|

市場調查報告書

商品編碼

1708937

電氣絕緣塗料市場(按產品、原料和地區分類)Electrical Insulation Coatings Market, By Product (Liquid, Powder), By Raw Material (Epoxy, PTFE, Ceramic, Others), By Geography (North America, Europe, Asia Pacific, Latin America, Middle East and Africa) |

||||||

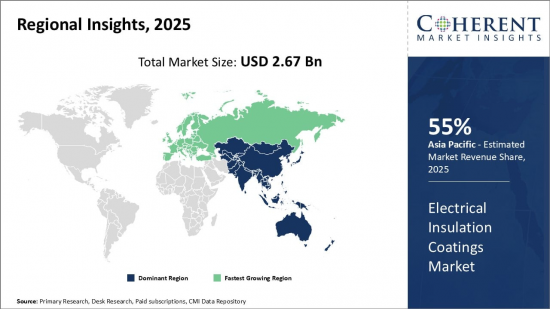

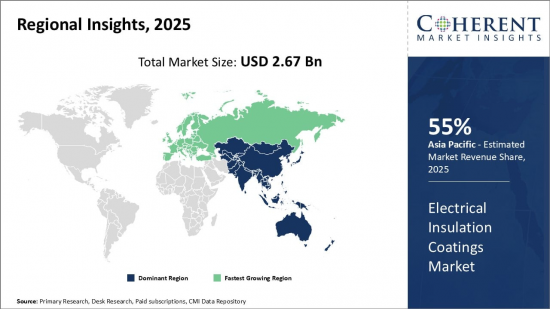

預計 2025 年全球電氣絕緣塗料市場規模為 26.7 億美元,到 2032 年將達到 31.1 億美元,2025 年至 2032 年的複合年成長率為 2.2%。

| 報告範圍 | 報告詳細資訊 | ||

|---|---|---|---|

| 基準年 | 2024 | 2025年的市場規模 | 26.7億美元 |

| 效能數據 | 2020-2024 | 預測期 | 2025-2032 |

| 預測期間:2025年至2032年的複合年成長率 | 2.20% | 2032年價值預測 | 31.1億美元 |

電絕緣塗層是一種應用於電氣元件或設備的保護塗層,用於隔離電壓和電流。它有助於最大限度地減少功率損耗並防止短路和設備故障。快速工業化、可再生能源領域的成長和基礎設施發展等因素正在刺激全球對電氣設備的需求,從而增加了對可靠絕緣塗層的需求。電氣絕緣塗料市場包括多種樹脂類型,包括環氧樹脂、矽膠、丙烯酸樹脂和聚氨酯,用於各種終端產業,包括汽車、船舶、航太和能源電力。環氧樹脂用於各種終端行業,包括汽車、船舶、航太和能源動力,以幫助保護繞組、電線、電纜和其他組件免受環境因素、電應力和熱循環的影響,這些因素會隨著時間的推移導致劣化。根據特定的絕緣要求,使用環氧樹脂、聚酯、聚氨酯、矽膠和三聚氰胺等多種樹脂體系來配製絕緣塗層。全球範圍內基礎設施建設的不斷增加以及輸配電網的升級,推動了對保護電力資產和確保電力供應可靠性的絕緣塗料的需求。此外,可再生能源項目投資的增加也推動了市場的發展。

市場動態

全球電氣絕緣塗料市場受到世界各地基礎設施發展計劃和可再生能源發電的強勁投資所推動。快速的都市化和商業建築數量的增加也是推動智慧電網和佈線系統安裝的主要驅動力。然而,他們受到有關塗料揮發性有機化合物(VOC)排放的嚴格環境法規的阻礙。從積極的一面來看,對生物基和石墨烯增強絕緣塗層的持續研究和開發為製造商帶來了高成長機會。此外,電氣行業擴大採用 3D 列印技術,預計將推動對專用絕緣塗層解決方案的需求。

研究的主要特點

本研究報告對全球電氣絕緣塗料市場進行了詳細分析,並給出了預測期(2025-2032)的市場規模和年複合成長率(CAGR%),假設 2024 年為基準年。

它還強調了各個領域的潛在商機,並說明了該市場的引人注目的投資提案矩陣。

它還提供了有關市場促進因素、限制因素、機會、新產品發布和核准、市場趨勢、區域前景和主要企業採用的競爭策略的重要見解。

全球電氣絕緣塗料市場的主要企業是根據公司亮點、產品系列、關鍵亮點、性能和策略等參數進行的分析。

研究中介紹的主要企業包括 ELANTAS PDG, Inc.、GLS Coatings Ltd.、SK FORMULATIONS INDIA PVT.LTD.、PTFE Applied Coatings、Axalta Coating Systems, LLC、Akzo Nobel NV、Evonik Industries AG、3M、PPG Industries, Inc. Elektrometallurgie mbH。

本報告的見解將使負責人和企業經營團隊能夠就未來的產品發布、類型升級、市場擴張和行銷策略做出明智的決策。

本研究報告針對該產業的各個相關人員,包括投資者、供應商、產品製造商、經銷商、新進業者和財務分析師。

相關人員可以透過全球電氣絕緣塗料市場分析中使用的各種策略矩陣更輕鬆地做出決策。

目錄

第1章 調查目的與前提條件

- 研究目標

- 先決條件

- 簡稱

第2章 市場展望

- 報告描述

- 市場定義和範圍

- 執行摘要

- 一致的機會圖(COM)

第3章市場動態、法規與趨勢分析

- 市場動態

- 了解日益成長的太空探勘需求

- 太空飛行安全

- 機會

- 影響分析

- 監管情景

- 產品發布/核准

- PEST分析

- 波特分析

- 併購場景

第4章 電氣絕緣塗料市場-冠狀病毒(COVID-19)大流行的影響

- COVID-19流行病學

- 供需側分析

- 對空間醫療市場的影響

5. 電氣絕緣塗料市場(依產品分類),2020-2032 年

- 介紹

- 液體

- 粉末

6. 電氣絕緣塗料市場(按原始材料分類),2020-2032 年

- 介紹

- 環氧樹脂

- PTFE

- 陶瓷製品

- 其他

7. 電氣絕緣塗料市場(按地區分類),2020-2032 年

- 介紹

- 北美洲

- 拉丁美洲

- 歐洲

- 亞太地區

- 中東

- 非洲

第8章 競爭態勢

- ELANTAS PDG, Inc

- GLS Coatings Ltd.

- SK FORMULATIONS INDIA PVT. LTD.

- PTFE Applied Coatings

- Axalta Coating Systems, LLC

- Akzo Nobel NV

- Evonik Industries AG

- 3M

- PPG Industries, Inc.

- Thermal Spray Coatings(A Fisher Barton Company)

- GfE Gesellschaft fur Elektrometallurgie mbH

第9章 章節

- 調查方法

- 關於出版商

Global Electrical Insulation Coatings Market is estimated to be valued at USD 2.67 Bn in 2025 and is expected to reach USD 3.11 Bn by 2032, growing at a compound annual growth rate (CAGR) of 2.2% from 2025 to 2032.

| Report Coverage | Report Details | ||

|---|---|---|---|

| Base Year: | 2024 | Market Size in 2025: | USD 2.67 Bn |

| Historical Data for: | 2020 To 2024 | Forecast Period: | 2025 To 2032 |

| Forecast Period 2025 to 2032 CAGR: | 2.20% | 2032 Value Projection: | USD 3.11 Bn |

Electrical insulation coatings refer to protective coatings applied to electrical components and devices to provide insulation from voltage and current. They help minimize power loss and prevent short circuits and equipment failure. Factors such as rapid industrialization, the growth of the renewable energy sector, and infrastructure development are stimulating demand for electrical equipment globally, driving the need for reliable insulation coatings. The electrical insulation coatings market comprises different resin types, including epoxy, silicone, acrylic, and polyurethane, which are used across diverse end use industries like automotive, marine, aerospace, and energy and power. They help protect electrical windings, wires, cables, and other components from environmental hazards, electrical stresses, and thermal cycling that can cause deterioration over time. Various resin systems, such as epoxy, polyester, polyurethane, silicone, and melamine, are used for formulating insulation coatings, depending on the specific insulation requirements. Growing infrastructure development and upgrading of transmission & distribution networks globally is fueling demand for insulation coatings to protect electrical assets and ensure reliability of power supply. Moreover, increasing investments in renewable energy projects is another factor boosting their market.

Market Dynamics:

The global electrical insulation coatings market is driven by robust investments in infrastructure development projects and renewable energy generation worldwide. Rapid urbanization and growth of commercial buildings is another key driver, as it is boosting installations of smart electrical grids and wiring systems. However, stringent environmental regulations regarding Volatile Organic Compounds (VOC) emissions from coating materials act as a restraint. On the positive side, ongoing research and development of bio-based and graphene enhanced insulation coatings present high growth opportunities for manufacturers. Additionally, the rising adoption of 3D printing technologies in the electrical industry will create more demand for specialized insulation coating solutions.

Key features of the study:

This report provides in-depth analysis of the global electrical insulation coatings market, and provides market size (US$ Billion) and compound annual growth rate (CAGR%) for the forecast period (2025-2032), considering 2024 as the base year

It elucidates potential revenue opportunities across different segments and explains attractive investment proposition matrices for this market

This study also provides key insights about market drivers, restraints, opportunities, new product launches or approval, market trends, regional outlook, and competitive strategies adopted by key players

It profiles key players in the global electrical insulation coatings market based on the following parameters - company highlights, products portfolio, key highlights, financial performance, and strategies

Key companies covered as a part of this study include ELANTAS PDG, Inc., GLS Coatings Ltd., SK FORMULATIONS INDIA PVT. LTD., PTFE Applied Coatings, Axalta Coating Systems, LLC, Akzo Nobel N.V., Evonik Industries AG, 3M, PPG Industries, Inc., Thermal Spray Coatings (A Fisher Barton Company), GfE Gesellschaft fur Elektrometallurgie mbH.

Insights from this report would allow marketers and the management authorities of the companies to make informed decisions regarding their future product launches, type up-gradation, market expansion, and marketing tactics

The global electrical insulation coatings market report caters to various stakeholders in this industry including investors, suppliers, product manufacturers, distributors, new entrants, and financial analysts

Stakeholders would have ease in decision-making through various strategy matrices used in analyzing the global electrical insulation coatings market

Electrical Insulation Coatings Market Segmentation

- Electrical Insulation Coatings Market By Product

- Liquid

- Powder

- Electrical Insulation Coatings Market By Raw Material

- Epoxy

- PTFE

- Ceramic

- Others

- Electrical Insulation Coatings Market By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

- Company Profiles

- ELANTAS PDG, Inc.,

- GLS Coatings Ltd.,

- SK FORMULATIONS INDIA PVT. LTD.,

- PTFE Applied Coatings,

- Axalta Coating Systems,

- Akzo Nobel N.V.,

- Evonik Industries AG,

- 3M,

- PPG Industries, Inc.,

- Thermal Spray Coatings (A Fisher Barton Company),

- GfE Gesellschaft fur Elektrometallurgie mbH.

Table of Contents

1. Research Objectives and Assumptions

- Research Objectives

- Assumptions

- Abbreviations

2. Market Purview

- Report Description

- Market Definition and Scope

- Executive Summary

- Electrical Insulation Coatings Market, By Product

- Electrical Insulation Coatings Market, By Raw Material

- Electrical Insulation Coatings Market, By Region

- Coherent Opportunity Map (COM)

3. Market Dynamics, Regulations, and Trends Analysis

- Market Dynamics

- Driver

- Understanding the growing need for space exploration

- Space flight safety

- Restraint

- Opportunities

- Impact Analysis

- Key Highlights

- Regulatory Scenario

- Product Launches/Approvals

- PEST Analysis

- PORTER's Analysis

- Merger and Acquisition Scenario

4. Electrical Insulation Coatings Market-Impact of Coronavirus (COVID-19) Pandemic

- COVID-19 Epidemiology

- Supply Side and Demand Side Analysis

- Impact Space Medicine Market

5. Electrical Insulation Coatings Market, By Product, 2020-2032, (US$ Bn)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021 - 2032

- Segment Trends

- Liquid

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

- Powder

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

6. Electrical Insulation Coatings Market, By Raw Material, 2020-2032, (US$ Bn)

- Introduction

- Market Share Analysis, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, 2021 - 2032

- Segment Trends

- Epoxy

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

- PTFE

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

- Ceramic

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

- Others

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, 2020-2032,(US$ Bn)

7. Electrical Insulation Coatings Market, By Region, 2020-2032, (US$ Bn)

- Introduction

- Market Share Analysis, By Region, 2025 and 2032 (%)

- Y-o-Y Growth Analysis, For Region 2020 -2032

- Country Trends

- North America

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Product, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Raw Material, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Bn)

- U.S.

- Canada

- Latin America

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Product, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Raw Material, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Bn)

- Brazil

- Argentina

- Mexico

- Rest of Latin America

- Europe

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Product, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Raw Material, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Bn)

- Germany

- U.K.

- Spain

- France

- Italy

- Russia

- Rest of Europe

- Asia Pacific

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Product, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Raw Material, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Bn)

- China

- India

- Japan

- Australia

- South Korea

- ASEAN

- Rest of Asia Pacific

- Middle East

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Product, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Raw Material, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country, 2020-2032,(US$ Bn)

- GCC Countries

- Israel

- Rest of Middle East

- Africa

- Introduction

- Market Size and Forecast, and Y-o-Y Growth, By Product, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Raw Material, 2020-2032,(US$ Bn)

- Market Size and Forecast, and Y-o-Y Growth, By Country/Region, 2020-2032,(US$ Bn)

- South Africa

- North Africa

- Central Africa

8. Competitive Landscape

- ELANTAS PDG, Inc

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- GLS Coatings Ltd.,

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- SK FORMULATIONS INDIA PVT. LTD.,

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- PTFE Applied Coatings

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Axalta Coating Systems, LLC,

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- Akzo Nobel N.V.,

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- Evonik Industries AG,

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- 3M,

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- PPG Industries, Inc.,

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- Thermal Spray Coatings (A Fisher Barton Company)

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- GfE Gesellschaft fur Elektrometallurgie mbH

- Company Highlights

- Product Portfolio

- Key Highlights

- Financial Performance

- Strategies

- Analyst Views

9. Section

- Research Methodology

- About us