|

市場調查報告書

商品編碼

1715444

全球線束測試儀市場:2025-2035Global Wire Harness Tester Market 2025-2035 |

||||||

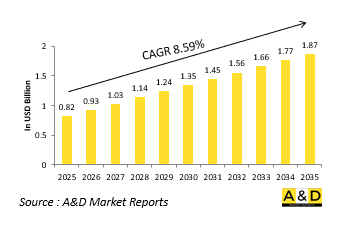

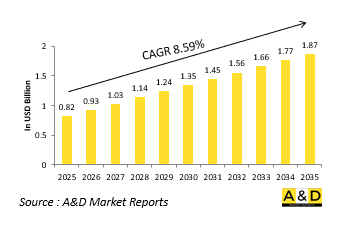

全球線束測試儀市場規模預計將在 2025 年增長至 8.2 億美元,到 2035 年將增長至 18.7 億美元,在 2025-2035 年預測期內的複合年增長率 (CAGR) 為 8.59%。

線束測試儀市場介紹:

軍用線束測試儀在確保國防平台至關重要的電氣互連繫統的完整性、性能和安全性方面發揮關鍵作用。這些測試儀用於驗證飛機、地面車輛、船舶和飛彈系統中關鍵系統之間傳輸電力和數據的線束的連續性、絕緣電阻、介電強度和正確結構。在軍事裝備運作的惡劣和嚴苛的環境中,即使是最輕微的接線缺陷(例如短路、斷路或接線錯誤)也可能導致任務失敗或設備損失。線束測試儀可以幫助在部署之前檢測此類問題,從而降低現場故障的風險並提高整體運行可靠性。這些系統支援各種活動,從製造品質檢查和倉庫級維護到飛行前檢查和生命週期監控。隨著現代國防平台電氣化和數位化程度的提高,線束網路的複雜性也隨之增加,需要準確、高效的測試。因此,線束測試儀現在已成為軍事維護和品質保證協議的基石,對陸地、空中、海上和太空的戰備和任務成功做出了重大貢獻。

技術對線束測試儀市場的影響:

軍用線束測試儀的發展受到自動化、數據分析和精密電子技術的進步的推動,使其更加有效和用戶友好。現代測試儀現在整合了觸控螢幕介面、可程式測試序列和高速診斷功能,可以快速識別廣泛而複雜的線束中的接線故障。這些系統也適用於混合訊號環境,其中同時存在電源線和數據線,確保每個電路路徑都在規格範圍內運作。嵌入式軟體可實現即時錯誤記錄和自動報告,減少人為錯誤並提高測試吞吐量。自學習演算法使測試儀能夠適應不斷變化的線束配置,而無需手動重新編程。此外,堅固耐用的便攜式設備還支援現場測試。數位孿生技術也正在集成,使工程師能夠模擬線束在不同操作壓力下的表現。隨著軍事系統不斷配備更多的感測器、處理器和電子控制單元,線束測試儀必須滿足日益增長的可擴展性、準確性和環境穩健性需求。

線束測試儀市場的關鍵推動因素:

對電子子系統和以數據為中心的戰爭策略的依賴日益增加,大大增加了對先進軍用線束測試儀的需求。隨著系統變得越來越複雜,軍事平台上的互連數量也不斷增加,需要進行嚴格的測試以防止可能影響任務結果的故障。戰鬥機、無人系統和海軍艦艇等高性能平台需要精確可靠的線束測試來支援先進的航空電子設備、武器控制和通訊系統。此外,國防計畫越來越重視優化維護,透過線束測試及早發現故障可以最大限度地減少非計劃性停機時間並降低生命週期成本。向模組化和即插即用架構的轉變也要求測試人員能夠在生產和現場操作中快速驗證可互換的線束段。法規遵循和品質保證要求將進一步推動標準化和自動化測試解決方案的採用。隨著軍隊對下一代系統(包括支援人工智慧的平台和電力推進)的電氣化和整合進行投資,對全麵線束驗證的需求正在增長。綜合起來,這些因素凸顯了測試在確保現代軍事行動中的系統完整性、安全性和準備度方面發揮的關鍵作用。

線束測試儀市場的區域趨勢:

軍用線束測試儀的區域趨勢由區域國防生產能力、現代化目標和運作要求決定。在北美,尤其是美國,自動化線束測試儀的廣泛採用既支援了遺留系統的維護,也支援了空中和海軍艦隊中下一代技術的整合。對高節奏操作和模組化物流的關注正在推動對便攜式和堅固性測試解決方案的投資。與北約的互通性和數位轉型目標保持一致,歐洲國家正在推動採用能夠處理複雜的多系統佈線配置的先進測試儀,特別是在航空航太和裝甲車領域。由於印度、中國、日本和韓國等國家本土製造業和平台開發的擴張,亞太地區的需求強勁。這些國家正在建立國內測試能力,以支持更廣泛的國防自力更生措施。中東地區正在大力投資測試基礎設施,以支援新收購的平台並提高維護自主性,並將線束測試納入更廣泛的維持計畫。拉丁美洲和非洲分階段的國防現代化努力和國際夥伴關係正在引入模組化和移動式線束測試飛機,通常作為更廣泛的支援方案的一部分,以提高平台可靠性和本地維護能力。

主要線束測試儀程式

歐盟委員會宣佈為 EDIRPA 計劃(透過聯合採購加強歐洲國防工業)下的通用裝甲車系統 (CAVS) 項目提供 6000 萬歐元的資金。這項雄心勃勃的計畫旨在開發現代化、標準化的裝甲車,以增強芬蘭、拉脫維亞、瑞典和德國軍隊的作戰能力。 CAVS計畫旨在滿足日益增長的部隊機動性和防護需求,同時促進歐洲國家之間的國防合作和裝備標準化。

本報告研究了全球線束測試儀市場,並按細分市場、技術趨勢、機會分析、公司概況和國家數據提供了 10 年市場預測。

目錄

全球線束測試儀市場 – 目錄

全球線束測試儀市場 - 報告定義

全球線束測試儀市場細分

按地區

按類型

依科技

依用途

未來10年全球線束系統市場分析

全球線束系統市場技術

本部分涵蓋預計將影響該市場的十大技術以及這些技術可能對整個市場產生的影響。

全球線束系統市場預測

上述部分詳細解釋了該市場 10 年期間的全球線束系統市場預測。

各地區線束系統市場趨勢及預測

本部分涵蓋全球線束系統市場的區域趨勢、推動因素、阻礙因素、課題以及政治、經濟、社會和技術方面。它還提供了詳細的區域市場預測和情境分析。區域分析包括主要公司概況、供應商格局和公司基準測試。目前市場規模是根據正常業務情境估算的。

北美

促進因素、阻礙因素與課題

害蟲

市場預測與情境分析

主要公司

供應商層級結構

企業基準

歐洲

中東

亞太地區

南美洲

各國門禁市場分析

本章重點介紹該市場的主要防禦計劃,並介紹該市場的最新新聞和專利。它還提供國家級的 10 年市場預測和情境分析。

美國

國防計畫

最新消息

專利

目前該市場的技術成熟度

市場預測與情境分析

加拿大

義大利

法國

德國

荷蘭

比利時

西班牙

瑞典

希臘

澳洲

南非

印度

中國

俄羅斯

韓國

日本

馬來西亞

新加坡

巴西

全球線束系統市場機會矩陣

全球線束系統市場報告專家意見

結論

關於航空和國防市場報告

The Global Wire Harness Tester market is estimated at USD 0.82 billion in 2025, projected to grow to USD 1.87 billion by 2035 at a Compound Annual Growth Rate (CAGR) of 8.59% over the forecast period 2025-2035.

Introduction to Wire Harness Tester Market:

Military wire harness testers play a vital role in ensuring the integrity, performance, and safety of electrical interconnect systems that are essential for defense platforms. These testers are used to validate the continuity, insulation resistance, dielectric strength, and proper configuration of wire harnesses that transmit power and data across critical systems in aircraft, ground vehicles, naval vessels, and missile systems. Given the hostile and demanding environments in which military equipment operates, even minor faults in wiring-such as shorts, opens, or misrouted circuits-can lead to mission failure or equipment loss. Wire harness testers help detect such issues before deployment, reducing the risk of in-field malfunctions and enhancing overall operational reliability. These systems support activities ranging from production quality checks and depot-level maintenance to pre-flight inspections and lifecycle monitoring. With increasing electrification and digital connectivity in modern defense platforms, the complexity of wire harness networks has grown, raising the stakes for accurate and efficient testing. As a result, wire harness testers are now a cornerstone of military maintenance and quality assurance protocols, contributing significantly to readiness and mission success across land, air, sea, and space operations.

Technology Impact in Wire Harness Tester Market:

The evolution of military wire harness testers has been driven by advancements in automation, data analytics, and precision electronics, making them more effective and user-friendly. Modern testers now integrate touch-screen interfaces, programmable test sequences, and high-speed diagnostics, enabling rapid identification of wiring faults across extensive and complex harnesses. These systems are increasingly capable of handling mixed-signal environments, where both power and data lines coexist, ensuring that each circuit path performs to its exact specifications. Embedded software enables real-time error logging and automated reporting, reducing human error and increasing testing throughput. The adoption of self-learning algorithms allows testers to adapt to evolving wire harness configurations without requiring manual reprogramming. In addition, ruggedized and portable units support in-field testing, essential for mobile maintenance crews and forward-deployed forces. Digital twin integration is also emerging, allowing technicians to simulate harness behavior under varying operational stresses. As military systems continue to incorporate more sensors, processors, and electronic control units, wire harness testers must meet rising demands for scalability, accuracy, and environmental resilience, underscoring the role of technology in safeguarding mission-critical interconnections.

Key Drivers in Wire Harness Tester Market:

The growing dependence on electronic subsystems and data-centric warfare strategies is significantly increasing the demand for advanced military wire harness testers. With rising system complexity, the number of interconnections in military platforms has expanded, necessitating rigorous testing to prevent faults that could compromise mission outcomes. High-performance platforms such as fighter jets, unmanned systems, and naval vessels require precise and reliable harness testing to support advanced avionics, weapon control, and communication systems. Additionally, defense programs are increasingly emphasizing maintenance optimization, where early fault detection through harness testing minimizes unscheduled downtimes and lowers lifecycle costs. The shift toward modularity and plug-and-play architectures also calls for testers capable of quickly validating replaceable harness segments during both production and field operations. Regulatory compliance and quality assurance mandates further drive the adoption of standardized and automated testing solutions. As armed forces invest in electrification and integration of next-generation systems, including AI-enabled platforms and electric propulsion, the need for comprehensive wire harness validation grows stronger. These factors collectively highlight the critical role of testing in ensuring system integrity, safety, and readiness in modern military operations.

Regional Trends in Wire Harness Tester Market:

Regional trends in military wire harness testers are shaped by local defense production capabilities, modernization goals, and operational requirements. In North America, particularly in the United States, widespread adoption of automated harness testers supports both legacy system sustainment and integration of next-generation technologies across air and naval fleets. The focus on high-tempo operations and modular logistics encourages investment in portable and ruggedized test solutions. European countries are aligning with NATO's interoperability and digital transformation objectives, driving adoption of advanced testers capable of handling complex multi-system wiring configurations, especially in aerospace and armored vehicle sectors. The Asia-Pacific region is witnessing robust demand, driven by expanding indigenous manufacturing and platform development in countries like India, China, Japan, and South Korea. These nations are building domestic testing capacity to support broader defense self-reliance initiatives. The Middle East is actively investing in test infrastructure to support newly acquired platforms and enhance maintenance autonomy, with wire harness testing being integrated into broader sustainment programs. In Latin America and Africa, gradual defense modernization efforts and international partnerships are introducing modular and mobile harness testers, often as part of broader support packages to enhance platform reliability and local maintenance capabilities.

Key Wire Harness Tester Program:

The European Commission has announced €60 million in funding for the Common Armoured Vehicle System (CAVS) project under the EDIRPA program (European Defense Industry Reinforcement Instrument through Joint Procurement). This ambitious initiative seeks to develop a modern, standardized armored vehicle to strengthen the operational capabilities of the armed forces in Finland, Latvia, Sweden, and Germany. The CAVS project aims to meet increasing demands for troop mobility and protection, while promoting defense collaboration and equipment standardization among European nations.

Table of Contents

Global wire harness systems Market - Table of Contents

Global wire harness systems market Report Definition

Global wire harness systems market Segmentation

By Region

By Type

By Technology

By Application

Global wire harness systems market Analysis for next 10 Years

The 10-year Globalwire harness systems market analysis would give a detailed overview of Globalwire harness systems market growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Global wire harness systems

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global wire harness systems market Forecast

The 10-year Globalwire harness systems market forecast of this market is covered in detailed across the segments which are mentioned above.

Regional wire harness systems market Trends & Forecast

The regional Globalwire harness systems market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Access Control Market

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Global wire harness systems market

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Global wire harness systems market Report

Hear from our experts their opinion of the possible analysis for this market.

Conclusions

About Aviation and Defense Market Reports

List of Tables

- Table 1: 10 Year Market Outlook, 2025-2035

- Table 2: Drivers, Impact Analysis, North America

- Table 3: Restraints, Impact Analysis, North America

- Table 4: Challenges, Impact Analysis, North America

- Table 5: Drivers, Impact Analysis, Europe

- Table 6: Restraints, Impact Analysis, Europe

- Table 7: Challenges, Impact Analysis, Europe

- Table 8: Drivers, Impact Analysis, Middle East

- Table 9: Restraints, Impact Analysis, Middle East

- Table 10: Challenges, Impact Analysis, Middle East

- Table 11: Drivers, Impact Analysis, APAC

- Table 12: Restraints, Impact Analysis, APAC

- Table 13: Challenges, Impact Analysis, APAC

- Table 14: Drivers, Impact Analysis, South America

- Table 15: Restraints, Impact Analysis, South America

- Table 16: Challenges, Impact Analysis, South America

- Table 17: Scenario Analysis, Scenario 1, By Region, 2025-2035

- Table 18: Scenario Analysis, Scenario 1, By Technology, 2025-2035

- Table 19: Scenario Analysis, Scenario 1, By Application, 2025-2035

- Table 20: Scenario Analysis, Scenario 1, By Type, 2025-2035

- Table 21: Scenario Analysis, Scenario 2, By Region, 2025-2035

- Table 22: Scenario Analysis, Scenario 2, By Technology, 2025-2035

- Table 23: Scenario Analysis, Scenario 2, By Application, 2025-2035

- Table 24: Scenario Analysis, Scenario 2, By Type, 2025-2035

List of Figures

- Figure 1: Global Wire Harness Tester Market Forecast, 2025-2035

- Figure 2: Global Wire Harness Tester Market Forecast, By Region, 2025-2035

- Figure 3: Global Wire Harness Tester Market Forecast, By Technology, 2025-2035

- Figure 4: Global Wire Harness Tester Market Forecast, By Application, 2025-2035

- Figure 5: Global Wire Harness Tester Market Forecast, By Type, 2025-2035

- Figure 6: North America, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 7: Europe, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 8: Middle East, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 9: APAC, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 10: South America, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 11: United States, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 12: United States, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 13: Canada, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 14: Canada, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 15: Italy, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 16: Italy, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 17: France, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 18: France, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 19: Germany, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 20: Germany, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 21: Netherlands, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 22: Netherlands, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 23: Belgium, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 24: Belgium, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 25: Spain, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 26: Spain, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 27: Sweden, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 28: Sweden, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 29: Brazil, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 30: Brazil, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 31: Australia, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 32: Australia, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 33: India, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 34: India, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 35: China, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 36: China, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 37: Saudi Arabia, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 38: Saudi Arabia, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 39: South Korea, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 40: South Korea, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 41: Japan, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 42: Japan, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 43: Malaysia, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 44: Malaysia, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 45: Singapore, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 46: Singapore, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 47: United Kingdom, Wire Harness Tester Market, Technology Maturation, 2025-2035

- Figure 48: United Kingdom, Wire Harness Tester Market, Market Forecast, 2025-2035

- Figure 49: Opportunity Analysis, Wire Harness Tester Market, By Region (Cumulative Market), 2025-2035

- Figure 50: Opportunity Analysis, Wire Harness Tester Market, By Region (CAGR), 2025-2035

- Figure 51: Opportunity Analysis, Wire Harness Tester Market, By Technology (Cumulative Market), 2025-2035

- Figure 52: Opportunity Analysis, Wire Harness Tester Market, By Technology (CAGR), 2025-2035

- Figure 53: Opportunity Analysis, Wire Harness Tester Market, By Application (Cumulative Market), 2025-2035

- Figure 54: Opportunity Analysis, Wire Harness Tester Market, By Application (CAGR), 2025-2035

- Figure 55: Opportunity Analysis, Wire Harness Tester Market, By Type (Cumulative Market), 2025-2035

- Figure 56: Opportunity Analysis, Wire Harness Tester Market, By Type (CAGR), 2025-2035

- Figure 57: Scenario Analysis, Wire Harness Tester Market, Cumulative Market, 2025-2035

- Figure 58: Scenario Analysis, Wire Harness Tester Market, Global Market, 2025-2035

- Figure 59: Scenario 1, Wire Harness Tester Market, Total Market, 2025-2035

- Figure 60: Scenario 1, Wire Harness Tester Market, By Region, 2025-2035

- Figure 61: Scenario 1, Wire Harness Tester Market, By Technology, 2025-2035

- Figure 62: Scenario 1, Wire Harness Tester Market, By Application, 2025-2035

- Figure 63: Scenario 1, Wire Harness Tester Market, By Type, 2025-2035

- Figure 64: Scenario 2, Wire Harness Tester Market, Total Market, 2025-2035

- Figure 65: Scenario 2, Wire Harness Tester Market, By Region, 2025-2035

- Figure 66: Scenario 2, Wire Harness Tester Market, By Technology, 2025-2035

- Figure 67: Scenario 2, Wire Harness Tester Market, By Application, 2025-2035

- Figure 68: Scenario 2, Wire Harness Tester Market, By Type, 2025-2035

- Figure 69: Company Benchmark, Wire Harness Tester Market, 2025-2035