9.3.6 Russia

- 9.3.7 Nordics

- 9.4 Asia Pacific

- 9.4.1 China

- 9.4.2 India

- 9.4.3 Japan

- 9.4.4 South Korea

- 9.4.5 ANZ

- 9.4.6 Southeast Asia

- 9.5 Latin America

- 9.5.1 Brazil

- 9.5.2 Mexico

- 9.5.3 Argentina

- 9.6 MEA

- 9.6.1 UAE

- 9.6.2 South Africa

- 9.6.3 Saudi Arabia

Chapter 10 Company Profiles

- 10.1 ACDelco

- 10.2 APA Industries

- 10.3 BorgWarner

- 10.4 Bosch Group

- 10.5 Crown Automotive Sales

- 10.6 CTR

- 10.7 Delphi Technologies

- 10.8 Dorman Products

- 10.9 First Line

- 10.10 HL Mando

- 10.11 Ingalls Engineering

- 10.12 JTEKT

- 10.13 Mando

- 10.14 Moog

- 10.15 Motorcraft

- 10.16 Nexteer Automotive Group Limited

- 10.17 NSK

- 10.18 Sankei Industry

- 10.19 Synergy Manufacturing

- 10.20 ZF Friedrichshafen