|

市場調查報告書

商品編碼

1716714

冷凝火管化學鍋爐市場機會、成長動力、產業趨勢分析及 2025 - 2034 年預測Condensing Fire Tube Chemical Boiler Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034 |

||||||

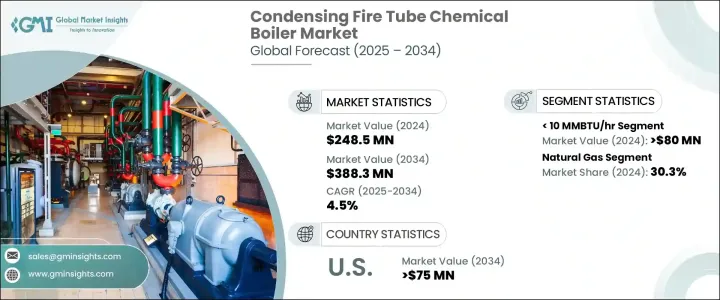

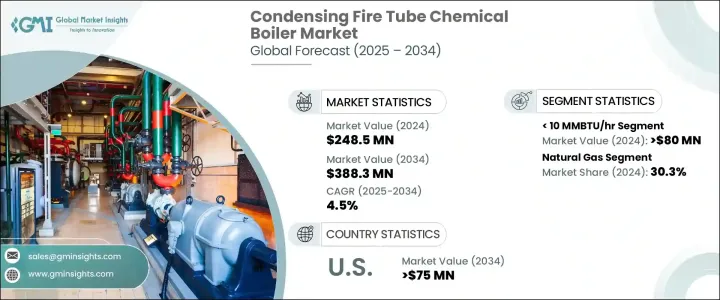

2024 年全球冷凝火管化學鍋爐市場價值為 2.485 億美元,預計 2025 年至 2034 年的複合年成長率為 4.5%。隨著全球各行各業不斷尋求更有效率、更環保的能源解決方案,受對更清潔能源系統的需求推動,該市場的需求正在激增。鍋爐設計技術的進步,特別是那些專注於減少排放和提高能源效率的進步,在塑造產業未來方面發揮著重要作用。遵守嚴格的環境法規的壓力越來越大,迫使企業投資更永續的解決方案。這導致人們更加重視開發和採用高性能冷凝火管化學鍋爐,有助於大幅節約能源並降低溫室氣體排放。

世界各地正在經歷快速的城市化和工業化,這推動了對能源基礎設施的投資。隨著化學過程中對可靠熱量和蒸汽的需求不斷增加,企業擴大採用冷凝火管化學鍋爐作為解決方案。能源和燃料價格上漲進一步刺激了市場發展,提高效率成為尋求管理營運成本的產業的首要任務。此外,持續的技術進步,例如用於預測性維護和即時監控的智慧控制系統的整合,正在提高運行效率並延長鍋爐壽命,使其對化學製造等精度至關重要的工業領域更具吸引力。

| 市場範圍 | |

|---|---|

| 起始年份 | 2024 |

| 預測年份 | 2025-2034 |

| 起始值 | 2.485億美元 |

| 預測值 | 3.883億美元 |

| 複合年成長率 | 4.5% |

到 2034 年,容量為 25 至 50 MMBTU/小時的冷凝火管化學鍋爐市場預計將產生 3,000 萬美元的收入。這些高效能鍋爐配備了省煤器等先進的熱回收系統,特別適合嚴重依賴精確熱過程的產業。智慧技術整合的日益成長的趨勢,提供即時監控和預測性維護功能,預計將成為該市場成長的主要驅動力。這些創新提高了營運性能,實現了長期節能,並確保了熱量和蒸汽生成過程的可靠性,這對於化學和製藥行業至關重要。

2024 年,天然氣冷凝火管化學鍋爐佔據了 30.3% 的市佔率。需求激增主要是由於人們從燃煤和燃油鍋爐轉向更永續的天然氣動力系統。隨著環保法規越來越嚴格,減少碳排放的呼聲也越來越高,企業紛紛選擇更具成本效益、環保的天然氣鍋爐。隨著天然氣價格穩定以及對高效蒸汽發電的需求不斷成長,天然氣鍋爐市場預計將進一步擴大。

在美國,2024 年冷凝火管化學鍋爐市場價值為 4,810 萬美元。對緊湊型高性能鍋爐的需求正在上升,尤其是在需要精確溫度控制和持續蒸汽生成的化工廠中。隨著鍋爐技術的進步,預計未來幾年該行業將實現顯著成長。

目錄

第1章:方法論與範圍

第2章:執行摘要

第3章:行業洞察

- 產業生態系統分析

- 監管格局

- 產業衝擊力

- 成長動力

- 產業陷阱與挑戰

- 成長潛力分析

- 波特的分析

- PESTEL分析

第4章:競爭格局

- 介紹

- 戰略展望

- 創新與永續發展格局

第5章:市場規模及預測:依產能,2021 - 2034 年

- 主要趨勢

- < 10 百萬英熱單位/小時

- 10 - 25 百萬英熱單位/小時

- 25 - 50 百萬英熱單位/小時

- 50 - 75 百萬英熱單位/小時

- 75 - 100 百萬英熱單位/小時

- 100 - 175 百萬英熱單位/小時

- 175 - 250 百萬英熱單位/小時

- > 250 百萬英熱單位/小時

第6章:市場規模及預測:依燃料,2021 - 2034 年

- 主要趨勢

- 天然氣

- 油

- 煤炭

- 其他

第7章:市場規模及預測:依地區,2021 - 2034

- 主要趨勢

- 北美洲

- 美國

- 加拿大

- 墨西哥

- 歐洲

- 法國

- 英國

- 波蘭

- 義大利

- 西班牙

- 奧地利

- 德國

- 瑞典

- 俄羅斯

- 亞太地區

- 中國

- 印度

- 菲律賓

- 日本

- 韓國

- 澳洲

- 印尼

- 中東和非洲

- 沙烏地阿拉伯

- 伊朗

- 阿拉伯聯合大公國

- 奈及利亞

- 南非

- 拉丁美洲

- 阿根廷

- 智利

- 巴西

第8章:公司簡介

- Alfa Laval

- Ariston Holding

- Babcock & Wilcox

- Babcock Wanson

- Bosch Industriekessel

- Clayton Industries

- Cleaver-Brooks

- Cochran

- Forbes Marshall

- Fulton

- Hoval

- Hurst Boiler & Welding

- Miura America

- Rakiro

- Rentech Boiler Systems

- Thermax

- Thermodyne Boilers

- Viessmann

The Global Condensing Fire Tube Chemical Boiler Market was valued at USD 248.5 million in 2024 and is projected to grow at a CAGR of 4.5% from 2025 to 2034. As industries across the globe continue to seek more efficient and eco-friendly energy solutions, this market is witnessing a surge in demand driven by the need for cleaner energy systems. Technological advancements in boiler design, particularly those focused on reducing emissions and boosting energy efficiency, are playing a significant role in shaping the industry's future. The rising pressure to adhere to stringent environmental regulations is compelling businesses to invest in more sustainable solutions. This has led to a greater emphasis on developing and adopting high-performance condensing fire tube chemical boilers that contribute to substantial energy savings and lower greenhouse gas emissions.

Regions across the world are experiencing rapid urbanization and industrialization, which is driving investments in energy infrastructure. As the demand for reliable heat and steam in chemical processes continues to rise, businesses are increasingly turning to condensing fire tube chemical boilers as a solution. The market is further fueled by rising energy and fuel prices, making efficiency improvements a priority for industries looking to manage operational costs. Moreover, ongoing technological advancements, such as the integration of smart control systems for predictive maintenance and real-time monitoring, are boosting operational efficiency and prolonging boiler lifespan, making them even more appealing to industrial sectors like chemical manufacturing, where precision is paramount.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $248.5 Million |

| Forecast Value | $388.3 Million |

| CAGR | 4.5% |

The market for condensing fire tube chemical boilers with capacities ranging from 25 to 50 MMBTU/hr is set to generate USD 30 million by 2034. These high-efficiency boilers, equipped with advanced heat recovery systems like economizers, are particularly suited to industries that rely heavily on precise thermal processes. The increasing trend toward smart technology integration, offering real-time monitoring and predictive maintenance capabilities, is expected to be a key driver of growth in this market. Such innovations are enhancing operational performance, offering long-term energy savings, and ensuring the reliability of heat and steam generation processes, which are vital in chemical and pharmaceutical sectors.

The natural gas condensing fire tube chemical boiler held a 30.3% share of the market in 2024. This surge in demand is largely due to the shift away from coal and oil-fired boilers toward more sustainable natural gas-powered systems. With environmental regulations becoming more stringent and the push for reduced carbon emissions intensifying, businesses are opting for natural gas boilers, which are more cost-effective and environmentally friendly. As natural gas prices stabilize and the need for efficient steam generation continues to grow, the market for natural gas boilers is expected to expand further.

In the U.S., the Condensing Fire Tube Chemical Boiler Market was valued at USD 48.1 million in 2024. The demand for compact, high-performance boilers is rising, especially in chemical plants that require precise temperature control and consistent steam generation. With advancements in boiler technology, this sector is expected to see significant growth in the coming years.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope & definitions

- 1.2 Market estimates & forecast parameters

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Regulatory landscape

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.2 Industry pitfalls & challenges

- 3.4 Growth potential analysis

- 3.5 Porter's analysis

- 3.5.1 Bargaining power of suppliers

- 3.5.2 Bargaining power of buyers

- 3.5.3 Threat of new entrants

- 3.5.4 Threat of substitutes

- 3.6 PESTEL analysis

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Strategic outlook

- 4.3 Innovation & sustainability landscape

Chapter 5 Market Size and Forecast, By Capacity, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 5.1 Key trends

- 5.2 < 10 MMBTU/hr

- 5.3 10 - 25 MMBTU/hr

- 5.4 25 - 50 MMBTU/hr

- 5.5 50 - 75 MMBTU/hr

- 5.6 75 - 100 MMBTU/hr

- 5.7 100 - 175 MMBTU/hr

- 5.8 175 - 250 MMBTU/hr

- 5.9 > 250 MMBTU/hr

Chapter 6 Market Size and Forecast, By Fuel, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 6.1 Key trends

- 6.2 Natural gas

- 6.3 Oil

- 6.4 Coal

- 6.5 Others

Chapter 7 Market Size and Forecast, By Region, 2021 - 2034 (USD Million, MMBTU/hr & Units)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.2.3 Mexico

- 7.3 Europe

- 7.3.1 France

- 7.3.2 UK

- 7.3.3 Poland

- 7.3.4 Italy

- 7.3.5 Spain

- 7.3.6 Austria

- 7.3.7 Germany

- 7.3.8 Sweden

- 7.3.9 Russia

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 India

- 7.4.3 Philippines

- 7.4.4 Japan

- 7.4.5 South Korea

- 7.4.6 Australia

- 7.4.7 Indonesia

- 7.5 Middle East & Africa

- 7.5.1 Saudi Arabia

- 7.5.2 Iran

- 7.5.3 UAE

- 7.5.4 Nigeria

- 7.5.5 South Africa

- 7.6 Latin America

- 7.6.1 Argentina

- 7.6.2 Chile

- 7.6.3 Brazil

Chapter 8 Company Profiles

- 8.1 Alfa Laval

- 8.2 Ariston Holding

- 8.3 Babcock & Wilcox

- 8.4 Babcock Wanson

- 8.5 Bosch Industriekessel

- 8.6 Clayton Industries

- 8.7 Cleaver-Brooks

- 8.8 Cochran

- 8.9 Forbes Marshall

- 8.10 Fulton

- 8.11 Hoval

- 8.12 Hurst Boiler & Welding

- 8.13 Miura America

- 8.14 Rakiro

- 8.15 Rentech Boiler Systems

- 8.16 Thermax

- 8.17 Thermodyne Boilers

- 8.18 Viessmann