|

市場調查報告書

商品編碼

1714098

鐵鳥地面測試設備市場:全球2025-2035年Global Iron bird test setups Market 2025-2035 |

||||||

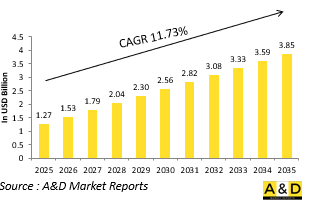

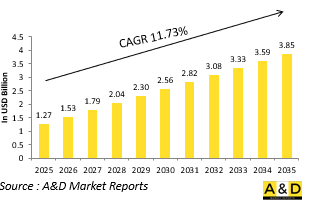

全球鐵鳥地面測試設備市場規模預計將從 2025 年的 12.7 億美元增長到 2035 年的 38.5 億美元,預測期內的複合年增長率為 11.73%。

鐵鳥地面測試設備市場:簡介

鐵鳥地面試驗設施是國防部門飛機系統開發和整合的重要組成部分。這些試驗台是地面平台,可以複製飛機或機身的結構和功能佈局,使工程師能夠在首次飛行之前對液壓、航空電子設備、電線、飛行控制、軟體整合等進行全面測試。在國防應用方面,鐵鳥對於降低先進戰鬥機、運輸機、無人機和旋翼機研發的技術風險至關重要。與電腦模擬或單一組件測試不同,Iron Bird 可以物理驗證複雜子系統之間的相互作用,發現實際配置中的液壓管路幹擾、控制邏輯故障和電訊號時序錯誤等問題。它們還提供了一個安全的環境來演練操作場景、模擬飛行中故障和評估可維護性。這對於準備和安全至關重要的軍事平台來說尤其重要。 Iron Bird 將從早期設計和工程階段一直使用到最終驗證階段,在此過程中不斷發展以適應配置變化並在實際生產部件可用時將其納入其中。這些設施對於確保飛行測試前的系統成熟度和整合度至關重要,可以節省時間和金錢,並有助於避免國防航空計劃中的嚴重故障。

鐵鳥地面測試設備市場:技術的影響

數位工程、系統整合和感測器測量技術的進步正在徹底改變國防航空航太鐵鳥地面測試設施。最具影響力的發展之一是數位孿生的引入。這將創建物理系統的即時數位複製品,該複製品將與鐵鳥的行為一起運行,從而實現地面測試期間的高級建模、預測性維護和控制系統最佳化。電傳操縱和光控操縱控制方案在下一代國防平台中擴大採用,需要一種能夠模擬和驗證複雜訊號處理和軟體定義控制規律的新型鐵鳥架構。此外,鐵鳥裝置還配備了高保真運動執行器和伺服液壓系統,能夠再現動態飛行負荷下的空氣動力和機械響應。這使得控制面和輔助動力系統能夠進行真實的測試。此外,模組化測試架提供即插即用功能,允許快速互換航空電子設備包和子系統以進行比較評估。數據採集方面也在不斷創新,使得數據能夠透過高速遙測、即時監控儀表板和整合分析平台反饋到類比迴路中。此外,一些先進的測試環境還支援硬體在環(HIL)和軟體在環(SIL)等接口,能夠在更接近實際任務的環境中同時測試嵌入式軟體和系統硬體。這些技術不僅提高了測試的準確性和覆蓋率,而且大大縮短了系統迭代開發的周轉時間。

鐵鳥地面測試設備市場:關鍵推動因素

鐵鳥地面試驗設施的擴建和完善是由全球國防工業的若干戰略和營運需求所推動的。首先是現代國防飛機的複雜性日益增加。這些飛機整合了眾多系統,包括隱形航空電子設備、電子戰模組、自適應飛行控制軟體和網路通訊節點。在飛行前驗證這些系統是否協同工作不再是一種選擇,而是一種要求,而 Iron Bird 是進行這種整合驗證和故障排除的最有效工具。下一個主要推動因素是國防市場縮短開發時間和降低專案成本的壓力。在開發早期解決整合問題有助於避免昂貴的重新設計和飛行中的意外故障,從而降低進度延誤的風險。此外,模組化、可升級平台的普及(特別是戰鬥機、無人機和多用途飛機所需的平台)需要靈活的試驗台,以便在不需要新原型的情況下驗證新配置。此外,國防計畫向國際合作的轉變使得 "鐵鳥" 計畫變得更加重要。 F-35 和 FCAS 等跨國平台需要標準化、可擴展的測試環境,以適應來自多個供應商的輸入。最後, "鐵鳥" 也將用於驗證培訓和維護協議,使支援和維護單位能夠在部署到現場之前練習故障診斷和零件更換。這些因素共同使得鐵鳥地面試驗設施在軍事航空研究、開發和採購框架內具有越來越大的戰略價值。

本報告調查了全球鐵鳥地面測試設備市場,並總結了當前的市場狀況、技術趨勢、市場影響因素分析、市場規模趨勢和預測、按地區進行的詳細分析、競爭格局以及主要公司的概況。

目錄

目錄

國防部門鐵鳥地面試驗設施:目錄

國防部門鐵鳥地面試驗設施:報告定義

全球國防部門的鐵鳥地面試驗設施:

按地區

按類型

按平台

通過考試

未來10年國防部門鐵鳥地面測試設備市場分析

全球國防部門鐵鳥地面測試設備市場:技術

全球國防部門鐵鳥地面測試設備市場:預測

全球國防部門鐵鳥地面測試設備市場:各地區趨勢與預測

北美

促進因素、阻礙因素與課題

抑制因子

市場預測與情境分析

主要公司

供應商層級格局

企業基準測試

歐洲

中東

亞太地區

南美洲

全球國防部門鐵鳥地面測試設備市場:國家分析

美國

國防計畫

最新消息

專利

目前技術成熟度

市場預測與情境分析

加拿大

義大利

法國

德國

荷蘭

比利時

西班牙

瑞典

希臘

澳洲

南非

印度

中國

俄羅斯

韓國

日本

馬來西亞

新加坡

巴西

全球國防部門鐵鳥地面測試設備市場:機會矩陣

全球國防領域鐵鳥地面測試設備市場:專家意見

概述

關於航空和國防市場報告

The Global Iron bird test setups market is estimated at USD 1.27 billion in 2025, projected to grow to USD 3.85 billion by 2035 at a Compound Annual Growth Rate (CAGR) of 11.73% over the forecast period 2025-2035.

Introduction to Iron bird test setups Market:

Iron bird test setups serve as an essential part of aircraft system development and integration in the defense sector. These test beds are ground-based platforms that replicate the structural and functional layout of an aircraft or airframe, enabling engineers to conduct full-scale testing of systems such as hydraulics, avionics, electrical wiring, flight control mechanisms, and software integration long before the first flight. In defense applications, iron birds are critical in reducing technical risks during the development of advanced fighters, transport aircraft, unmanned aerial vehicles (UAVs), and rotorcraft. Unlike computer simulations or isolated component tests, iron bird setups allow for physical verification of the interplay between complex subsystems, revealing issues like hydraulic line interference, control logic faults, or electrical signal timing errors. They also provide a safe environment to rehearse operational scenarios, simulate in-flight failures, and evaluate maintenance accessibility-particularly important in military platforms where mission readiness and safety are paramount. Iron birds are often used from the early engineering phases through late-stage validation, evolving to reflect configuration changes and incorporating actual production parts as they become available. Their role is indispensable in ensuring system maturity and integration before actual flight testing begins, saving time, costs, and mitigating mission-critical failures in defense aviation programs.

Technology Impact in Iron bird test setups Market:

Advancements in digital engineering, systems integration, and sensor instrumentation are significantly transforming iron bird test setups in defense aerospace. One of the most impactful developments is the integration of digital twins, which create real-time digital replicas of physical systems that operate in sync with the iron bird's behavior. This allows for advanced modeling, predictive maintenance, and control system optimization during ground testing. Fly-by-wire and fly-by-light systems, increasingly used in next-generation defense platforms, have necessitated new iron bird architectures that can simulate and validate complex signal processing and software-defined control laws. High-fidelity motion actuators and servo-hydraulic systems are now embedded into iron bird rigs to simulate aerodynamic forces and mechanical responses under dynamic flight loads, enabling realistic testing of control surfaces and power-assisted systems. Additionally, modular test racks equipped with plug-and-play capability allow teams to rapidly swap avionics packages and subsystems for comparative evaluation. Data acquisition has also been revolutionized with high-speed telemetry, real-time monitoring dashboards, and integrated analytics platforms that feed data into simulation loops. Some advanced setups now support hardware-in-the-loop (HIL) and software-in-the-loop (SIL) interfaces, enabling concurrent testing of embedded software and system hardware in mission-like environments. These technologies are not only improving test accuracy and coverage but also significantly reducing turnaround times between system iterations.

Key Drivers in Iron bird test setups Market:

Several strategic and operational imperatives are driving the expansion and sophistication of iron bird test setups in the global defense industry. First and foremost is the escalating complexity of modern defense aircraft, which integrate a multitude of systems-from stealthy avionics and electronic warfare modules to adaptive flight control software and networked communication nodes. Verifying that these systems function harmoniously before live flight is no longer optional but essential, and iron bird setups are the most effective tools for holistic integration and troubleshooting. Another major driver is the increased pressure to shorten development timelines and reduce program costs in competitive defense markets. By resolving integration issues early in the development cycle, iron bird tests help avoid expensive redesigns and costly in-flight anomalies, which can derail program schedules. The growing emphasis on modular and upgradeable platforms-especially for fighters, UAVs, and multirole aircraft-requires flexible test beds that can validate new configurations without the need for new prototypes. Furthermore, as defense programs increasingly involve international collaboration, joint ventures and multinational platforms such as the F-35 or FCAS necessitate standardized and scalable testing environments that can accommodate input from multiple suppliers. Lastly, iron bird setups support training and maintenance protocol validation, enabling logistics and maintenance teams to rehearse fault diagnosis and component replacement before field deployment. These drivers collectively underscore the rising strategic value of iron bird test setups in military aviation R&D and acquisition frameworks.

Regional Trends in Iron bird test setups Market:

The evolution of iron bird test capabilities varies by region, reflecting local defense priorities, aerospace infrastructure, and industrial maturity. In North America, the United States remains a global leader in iron bird implementation, with advanced test facilities maintained by OEMs like Lockheed Martin, Boeing, and Northrop Grumman. These setups support an array of programs from sixth-generation fighters to long-range bombers and tactical drones, often with HIL integration and support for live software patches. The U.S. Department of Defense (DoD) emphasizes rapid prototyping and integration, prompting the use of multiple iron bird configurations to parallel-track component maturity. Canada, while more focused on support roles, leverages iron bird testing through partnerships with American firms and government research agencies for its aerial surveillance and logistics platforms. In Europe, leading aerospace nations such as Germany, France, and the UK invest in iron bird capabilities to support collaborative programs like Tempest and FCAS, with test setups tailored for modularity and real-time data exchange among partner firms. European iron birds also play a key role in validating sustainable propulsion systems and hybrid-electric configurations. In Asia-Pacific, China has rapidly advanced its iron bird infrastructure to support the development of indigenous fighters, transport aircraft, and stealth drones. Chinese setups often emphasize independent sensor fusion and powertrain integration under cybersecure conditions. India, with HAL and DRDO at the forefront, is enhancing its iron bird capabilities for platforms like Tejas, AMCA, and Ghatak UCAV, with a growing emphasis on modular avionics and flight software debugging. Japan and South Korea are deploying advanced iron bird testbeds to support stealth fighters and surveillance aircraft, with particular focus on export compliance and interoperability. In the Middle East, nations like the UAE and Saudi Arabia are building foundational iron bird infrastructure to support joint aerospace manufacturing and MRO (maintenance, repair, overhaul) capabilities under national defense industrialization goals. Across regions, the trend is clear: iron bird setups are becoming more digitally connected, modular, and aligned with agile development principles, enabling faster, safer, and more efficient defense aviation programs worldwide.

Key Iron bird test setups Program:

Boeing has been awarded the Engineering and Manufacturing Development (EMD) contract for the U.S. Air Force's Next-Generation Air Dominance (NGAD) fighter jet program. In an announcement made from the Oval Office, President Donald Trump, Defense Secretary Pete Hegseth, and Air Force Chief General David Allvin confirmed that the new aircraft will be designated the F-47-marking the United States' first sixth-generation fighter. This milestone marks Boeing's first "clean-sheet" fighter design to be selected since its 1997 merger with McDonnell Douglas. Unlike aircraft such as the F-15EX, which are based on legacy McDonnell Douglas platforms, a clean-sheet design begins entirely from scratch, tailored specifically to meet the mission requirements and vision of the customer.

Table of Contents

Global Iron bird test setups in defense- Table of Contents

Global Iron bird test setups in defense Report Definition

Global Iron bird test setups in defense Segmentation

By Region

By Type

By Platform

By Test

Global Iron bird test setups in defense Analysis for next 10 Years

The 10-year Global Iron bird test setups in defense analysis would give a detailed overview of Global Iron bird test setups in defense growth, changing dynamics, technology adoption overviews and the overall market attractiveness is covered in this chapter.

Market Technologies of Global Iron bird test setups in defense

This segment covers the top 10 technologies that is expected to impact this market and the possible implications these technologies would have on the overall market.

Global Iron bird test setups in defense Forecast

The 10-year Global Iron bird test setups in defense forecast of this market is covered in detailed across the segments which are mentioned above.

Regional Global Iron bird test setups in defense Trends & Forecast

The regional counter drone market trends, drivers, restraints and Challenges of this market, the Political, Economic, Social and Technology aspects are covered in this segment. The market forecast and scenario analysis across regions are also covered in detailed in this segment. The last part of the regional analysis includes profiling of the key companies, supplier landscape and company benchmarking. The current market size is estimated based on the normal scenario.

North America

Drivers, Restraints and Challenges

PEST

Market Forecast & Scenario Analysis

Key Companies

Supplier Tier Landscape

Company Benchmarking

Europe

Middle East

APAC

South America

Country Analysis of Global Iron bird test setups in defense

This chapter deals with the key defense programs in this market, it also covers the latest news and patents which have been filed in this market. Country level 10 year market forecast and scenario analysis are also covered in this chapter.

US

Defense Programs

Latest News

Patents

Current levels of technology maturation in this market

Market Forecast & Scenario Analysis

Canada

Italy

France

Germany

Netherlands

Belgium

Spain

Sweden

Greece

Australia

South Africa

India

China

Russia

South Korea

Japan

Malaysia

Singapore

Brazil

Opportunity Matrix for Global Iron bird test setups in defense

The opportunity matrix helps the readers understand the high opportunity segments in this market.

Expert Opinions on Global Iron bird test setups in defense

Hear from our experts their opinion of the possible analysis for this market.

Conclusions

About Aviation and Defense Market Reports

List of Tables

- Table 1: 10 Year Market Outlook, 2025-2035

- Table 2: Drivers, Impact Analysis, North America

- Table 3: Restraints, Impact Analysis, North America

- Table 4: Challenges, Impact Analysis, North America

- Table 5: Drivers, Impact Analysis, Europe

- Table 6: Restraints, Impact Analysis, Europe

- Table 7: Challenges, Impact Analysis, Europe

- Table 8: Drivers, Impact Analysis, Middle East

- Table 9: Restraints, Impact Analysis, Middle East

- Table 10: Challenges, Impact Analysis, Middle East

- Table 11: Drivers, Impact Analysis, APAC

- Table 12: Restraints, Impact Analysis, APAC

- Table 13: Challenges, Impact Analysis, APAC

- Table 14: Drivers, Impact Analysis, South America

- Table 15: Restraints, Impact Analysis, South America

- Table 16: Challenges, Impact Analysis, South America

- Table 17: Scenario Analysis, Scenario 1, By Region, 2025-2035

- Table 18: Scenario Analysis, Scenario 1, By Test, 2025-2035

- Table 19: Scenario Analysis, Scenario 1, By Platform, 2025-2035

- Table 20: Scenario Analysis, Scenario 1, By Type, 2025-2035

- Table 21: Scenario Analysis, Scenario 2, By Region, 2025-2035

- Table 22: Scenario Analysis, Scenario 2, By Test, 2025-2035

- Table 23: Scenario Analysis, Scenario 2, By Platform, 2025-2035

- Table 24: Scenario Analysis, Scenario 2, By Type, 2025-2035

List of Figures

- Figure 1: Global Iron Bird Test Setups Market Forecast, 2025-2035

- Figure 2: Global Iron Bird Test Setups Market Forecast, By Region, 2025-2035

- Figure 3: Global Iron Bird Test Setups Market Forecast, By Test, 2025-2035

- Figure 4: Global Iron Bird Test Setups Market Forecast, By Platform, 2025-2035

- Figure 5: Global Iron Bird Test Setups Market Forecast, By Type, 2025-2035

- Figure 6: North America, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 7: Europe, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 8: Middle East, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 9: APAC, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 10: South America, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 11: United States, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 12: United States, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 13: Canada, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 14: Canada, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 15: Italy, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 16: Italy, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 17: France, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 18: France, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 19: Germany, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 20: Germany, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 21: Netherlands, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 22: Netherlands, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 23: Belgium, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 24: Belgium, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 25: Spain, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 26: Spain, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 27: Sweden, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 28: Sweden, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 29: Brazil, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 30: Brazil, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 31: Australia, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 32: Australia, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 33: India, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 34: India, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 35: China, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 36: China, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 37: Saudi Arabia, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 38: Saudi Arabia, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 39: South Korea, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 40: South Korea, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 41: Japan, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 42: Japan, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 43: Malaysia, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 44: Malaysia, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 45: Singapore, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 46: Singapore, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 47: United Kingdom, Iron Bird Test Setups Market, Technology Maturation, 2025-2035

- Figure 48: United Kingdom, Iron Bird Test Setups Market, Market Forecast, 2025-2035

- Figure 49: Opportunity Analysis, Iron Bird Test Setups Market, By Region (Cumulative Market), 2025-2035

- Figure 50: Opportunity Analysis, Iron Bird Test Setups Market, By Region (CAGR), 2025-2035

- Figure 51: Opportunity Analysis, Iron Bird Test Setups Market, By Test (Cumulative Market), 2025-2035

- Figure 52: Opportunity Analysis, Iron Bird Test Setups Market, By Test (CAGR), 2025-2035

- Figure 53: Opportunity Analysis, Iron Bird Test Setups Market, By Platform (Cumulative Market), 2025-2035

- Figure 54: Opportunity Analysis, Iron Bird Test Setups Market, By Platform (CAGR), 2025-2035

- Figure 55: Opportunity Analysis, Iron Bird Test Setups Market, By Type (Cumulative Market), 2025-2035

- Figure 56: Opportunity Analysis, Iron Bird Test Setups Market, By Type (CAGR), 2025-2035

- Figure 57: Scenario Analysis, Iron Bird Test Setups Market, Cumulative Market, 2025-2035

- Figure 58: Scenario Analysis, Iron Bird Test Setups Market, Global Market, 2025-2035

- Figure 59: Scenario 1, Iron Bird Test Setups Market, Total Market, 2025-2035

- Figure 60: Scenario 1, Iron Bird Test Setups Market, By Region, 2025-2035

- Figure 61: Scenario 1, Iron Bird Test Setups Market, By Test, 2025-2035

- Figure 62: Scenario 1, Iron Bird Test Setups Market, By Platform, 2025-2035

- Figure 63: Scenario 1, Iron Bird Test Setups Market, By Type, 2025-2035

- Figure 64: Scenario 2, Iron Bird Test Setups Market, Total Market, 2025-2035

- Figure 65: Scenario 2, Iron Bird Test Setups Market, By Region, 2025-2035

- Figure 66: Scenario 2, Iron Bird Test Setups Market, By Test, 2025-2035

- Figure 67: Scenario 2, Iron Bird Test Setups Market, By Platform, 2025-2035

- Figure 68: Scenario 2, Iron Bird Test Setups Market, By Type, 2025-2035

- Figure 69: Company Benchmark, Iron Bird Test Setups Market, 2025-2035